Indirect sulfur source preparation method of gadolinium oxysulfide scintillation ceramic powder

A technology of gadolinium oxysulfide and scintillation ceramics, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

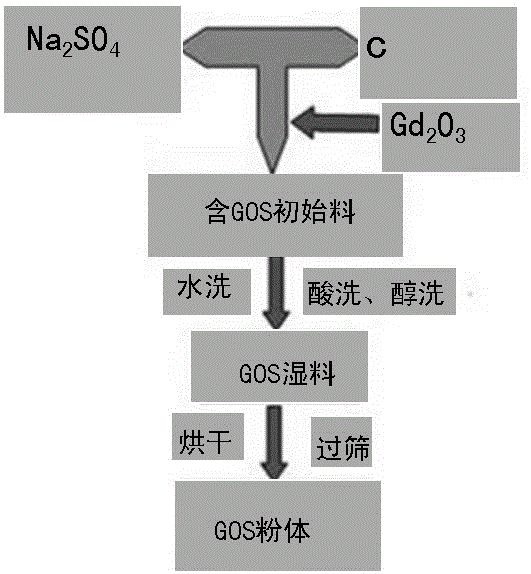

[0030] The invention discloses a method for preparing an indirect sulfur source of scintillation ceramic powder, comprising:

[0031] Weigh carbon, sodium sulfate and gadolinium oxide powder in a ratio of 1:1:0.05 to 1:6:2, add rare earth active ions that are 1% to 0.0001% of the mass of gadolinium oxide powder, and the obtained raw materials are ball milled, dried, Gd can be obtained by sieving, calcining and washing 2 o 2 S: X powder.

[0032] The rare earth activating ion X includes Ce, Tb, Nd and other rare earth elements, which can be one of them or a mixture of several of them in different proportions. It can be introduced in the form of oxides, and also includes sulfates, nitrates, carbonates, etc. of such rare earth elements.

[0033] The mixture is put into an alumina crucible after dry pressing, and calcined in a muffle furnace at a high temperature of 600-1400°C, and the holding time is 10min-10h.

[0034] After the calcined powder is taken out and crushed, it i...

Embodiment 1

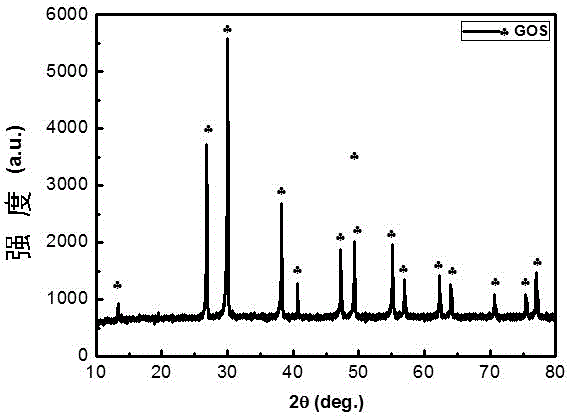

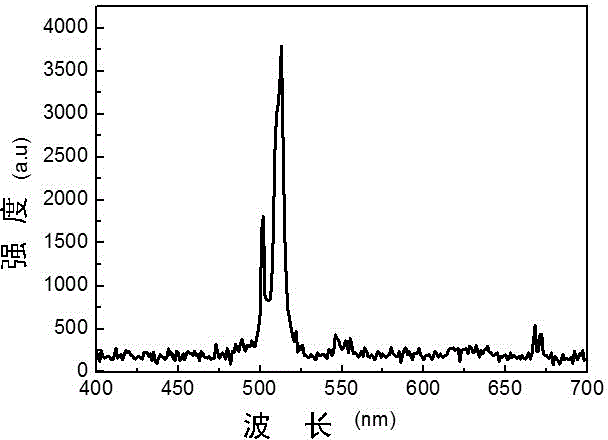

[0055] Weigh 20g of high-purity sodium sulfate and 3g of high-purity activated carbon, add 1.2g of gadolinium oxide and 0.002g of hexapraseodymium oxide, pour it into an agate ball mill jar, add 150g of alumina balls and 25ml of alcohol, and mill on a planetary ball mill After 4 hours, the mixed powder was dried in an oven at 100°C, passed through a 200-mesh sieve, put into a double crucible, and filled with activated carbon to form a protective atmosphere. Cover it with an alumina plate, put it in a muffle furnace for 180 minutes and raise the temperature to 900°C, keep it at this temperature for 3 hours, and then cool it down naturally. Take out the powder and add 5% dilute nitric acid, soak for 30min, filter, add 500ml of water to wash 3 times, and finally wash once with alcohol. Put it in a glass petri dish and dry it in an oven at 70°C to get high-quality Gd 2 o 2 S: Pr phosphor. figure 2 Indicates that Gd is generated 2 o 2 S, and has good crystallinity. image 3 ...

Embodiment 2

[0057] Weigh 150g of high-purity sodium sulfate and 23g of high-purity activated carbon, add 50g of gadolinium oxide and 0.004g of hexapraseodymium oxide, pour it into an agate ball mill jar, add 345g of alumina balls and 120ml of alcohol, and mill on a planetary ball mill for 4 hours The mixed powder is dried in an oven at 100°C, then passed through a 200-mesh sieve, put into a crucible, covered with an alumina plate, placed in a muffle furnace that can pass through an inert atmosphere and heated to 1000°C for 200 minutes, and then The temperature was kept for 3 hours and then cooled naturally. Take out the powder and add 5% dilute nitric acid, soak for 30min (Gd 2 o 2 S is insoluble in dilute nitric acid solution, this process can remove excess gadolinium oxide), filter, then pour off the supernatant, add 1000ml of water to wash twice, and finally wash with alcohol. Put it in a glass petri dish and dry it in an oven at 70°C to get high-quality Gd 2 o 2 S: Pr phosphor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com