Patents

Literature

35 results about "Gadolinium oxysulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

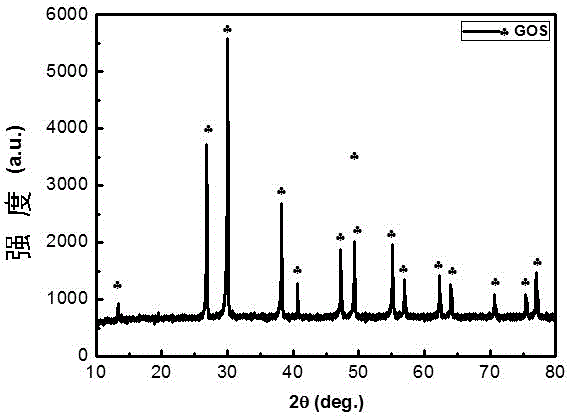

Gadolinium oxysulfide (Gd₂O₂S), also called gadolinium sulfoxylate, GOS or Gadox, is an inorganic compound, a mixed oxide-sulfide of gadolinium. Its CAS number is 12339-07-0.

Method for improving the screen brightness of gadolinium oxysulfide x-ray phosphors

InactiveUS6103296AIncrease screen brightnessAmeliorates the damage caused by deagglomerationRare earth metal sulfidesBleaching apparatusPhysicsGadolinium oxysulfide

A method is provided for improving the x-ray screen brightness of gadolinium oxysulfide x-ray phosphors. The method applies annealing and acid washing steps in a specific order following deagglomeration of the phosphor in order to ameliorate the loss of brightness caused by the deagglomeration.

Owner:GLOBAL TUNGSTEN & POWDERS CORP

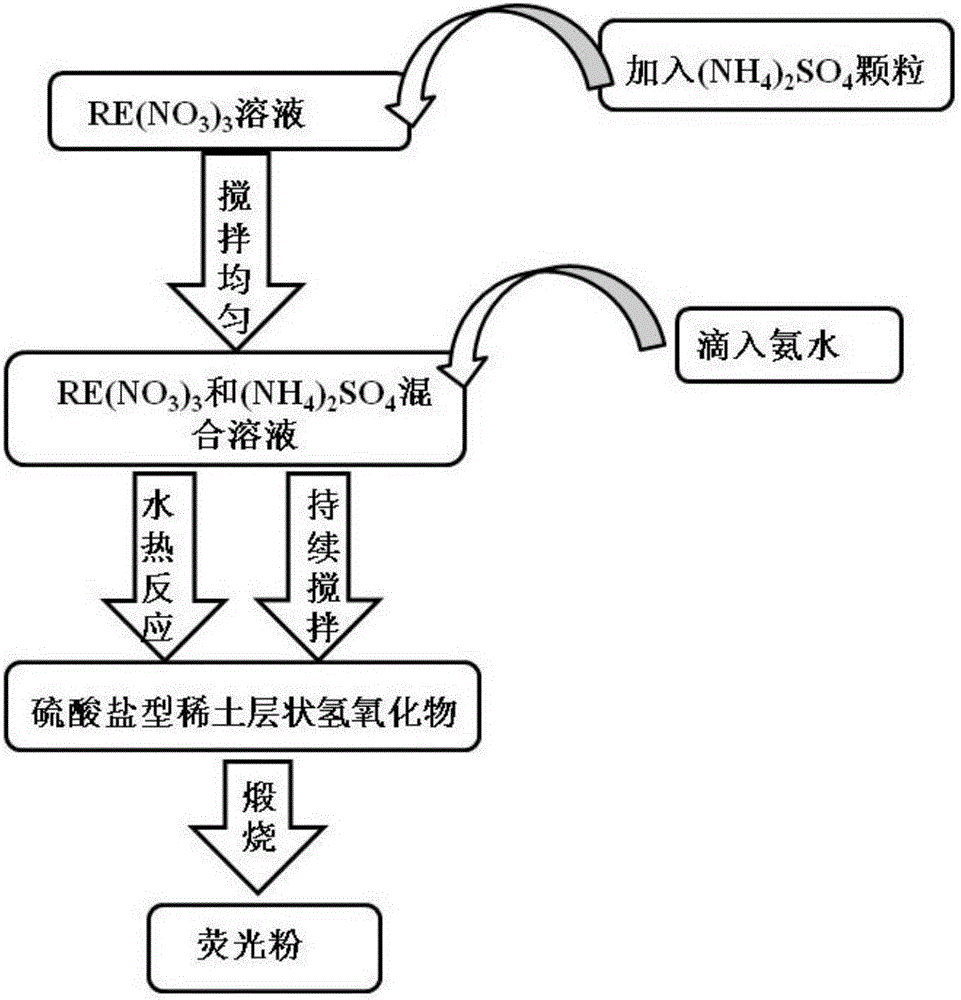

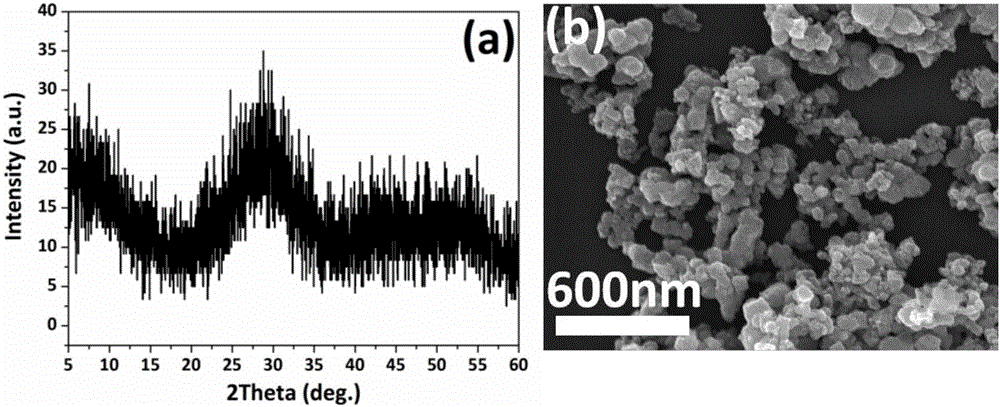

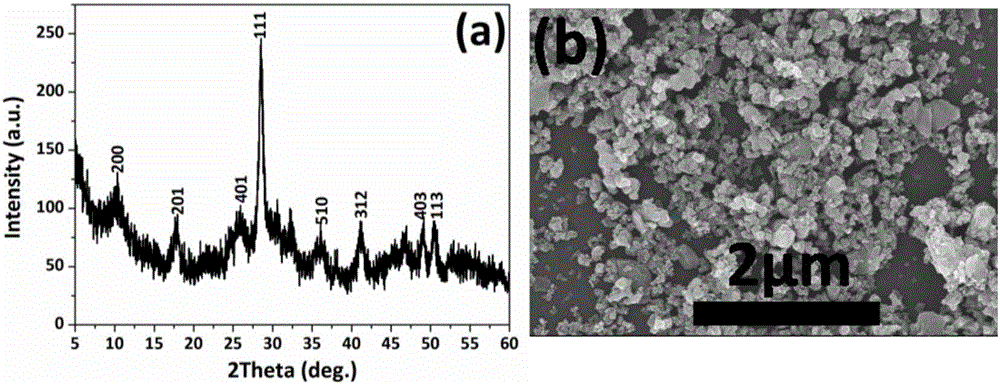

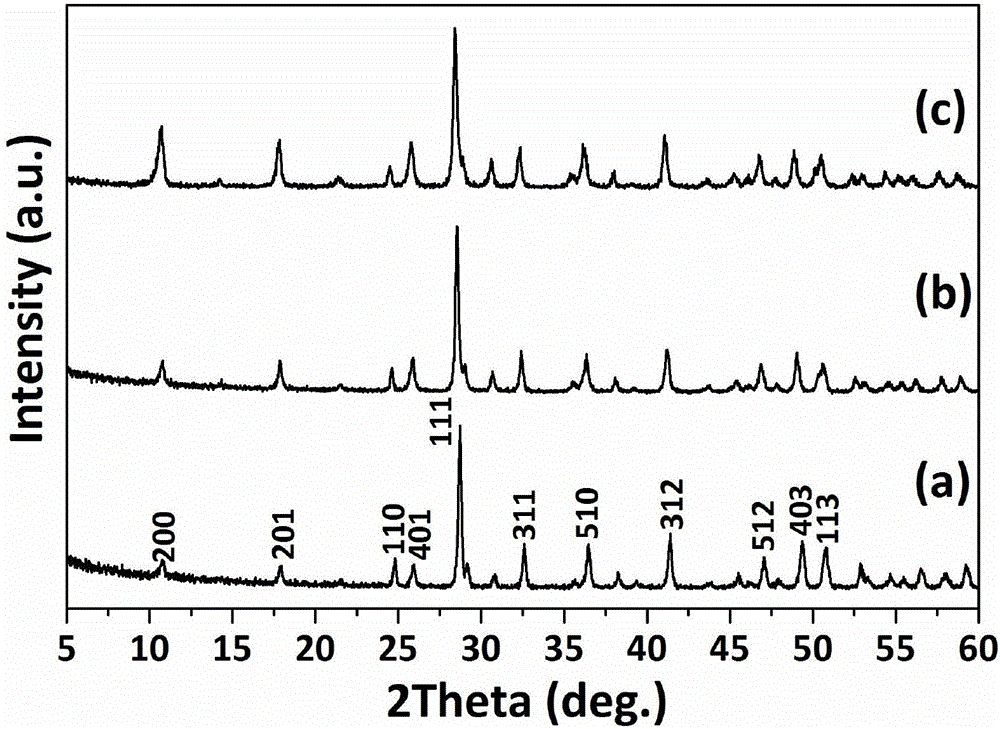

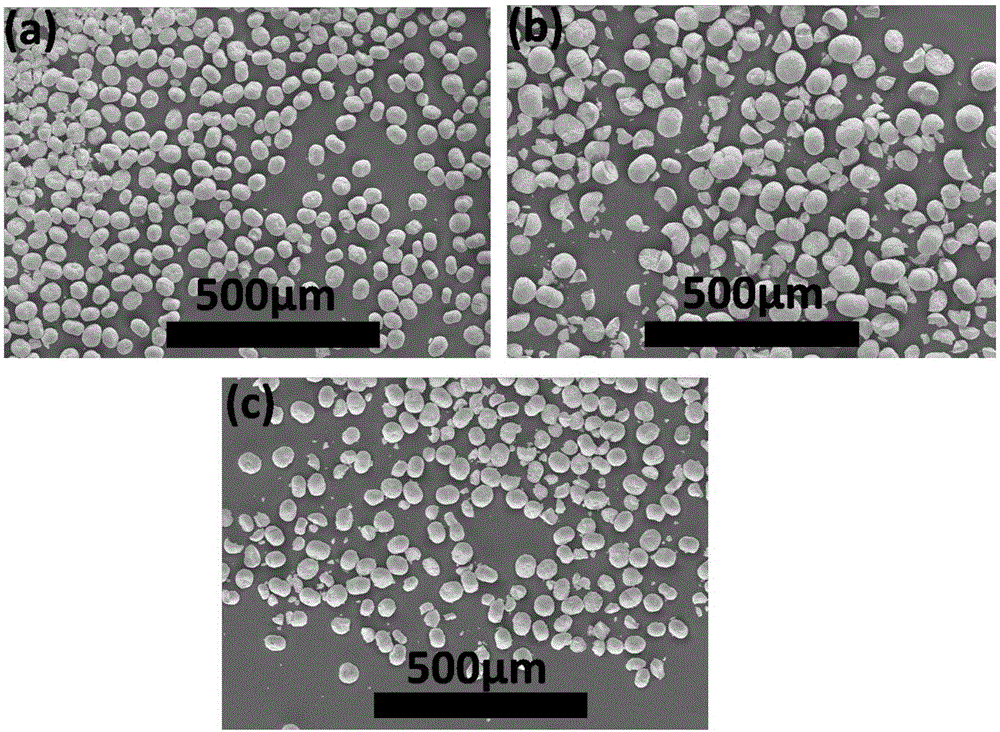

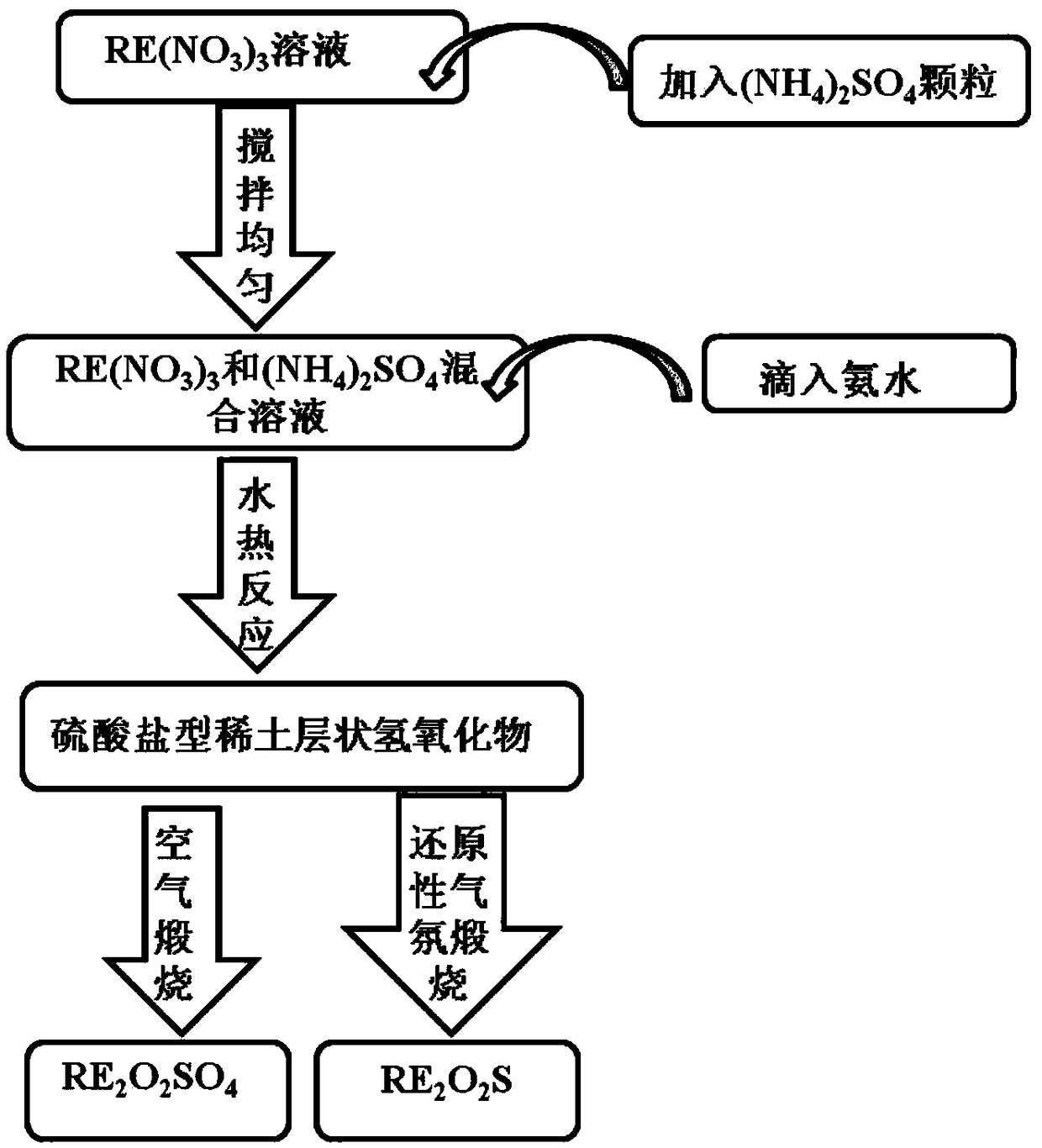

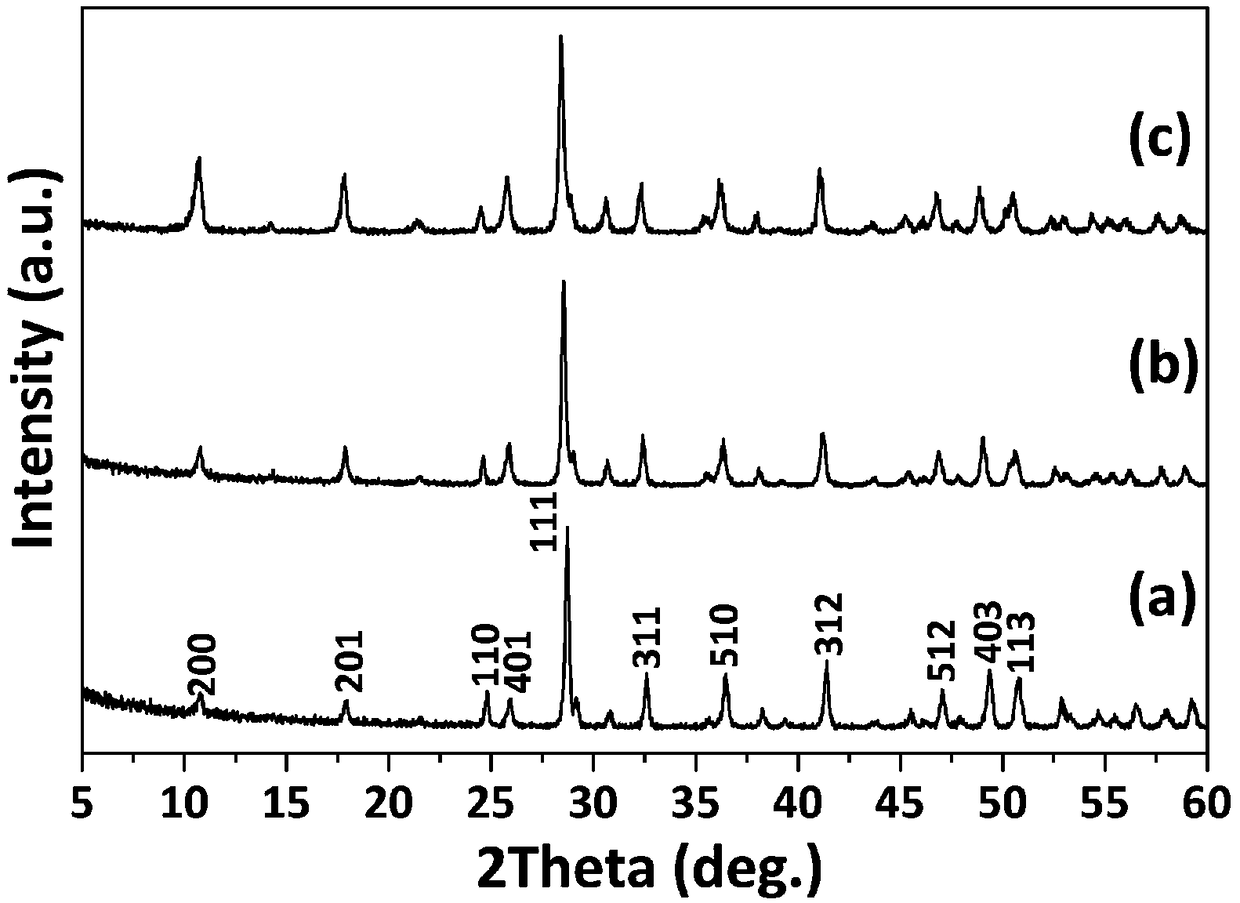

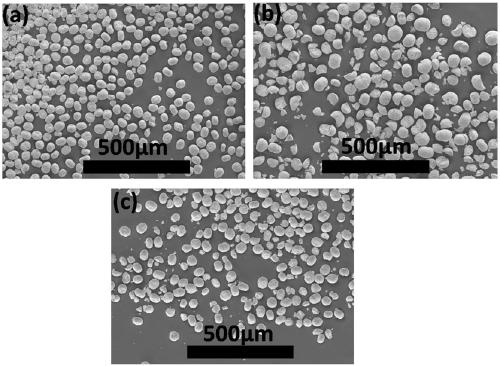

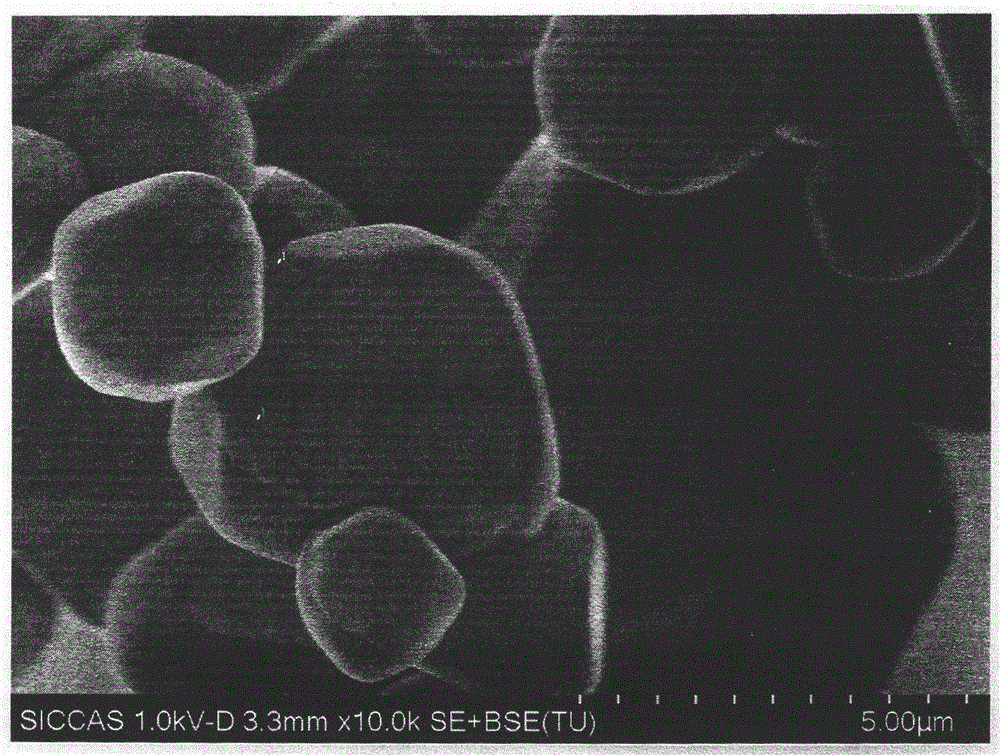

Preparing method of rare earth-doped gadolinium oxysulfide fluorescent powder

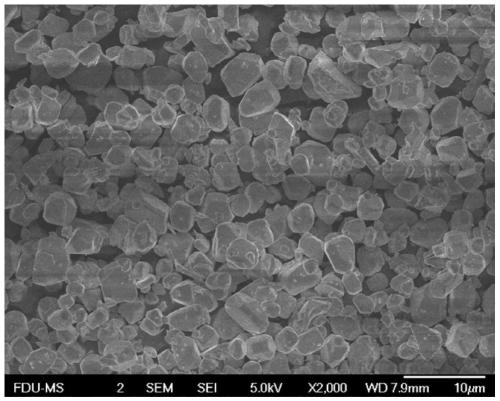

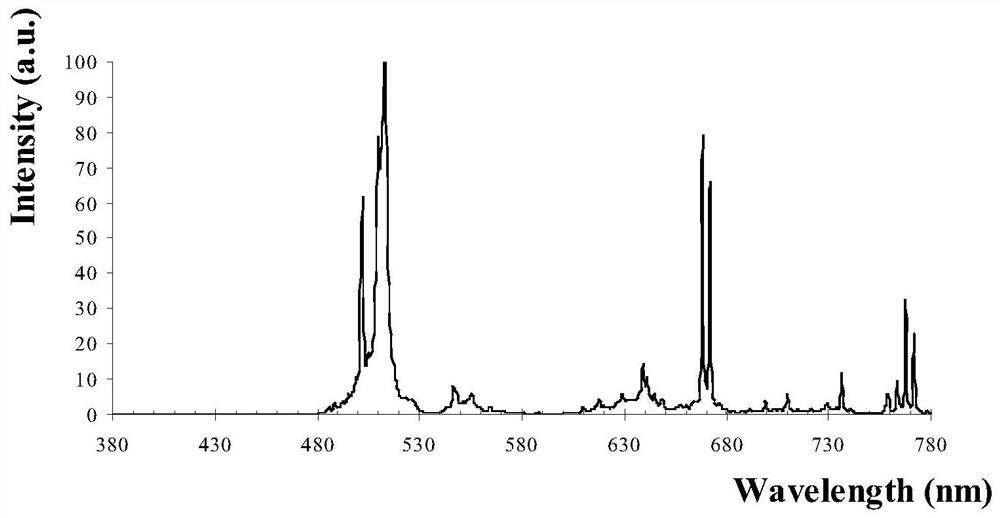

ActiveCN106544025AEffective adjustment of shapeSimple technical solutionRare earth metal sulfatesRare earth metal sulfidesGadolinium oxysulfideNitrate

The invention discloses a preparing method of rare earth-doped gadolinium oxysulfide fluorescent powder, and belongs to the technical field of materials. The preparing method comprises the first step of preparing a RE(NO3)3 solution, wherein the RE(NO3)3 solution is mixed liquid of Gd(NO3)3 and activating agent nitrate; the second step of dissolving ammonium sulfate into the RE(NO3)3 solution, continuously stirring the mixture and adding ammonium hydroxide into the mixture, and adjusting a pH value to obtain turbid liquid; the third step of conducting reaction on the turbid liquid at the temperature of minus 1-150 DEG C for 1-72 hours to obtain a reaction product; the fourth step of conducting centrifugal separation, cleaning and drying on the reaction product to obtain a white powder precursor; roasting the white powder precursor in reducing atmosphere to obtain (Gd,Tb)202S or (Gd,Pr)202S fluorescent powder. According to the technical scheme, the preparing method is simple and easy to operate, in the process of preparing (Gd,Tb)202S or (Gd,Pr)202S, sulfocompound which is harmful to the environment is not involved; in addition, (Gd,Tb)202S or (Gd,Pr)202S of various morphologies (nano-particles, agglomerated balls and standard hexagon micron sheet bars) can be obtained.

Owner:NORTHEASTERN UNIV

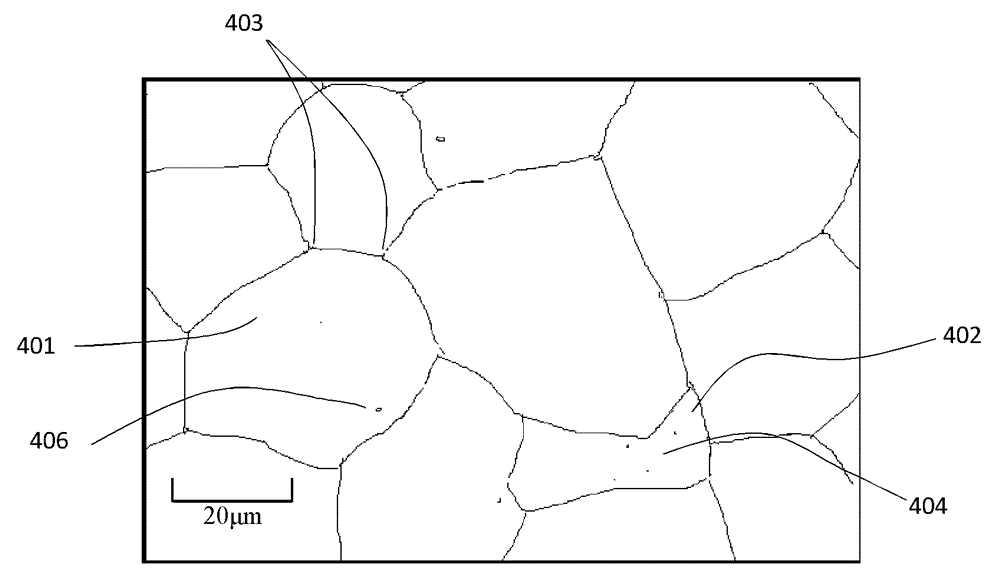

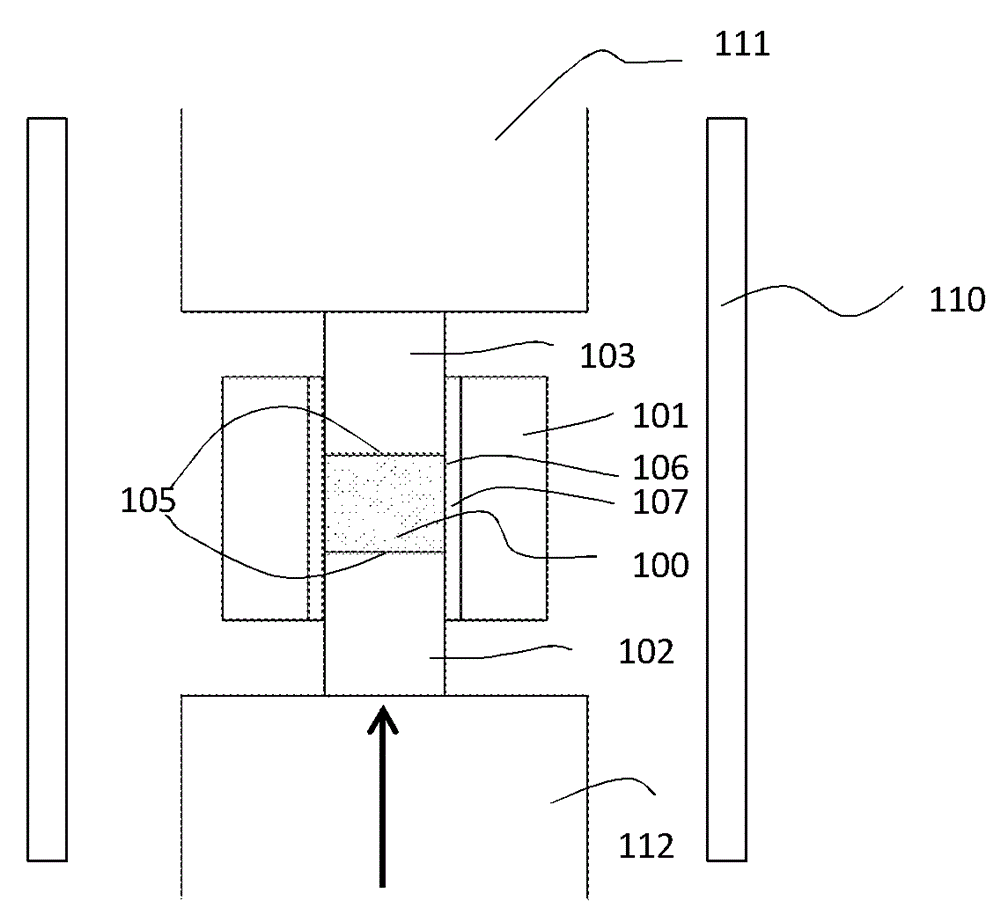

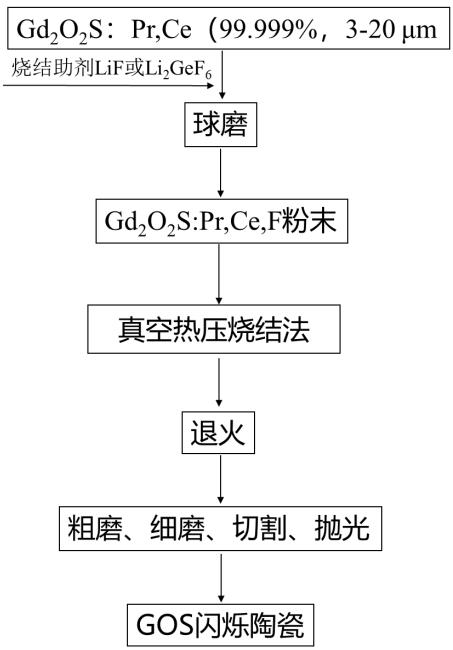

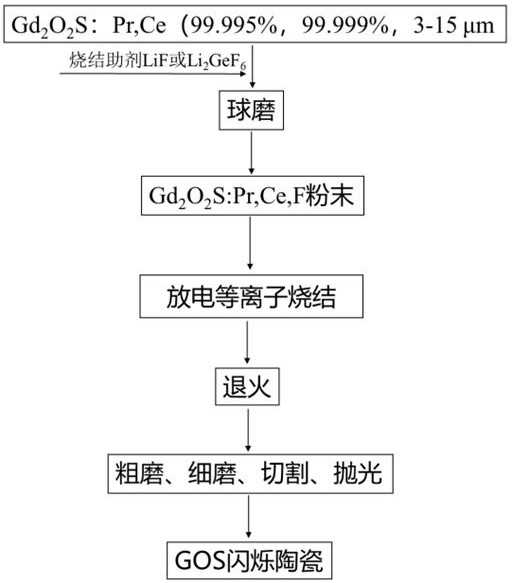

Sulfur oxide gadolinium (Gd2O2S) scintillation ceramics preparation method

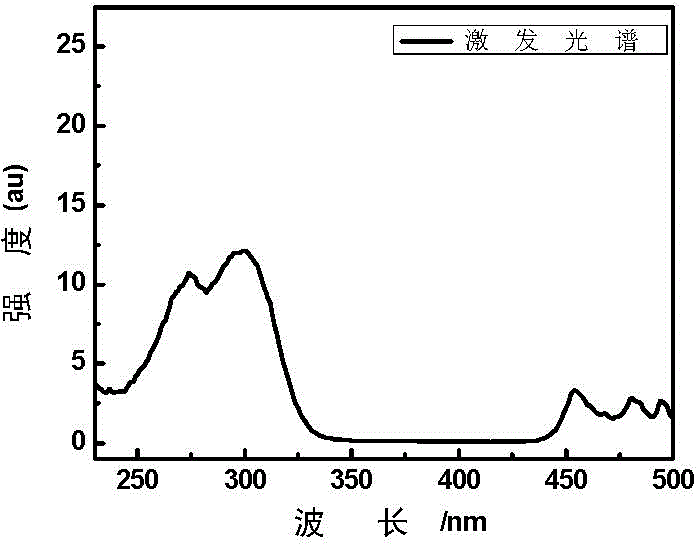

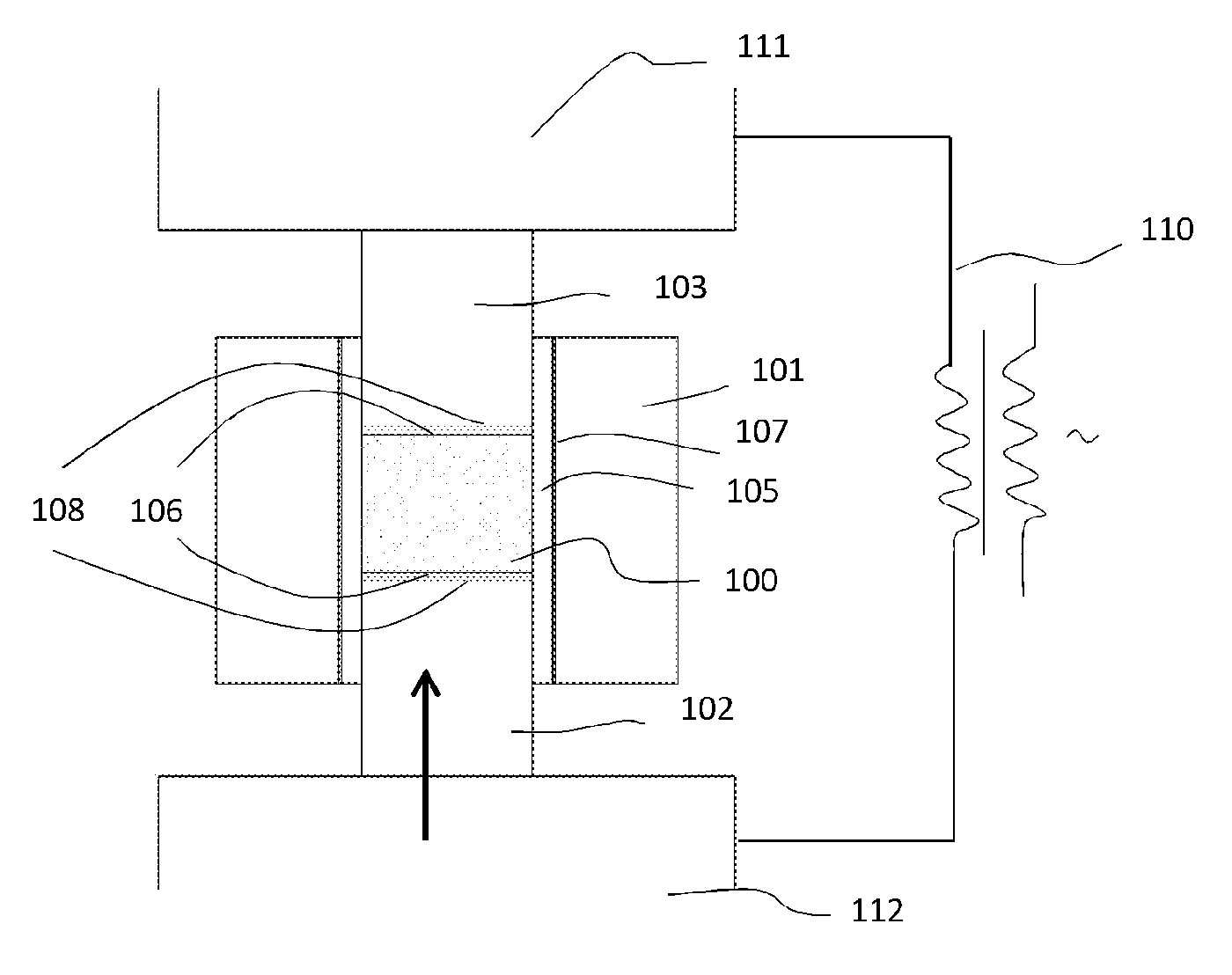

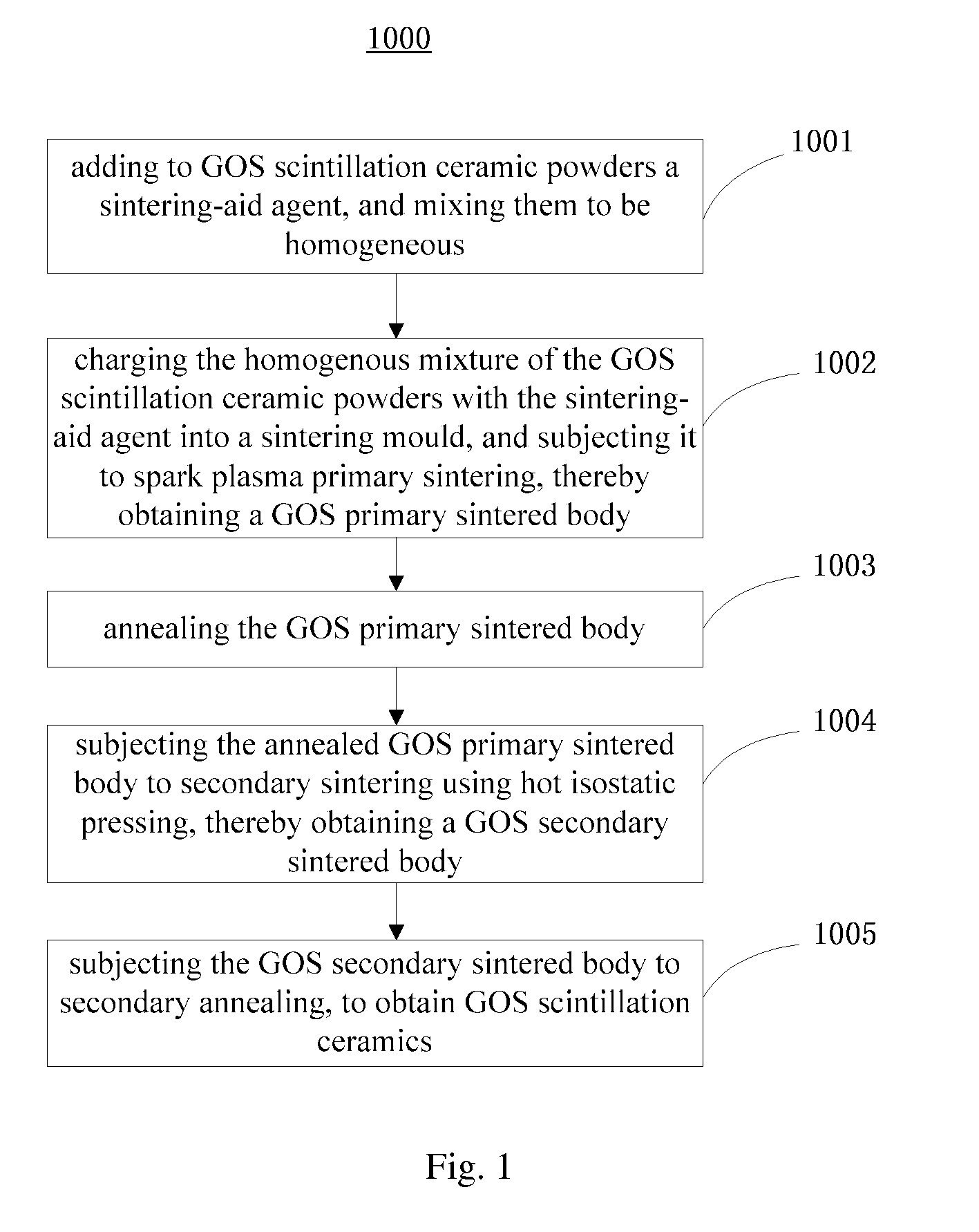

ActiveCN105330289AEfficient preparationLuminescent compositionsRadiation intensity measurementGadolinium oxysulfideGadolinium oxide

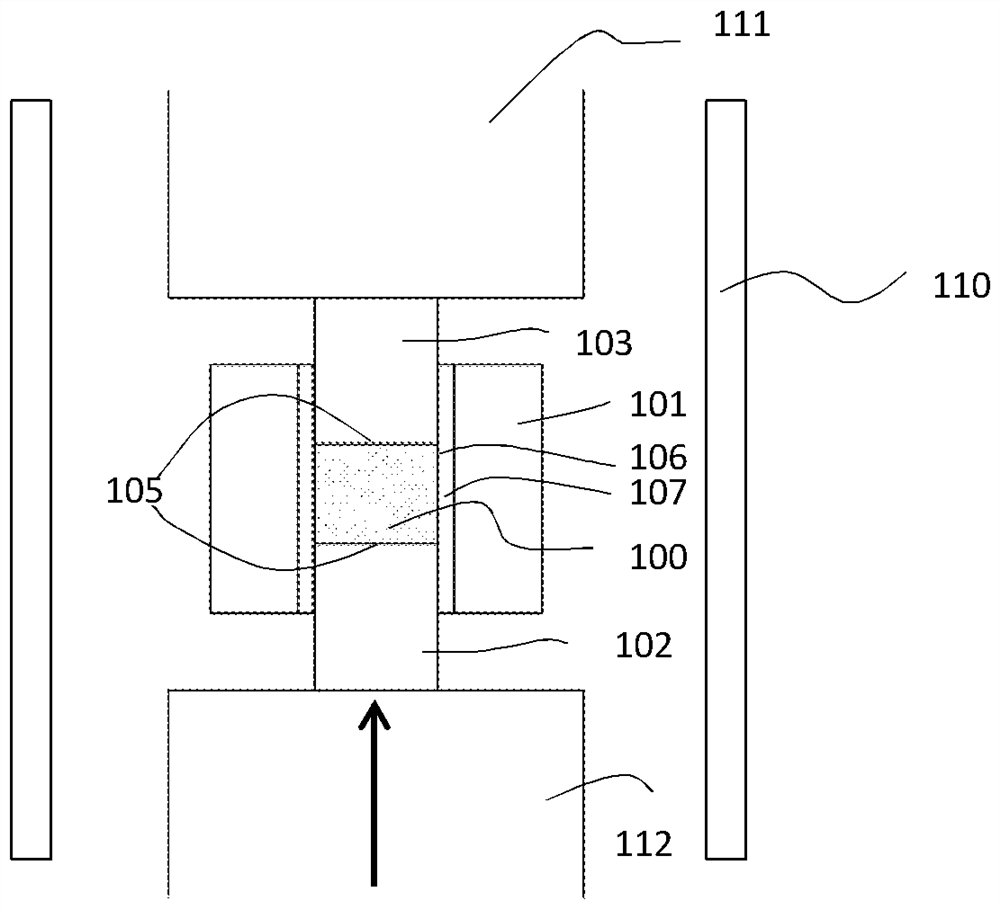

The invention relates to a method for rapidly preparing sulfur oxide gadolinium (having a general chemical formula being Gd2O2S, GOS for short) polycrystalline scintillation ceramics doped with at least one element from Pr, Ce, Tb and Eu by employing an uniaxial pressurization Spark Plasma Sintering (SPS) technology and combining a hot isostatic pressing secondary sintering technology optionally.

Owner:TSINGHUA UNIV +1

Gadolinium oxysulfide scintillation ceramic preparation method

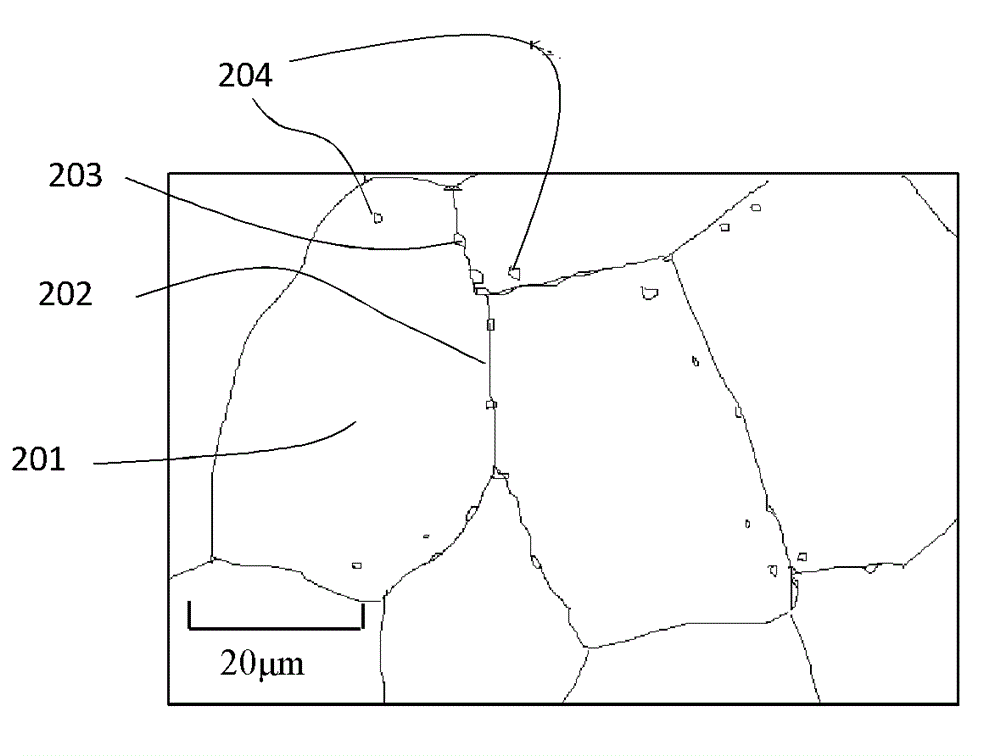

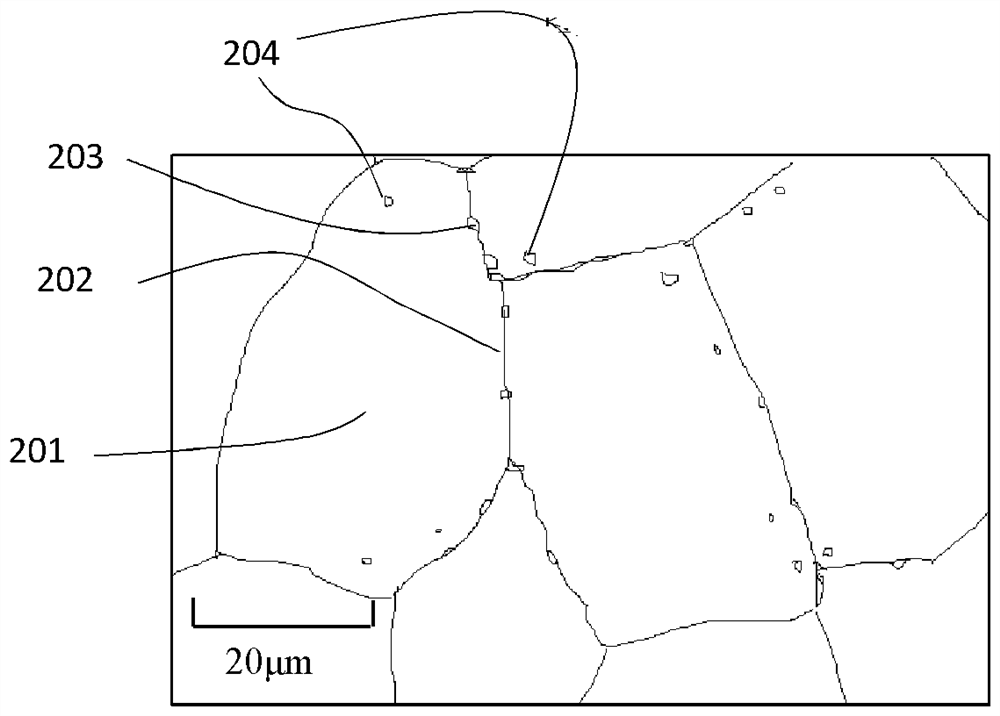

InactiveCN105439561AHigh densityInternal grain fineX/gamma/cosmic radiation measurmentLuminescent compositionsGadolinium oxysulfideGadolinium oxide

The present invention relates a low-cost two-step-sintering preparation method of gadolinium oxysulfide (GOS with the chemical formula of Gd2O2S) scintillation ceramic doped with at least one element of Pr, Ce, Tb and Eu, and the method includes hot uniaxial pressing and hot isostatic-pressing secondary sintering.

Owner:TSINGHUA UNIV +1

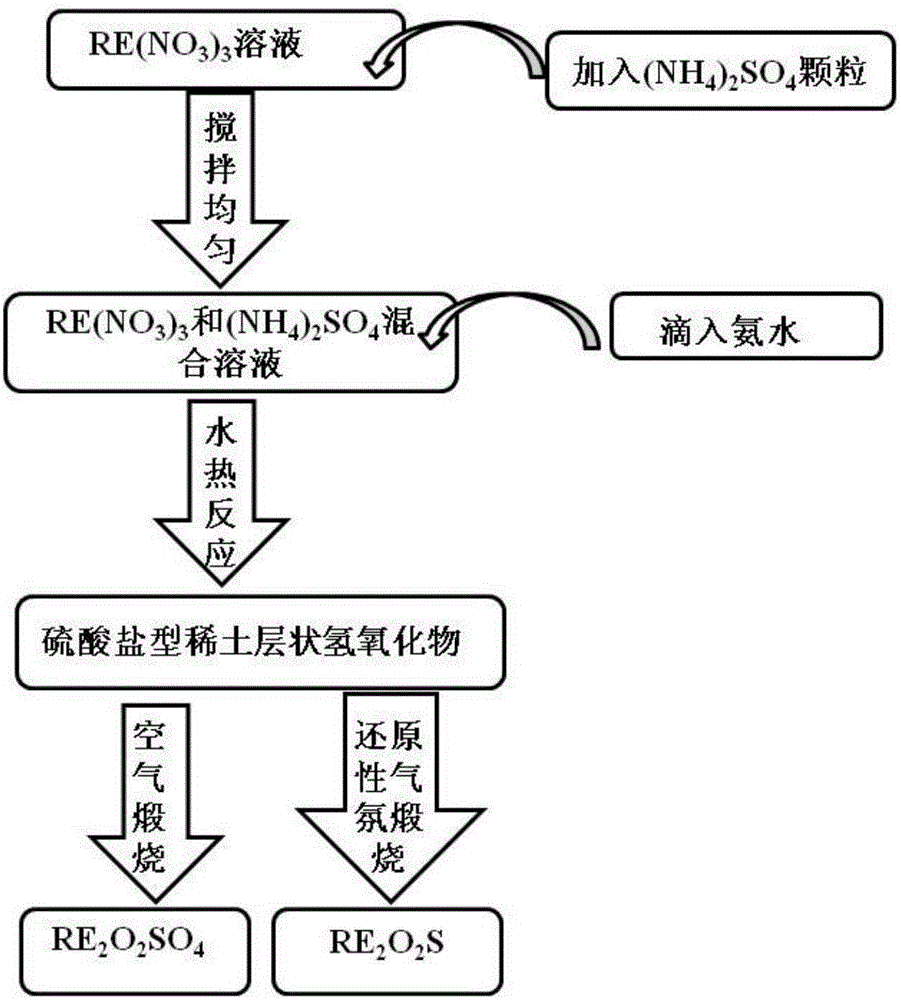

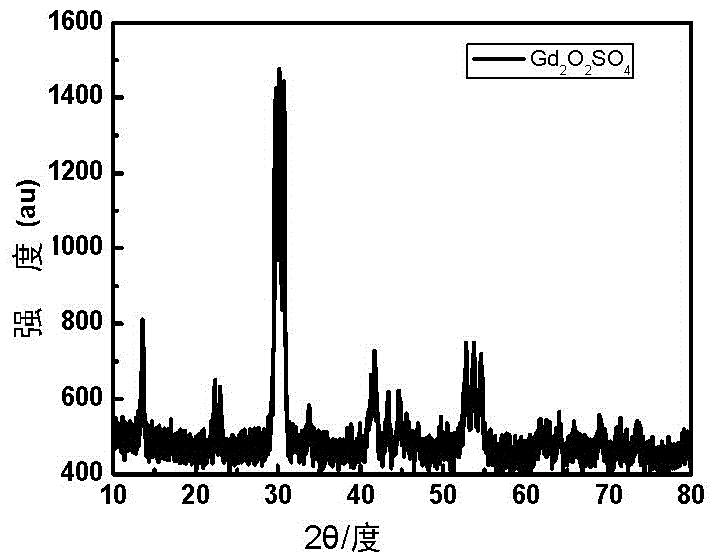

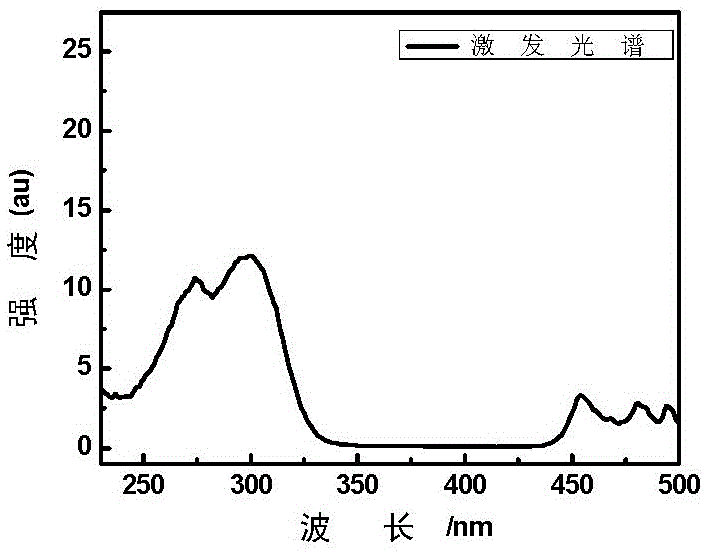

Preparation method of rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulphate up-conversion phosphor

ActiveCN106520121ASolve the discharge problemRealize green manufacturingLuminescent compositionsOxygenUp conversion

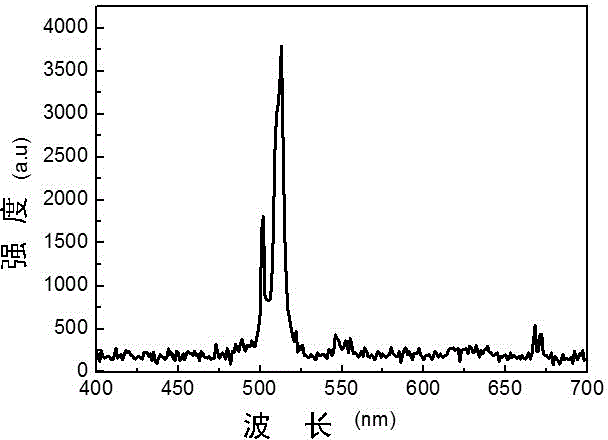

The invention provides a preparation method of rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulphate up-conversion phosphor, and belongs to the field of material science. The method comprises the following steps that 1, Gd(NO3)3.6H2O, Yb(NO3)3.6H2O and Ln(NO3)3.6H2O are mixed, deionized water is added, and a RE(NO3)3 solution is obtained; 2, ammonium sulfate is dissolved into the RE(NO3)3 solution, stirring is conducted, stirring continues, ammonia water is added, the pH value is regulated, and suspension is obtained; 3, the suspension is subjected to a hydrothermal reaction for 1-72 h at the temperature of 100 DEG C to 150 DEG C and then naturally cooled to room temperature, and a reaction product is obtained; 4, the reaction product is centrifugally separated, washed and dried, and a white powder precursor is obtained; 5, the white powder precursor is calcined, and the rare earth ion-doped Gd2O2S or Gd2O2SO4 up-conversion phosphor is obtained. According to the method, the problems of usage of sulfur-containing raw materials and discharge of harmful by-products in a conventional method are effectively solved, and the method is a green and environment-friendly preparation technique.

Owner:NORTHEASTERN UNIV

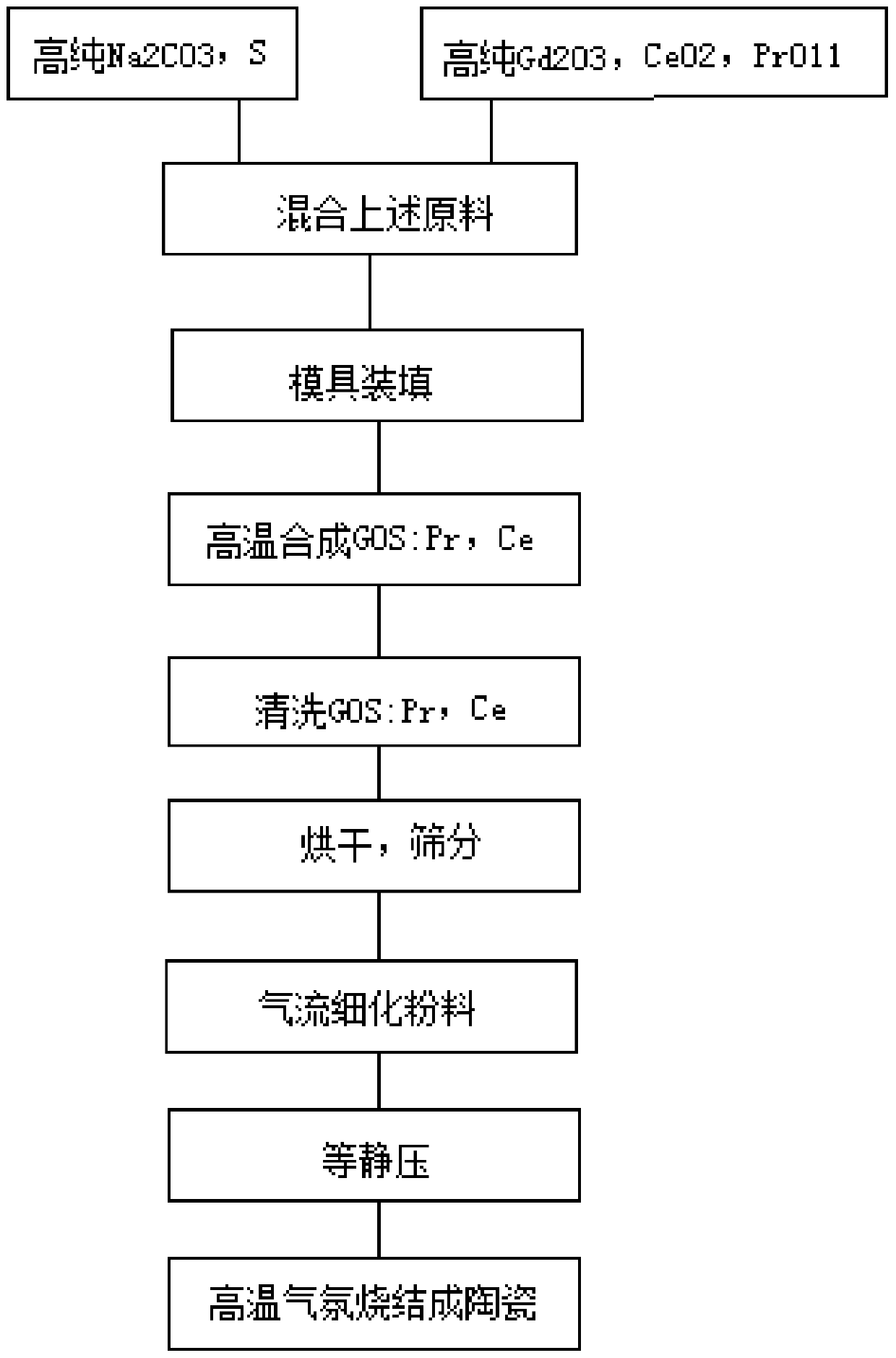

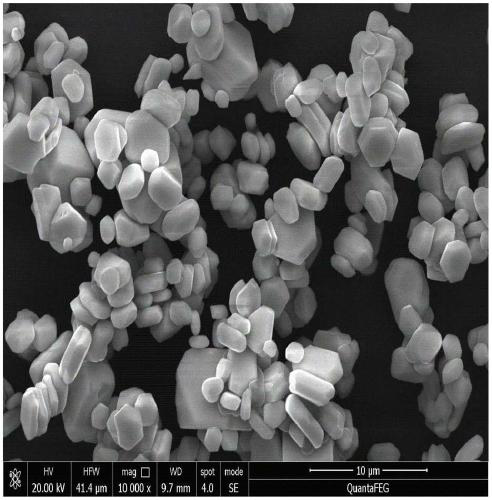

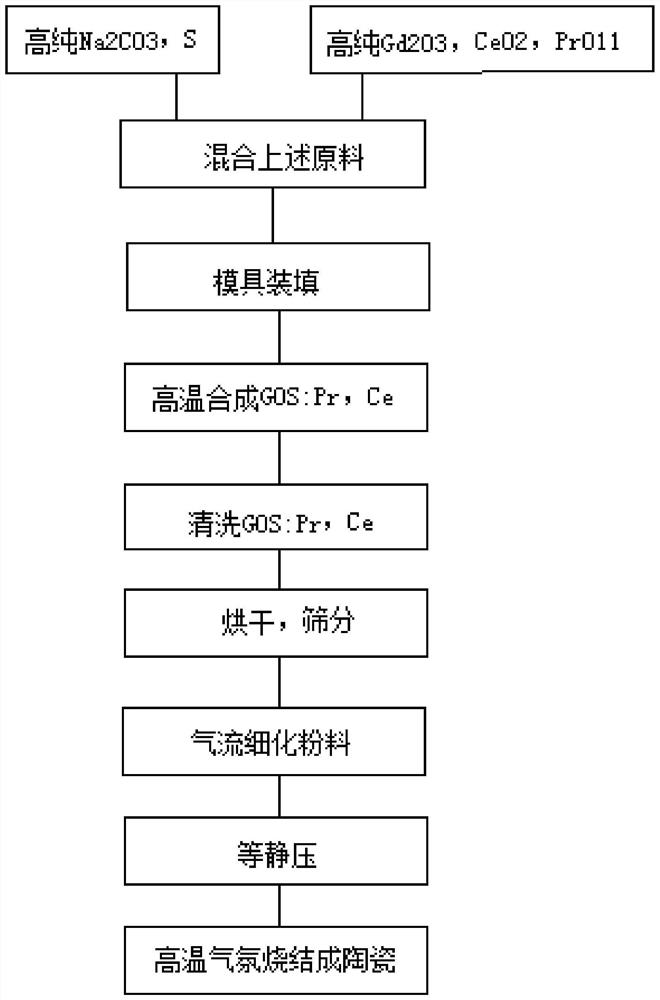

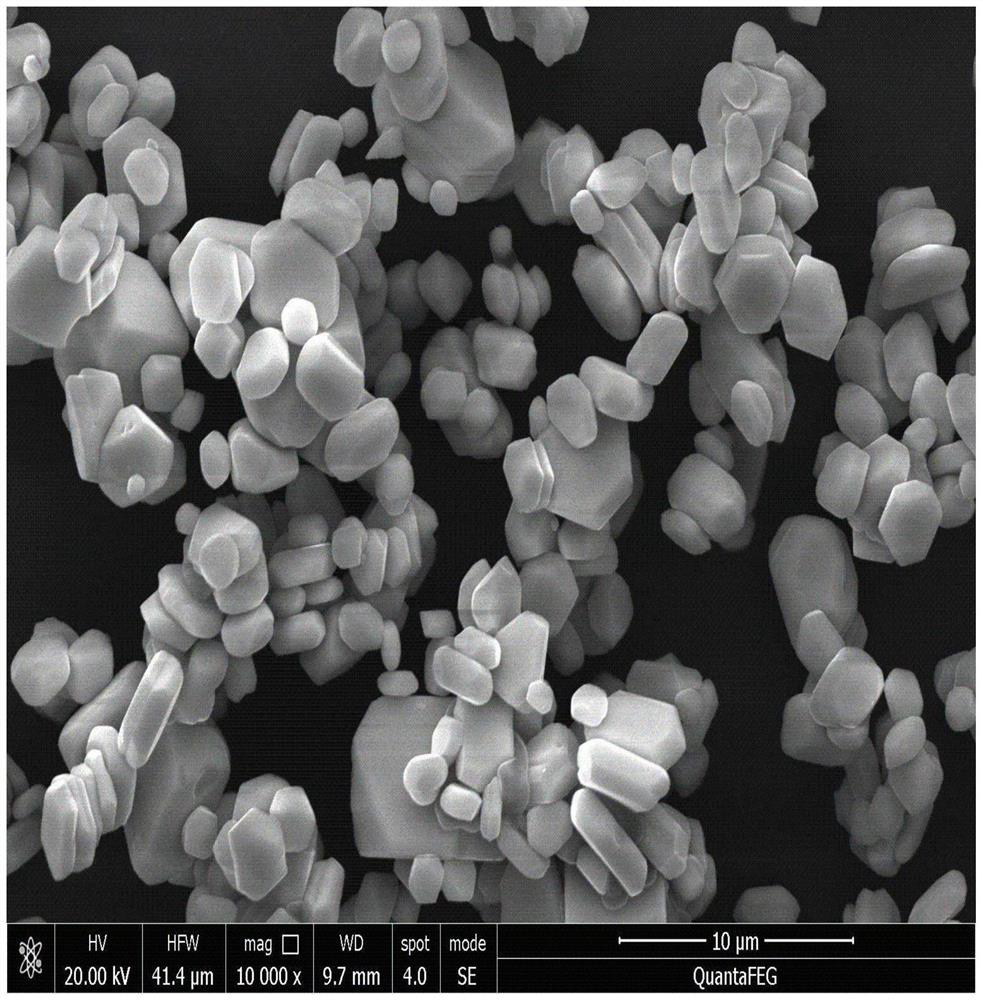

Gadolinium oxysulfide powder for X-ray detection and preparation method of scintillation ceramic

ActiveCN110282650AHigh purityEasy to manufactureRare earth metal sulfidesGadolinium oxysulfideSulfur

The invention discloses gadolinium oxysulfide powder for X-ray detection and a preparation method of scintillation ceramic. The method comprises the steps that high-purity gadolinium oxide, elemental sulfur, sodium carbonate and sodium carbonate powder are mixed to be raw materials, a mold for a special purpose is filled with the raw materials, the raw materials further include rare earth activated ions or rare earth oxide, and the raw materials are subjected to a high temperature reaction and washing to form Gd2O2S:Pr,Ce powder. Accordingly, an independent reduction reaction system is provided, the productivity is high, and the effect of uniform granulation is achieved.

Owner:江苏灵湾特种陶瓷科技有限公司

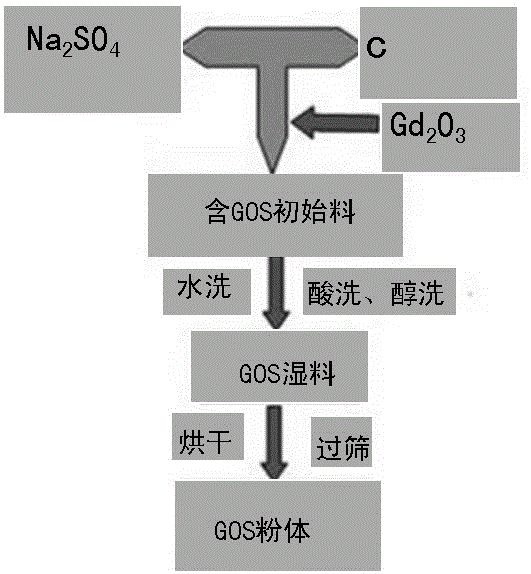

Indirect sulfur source preparation method of gadolinium oxysulfide scintillation ceramic powder

InactiveCN105800662AReduce usageImprove protectionRare earth metal compoundsGadolinium oxysulfideSulfur

The invention provides an indirect sulfur source preparation method of gadolinium oxysulfide scintillation ceramic powder. The method comprises weighing carbon, sodium sulfate and gadolinium oxide powder, blending the powder, calcining the mixed powder at a temperature of 600-1400 DEG C in an inert atmosphere and removing impurities to obtain gadolinium oxysulfide. A sulfur source is sodium sulfide prepared from carbon and sodium sulfate and the sulfur source and gadolinium oxide undergo a reaction to produce gadolinium oxysulfide. A mass ratio of the carbon, sodium sulfate to gadolinium oxide powder is 1: 1: 0.05 to 1: 7: 2, preferably, the mass ratio is 1: 1: 0.05 to 1: 6: 2 and more preferably, the mass ratio is 1: 5.875: 0.05 to 1: 7: 2.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

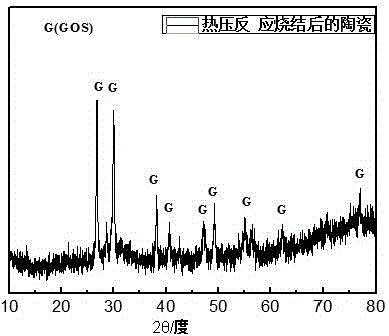

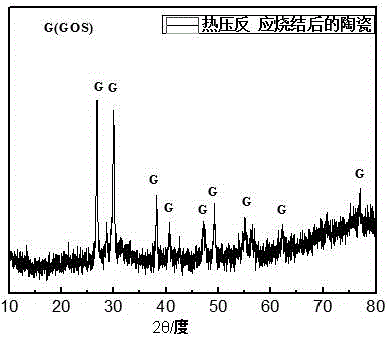

Hot-pressing reaction sintering method for gadolinium oxysulfide scintillating ceramics

ActiveCN105800663AReduce distractionsLower requirementRare earth metal compoundsGadolinium oxysulfideActivated carbon

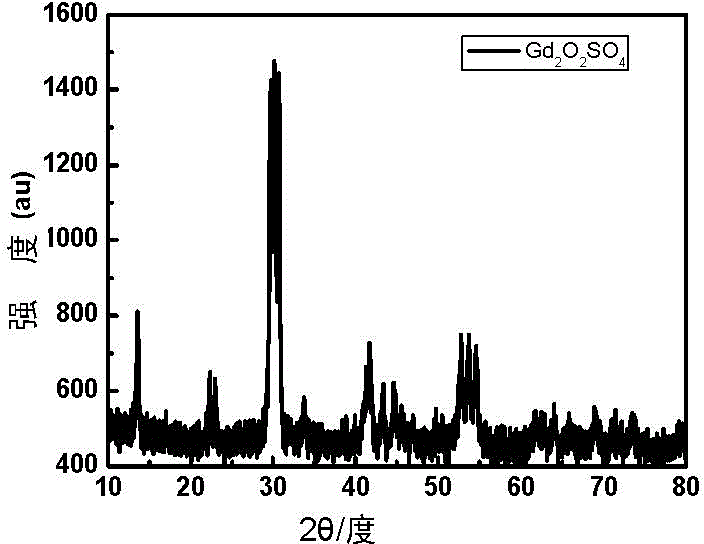

The invention relates to a hot-pressing reaction sintering method for gadolinium oxysulfide scintillating ceramics, wherein the hot-pressing reaction sintering method includes the steps: Gd2O2SO4 and a reducing agent powder are mixed evenly to obtain a raw material powder, and the raw material powder is subjected to step-wise sintering, wherein the reducing agent includes activated carbon, graphene, coke and charcoal, the step-wise sintering comprises first-stage sintering at the temperature of 820-950 DEG C and the pressure of 10-75 MPa and second-stage sintering at the temperature of 1000-1500 DEG C and the pressure of 30-150 MPa, and an inert atmosphere, a reducing atmosphere or vacuum is maintained in the sintering process.

Owner:中科西卡思(苏州)科技发展有限公司

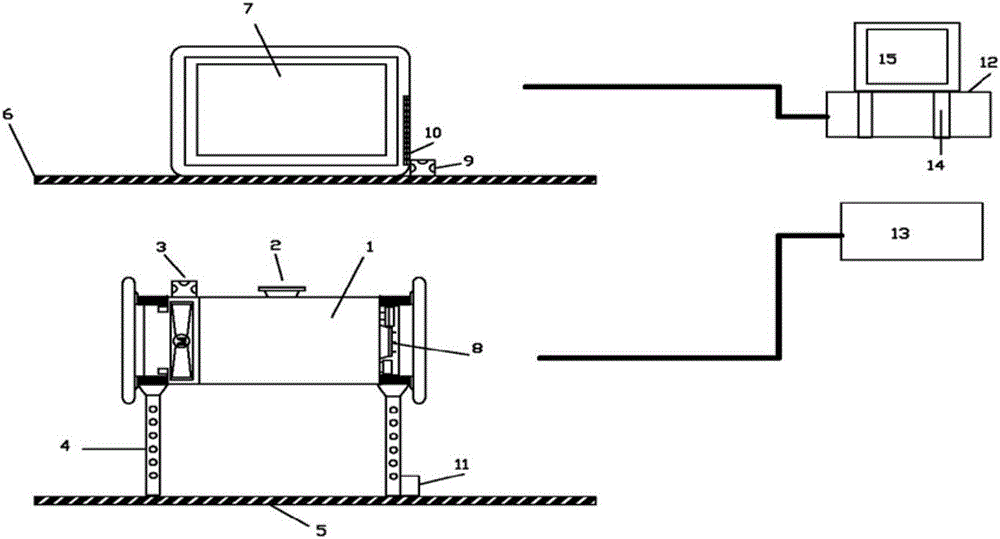

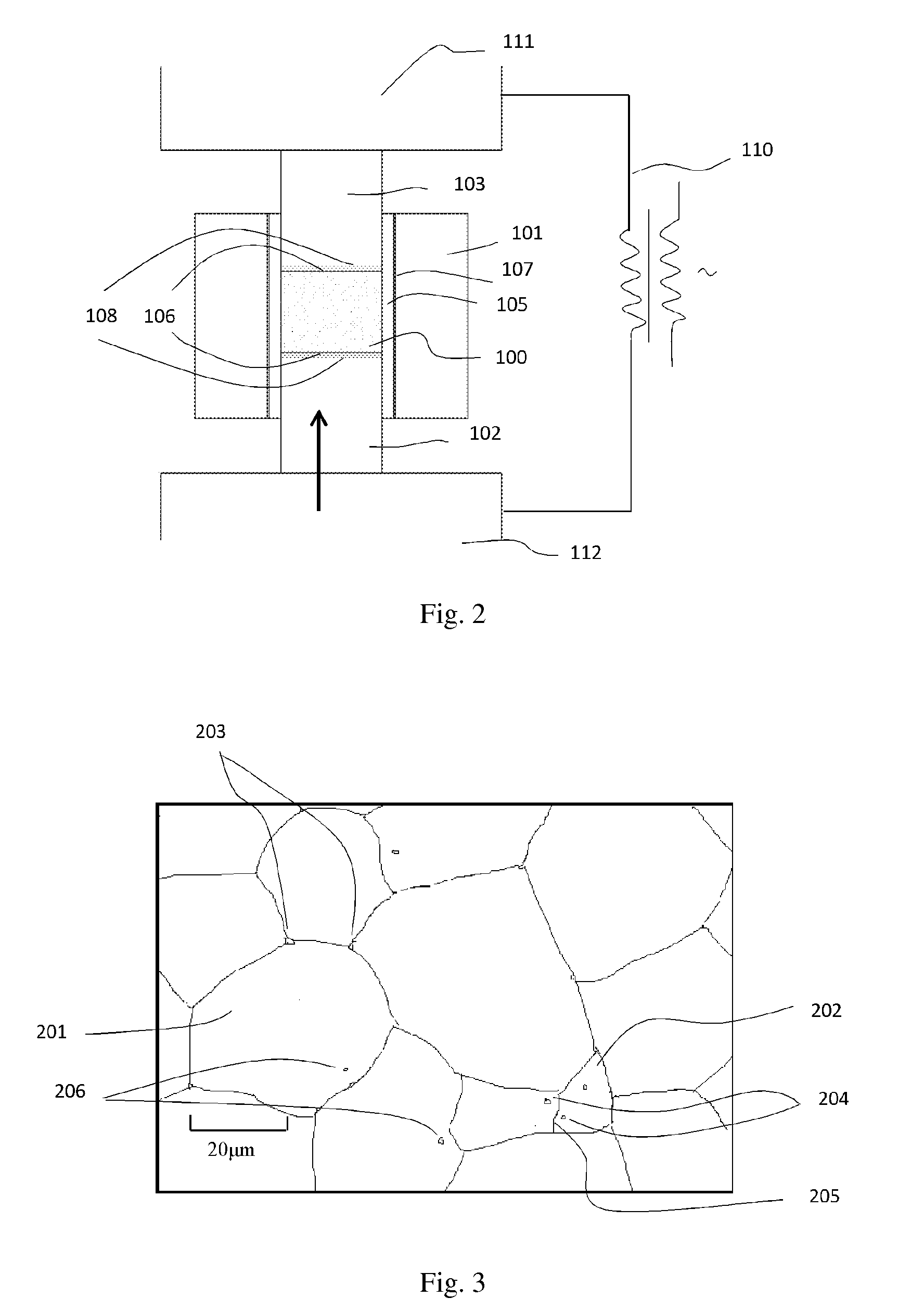

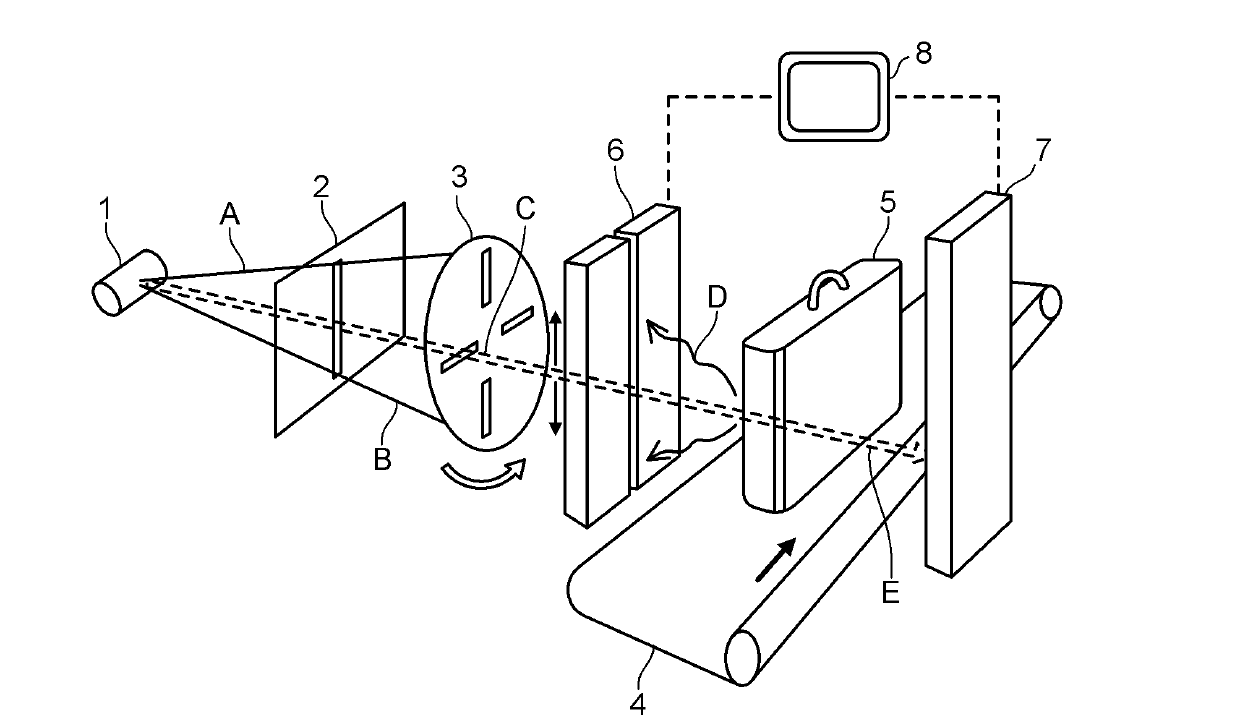

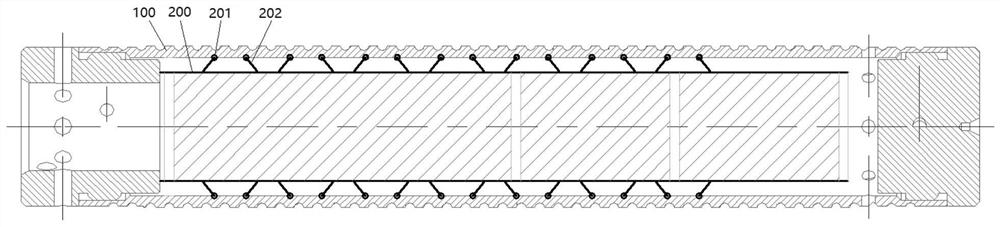

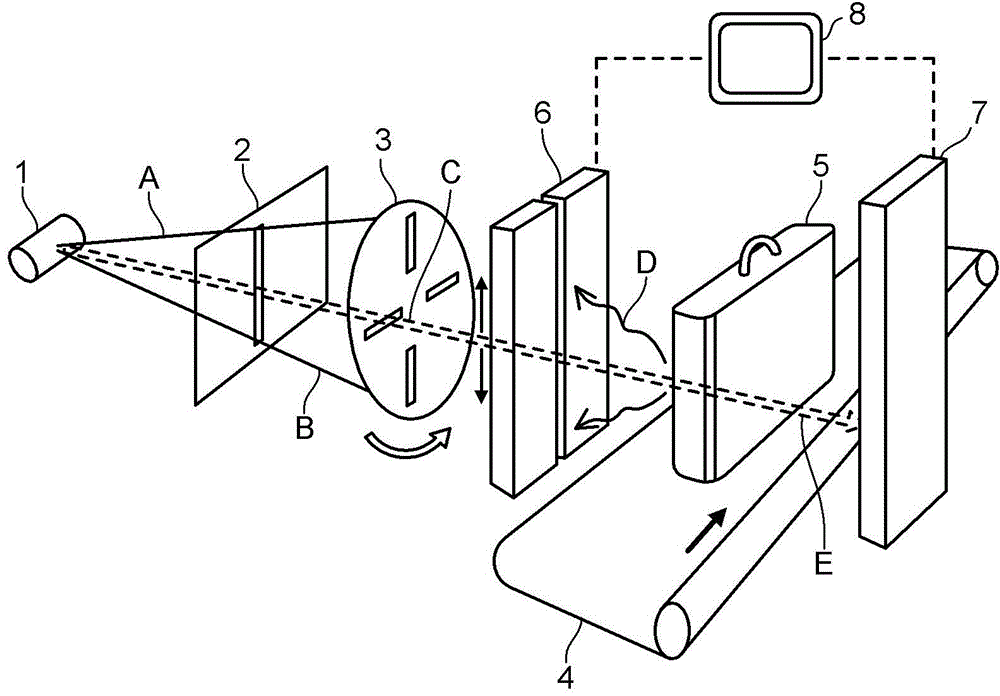

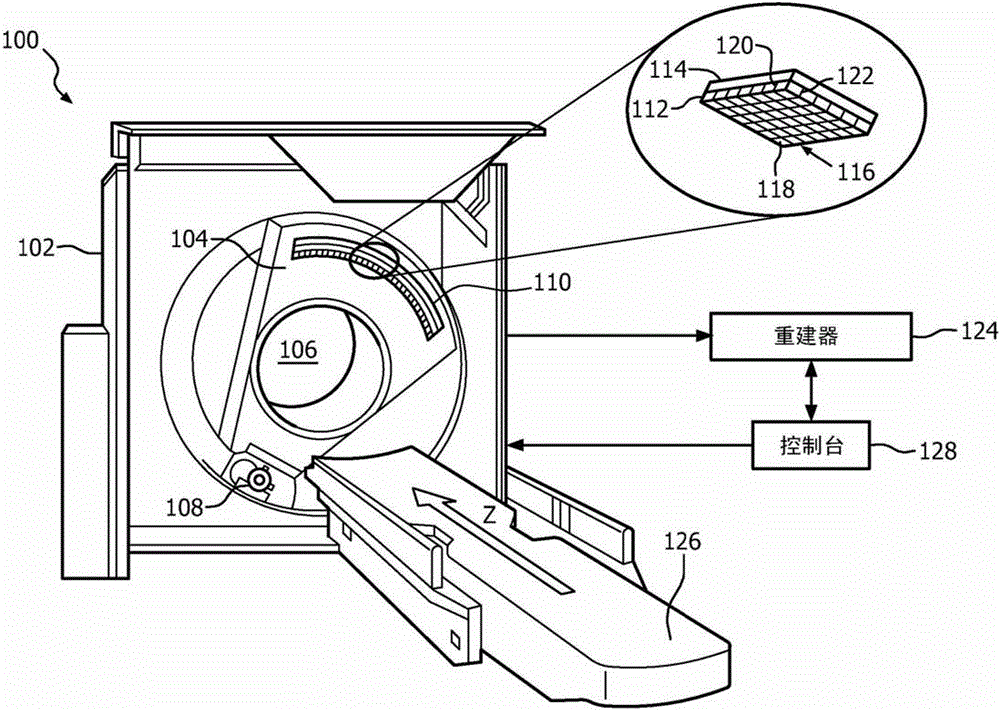

Reinforced concrete structure X-ray imaging detector

InactiveCN106066336AGuaranteed accuracyEasy to detectMaterial analysis by transmitting radiationGadolinium oxysulfideHigh frequency power

The invention relates to a reinforced concrete structure X-ray imaging detector, belongs to the field of reinforced concrete structure X-ray imaging detection, and concretely relates to reinforced concrete cast structure layer, beam, column and plate X-ray imaging detection. The reinforced concrete structure X-ray imaging detector comprises an X-ray source generator device, an X-ray source modulator outputs a controllable high-frequency power supply feedback sampling signal in order to make amount-adjustable X-ray be emitted from the X-ray source generator device and penetrate through a detected substance, a gadolinium oxysulfide amorphous silicon flat detector receives the obtained X-ray, converts the X-ray into a digital signal and transmits the digital signal to a computer, the computer acquires and displays the real image of the internal of the detected substance in order to accurately judge the crack, the cavity, the shape structure change and the substance density in the detected substance, and a magnetic positioning, receiving and emitting device controls the journey of a mobile track in order to realize synchronous motion, reach detection full-coverage rate and guarantee the operating safety.

Owner:杭州惠威无损探伤设备有限公司

PROCESS FOR THE PREPARATION OF GADOLINIUM OXYSULFIDE (Gd2O2S) SCINTILLATION CERAMICS

ActiveUS20160046861A1Efficient preparationSynthetic resin layered productsLuminescent compositionsGadolinium oxysulfideCeramic

The present disclosure is directed to a rapid process for the preparation of gadolinium oxysulfide having a general formula of Gd2O2S, referred to as GOS, scintillation ceramics by using the combination of spark plasma primary sintering (SPS) and hot isostatic pressing secondary sintering.

Owner:TSINGHUA UNIV +1

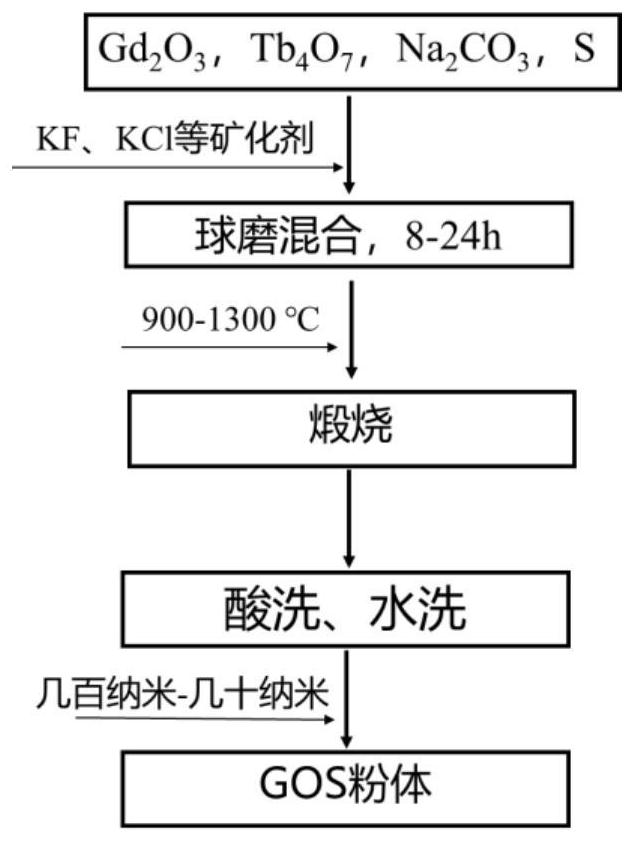

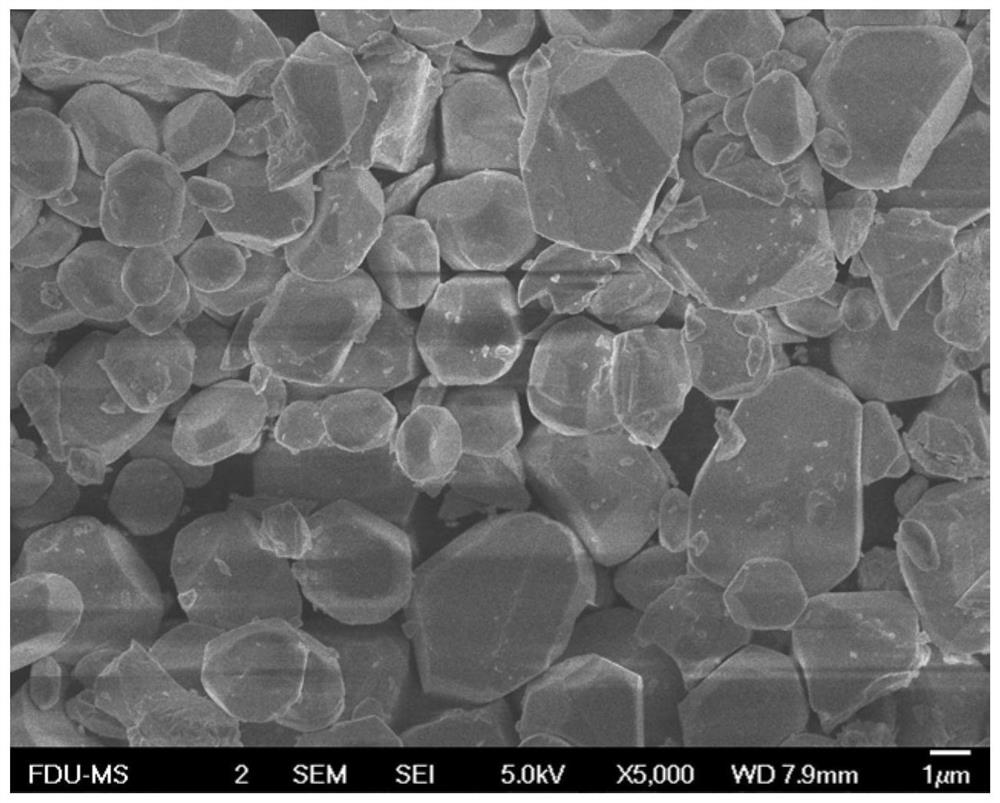

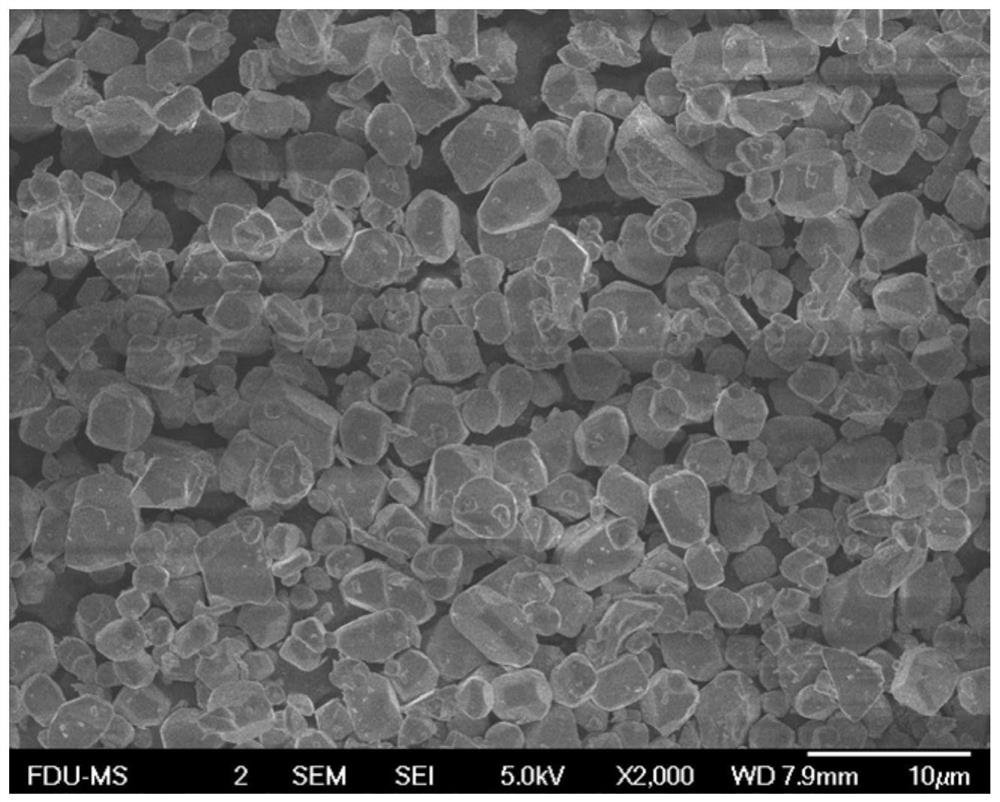

Preparation method of gadolinium oxysulfide powder

PendingCN114162847AReduce usageAvoid dischargeRare earth metal sulfidesRare earth metal compounds preparation/treatmentGadolinium oxysulfidePhysical chemistry

The invention provides a preparation method of gadolinium oxysulfide powder, which comprises the following steps: A) mixing Gd2O3, an activating agent, a fluxing agent and sulfur according to a stoichiometric ratio to obtain mixed powder; b) carrying out ball milling on the mixed powder and a mineralizing agent to obtain precursor powder; and C) calcining the precursor powder to obtain primary powder, and performing acid pickling and vacuum drying on the primary powder to obtain the gadolinium oxysulfide powder. The preparation method of the gadolinium oxysulfide powder provided by the invention is green and environment-friendly, and the gadolinium oxysulfide powder with fine and uniform particle size can be prepared.

Owner:安徽光智科技有限公司

Preparation method and application of gadolinium oxysulfide scintillation ceramic

PendingCN114031403AGrain refinementImprove compactnessX/gamma/cosmic radiation measurmentGadolinium oxysulfideHigh density

The invention discloses a preparation method of gadolinium oxysulfide scintillation ceramics, which is characterized in that Gd2O2S scintillation powder is sintered and molded by one-step sintering through a vacuum hot pressing sintering or spark plasma sintering method, and gadolinium oxysulfide polycrystalline scintillation ceramic doped with at least one element of Pr, Eu, Tb, Sm, Yb and Tm is efficiently obtained. According to the method, qualified gadolinium oxysulfide scintillation ceramic can be obtained through one-time sintering, secondary sintering does not need to be carried out through a method combining SPS or uniaxial hot pressing with hot isostatic pressing, and the defects that in the current hot isostatic pressing technology, a green body needs to be sintered firstly, gadolinium oxysulfide powder metal needs a vacuum sealing technology, the cost is high, and the technological process is complex are overcome; and the production process is more energy-saving and more efficient. According to the method, the temperature rise rate, pressure, temperature and time of sintering are combined, so that the characteristics of fine grain size and high density of a gadolinium oxysulfide scintillation ceramic finished product are effectively ensured, and popularization and application are facilitated.

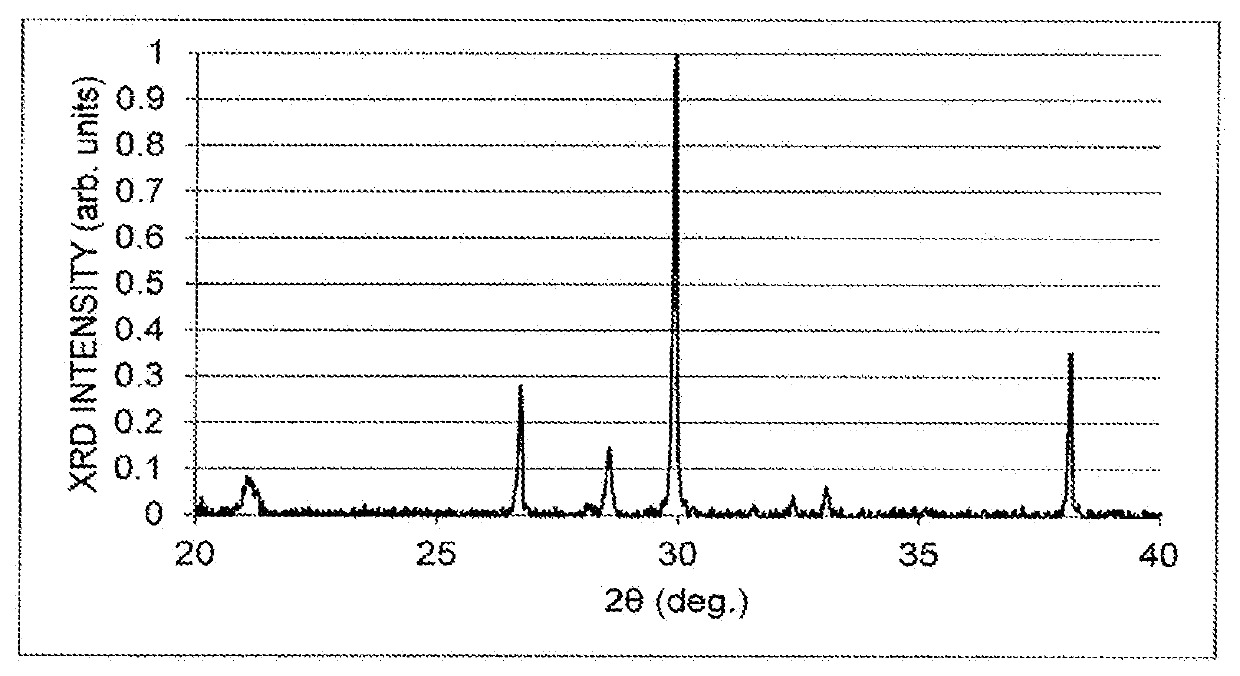

Gadolinium oxysulfide sintered body, and scintillator, scintillator array, radiation detector, and radiation inspection apparatus including gadolinium oxysulfide sintered body

PendingCN110225898AImprove light outputHigh sensitivityMaterial analysis using wave/particle radiationLuminescent compositionsGadolinium oxysulfidePhysical chemistry

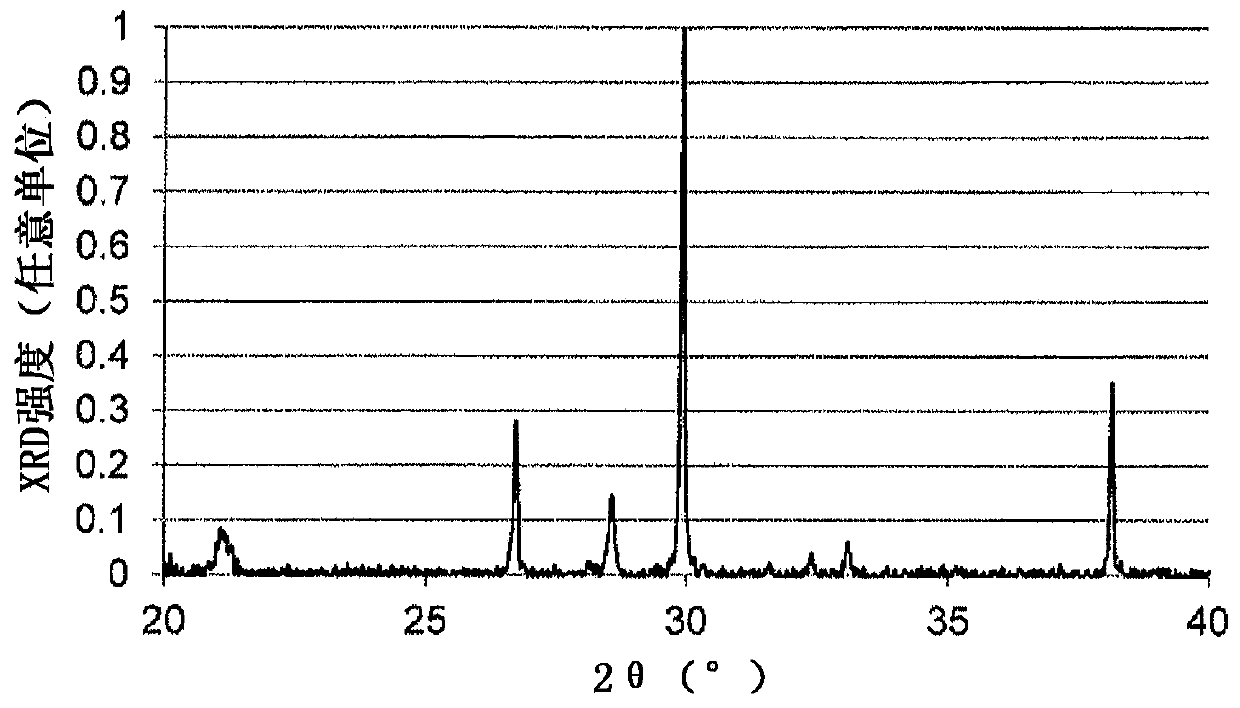

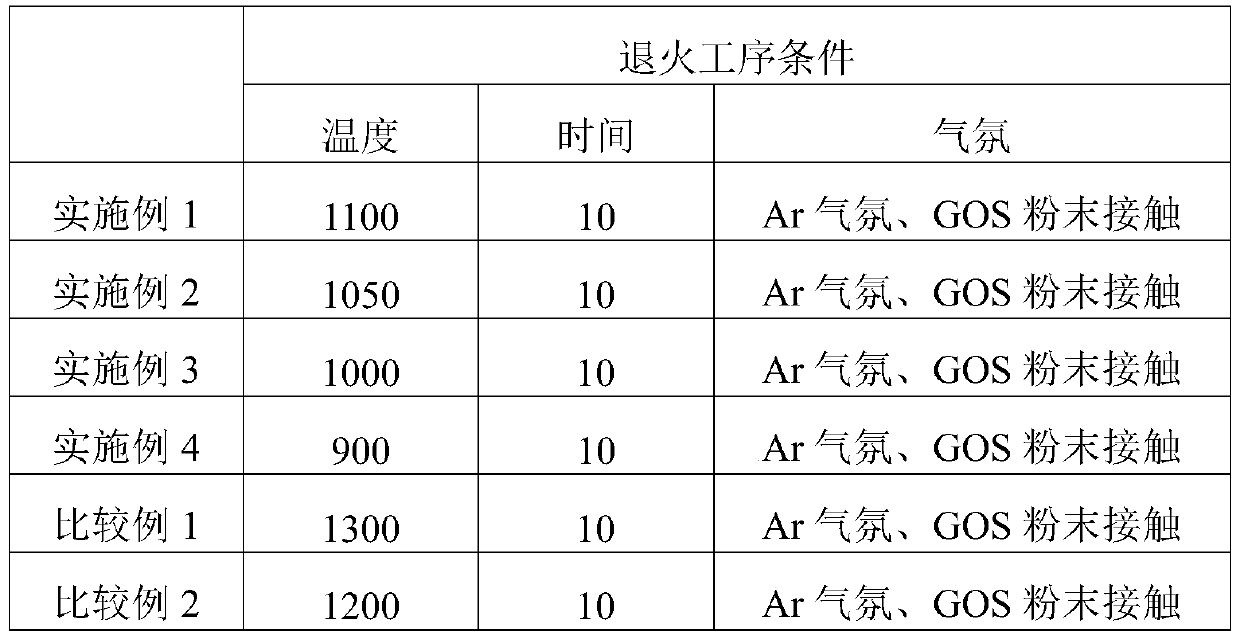

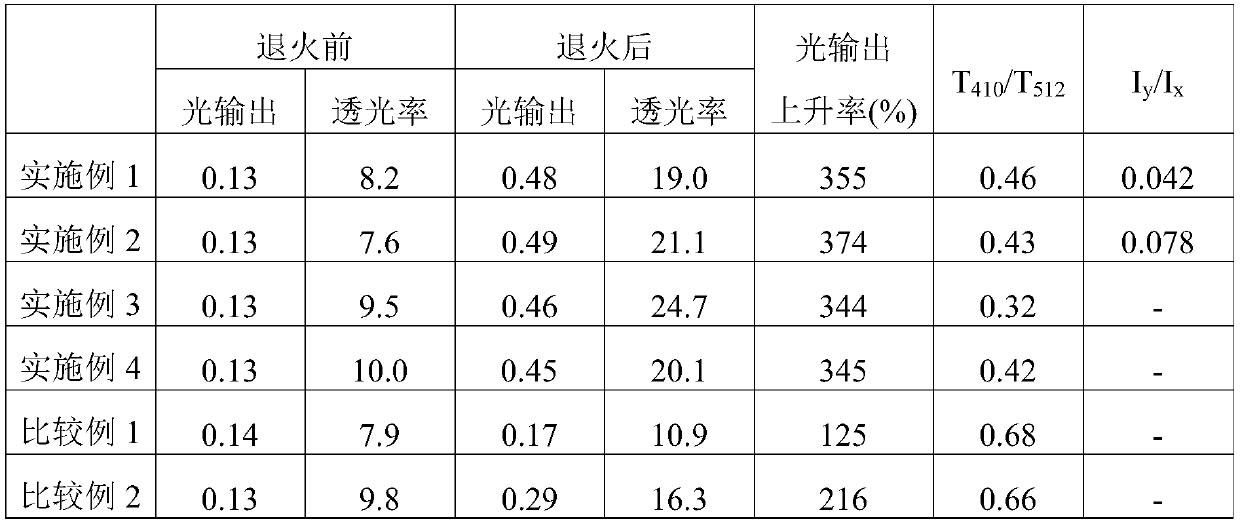

The present invention provides a gadolinium oxysulfide sintered body having high optical output. The problem is overcome by using a gadolinium oxysulfide sintered body comprising at least one augmenting agent selected from the group consisting of praseodymium, terbium, and cerium, wherein the ratio of the light transmittance at 410 nm T410 relative to the light transmittance at 512 nm T510 (T410 / T512) is 0.31 to 0.61, while, in the XRD diffraction pattern, the ratio of the diffraction peak intensity Iy of phases other than gadolinium oxysulfide appearing at 2theta = 20 to 29 degrees relative to the (102) or (011) diffraction peak intensity Ix of gadolinium oxysulfide appearing at 2theta = 30 + / - 1 degrees (Iy / x) is 0.1 or less.

Owner:MITSUBISHI CHEM CORP

Preparation method of gadolinium oxysulfide scintillation ceramic

InactiveCN112358296AHigh densityInternal grain fineX/gamma/cosmic radiation measurmentLuminescent compositionsGadolinium oxysulfideGadolinium oxide

The invention relates to a preparation method of gadolinium oxysulfide scintillation ceramic, particularly to a low-cost two-step sintering preparation method of scintillation ceramic with GOS (general chemical formula of Gd2O2S) doped with at least one element of Pr, Ce, Tb and Eu, wherein the method comprises uniaxial hot pressing primary sintering and hot isostatic pressing secondary sintering.

Owner:TSINGHUA UNIV +1

Preparation method of gadolinium oxysulfide powder and scintillation ceramics for X-ray detection

ActiveCN110282650BHigh purityEasy to manufactureRare earth metal sulfidesGadolinium oxysulfidePhysical chemistry

The invention discloses a preparation method of gadolinium oxysulfide powder for X-ray detection and scintillation ceramics thereof, which comprises raw materials mixed with high-purity gadolinium oxide, elemental sulfur, soda ash and sodium carbonate powder, and the raw materials are filled into a special mold Specifically, the raw material also includes rare earth activated ions or rare earth oxides, and the raw material forms Gd through high temperature reaction and cleaning. 2 o 2 S: Pr, Ce powder. The invention has an independent reduction reaction system, high production capacity, and the effect of uniform granulation.

Owner:江苏灵湾特种陶瓷科技有限公司

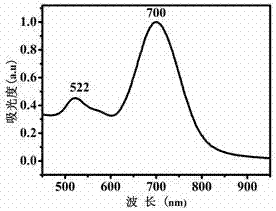

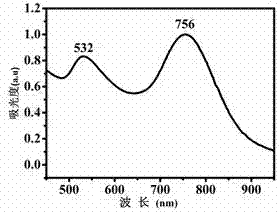

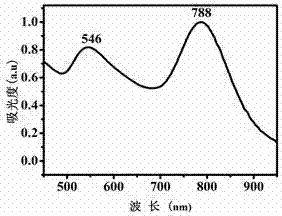

Modified gold nanorod @ gadolinium oxysulfide (Gd2O2S) and preparation method thereof

InactiveCN107243631ALow biological toxicityImprove light and heat stabilityMaterial nanotechnologyEnergy modified materialsGadolinium oxysulfideGold nanorod

The invention relates to a preparation method of a gadolinium oxysulfide (Gd2O2S) gold nanorod core-shell structure. The preparation method comprises the following steps: preparing seed crystals, preparing a growth solution, preparing gold nanorods and preparing the Gd2O2S gold nanorod core-shell structure (GNRs@Gd2O2S). The modified gold nanorod @ gadolinium oxysulfide (Gd2O2S) and the preparation method thereof have the characteristics as follows: the preparation method is simple and repeatable, the biocompatibility is good, and good light-heat conversion efficiency is achieved; besides, both magnetic resonance imaging (MRI) and photoacoustic imaging (PAI) can be carried out, the diagnosis and treatment of tumor are combined, and good biological-medical and cancer therapic application prospects are achieved.

Owner:FUZHOU UNIV

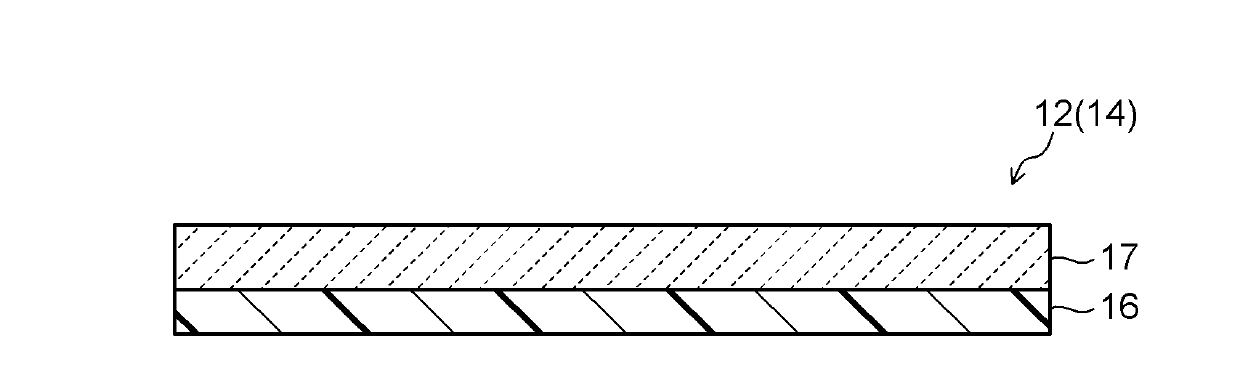

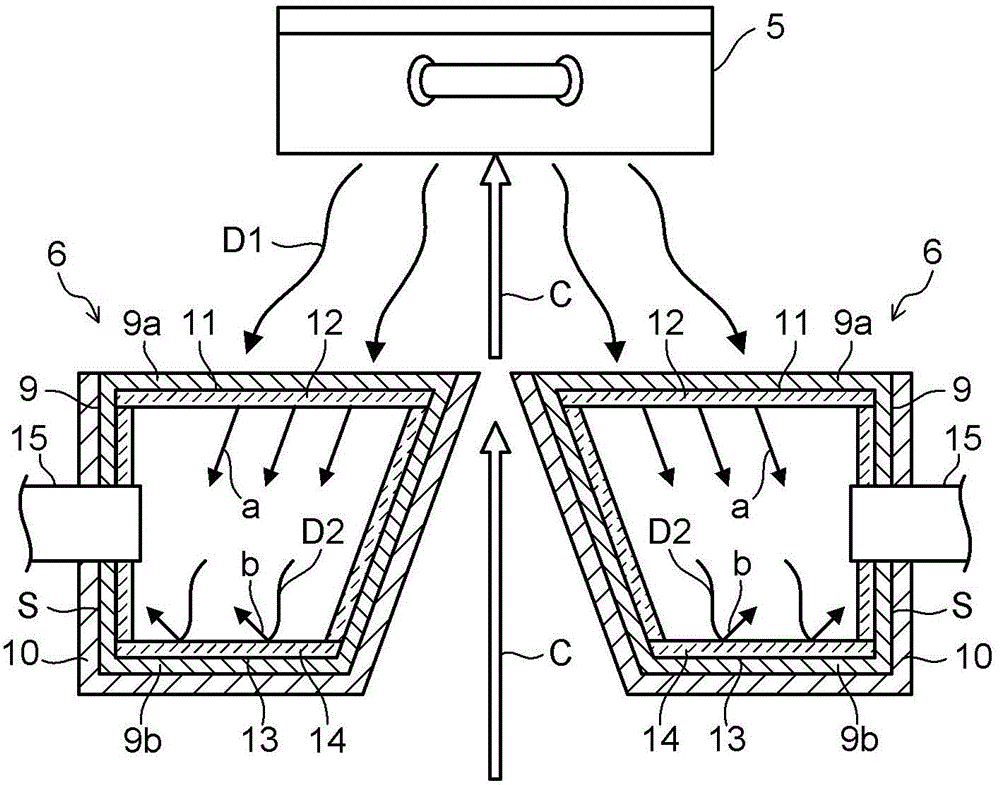

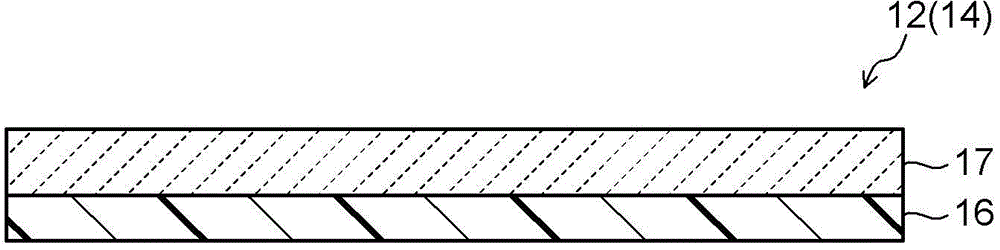

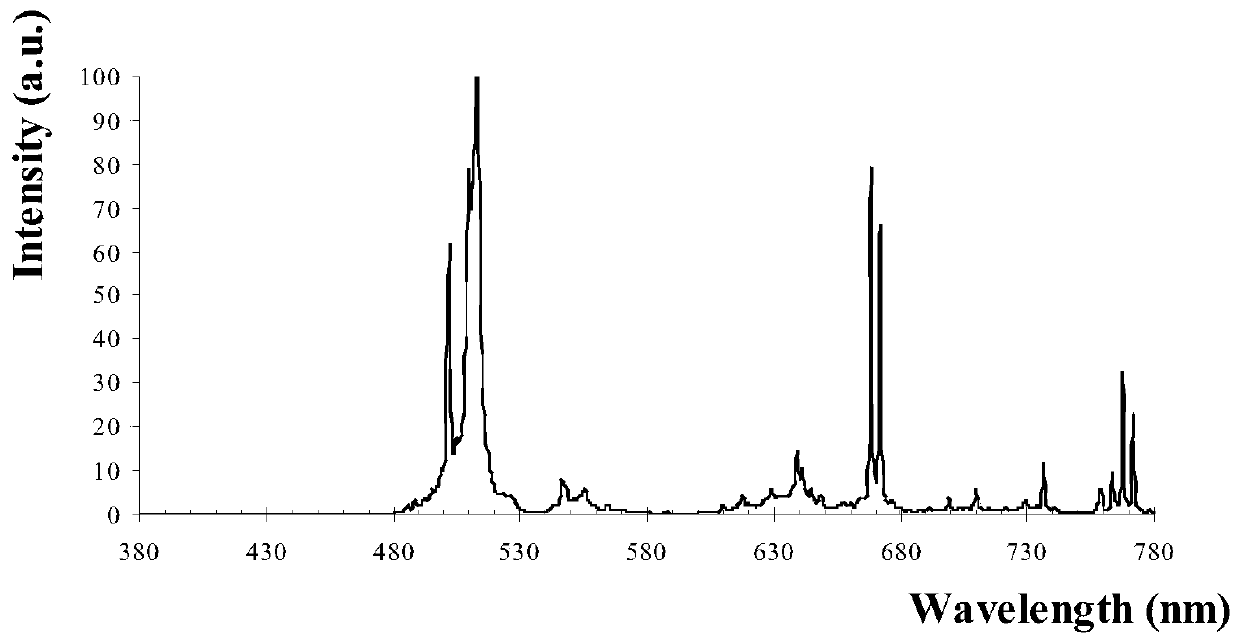

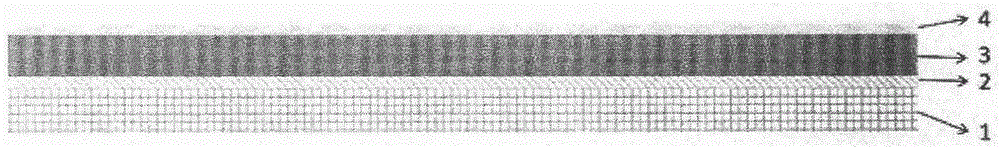

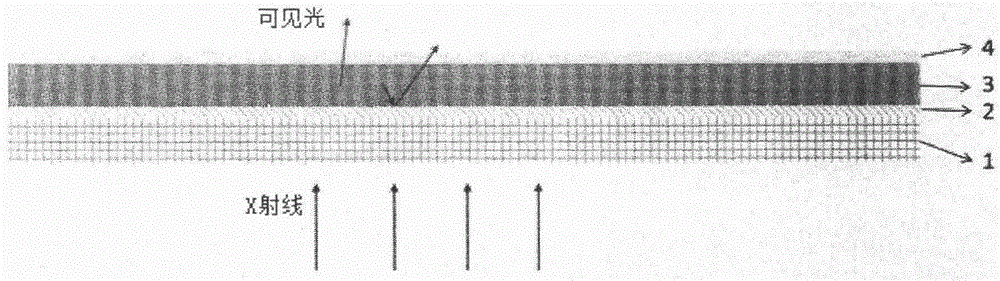

Fluorescent screen, x-ray detector, and x-ray inspection apparatus

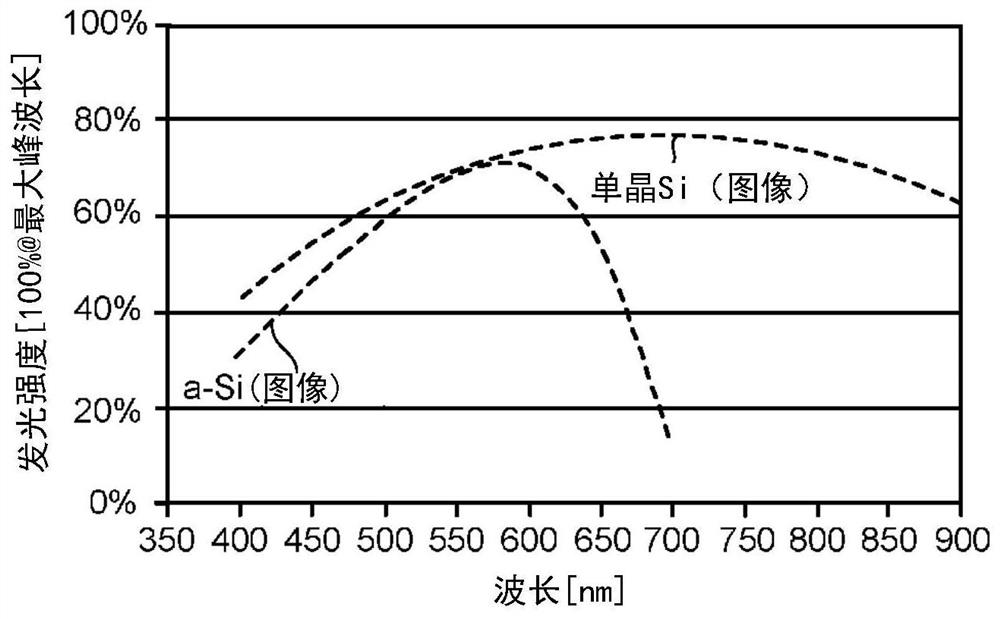

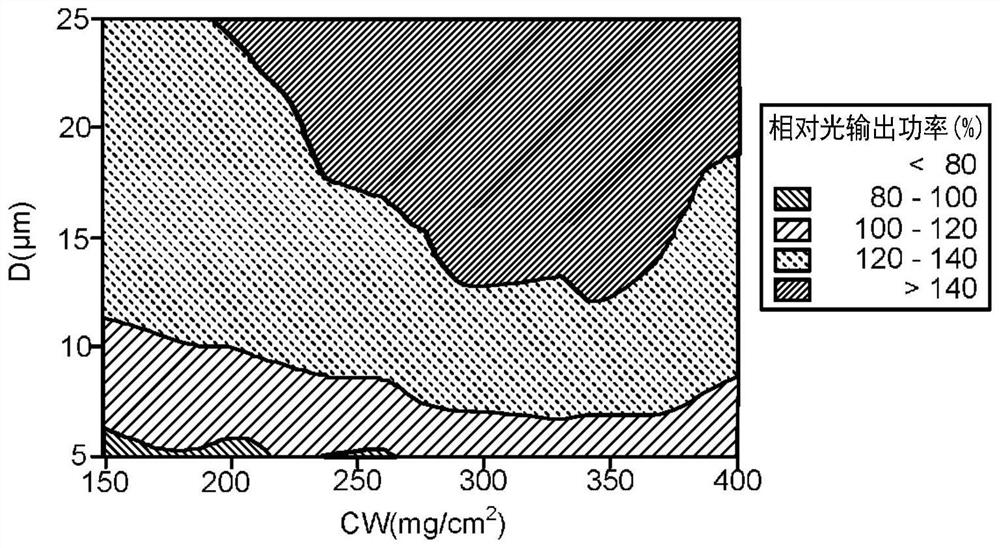

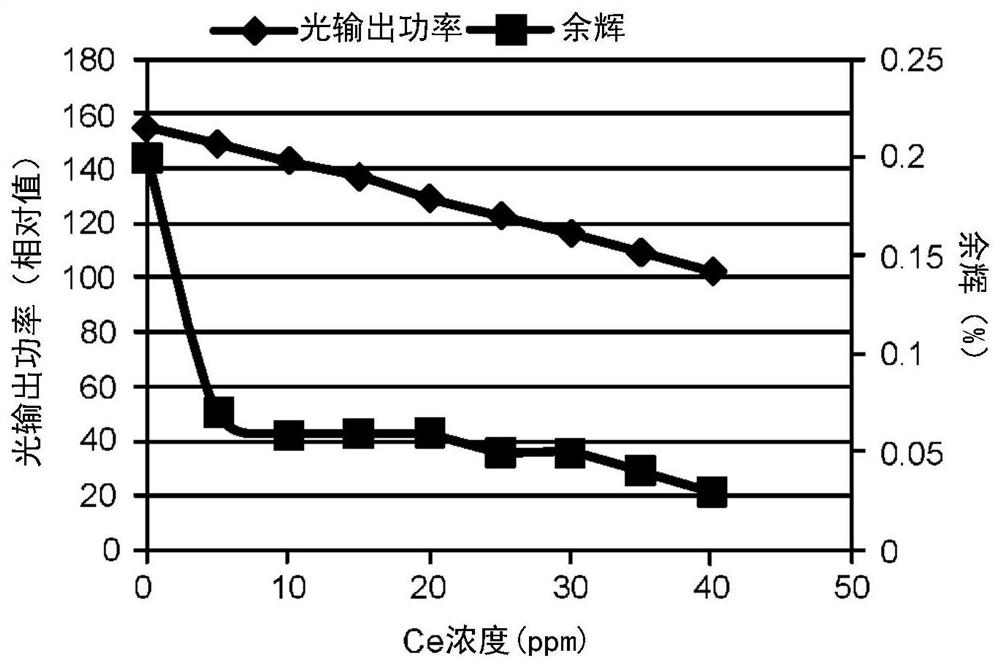

PendingCN113287176AX-ray/infra-red processesX/gamma/cosmic radiation measurmentGadolinium oxysulfidePhosphor

A fluorescent screen is configured to convert an X-ray into visible light to one embodiment. The screen includes a gadolinium oxysulfide phosphor activated with praseodymium and cerium. The phosphor contains praseodymium having a concentration of 0.01 mass % or more and 0.3 mass % or less and cerium having a concentration of 5 ppm or more and 30 ppm or less. An average particle diameter of the phosphor is 10 [mu]m or more and 20 [mu]m or less. A weight per unit area of the phosphor is 270 mg / cm2 or more and 380 mg / cm2 or less.

Owner:KK TOSHIBA +1

Method for preparing gadolinium oxysulfide ceramic hollow microspheres

The invention discloses a method for preparing gadolinium oxysulfide ceramic hollow microspheres, which comprises the following steps: adding additives into a water solvent, uniformly mixing to prepare a premixed solution, and the additives comprise a dispersing agent, a monomer, a cross-linking agent, a green body reinforcing agent, a closed pore forming agent and a sintering aid; carrying out ball milling on Gd2O2S ceramic powder and the premixed liquid to prepare Gd2O2S slurry with the solid content of 75-85%, adding an initiator and a catalyst, and uniformly mixing for later use; a semi-arc-shaped super-hydrophobic track coated with a super-hydrophobic film is manufactured, the track is arranged on an inclined rack, and a heating belt is attached to the lower portion of the inclined plane of the track; a dispensing machine needle head is selected to enable a titration needle cylinder to be located at the position 18-15 cm above the track, Gd2O2S ceramic slurry is injected into the titration needle cylinder, the inclined plane is controlled to be heated to 150-210 DEG C, the size of liquid drops is controlled to be 0.18-1 mm through the air inlet pressure of compressed air and the size of a needle hole, the liquid drops drop on the metal track coated with the super-hydrophobic film from the top end of the inclined plane, and the Gd2O2S ceramic slurry is obtained. The Gd2O2S microspheres roll downwards and are heated and cured into Gd2O2S microsphere blanks; and drying and degreasing the formed Gd2O2S ball blank, and sintering to obtain the Gd2O2S ceramic hollow microsphere.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Gadolinium oxysulfide sintered body, and scintillator, scintillator array, radiation detector, and radiation inspection apparatus including gadolinium oxysulfide sintered body

ActiveUS20190345383A1Improve light outputImprove signal-to-noise ratioMaterial analysis using wave/particle radiationLuminescent compositionsGadolinium oxysulfideCerium

The present invention provides a gadolinium oxysulfide sintered body having a high light output. The problem is resolved by a gadolinium oxysulfide sintered body in which the ratio of the light transmittance T410 of 410 nm to the light transmittance T512 of 512 nm (T410 / T512) is from 0.31 to 0.61, or a gadolinium oxysulfide sintered body in which the ratio of the diffraction peak intensity Iy of a phase different from gadolinium oxysulfide appearing at 2θ=from 20 to 29° to the diffraction peak intensity (Ix) of (102) or (011) of gadolinium oxysulfide appearing at 2θ=30°±1° (Iy / Ix) is 0.1 or less in an XRD diffraction pattern and which contains one or more activators selected from the group consisting of praseodymium, terbium, and cerium.

Owner:MITSUBISHI CHEM CORP

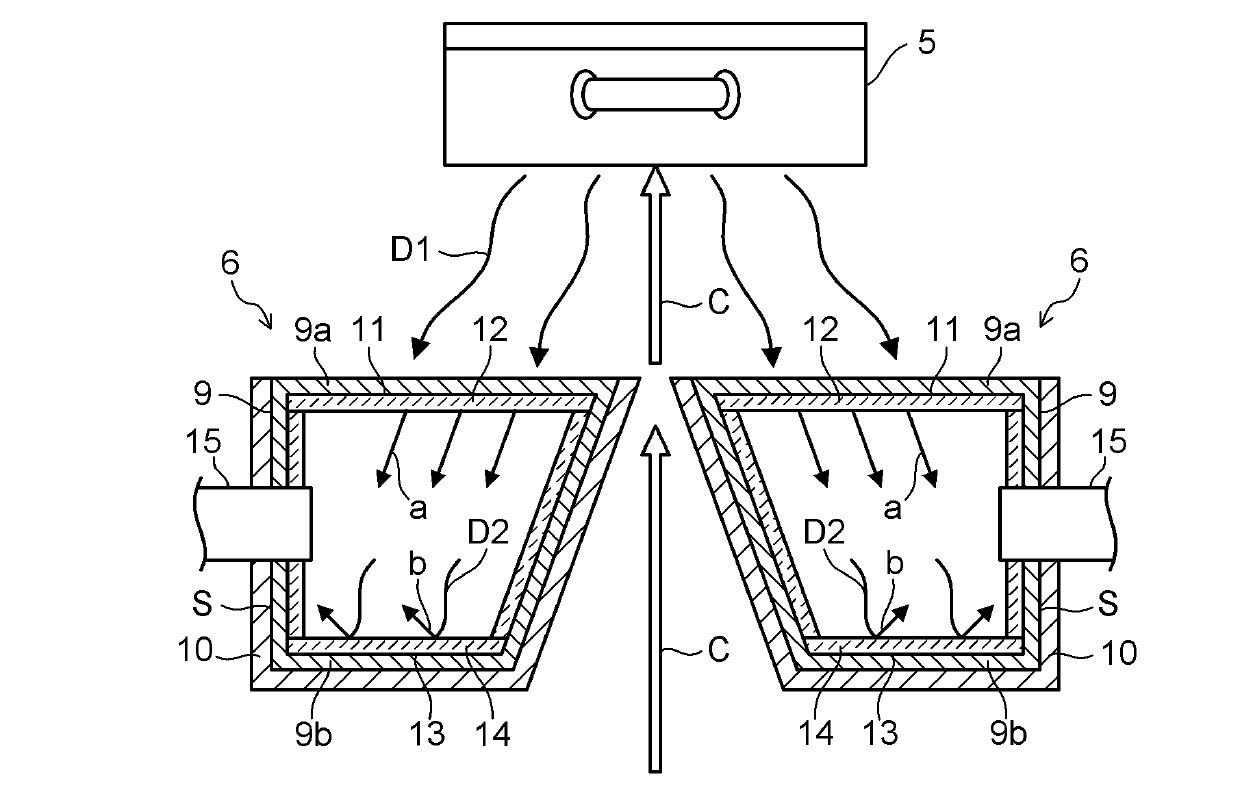

Intensifying screen for x-ray detector, x-ray detector, and x-ray inspection device

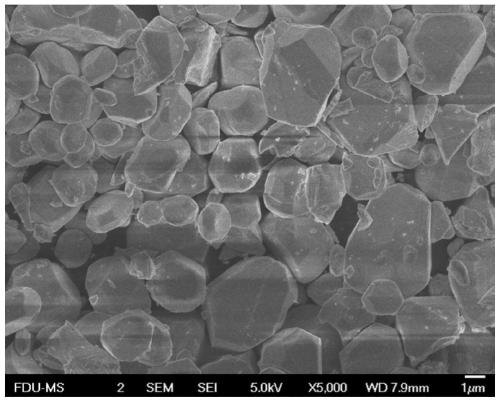

ActiveCN103140898AReduce riskCheck image clarityX-ray/infra-red processesLuminescent compositionsSoft x rayGadolinium oxysulfide

An X-ray detector (6) of an embodiment is provided with a transmission-type fluorescence generation portion (11) provided on an incident portion (9a) of a detector body (9), and a reflection-type fluorescence generation portion (13) provided on a portion (9b) other than the incident portion (9a) of the detector body. The transmission-type fluorescence generation portion (11) and the reflection-type fluorescence generation portion (13) are each provided with an intensifying screen provided with a phosphor layer containing praseodymium-activated gadolinium oxysulfide phosphor particles, among which the percentage of particles having a particle diameter within plus or minus 30% of a median particle diameter is 45 vol% or more, and the filling percentage of which is 60 vol% or more, and / or an intensifying screen provided with a phosphor layer containing europium-activated barium chloride fluoride phosphor particles, among which the percentage of particles having a particle diameter within plus or minus 30% of a median particle diameter is 45 vol% or more, and the filling percentage of which is 45 vol% or more.

Owner:KK TOSHIBA +1

Regenerator and refrigerating machine

PendingCN112984853AImprove cooling efficiencyChange flowCompression machinesHeat-exchange elementsGadolinium oxysulfideEngineering

The invention discloses a regenerator and a refrigerating machine. The regenerator comprises a heat exchange cavity which is divided into a first filling area, a second filling area and a third filling area in the axis direction of the regenerator, wherein the first filling area is filled with lead balls; the second filling area is filled with holmium copper balls and gadolinium oxysulfide balls, and the diameters of the holmium copper balls are smaller than those of the gadolinium oxysulfide balls; and the third filling area is filled with gadolinium oxysulfide balls. According to the regenerator disclosed by the invention, by reasonably setting the distribution of the refrigerating medium and setting the components of the refrigerating medium, the temperature from a 10K temperature zone to a 4K temperature zone is divided into two stages, so that the refrigerating efficiency of the regenerator from the 10K temperature zone to the 4K temperature zone is improved.

Owner:氢合科技(广州)有限公司

Chemical sensibilization method of plate type silver iodo-bromide grain emulsion

InactiveCN105242490AImprove stabilityImprove the preservation effectPhotosensitive materialsGadolinium oxysulfideEmulsion

The invention discloses a chemical sensibilization method of plate type silver iodo-bromide grain emulsion. The chemical sensibilization method comprises the following steps: stirring and dispersing a certain amount of gadolinium oxysulfide powder into 3 to 8 percent of a gelatin aqueous solution, and performing ultrasonic treatment to enable gadolinium oxysulfide particles to be uniformly dispersed into the gelatin solution; then pouring the uniformly dispersed gadolinium oxysulfide gelatin aqueous solution into a ball grinding tank for grinding to obtain a gelatin system containing gadolinium oxysulfide particles of which the diameter is 1 to 10 microns and the particle size distribution is narrow; finally, under the constant temperature of 45 to 55 DEG C, adding the gelatin system with the micron gadolinium oxysulfide particles subjected to ball grinding, and quickly freezing the gelatin system for storage. Compared with the conventional sulfur and gold chemical sensibilization, the plate type silver iodo-bromide grain emulsion subjected to gadolinium oxysulfide chemical sensibilization has the advantage that the photosensitivity can be improved by 3 times; the plate type silver iodo-bromide grain emulsion subjected to chemical sensibilization by the gadolinium oxysulfide gelatin system can still keep high stability of the particle size and can be stored for a long time.

Owner:南京瑞盈环保科技有限公司

Preparation method of rare earth-doped gadolinium oxysulfide and gadolinium oxysulfate up-conversion phosphor

ActiveCN106520121BSolve the discharge problemRealize green manufacturingLuminescent compositionsOxygenUp conversion

A method for preparing rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulfate upconversion phosphor, belonging to the field of material science. The method includes the following steps: (1) Mix Gd(NO3)3·6H2O, Yb(NO3)3·6H2O and Ln(NO3)3·6H2O, add deionized water to obtain RE(NO3)3 solution; (2) ) Dissolve ammonium sulfate in the RE(NO3)3 solution and stir, continue stirring, add ammonia water, adjust the pH value, and obtain a suspension; (3) Hydrothermally react the suspension at 100 to 150°C for 1 to 72 hours , naturally cooled to room temperature to obtain the reaction product; (4) Centrifuge, clean, and dry the reaction product to obtain a white powder precursor; (5) Calculate the white powder precursor to obtain rare earth ion-doped Gd2O2S or Gd2O2SO4 upconversion phosphor. This method effectively solves the use of sulfur-containing raw materials and the discharge of harmful by-products in conventional methods, and is a green and environmentally friendly preparation technology.

Owner:NORTHEASTERN UNIV LIAONING

Hot-pressing reaction sintering method of gadolinium oxysulfide scintillation ceramics

ActiveCN105800663BReduce distractionsLower requirementRare earth metal compoundsGadolinium oxysulfideActivated carbon

Owner:中科西卡思(苏州)科技发展有限公司

Intensifying paper for x-ray detector, x-ray detector, and x-ray inspection device

ActiveCN103140898BReduce riskCheck image clarityX-ray/infra-red processesLuminescent compositionsGadolinium oxysulfidePhosphor

In an embodiment, an X-ray detector has a transmissive fluorescence generating portion, and a reflective fluorescence generating portion. The transmissive and reflective fluorescence generating portions have at least one of an intensifying screen having a phosphor layer that contains praseodymium-activated gadolinium oxysulfide phosphor particles in which a ratio of particles having a particle diameter falling in ±30% of a center particle diameter is 45% by volume or more and their filling rate is 60% by volume or more, and an intensifying screen having a phosphor layer that contains europium-activated barium fluorochloride phosphor particles in which a ratio of particles having a particle diameter falling in ±30% of a center particle diameter is 45% by volume or more and their filling rate is 45% by volume or more.

Owner:KK TOSHIBA +1

Preparation method of gadolinium oxysulfide powder and sparkling ceramics

ActiveCN110204336ALow sintering activityUniform particle sizeLuminescent compositionsGadolinium oxysulfideCeramic sintering

The invention provides a preparation method of gadolinium oxysulfide powder and sparkling ceramics. The preparation method of Gd2O2S powder includes the following steps that Gd2O3, sulfuric acid and rare earth oxides are mixed and stirred to obtain precursor powder; the precursor powder is calcined at 700-800 DEG C; the well calcined precursor powder and a solid reducing agent are subjected to ball milling and mixed; the mixed powder is reduced in a reducing atmosphere, and (Gd1-XBX)2O2S powder is obtained, wherein B refers to one or more of Pr, Tb, Ce and Eu and X=0.005-0.15; ethyl alcohol isadded into the (Gd1-XBX)2O2S powder, pelleting is performed through a pelletizer after stirring, and the (Gd1-XBX)2O2S powder with the particle size more than 95% is obtained. A commercially feasiblecomplete method for preparing Gd2O2S powders, pre-pressing powders and sintering ceramics is provided, and the method has the advantages that the cost is low, batch manufacture is easy and stabilityand reliability are achieved.

Owner:上海御光新材料科技股份有限公司

A kind of preparation method of gadolinium oxysulfide powder and sparkle ceramics

ActiveCN110204336BLow sintering activityUniform particle sizeLuminescent compositionsCeramic sinteringGadolinium oxysulfide

The invention provides a preparation method of gadolinium oxysulfide powder and sparkling ceramics. The preparation method of Gd2O2S powder includes the following steps that Gd2O3, sulfuric acid and rare earth oxides are mixed and stirred to obtain precursor powder; the precursor powder is calcined at 700-800 DEG C; the well calcined precursor powder and a solid reducing agent are subjected to ball milling and mixed; the mixed powder is reduced in a reducing atmosphere, and (Gd1-XBX)2O2S powder is obtained, wherein B refers to one or more of Pr, Tb, Ce and Eu and X=0.005-0.15; ethyl alcohol isadded into the (Gd1-XBX)2O2S powder, pelleting is performed through a pelletizer after stirring, and the (Gd1-XBX)2O2S powder with the particle size more than 95% is obtained. A commercially feasiblecomplete method for preparing Gd2O2S powders, pre-pressing powders and sintering ceramics is provided, and the method has the advantages that the cost is low, batch manufacture is easy and stabilityand reliability are achieved.

Owner:上海御光新材料科技股份有限公司

Fluorescent screen for X ray detection and preparation method thereof

PendingCN106373631AHigh detection efficiency of X-raysHigh resolutionX-ray/infra-red processesConversion screensGadolinium oxysulfideX-ray

The invention discloses a fluorescent screen for X ray detection. The fluorescent screen comprises a support layer and a fluorescent layer supported on the support layer; and the fluorescent layer contains gadolinium oxysulfide. Meanwhile, the invention also discloses a method for preparing a fluorescent screen. The fluorescent screen made of gadolinium oxysulfide can emit visible light after absorbing an X ray; and on the basis of cooperation with a photoelectric converter, photoelectric conversion of the X ray is realized. When the fluorescent screen is prepared by the preparation method, advantages of simple process and low cost are realized.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

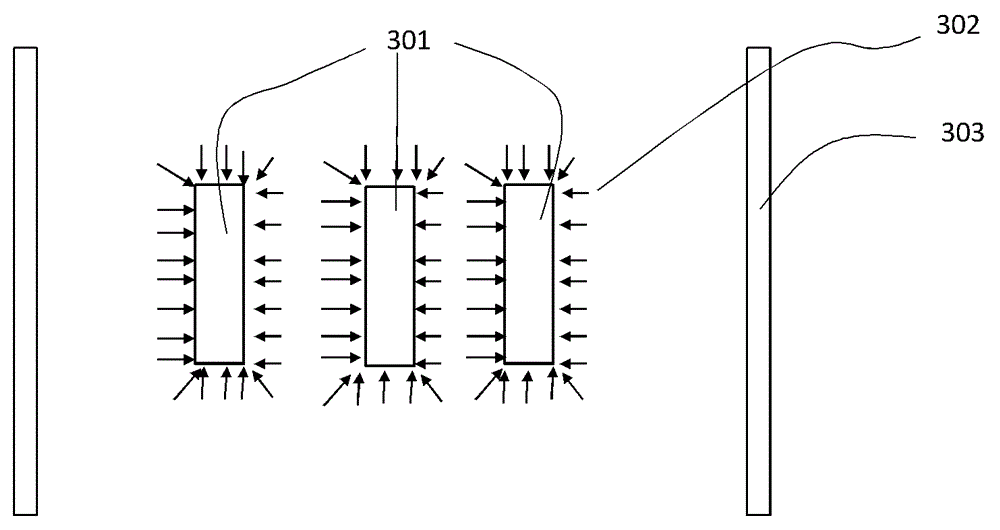

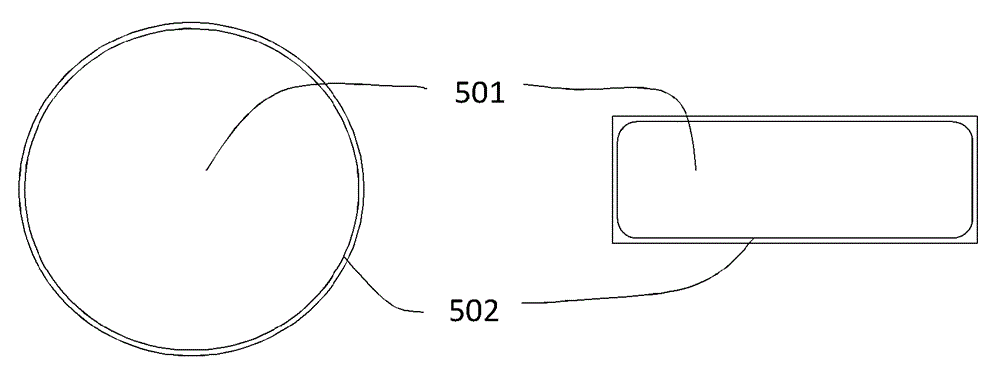

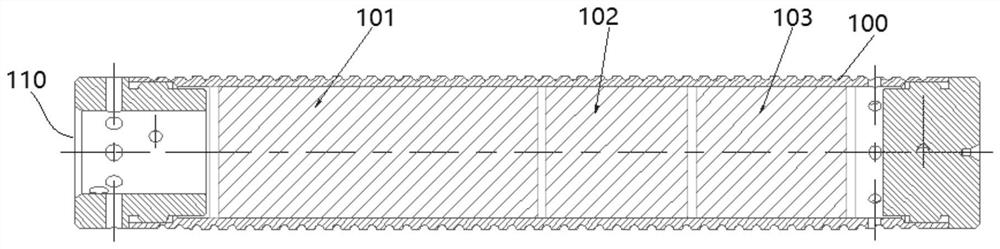

Method for producing scintillator arrays with silver (ag) based gaps

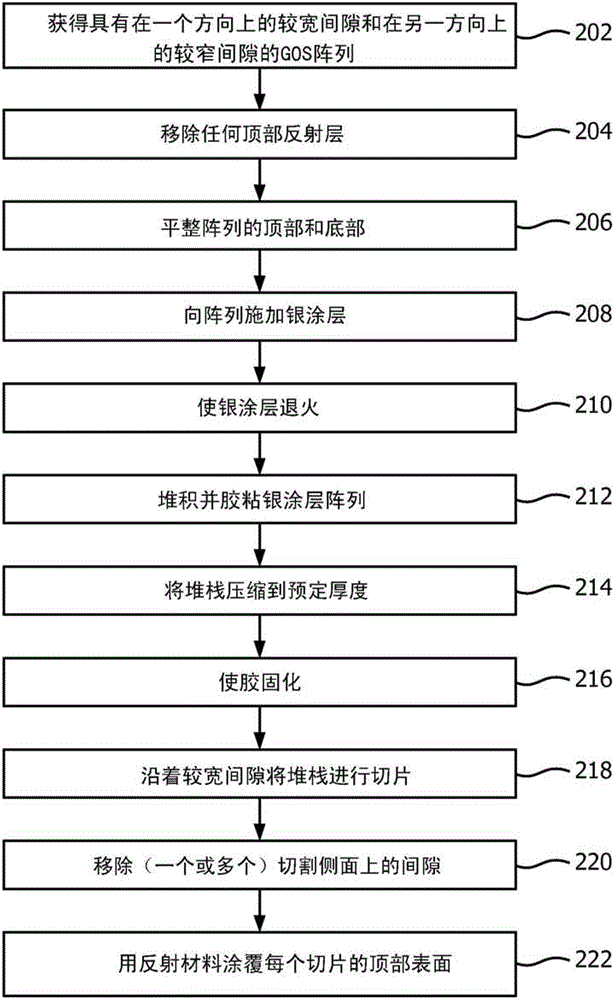

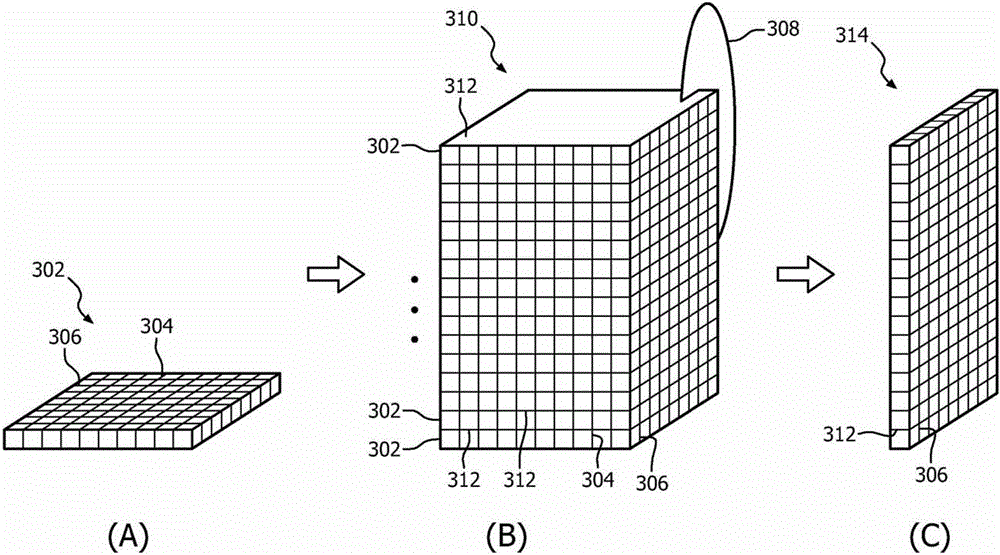

A method includes obtaining a plurality of the two dimensional arrays of gadolinium oxysulfide. An array has wider width non-silver based spacers (304) that extend between rows or columns of dixels and narrower width non-silver based spacers (306) that extend between the other of the rows or columns of dixels. The method further includes applying a silver coating (312) to at least one of a top or bottom surface of the arrays. The method further includes forming a stack by stacking the silver coated arrays, one on top of another (FIG. 3B), with substantially equal layers of adhesive between adjacent arrays. The method further includes slicing the stack through the wider non-silver based spacers to form two dimensional arrays of scintillator dixels (314) having silver based spacers (312) along at least one direction of the array.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

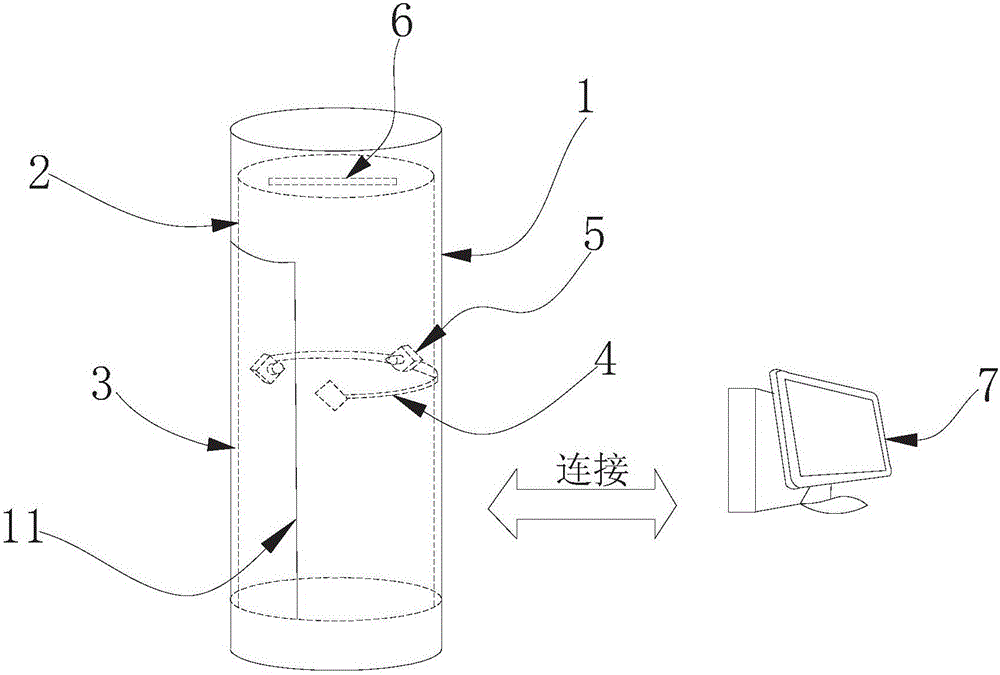

Medical nuclide imaging system and method based on photosensitive tights

InactiveCN105054955AIncrease elasticityReduce complexityRadiation diagnosticsLight equipmentFluorescence

The invention discloses a medical nuclide imaging system and a medical nuclide imaging method based on photosensitive tights. The imaging system comprises an imaging darkroom, three CCD cameras, a control system, a lifting system and the photosensitive tights, wherein the photosensitive tights are prepared by uniformly mixing acrylic fibers and Gd2S2O (gadolinium oxysulfide) rare earth material. During the imaging process, a to-be-tested person receives intravenous injection of corresponding radionuclide, then enters the imaging darkroom for imaging at the proper moment, after lighting equipment inside the imaging darkroom is turned on, the to-be-tested person stands in an imaging area, and the three CCD cameras photograph the to-be-tested person; then the to-be-tested person stands still, the lighting equipment inside the imaging darkroom is turned off, the three CCD cameras collect fluorescence signals converted by the photosensitive tights and on the body surface of the to-be-tested person, and finally a fluorescence signal image and a picture image are displayed in a mixing manner. With the adoption of the medical nuclide imaging system and the medical nuclide imaging method, optical imaging of the medical radionuclide is realized, and the medical nuclide imaging system and the medical nuclide imaging method have the characteristics of whole body imaging, real-time imaging, simplicity and convenience in operation, low cost, and the like.

Owner:XIDIAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com