Preparation method of gadolinium oxysulfide powder

A technology of gadolinium oxysulfide and powder is applied in the field of preparation of infrared materials, which can solve the problems of long reaction time, uneven particle size distribution of powder, agglomeration and the like, and achieve the effect of avoiding the discharge of harmful by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

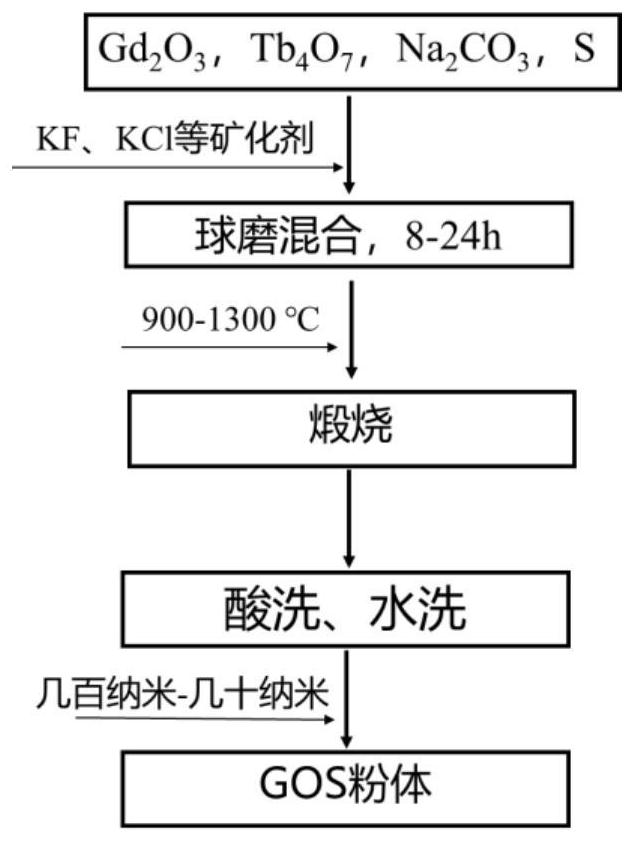

[0022] Aiming at the problem of environmental pollution in the preparation of gadolinium oxysulfide powder by vulcanization method in the prior art, this application provides a preparation method for preparing gadolinium oxysulfide powder, the preparation method is green and environmentally friendly, and the gadolinium oxysulfide powder has The particle size is small. The preparation process of the application gadolinium oxysulfide powder is as follows figure 1 As shown, the embodiment of the present invention specifically discloses a preparation method of gadolinium oxysulfide powder, comprising the following steps:

[0023] A) will Gd 2 o 3 , activator, flux and sulfur are mixed in a stoichiometric ratio to obtain a mixed powder;

[0024] B) ball milling the mixed powder and the mineralizer to obtain a precursor powder;

[0025] C) Calcining the precursor powder to obtain a primary powder, pickling the primary powder, and drying in a vacuum to obtain a gadolinium oxysulf...

Embodiment 1

[0033] A preparation method of ideal matrix material ultrafine gadolinium oxysulfide powder, the Gd 2 o 2 The preparation method of S powder comprises the steps:

[0034] (1) 181.3g Gd 2 o 3 , 15.312g Tb 4 o 7 or 20.428g Pr 6 o 11 One of the flux Na 2 CO 3 , 128.24g S is proportioned according to stoichiometry, and is initially mixed to obtain a mixed powder; the addition of flux is 0.5wt%;

[0035] (2) Add a certain proportion of mineralizers KF and KCl to the mixed powder, the addition amount is 0.5wt%, and add it into the planetary ball mill according to a certain ball-to-material ratio and mix evenly, and the ball-mill ratio is 2:1 to obtain the precursor powder;

[0036] (3) Calcining the obtained precursor powder at 1100°C for 1 h in a reducing atmosphere to obtain a primary powder; the SO produced during the calcination process 2 The gas can be recovered SO by activated carbon dry method 2 ; The reducing atmosphere is N 2 +H 2 Mix in proportion, where N 2...

Embodiment 2

[0040] A preparation method of ideal matrix material ultrafine gadolinium oxysulfide powder, the Gd 2 o 2 The preparation method of S powder comprises the steps:

[0041] (1) 181.3g Gd 2 o 3 , 15.312g Tb 4 o 7 or 20.428g Pr 6 o 11 One of the flux Li 2 CO 3 , 128.24g S is proportioned according to stoichiometry, and is initially mixed to obtain a mixed powder; the addition of flux is 0.5wt%;

[0042] (2) Add a certain proportion of mineralizers KF and KCl to the mixed powder, the addition amount is 0.5wt%, and add it into the planetary ball mill according to a certain ball-to-material ratio and mix evenly, and the ball-mill ratio is 8:1 to obtain the precursor powder;

[0043] (3) Calcining the obtained precursor powder at 1100°C for 1 h in a reducing atmosphere to obtain a primary powder; the SO produced during the calcination process 2 The gas can be recovered SO by activated carbon dry method 2 ; The reducing atmosphere is N 2 +H 2 Mix in proportion, where N 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com