Patents

Literature

45results about "Rare earth metal sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth nano phosphor and method of preparing the same

InactiveUS20090140203A1Improve luminous efficiencyRare earth metal sulfatesMaterial nanotechnologyInorganic saltsRare earth metal compounds

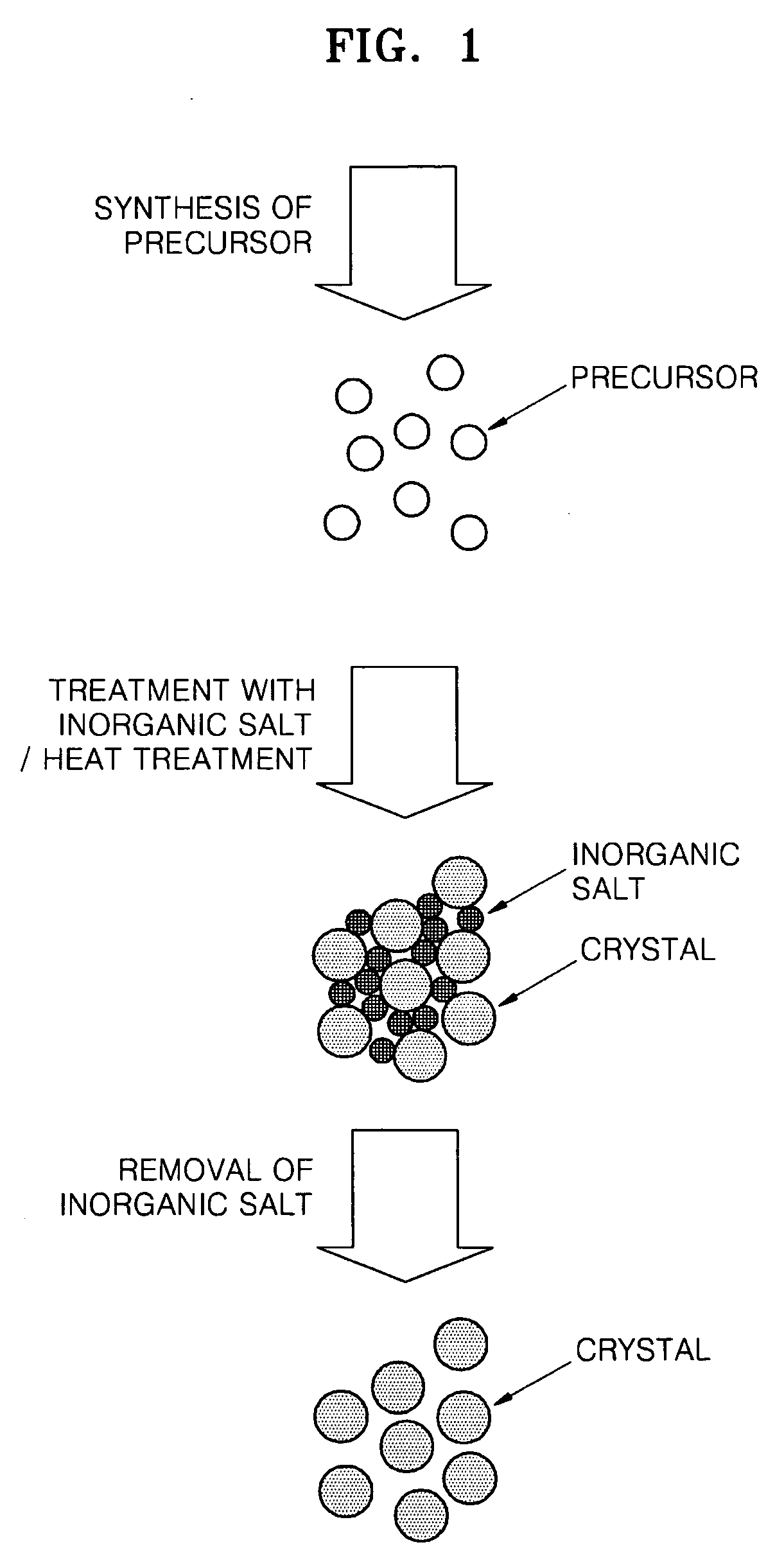

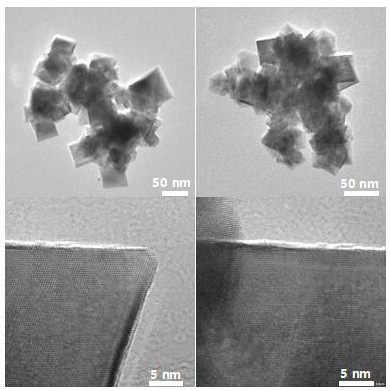

Provided are a rare earth nano phosphor and a method of preparing a rare earth nano phosphor, the method includes: (a) synthesis of rare earth nano phosphor precursor particles by radiating microwave energy to a solvent where rare earth metal compounds are dissolved; and (b) sintering of inorganic salt and the rare earth nano phosphor precursor mixture.

Owner:SAMSUNG DISPLAY CO LTD

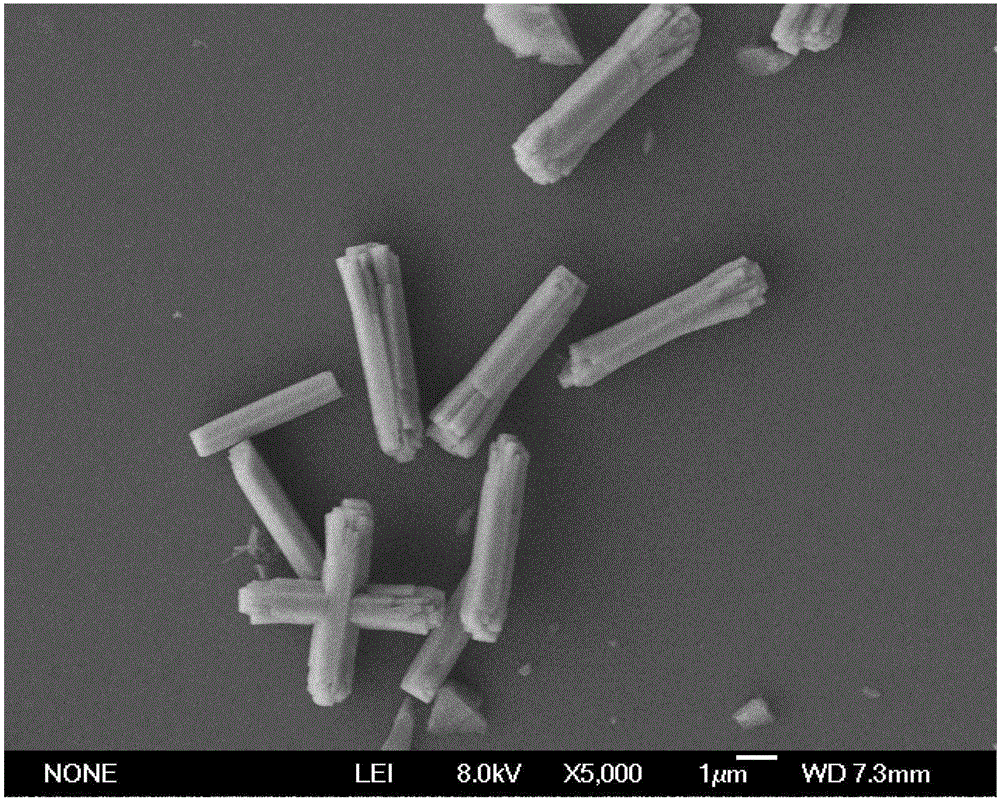

Preparing method of rare earth-doped gadolinium oxysulfide fluorescent powder

ActiveCN106544025AEffective adjustment of shapeSimple technical solutionRare earth metal sulfatesRare earth metal sulfidesGadolinium oxysulfideNitrate

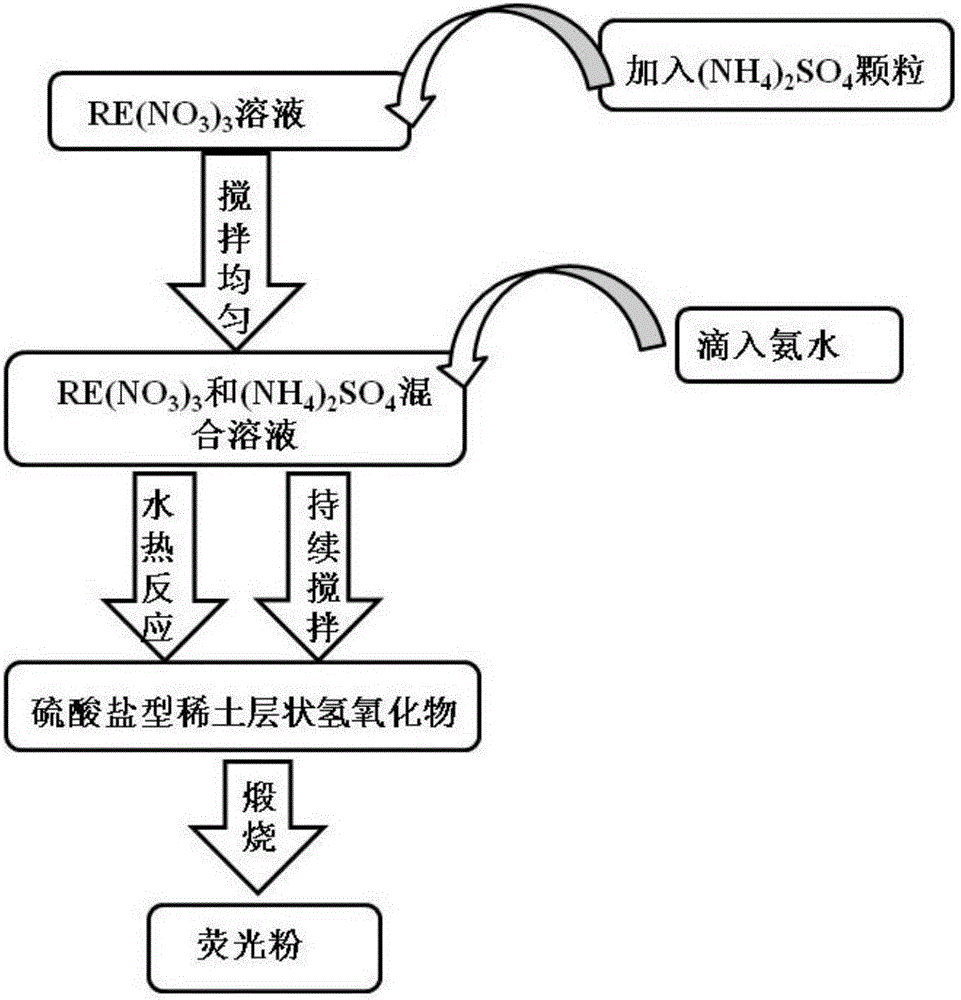

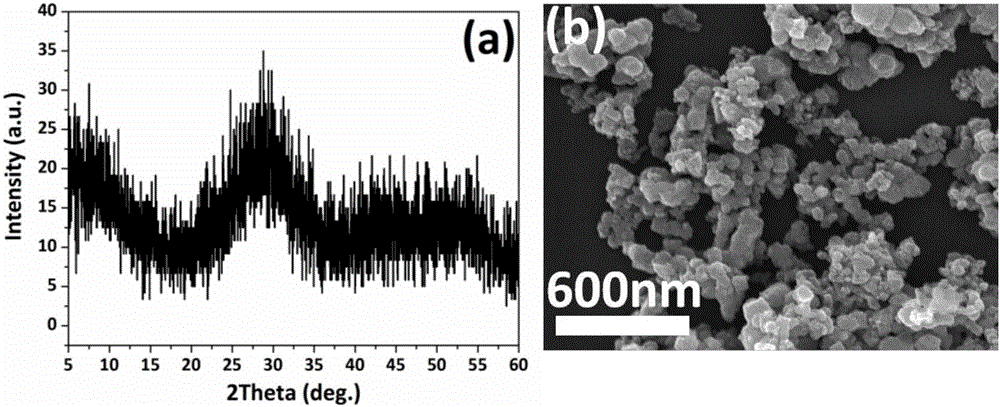

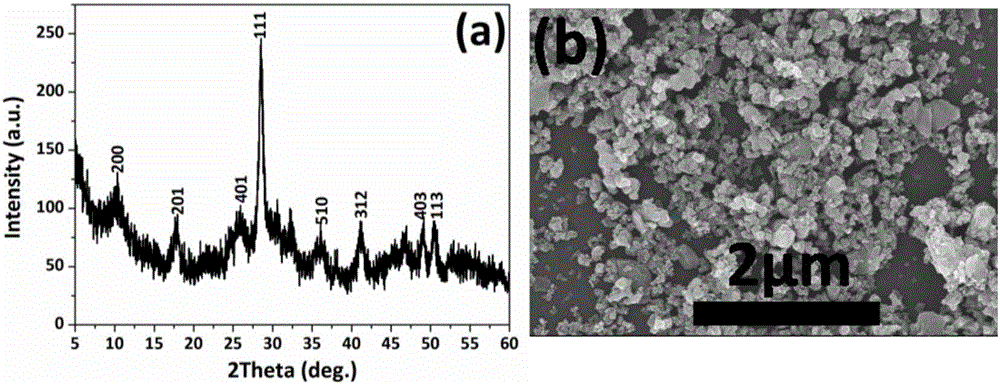

The invention discloses a preparing method of rare earth-doped gadolinium oxysulfide fluorescent powder, and belongs to the technical field of materials. The preparing method comprises the first step of preparing a RE(NO3)3 solution, wherein the RE(NO3)3 solution is mixed liquid of Gd(NO3)3 and activating agent nitrate; the second step of dissolving ammonium sulfate into the RE(NO3)3 solution, continuously stirring the mixture and adding ammonium hydroxide into the mixture, and adjusting a pH value to obtain turbid liquid; the third step of conducting reaction on the turbid liquid at the temperature of minus 1-150 DEG C for 1-72 hours to obtain a reaction product; the fourth step of conducting centrifugal separation, cleaning and drying on the reaction product to obtain a white powder precursor; roasting the white powder precursor in reducing atmosphere to obtain (Gd,Tb)202S or (Gd,Pr)202S fluorescent powder. According to the technical scheme, the preparing method is simple and easy to operate, in the process of preparing (Gd,Tb)202S or (Gd,Pr)202S, sulfocompound which is harmful to the environment is not involved; in addition, (Gd,Tb)202S or (Gd,Pr)202S of various morphologies (nano-particles, agglomerated balls and standard hexagon micron sheet bars) can be obtained.

Owner:NORTHEASTERN UNIV

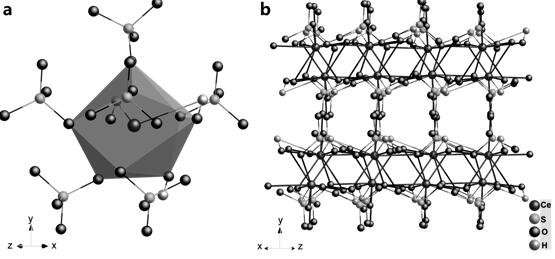

Preparation methods of rare earth layered hydroxide nanosheets and rare earth layered hydroxide nanosheet sol

InactiveCN108059182ASimple preparation processEasy to operateRare earth metal sulfatesNanotechnologyRare earthLanthanum nitrate

The invention relates to preparation methods of rare earth layered hydroxide nanosheets and rare earth layered hydroxide nanosheet sol. The preparation method of the nanosheets comprises the followingsteps: preparing a lanthanum nitrate solution with a corresponding concentration, dissolving ammonium sulfate particles into the lanthanum nitrate solution according to a proportion so as to form a mixed solution, adjusting the pH of the mixed solution to 6-10, and continuously stirring to obtain uniform suspension; carrying out a reaction to obtain a product, immediately carrying out centrifugalseparation on the product, and drying to obtain the rare earth layered hydroxide La2(OH)4SO4.nH2O nanosheets. The rare earth layered hydroxide nanosheet sol is prepared by putting the prepared nanosheets into a formamide solution, carrying out ultrasonic centrifugal treatment, and then taking the supernatant. According to the preparation method, the rare earth layered hydroxide La2(OH)4SO4.nH2O nanosheets can be prepared in one step by using an ice-bath method, so that the problem that in the prior art, the compounds cannot be prepared into single-layer nanosheets by using the conventional intercalation-stripping method can be solved; furthermore, the preparation methods are simple in process and convenient to operate, and can realize mass production; the corresponding nanosheet sol is good in stability and material-saving.

Owner:BOHAI UNIV

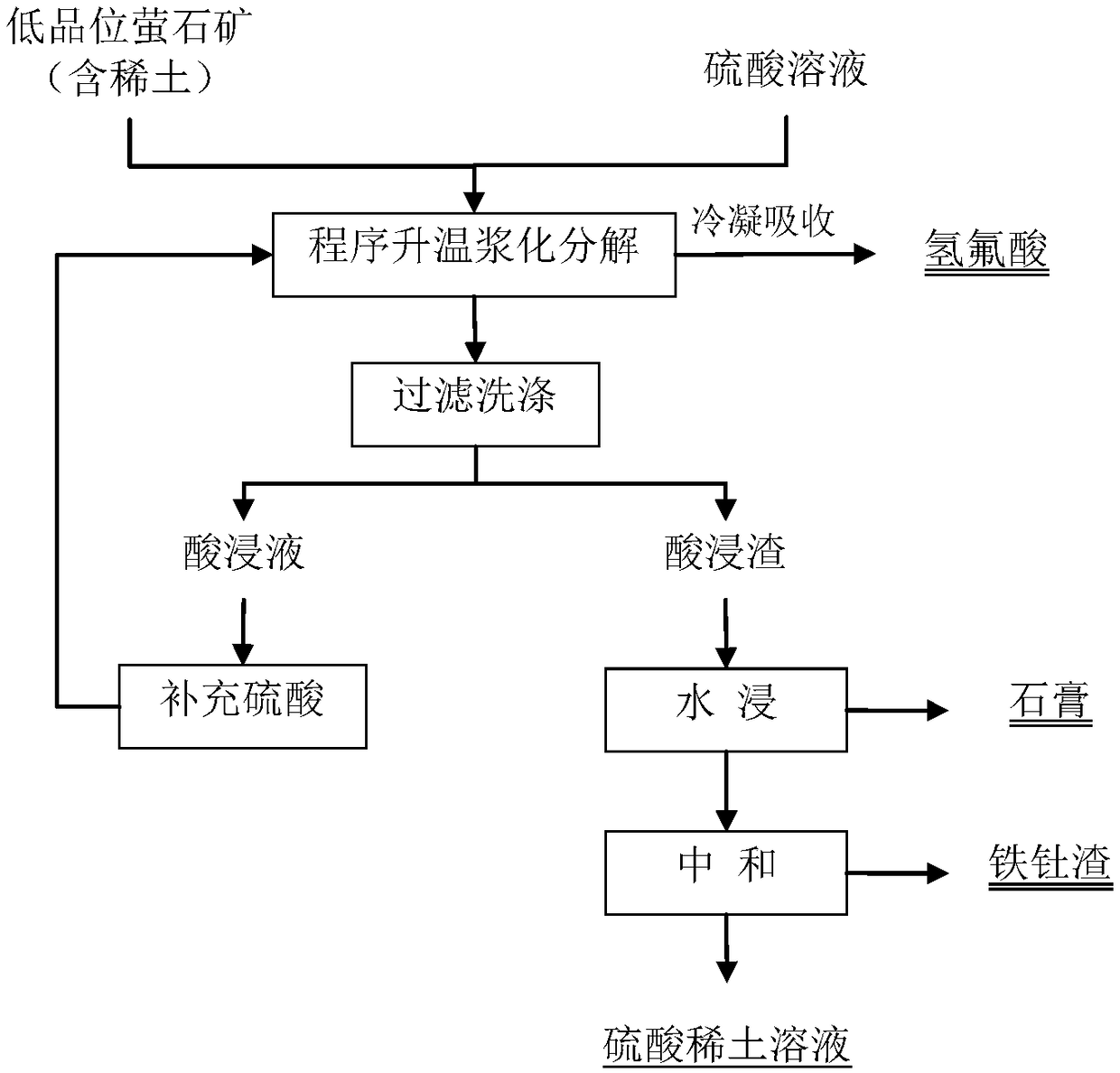

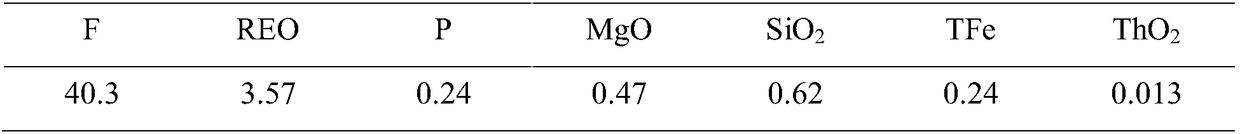

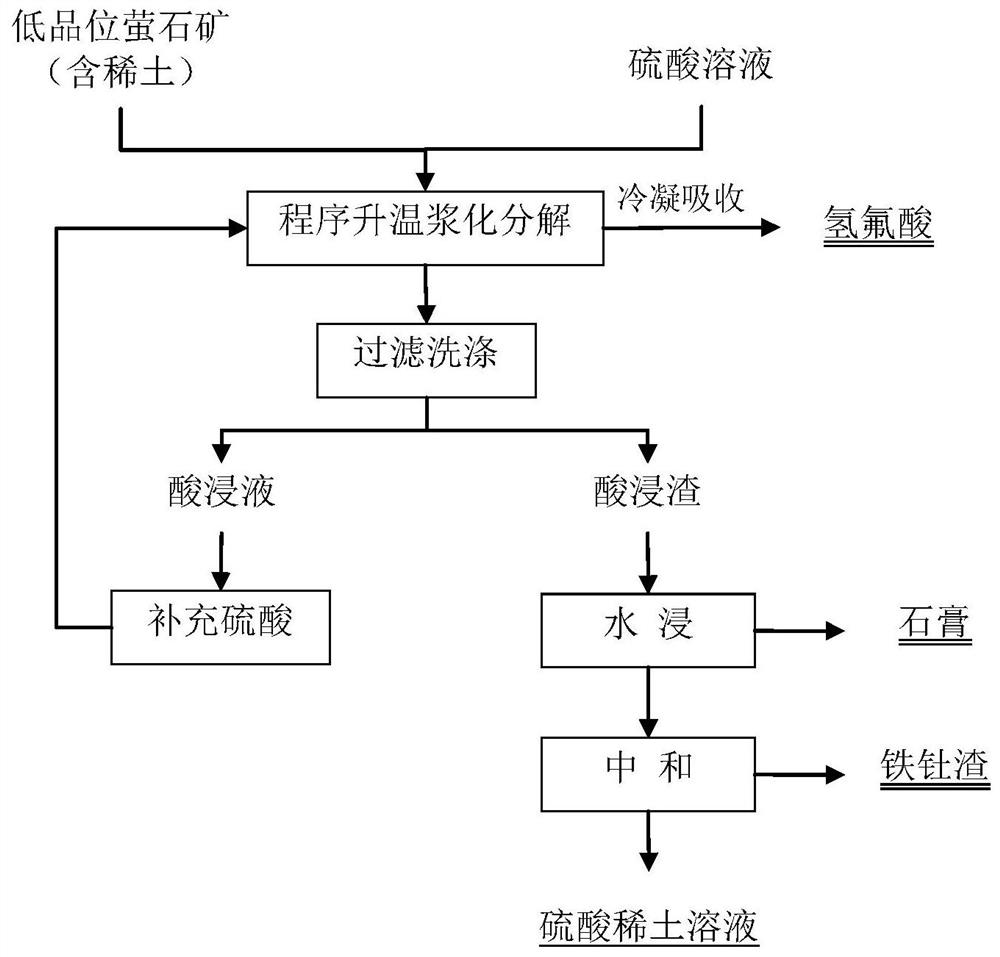

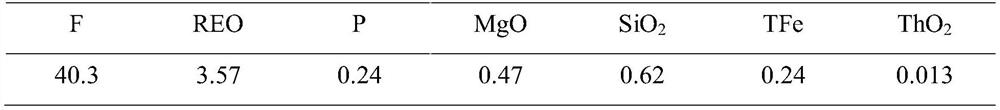

Method for treating rare-earth-containing low-grade fluorite minerals

ActiveCN109371239AGuaranteed recyclingGuaranteed purityRare earth metal sulfatesHydrogen fluorideSlagDecomposition

The invention relates to a method for treating rare-earth-containing low-grade fluorite minerals, and belongs to the field of hydrometallurgy. The rare-earth-containing low-grade fluorite minerals areused as a target, and provides a method for performing program temperature control segmented slurry decomposition treatment by adopting an absolute excess sulfuric acid solution, a low-temperature section is controlled to preferentially decompose the fluorite minerals, then raising the temperature to decompose the rare earth minerals. The hydrofluoric acid is recycled from tail gas, the reacted acid leaching slag is leached with water to obtain the rare earth, neutralization and thorium removal are carried out to recover the rare earth and the gypsum which is reach the radioactive standard, and the acid leaching solution is used for circularly decomposing the new fluorite minerals after supplementing sulfuric acid. According to the method for treating rare-earth-containing low-grade fluorite minerals, CaF2 and fluorine-carbon cerium ore in the rare-earth-containing low-grade fluorite minerals reach a relatively high decomposition rate through the program temperature control slurryingreaction, the consumption of sulfuric acid is low, the purity of the hydrofluoric acid recovered from the tail gas is high, hydrofluoric acid, gypsum and a sulfuric acid rare-earth solution are obtained, the comprehensively utilize of fluorine, calcium and rare earth resources in the rare-earth-containing low-grade fluorite minerals is realized, The whole process has no three-waste pollution and is clean and environment-friendly.

Owner:BAOTOU RES INST OF RARE EARTHS +1

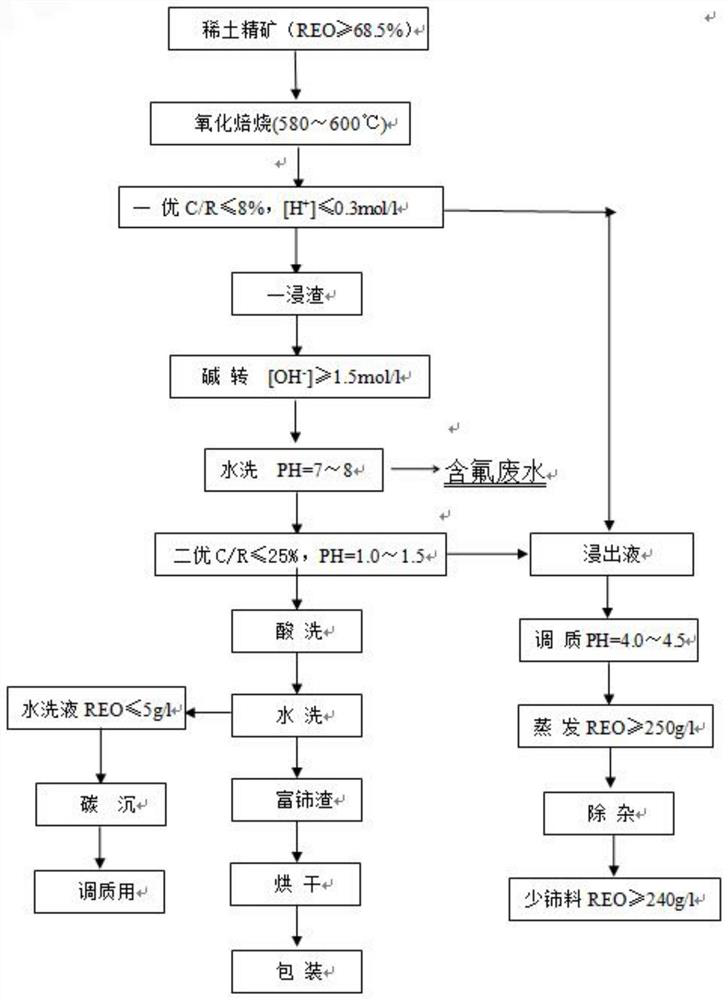

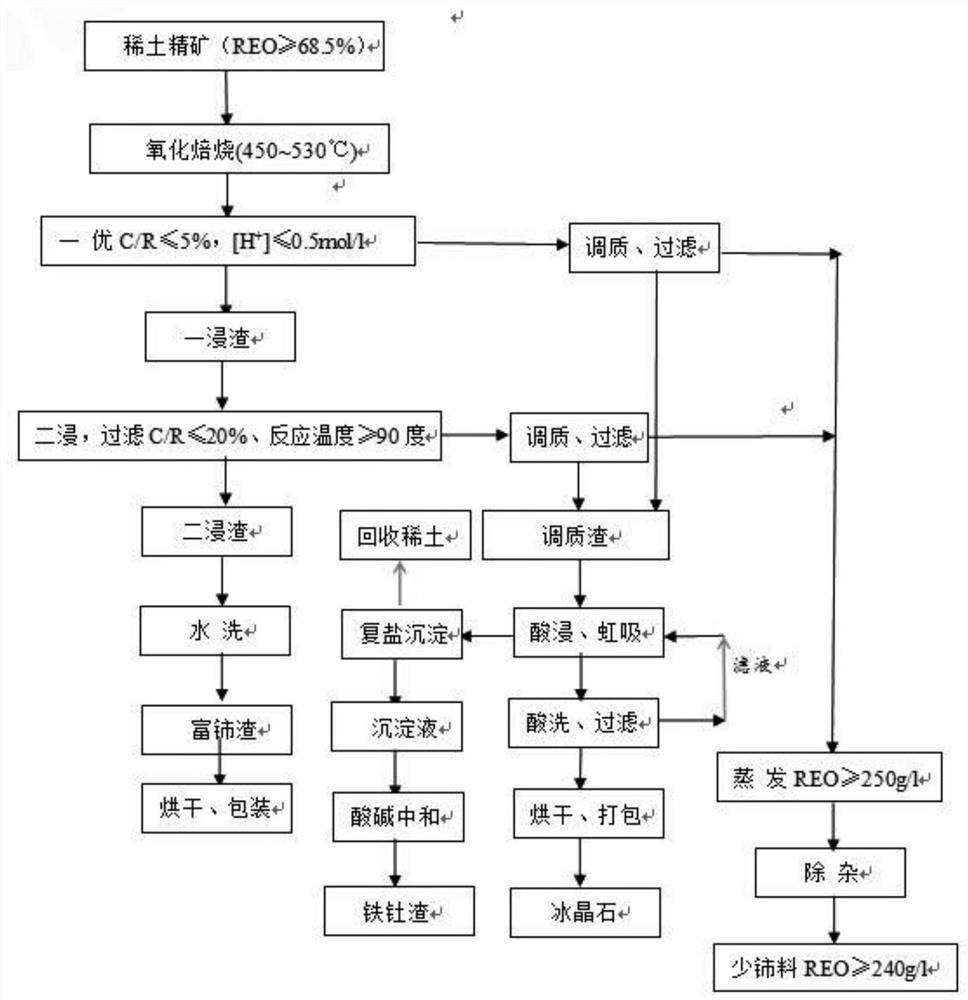

Method for extracting rare earth and recovering fluorine resource from bastnaesite

ActiveCN113667841AEfficient recyclingSave energyRare earth metal sulfatesAluminium fluoridesPregnant leach solutionSewage treatment

The invention discloses a method for extracting rare earth and recycling fluorine resources from bastnaesite. The method comprises the following steps that S1, oxidizing roasting is carried out on rare earth concentrate, and then hydrochloric acid leaching is carried out to obtain primary leaching liquid and primary leaching residues; S2, clear water and a hydrochloric acid complexing agent are added into the primary leaching residues, and secondary leaching residues and secondary leaching liquid are obtained after filtering; S3, quenching and tempering and filtering treatment are carried out on the primary leaching liquid and the secondary leaching liquid, and quenched and tempered residues are obtained; and S4, the quenched and tempered residues are dissolved by using hydrochloric acid, filtering and separating are carried out to obtain filter residues, chlorohydric acid pickling is carried out on the filter residues for multiple times, and then drying and packaging are carried out. According to the method, the fluorine resources are recovered by adding the hydrochloric acid complexing agent and the like, alkali conversion is not needed, energy is greatly saved, the production process is simplified, the product cryolite with high added value is formed, due to the fact that high-salt wastewater is not generated, a high-salt recovery system is not needed, the sewage treatment cost is greatly reduced, and the defects in the prior art are overcome.

Owner:四川省冕宁县方兴稀土有限公司

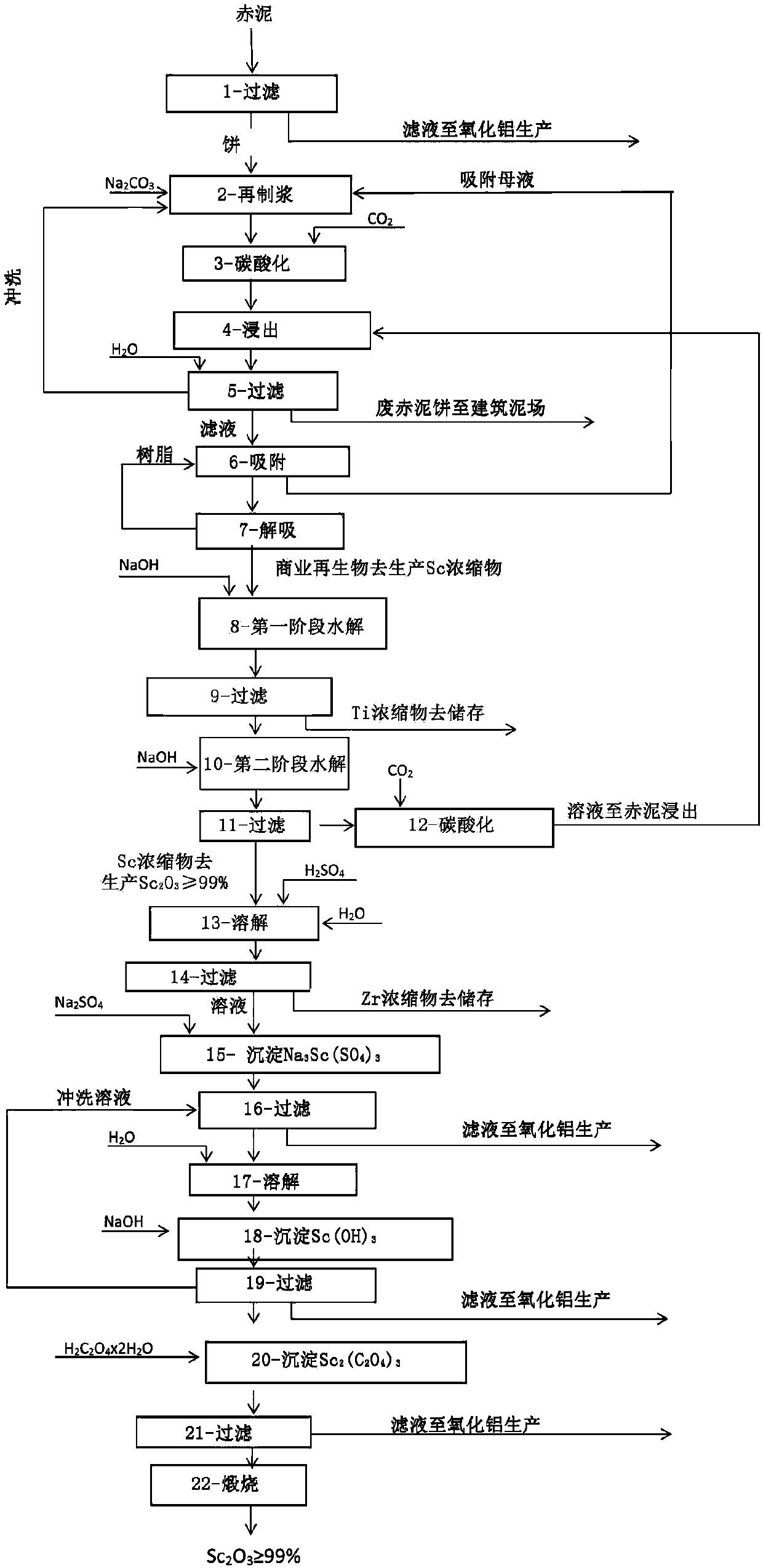

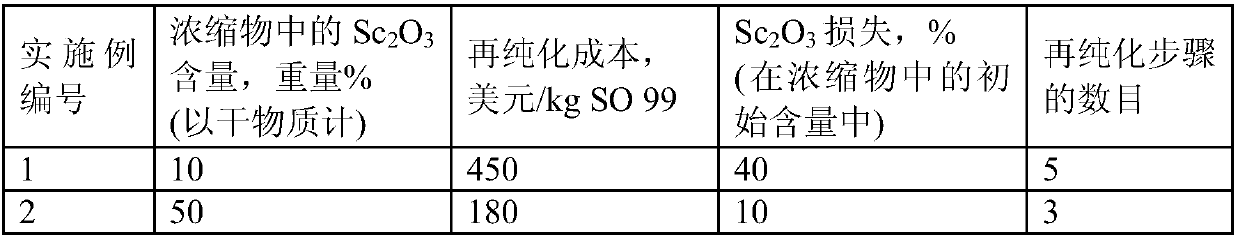

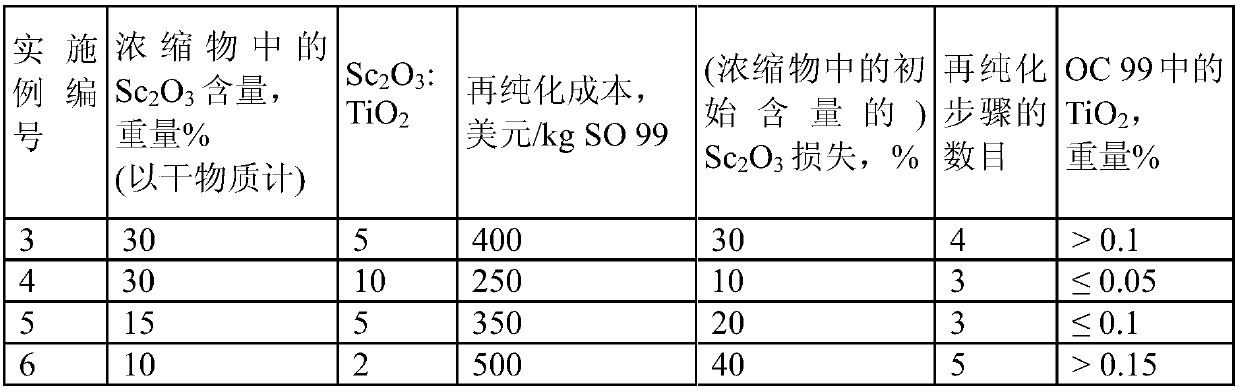

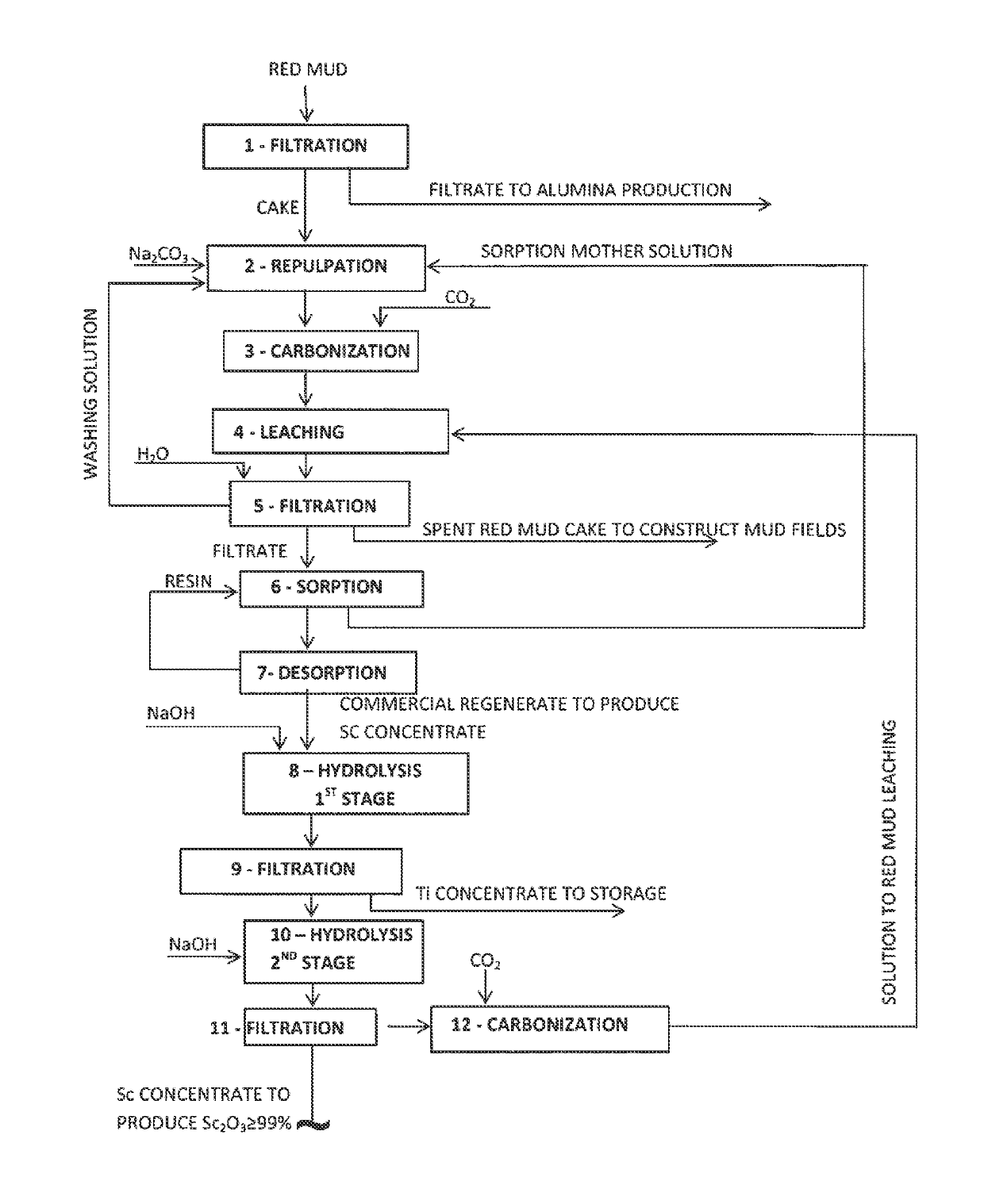

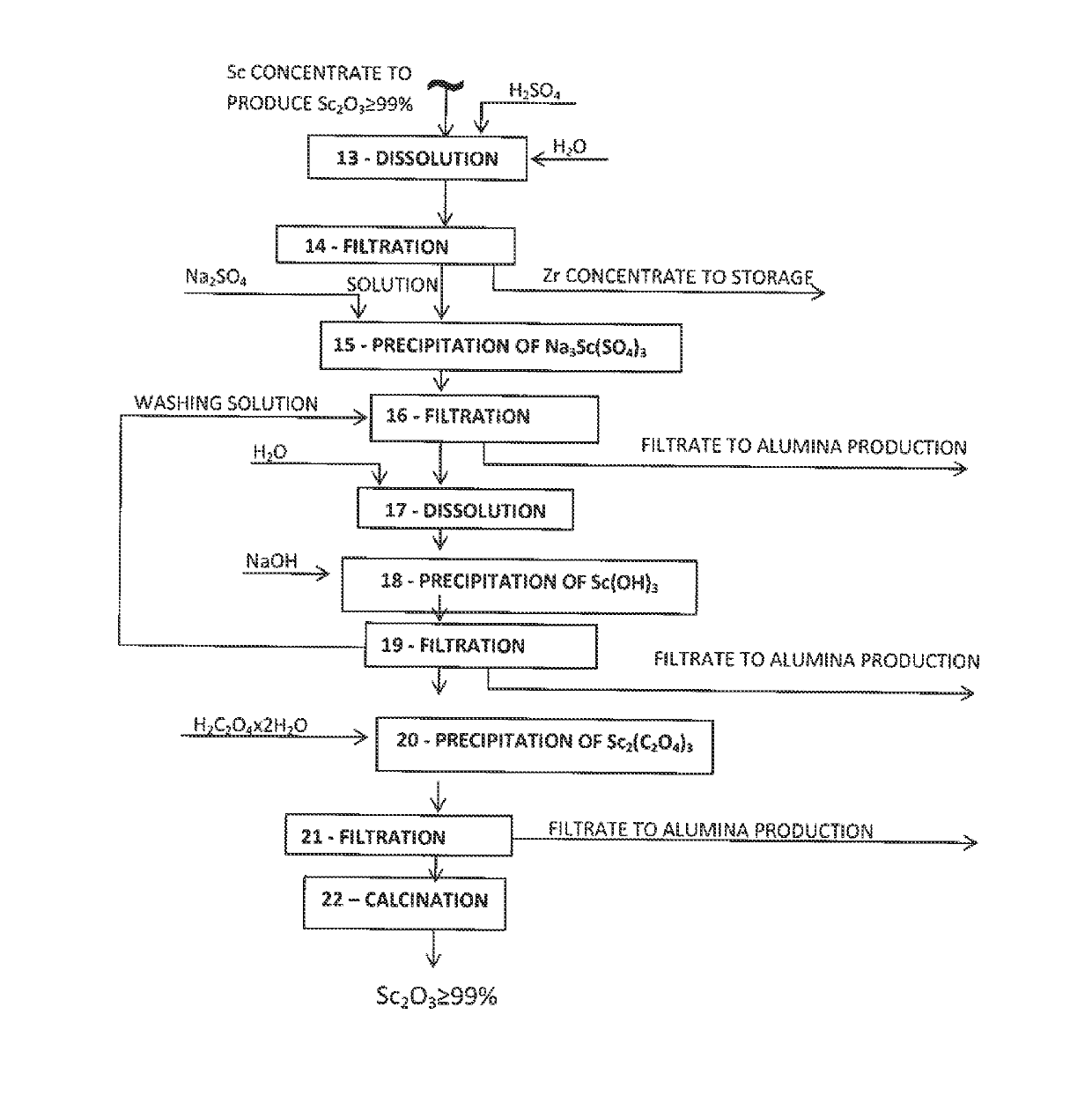

Production of a scandium-containing concentrate and subsequent extraction of high-purity scandium oxide therefrom

ActiveCN108026609ASimple processReduce manufacturing costRare earth metal sulfatesScandium oxides/hydroxidesFiltrationIon exchange

The invention relates to a technology for producing a scandium-containing concentrate from alumina production waste and obtaining a high-purity scandium oxide. The method comprises leaching red mud with a solution containing a mixture of sodium carbonate and sodium bicarbonate, absorbing scandium from the solution on a phosphorus-containing ion exchanger, and desorbing the scandium with a sodium carbonate solution to obtain commercial-grade reclaimed scandium, from which scandium concentrate is precipitated. Said concentrate contains no less than 15 mass% SC2O3, no more than 3 mass% TiO2, andno more than 15 mass% ZrO2, and the scandium in the concentrate is in the form of a mixture of the hydroxide Sc(OH)3 and the basic salt ScOHCO3*4H2O. A method is also proposed that comprises dissolving a scandium-containing concentrate in sulfuric acid, removing the acid-insoluble precipitate, transforming the scandium into a precipitate, filtering, washing, drying, and sintering to obtain a scandium oxide precipitate. After the acid-insoluble scandium precipitate is removed, the scandium is precipitated from the filtrate, removed by filtration, and washed, the binary salt is dissolved in water, and scandium hydroxide is precipitated with caustic soda. The cake is then transformed into scandium oxalate, removed by filtration, and washed with water, and the scandium oxalate is calcined to obtain scandium oxide with a purity approaching 99 mass%.

Owner:OBSHCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU OBEDINENNAYA KOMPANIYA RUSAL INZHENERNO TEKHNOLOGICHESKIY TSENTR

Rare-earth salt sulfate and preparation method thereof

ActiveCN104445342ANo pollution in the processLow costRare earth metal sulfatesCooking & bakingSolubility

The invention discloses a rear-earth salt sulfate with good water solubility prepared through rear-earth salt sulfate. The rear-earth salt sulfate is characterized in that the rear-earth salt sulfate is powder-like odorless crystals in appearance, the chemical formula is RE2(SO4)3.nH2O, the rear-earth salt sulfate is dissolved in water and acid, the solution is clear, the solubility in water is decreased along with the increase of temperature, and the solubility in a sulfuric acid solution is decreased along with the increase of temperature. The preparation method comprises the following steps: adding rear-earth salt sulfate to the sulfuric acid solution for acid solubility, filtering and removing impurities, crystallization, rinsing and dehydration, and baking. The rear-earth salt sulfate is simple in technological process, low in acid soluble acidity, less in spent acid, less in equipment corrosion, free of environmental pollution, high in product yield and low in cost; the prepared rear-earth salt sulfate is good in water solubility.

Owner:YIYANG HONGYUAN RARE EARTH

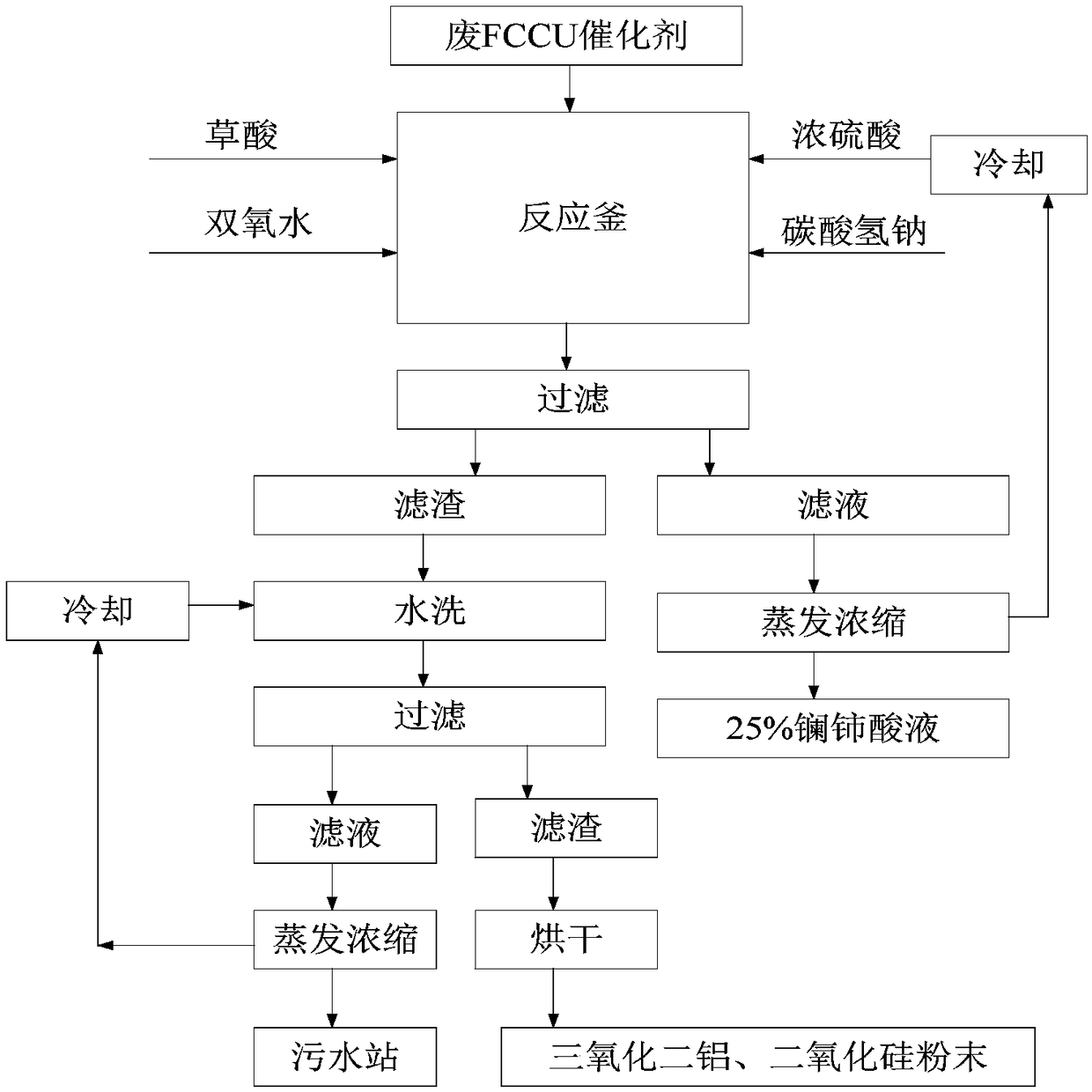

Comprehensive utilization method of waste FCCU catalyst

InactiveCN108483479ANo toxicityAvoid poisoning hazardsRare earth metal sulfatesSilicaWater useSodium bicarbonate

The invention discloses a comprehensive utilization method of waste FCCU catalyst. The comprehensive utilization method of waste FCCU catalyst comprises following steps: waste FCCU catalyst is introduced into a reaction vessel, concentrated sulfuric acid with a mass concentration of 98% is added for immersion, hydrogen peroxide and oxalic acid are added for mixing and stirring, and sodium bicarbonate is added, so that the pores on catalyst microspheres are cut through by micro pulse generated in neutralization reaction process of sodium bicarbonate with concentrated sulfuric acid; after reaction, filtering is carried out; an obtained filtrate is delivered through an evaporator for recovery of about 80% sulfuric acid in the filtrate, the left sulfuric acid is stored in the evaporator for mixing with reaction liquid obtained in a next time of reaction, a plurality of evaporative concentration is carried out so as to obtain an acid solution rich in lanthanum and cerium, wherein the concentration of the acid solution is 25%; an obtained filter residue is subjected to water washing acid removing and drying collecting so as to obtain aluminium trioxide and silica powder, an obtained water washing liquid is subjected to evaporative concentration and cooling, and is recycled as water used in water washing acid removing, and a part of the water washing liquid is discharged into a sewagetreatment station for treatment and recycling. The raw materials adopted in the comprehensive utilization method posses no direct toxicity, operation complexity is low, energy consumption is low, recovery rate is high, after waste FCCU catalyst recycling, residual refuse accounts for 0.5% or lower.

Owner:崔延强

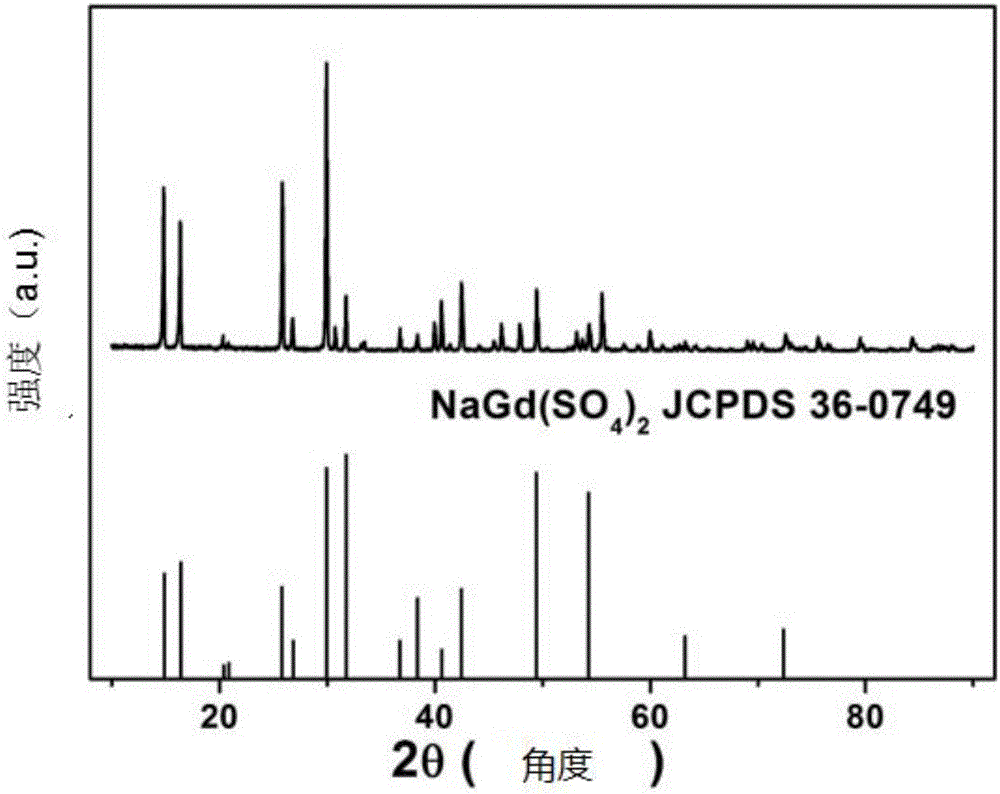

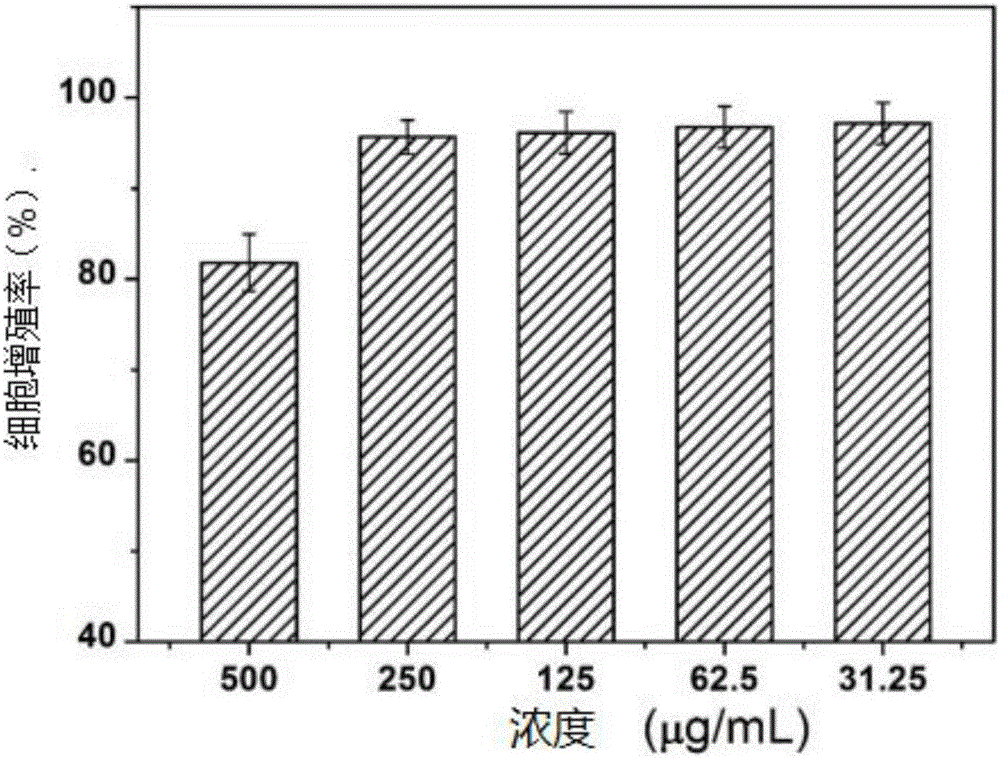

Preparation method and application of gadolinium sodium sulfate

ActiveCN106745168AHigh crystallinityPhase stableRare earth metal sulfatesNMR/MRI constrast preparationsSolvothermal reactionSodium sulfate

The invention provides a preparation method of gadolinium sodium sulfate. The preparation method comprises the following steps: mixing a gadolinium salt solution, ethylene glycol and polyvinylpyrrolidone to obtain a mixed solution; adding a mixed solution of sulfuric acid and absolute ethyl alcohol and a sodium hydroxide solution into the mixed solution for solvothermal reaction to obtain the gadolinium sodium sulfate. The preparation method of the gadolinium sodium sulfate, which is provided by the invention, is simple and feasible; the raw materials are readily available and low-cost; furthermore, the obtained gadolinium sodium sulfate is high in purity, high in crystallizing degree and stable in phase; an aqueous solution of the gadolinium sodium sulfate is high in nuclear magnetic signal strength, and is suitable for being prepared into a T1 contrast agent of nuclear magnetic resonance. An experimental result shows that the purity of the gadolinium sodium sulfate prepared through the method can reach 99.9 percent.

Owner:QINGDAO UNIV OF SCI & TECH

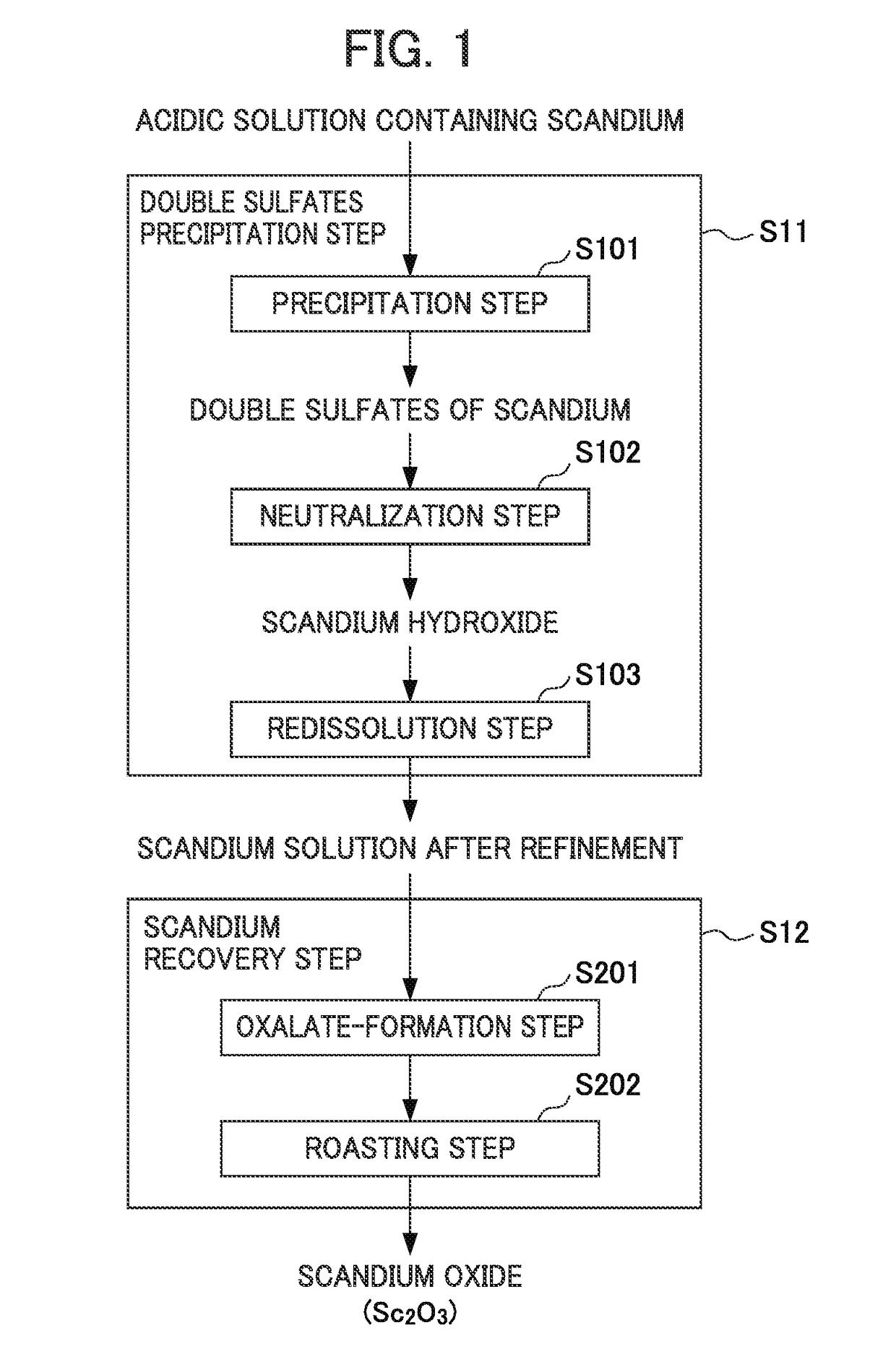

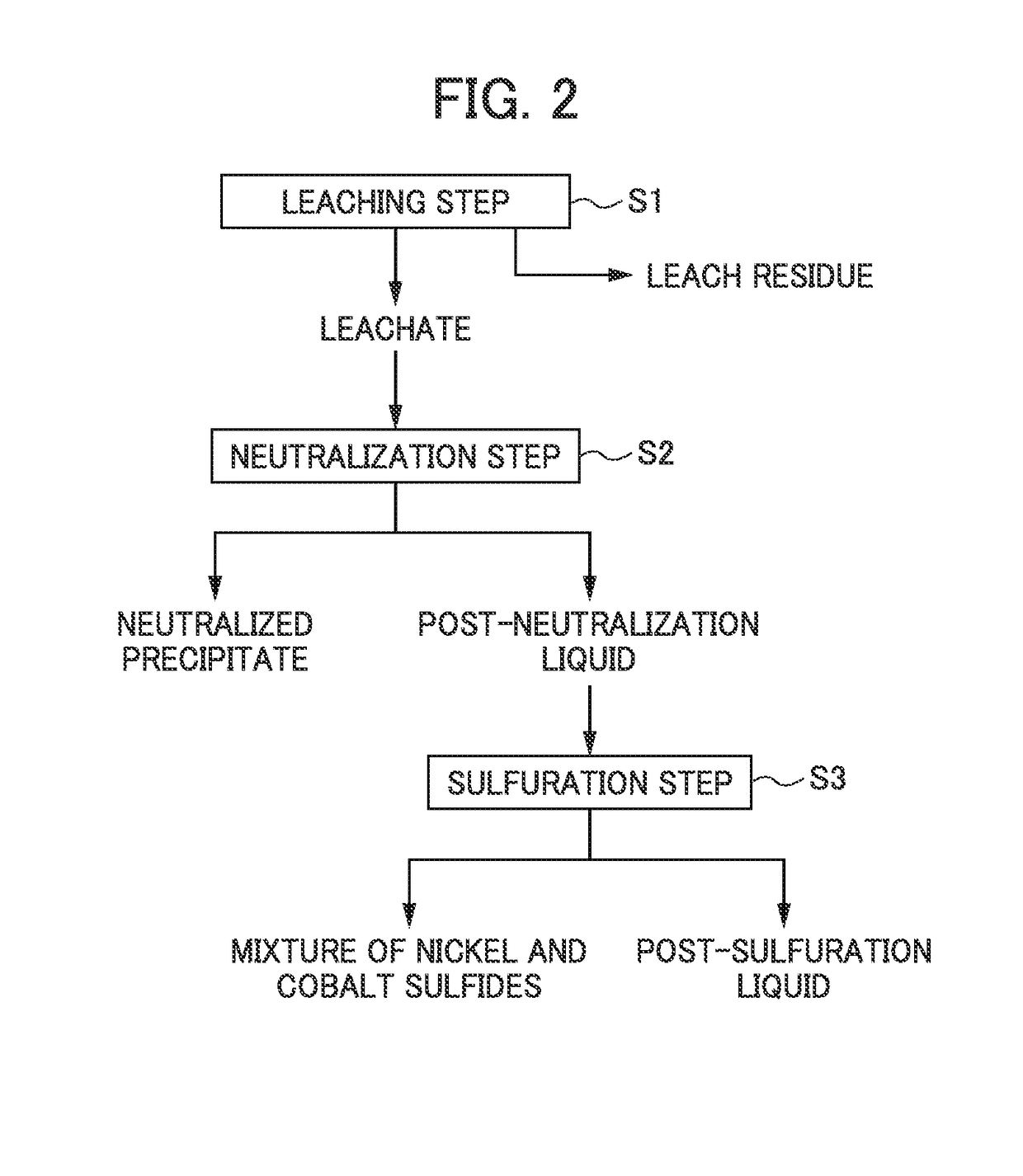

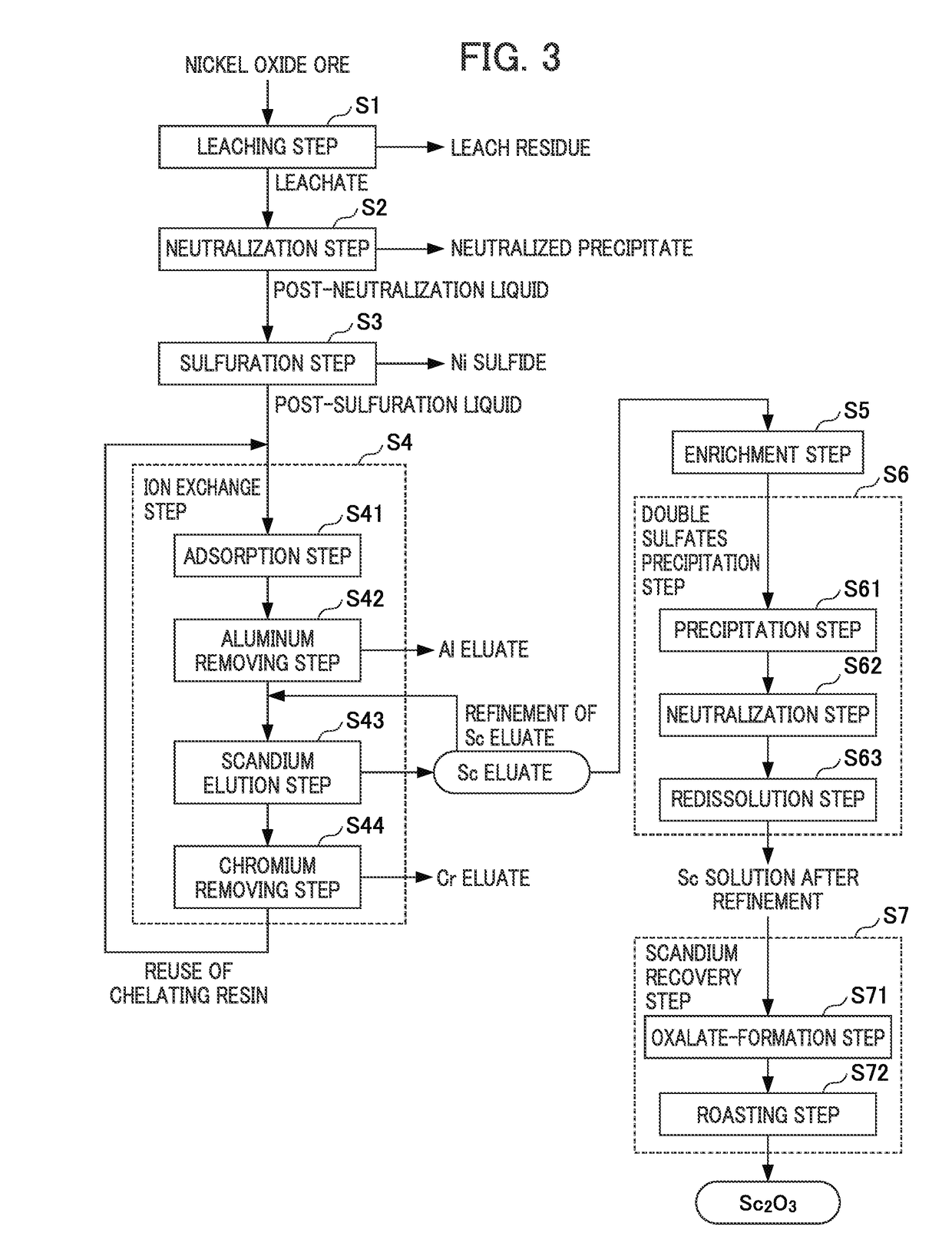

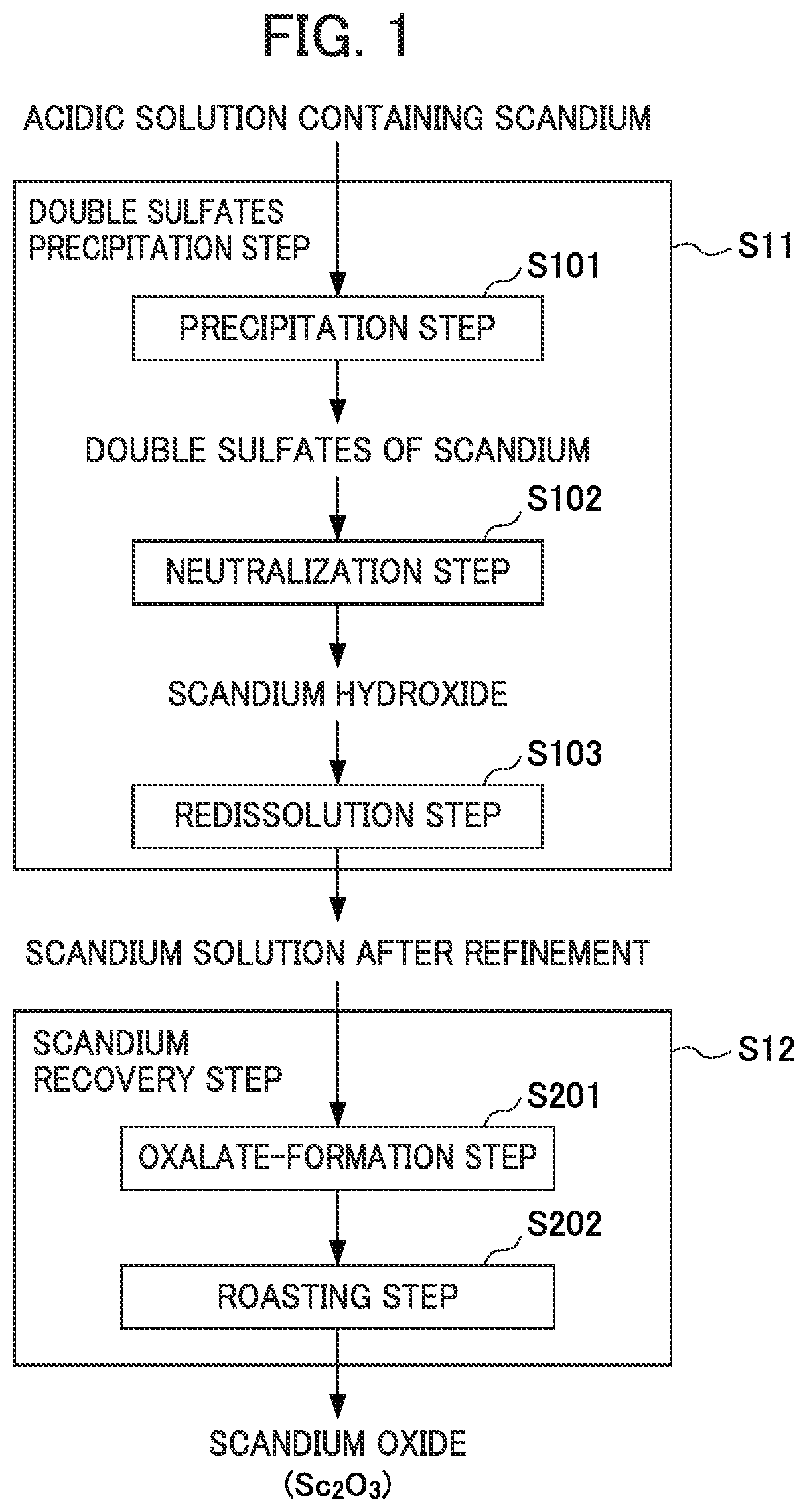

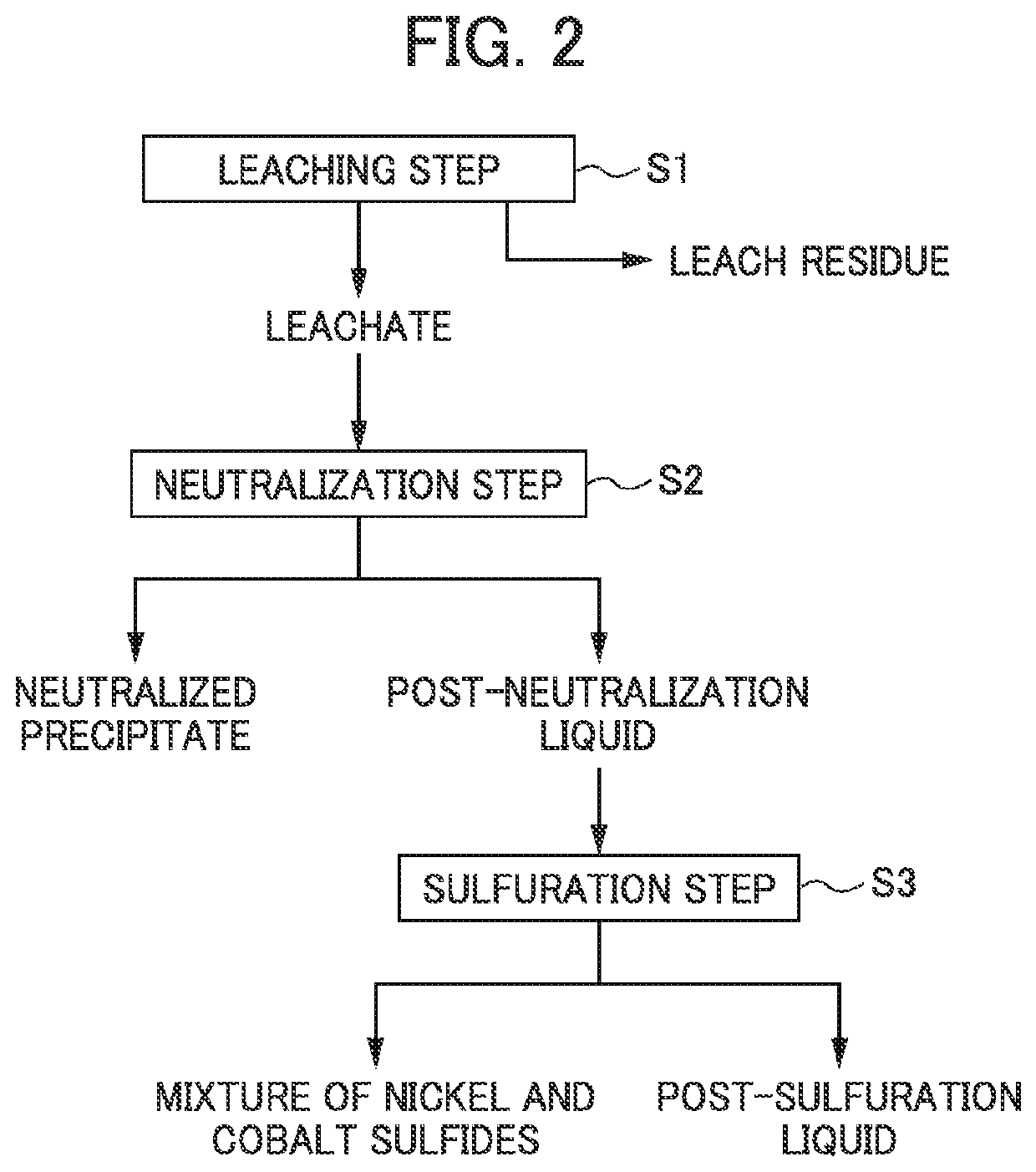

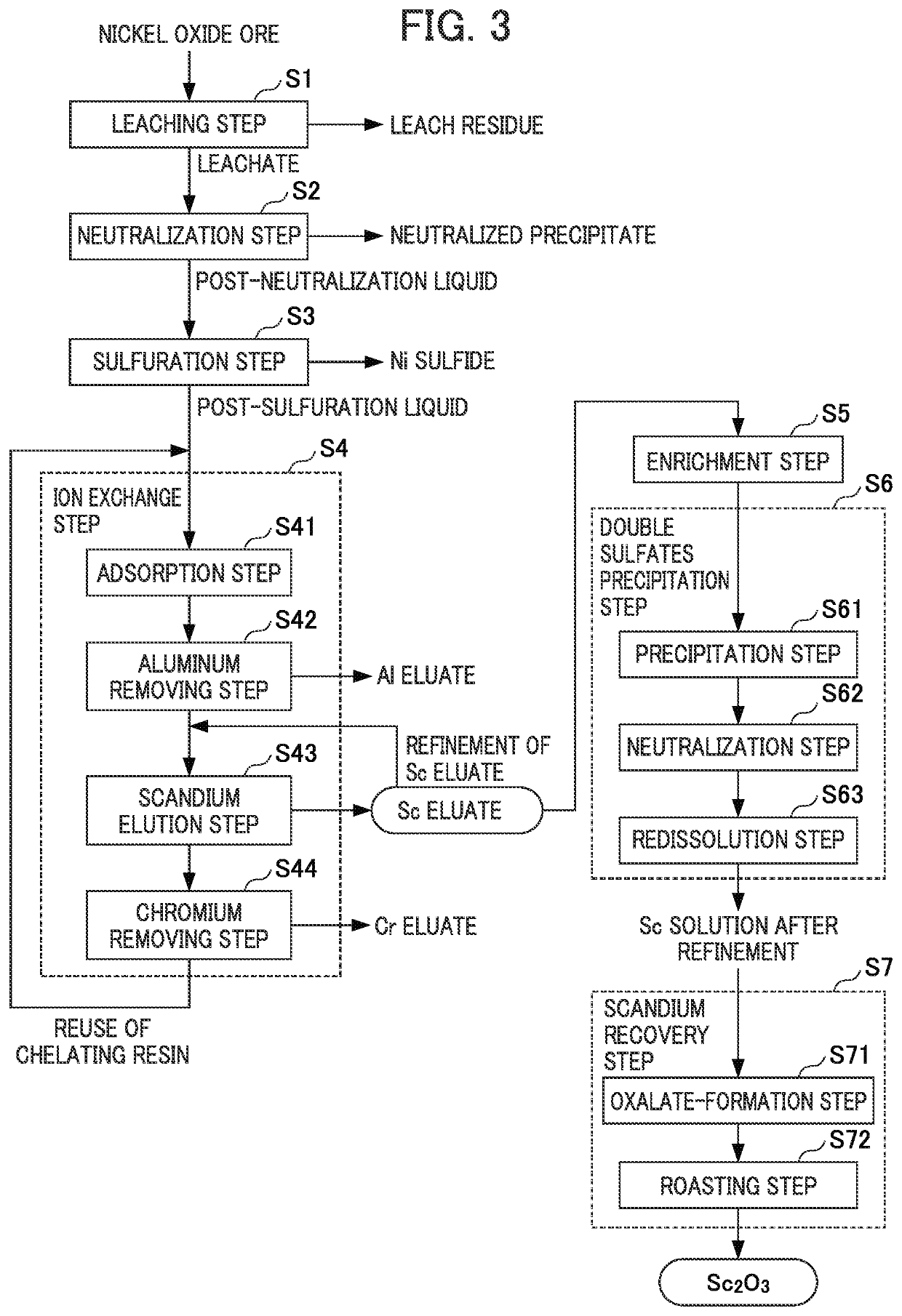

Method for recovering scandium

ActiveUS20180087128A1Recovered conveniently and efficientlyRare earth metal sulfatesRare earth metal chloridesSulfateDissolution

According to this method for recovering scandium, an acidic solution containing scandium is used and a scandium dissolution liquid after purification is obtained by a double sulfate precipitation step, and scandium is recovered from the obtained scandium dissolution liquid, as follows: [A] A precipitation step wherein sodium sulfate is added into the acidic solution containing scandium, so that a precipitate of a scandium double sulfate is obtained; [B] A neutralization step wherein pure water is added to the precipitate of a scandium double sulfate obtained in the precipitation step to dissolve the precipitate of a scandium double sulfate therein, and scandium hydroxide is obtained by adding a neutralizing agent into the obtained dissolution liquid; and [C] A re-dissolution step wherein an acid is added to the scandium hydroxide obtained in the neutralization step, so that a scandium dissolution after purification, in which the scandium hydroxide is dissolved, is obtained.

Owner:SUMITOMO METAL MINING CO LTD

Production of scandium-containing concentrate and further extraction of high-purity scandium oxide from the same

ActiveUS20190161828A1High purityRare earth metal sulfatesScandium oxides/hydroxidesRed mudScandium oxide

The invention relates to a method for producing a scandium-containing concentrate from the wastes of alumina production and extracting high-purity scandium oxide from the same. Provided is a method for producing a scandium-containing concentrate from a red mud, wherein the Sc2O3 content therein is least of 15 wt. % (in terms of dry matter), the TiO2 content not more than 3 wt. % (in terms of dry matter), the ZrO2 content not more than 15 wt. % (in terms of dry matter), and wherein scandium in the concentrate is in form of a mixture of Sc(OH)3 hydroxide with ScOHCO3×4H2O. Also provided is a method for producing high-purity scandium oxide, with a purity of approximately 99 wt. %.

Owner:UNITED CO RUSAL ENG & TECHNOLOGHY CENT LLC

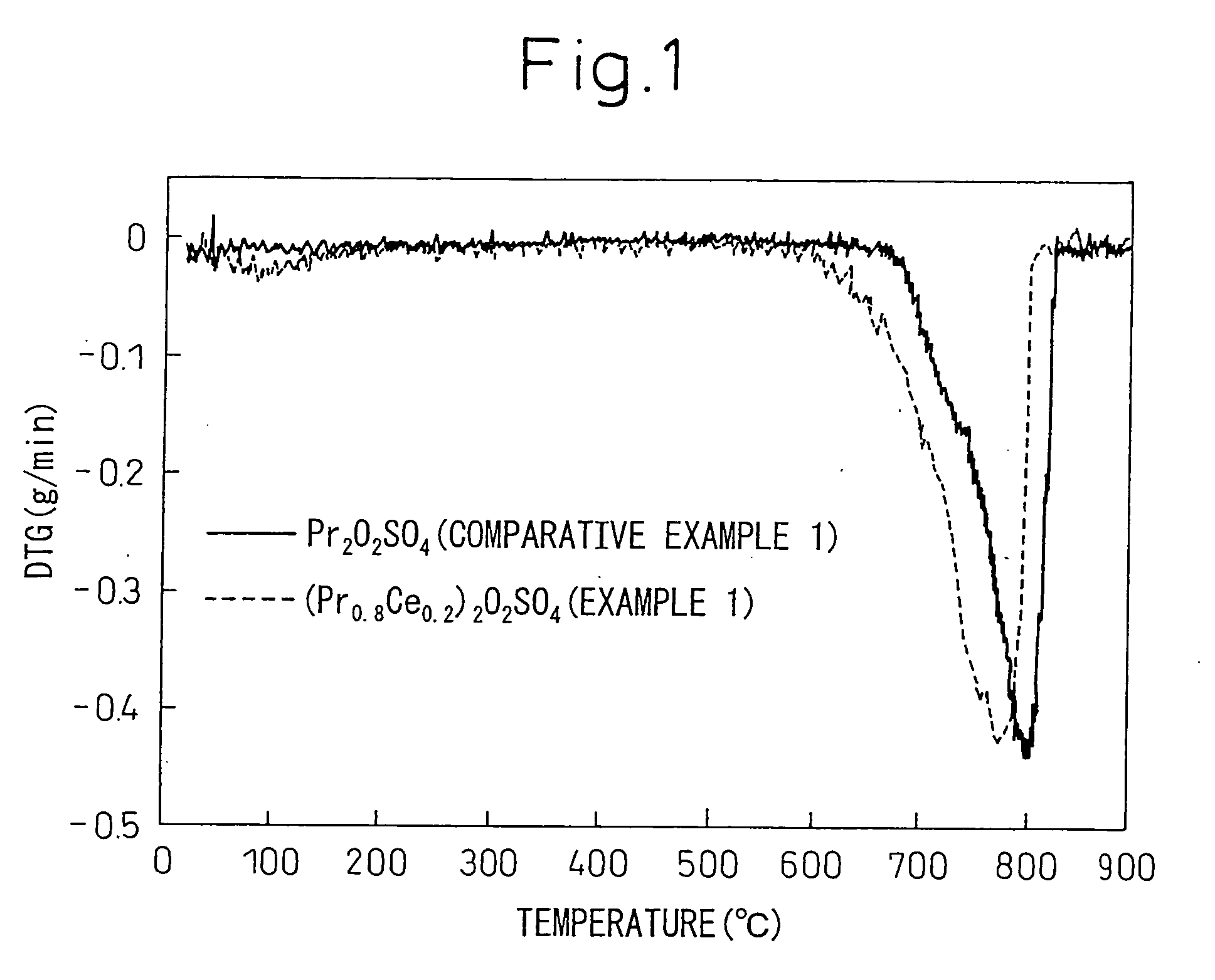

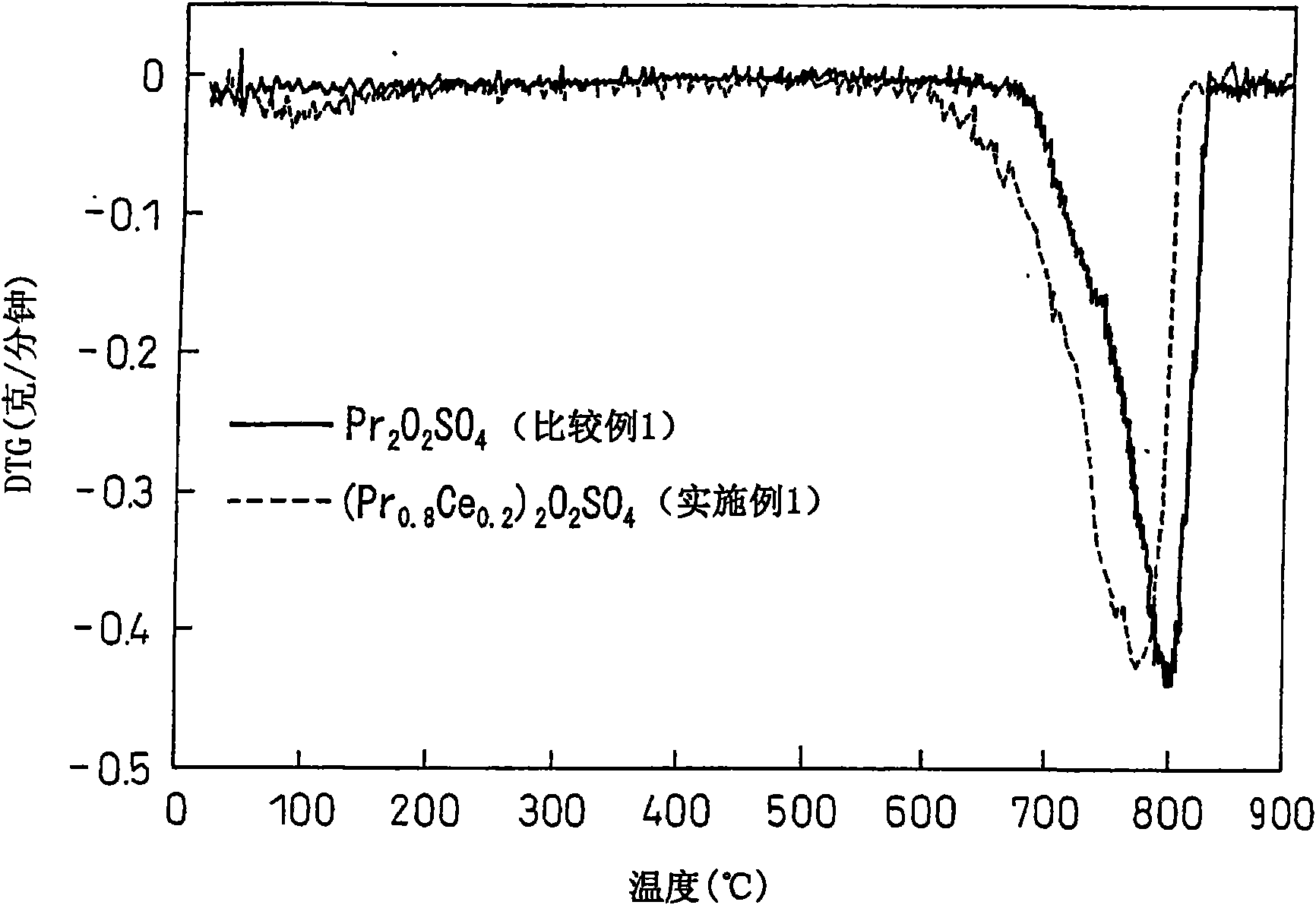

Oxygen storage/release material and exhaust gas purifying catalyst comprising the same

There is provided an oxygen storage / release material using a rare earth oxysulfate or oxysulfide, which has a high oxygen storage / release capacity even at lower temperatures. The oxygen storage / release material of the present invention comprises a compound consisting of Pr2O2SO4 and / or Pr2O2S in which at least a part of Pr is replaced with Ce.

Owner:NAT UNIV CORP KUMAMOTO UNIV +1

Oxygen storage/release material and exhaust gas purifying catalyst comprising the same

There is provided an oxygen storage / release material using a rare earth oxysulfate or oxysulfide, which has a high oxygen storage / release capacity even at lower temperatures. The oxygen storage / release material of the present invention comprises a compound consisting of Pr2O2SO4 and / or Pr2O2S in which at least a part of Pr is replaced with Ce.

Owner:NAT UNIV CORP KUMAMOTO UNIV +1

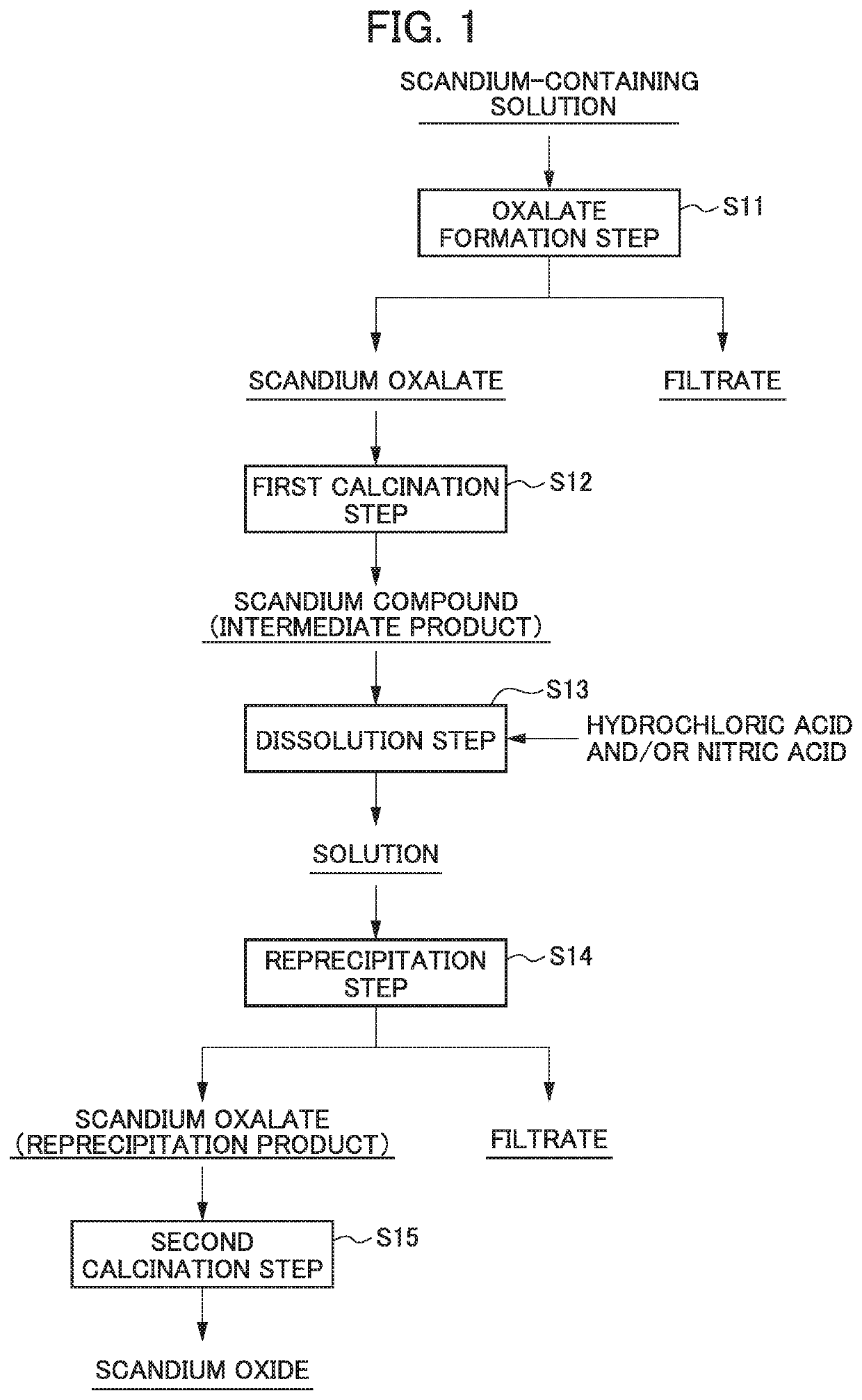

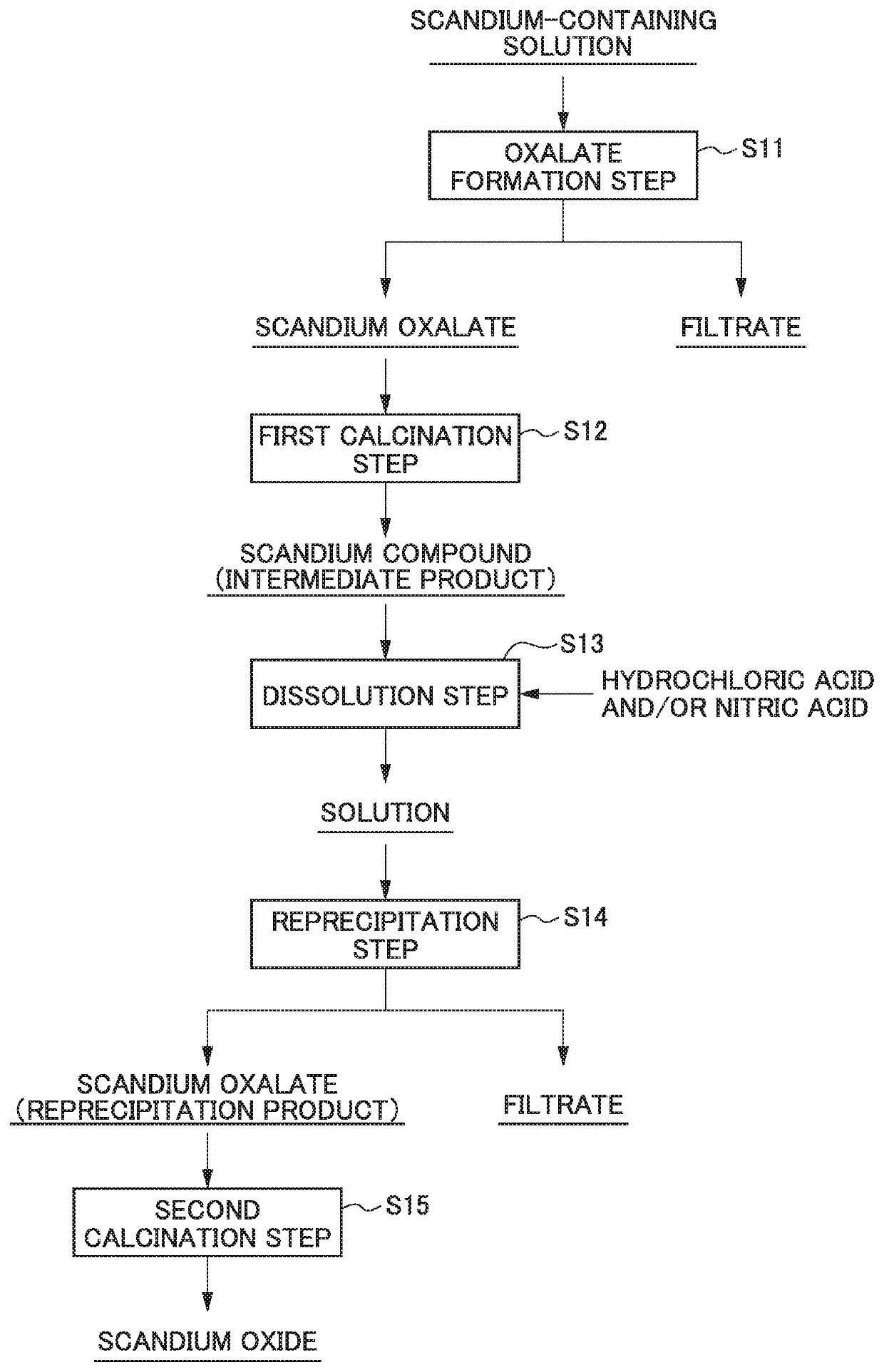

Method for producing high-purity scandium oxide

ActiveUS20210032119A1Efficiently obtainedRare earth metal sulfatesScandium oxides/hydroxidesOXALIC ACID DIHYDRATEOxalate

Provided is a method for obtaining high-purity scandium oxide efficiently from a solution containing scandium. The method for producing high-purity scandium oxide of the present invention has a first firing step S12 for subjecting a solution containing scandium to oxalation treatment using oxalic acid and firing the obtained crystals of scandium oxalate at a temperature of 400 to 600° C., inclusive, a dissolution step S13 for dissolving the scandium compound obtained by firing in one or more solutions selected from hydrochloric acid and nitric acid to obtain a solution, a reprecipitation step S14 for subjecting the solution to oxalation treatment using oxalic acid and generating a reprecipitate of scandium oxalate, and a second firing step S15 for firing the reprecipitate of obtained scandium oxalate to obtain scandium oxide.

Owner:SUMITOMO METAL MINING CO LTD

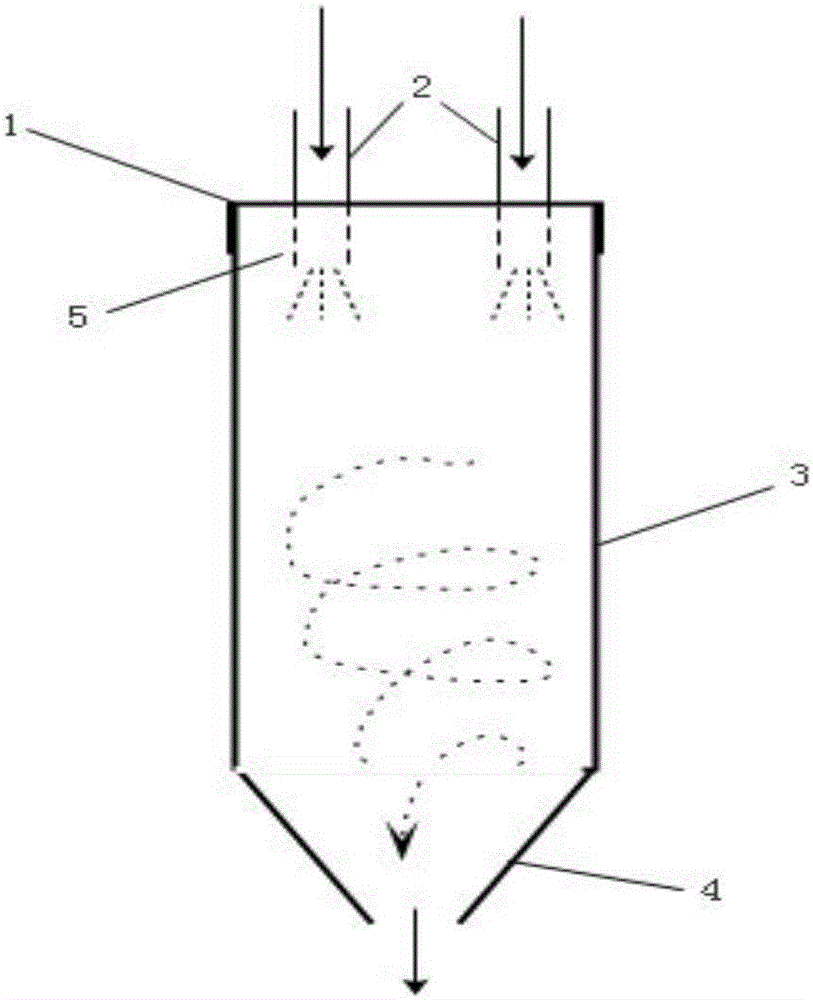

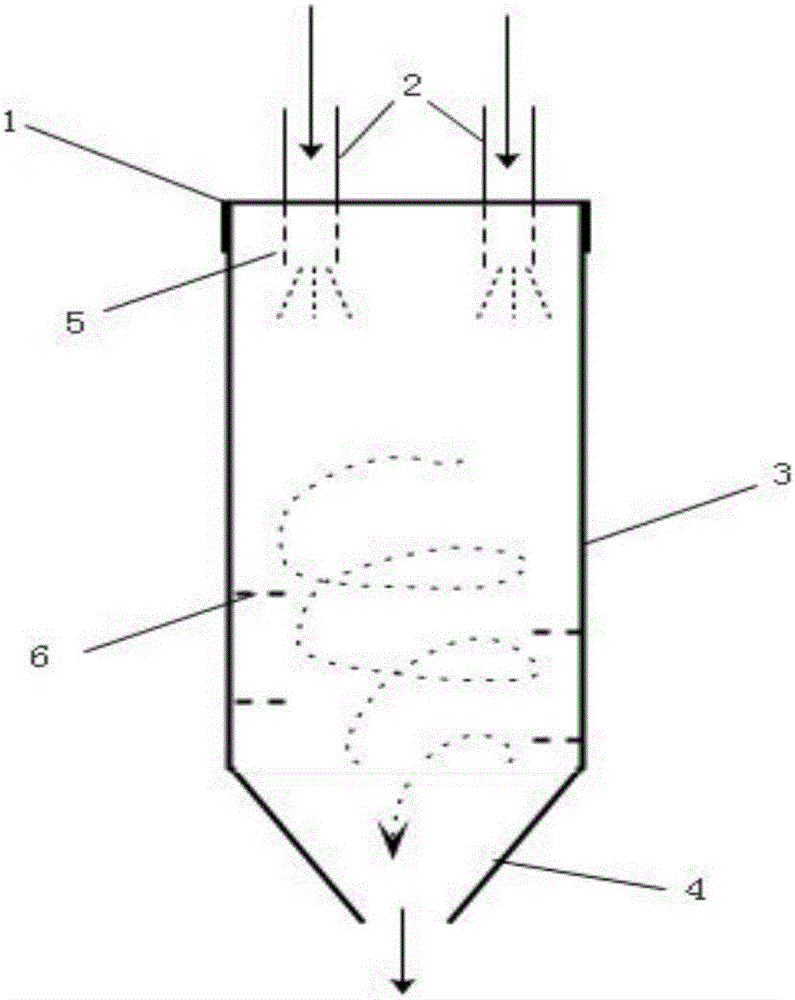

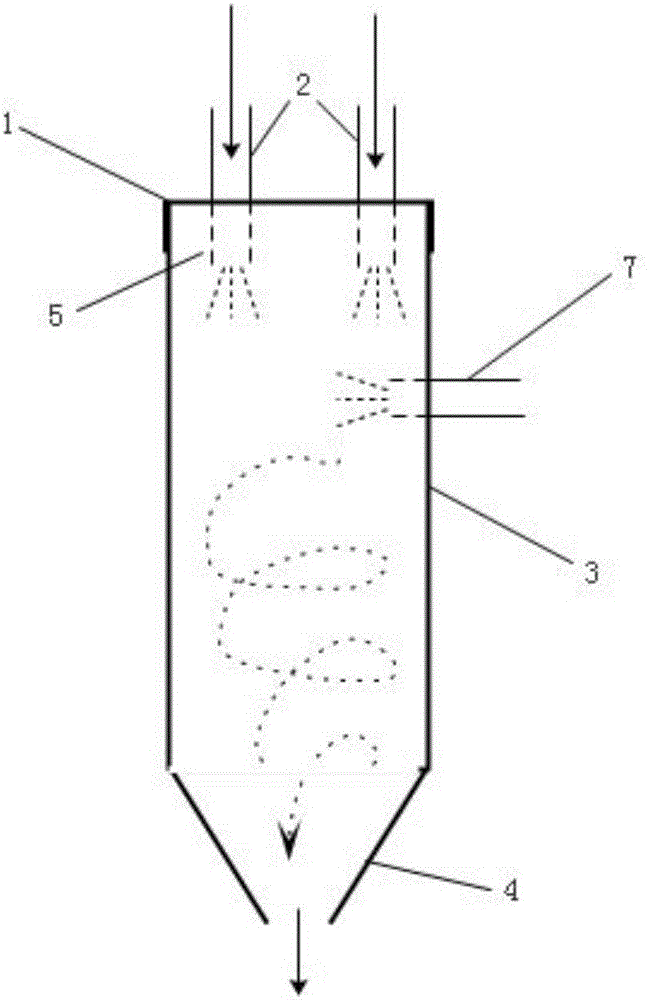

Reaction device and method for preparing superfine rare earth compound through same

InactiveCN106362657AReduce volumeEasy to useRare earth metal sulfatesRare earth metal chloridesRare earthEngineering

Owner:QIANDONG RARE EARTH GRP

Oxygen-containing lanthanum sulfate thin film and preparation method thereof by layer-by-layer self assembly of nanosheets

ActiveCN108217711ASave rare earth resourcesControl thicknessRare earth metal sulfatesNanotechnologyOxygenLayer by layer self assembly

The invention discloses an oxygen-containing lanthanum sulfate thin film and a preparation method thereof by layer-by-layer self assembly of nanosheets, and belongs to the technical field of materialscience. The oxygen-containing lanthanum sulfate thin film is made of (La, Eu)2O2SO4, and is 5-50nm in thickness. The preparation method of the thin film by layer-by-layer self assembly of the nanosheets comprises the following steps: mixing lanthanum nitrate solution and europium nitrate solution, adding and dissolving ammonium sulfate particles, then adding ammonia water, regulating pH to 6-10,reacting the obtained uniform suspension for 1-48 hours at the temperature of minus 4 to 4 DEG C, thus obtaining a product, separating and drying, and then adding absolute ethyl alcohol, thus obtaining nanosheet sol; adopting a spin-coating technology to spin-coat the nanosheet sol on a sapphire substrate subjected to infiltrating pretreatment, and by layer-by-layer spin-coating self assembly, obtaining a (La, Eu)2(OH)4SO4.nH2O precursor thin film; drying and calcining to obtain the (La, Eu)2O2SO4 thin film. The oxygen-containing lanthanum sulfate thin film and the preparation method disclosedby the invention have the advantages that the thickness of the oxygen-containing lanthanum sulfate thin film can be controlled by controlling the thickness of the precursor thin film; the film formation is convenient, and the film formation quality is high.

Owner:BOHAI UNIV

Rare earth solution preparation process capable of quickly and efficiently removing acid

ActiveCN111392761AQuick removalImprove efficiencyRare earth metal sulfatesRare earth metal chloridesPhysical chemistryStrong acids

The invention discloses a rare earth solution preparation process capable of quickly and efficiently removing acid. The preparation process comprises the following steps: drying and crushing, grinding, dissolving and stirring, stabilizing the solution, carrying out microwave digestion and carrying out double-layer acid removal. According to the rare earth solution preparation process capable of rapidly and efficiently removing acid, rare earth mineral powder is prepared through the processes of drying, crushing and grinding, after the rare earth mineral powder is dissolved through strong acidand stabilized through a metallic soap stabilizer, part of dissolved sample acid is removed through sulfuric acid or perchloric acid by heating, and then residual acid removing is conducted through atemperature-controlled acid removing instrument; with application of the process, the sample dissolving acid in the rare earth solution can be quickly removed, the residue of the sample dissolving acid is effectively reduced, the time of the preparation process flow is shortened, the acid driving efficiency and the preparation efficiency of the rare earth solution are improved and the process is worthy of popularization.

Owner:中稀(宜兴)稀土新材料有限公司

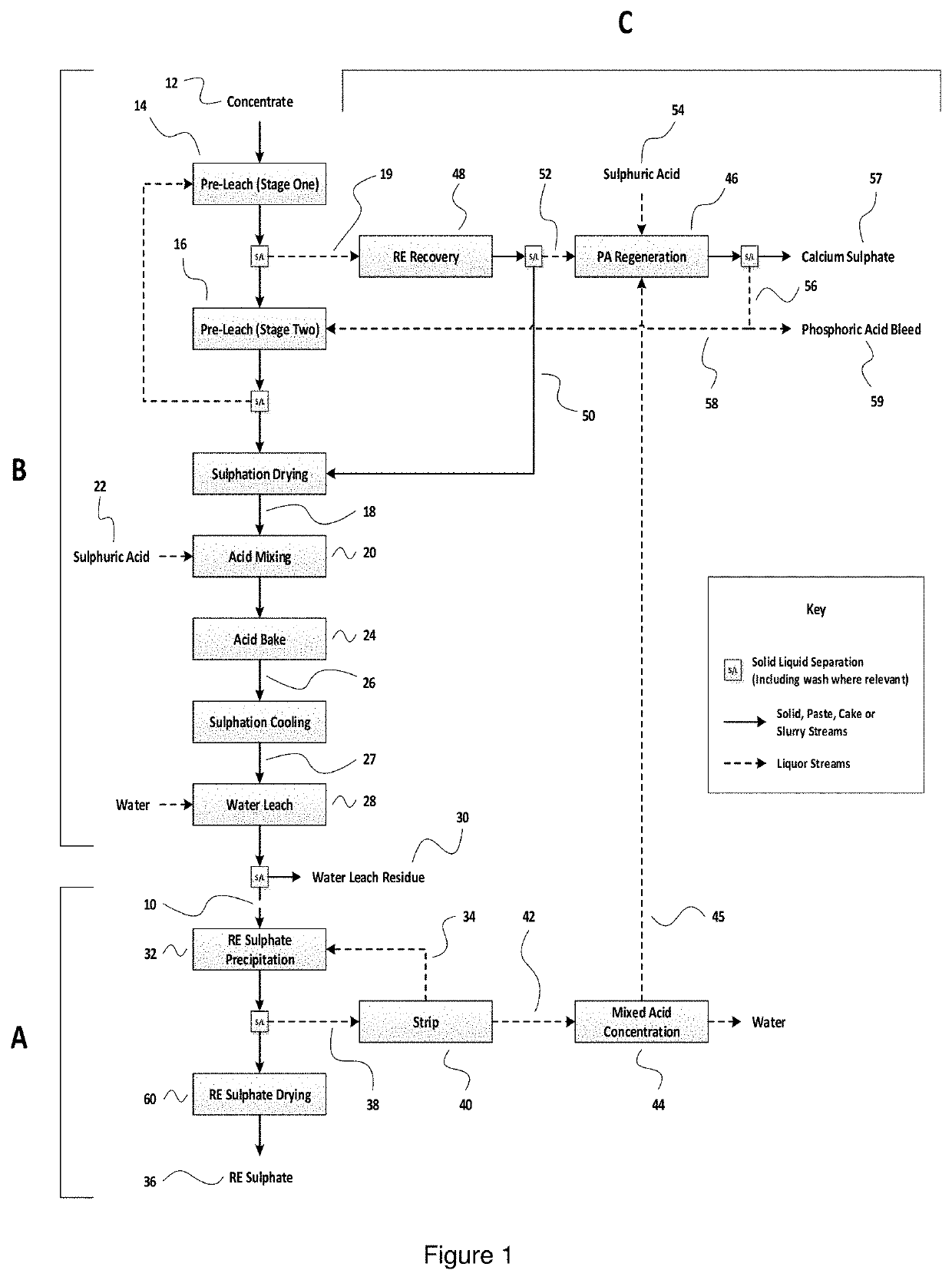

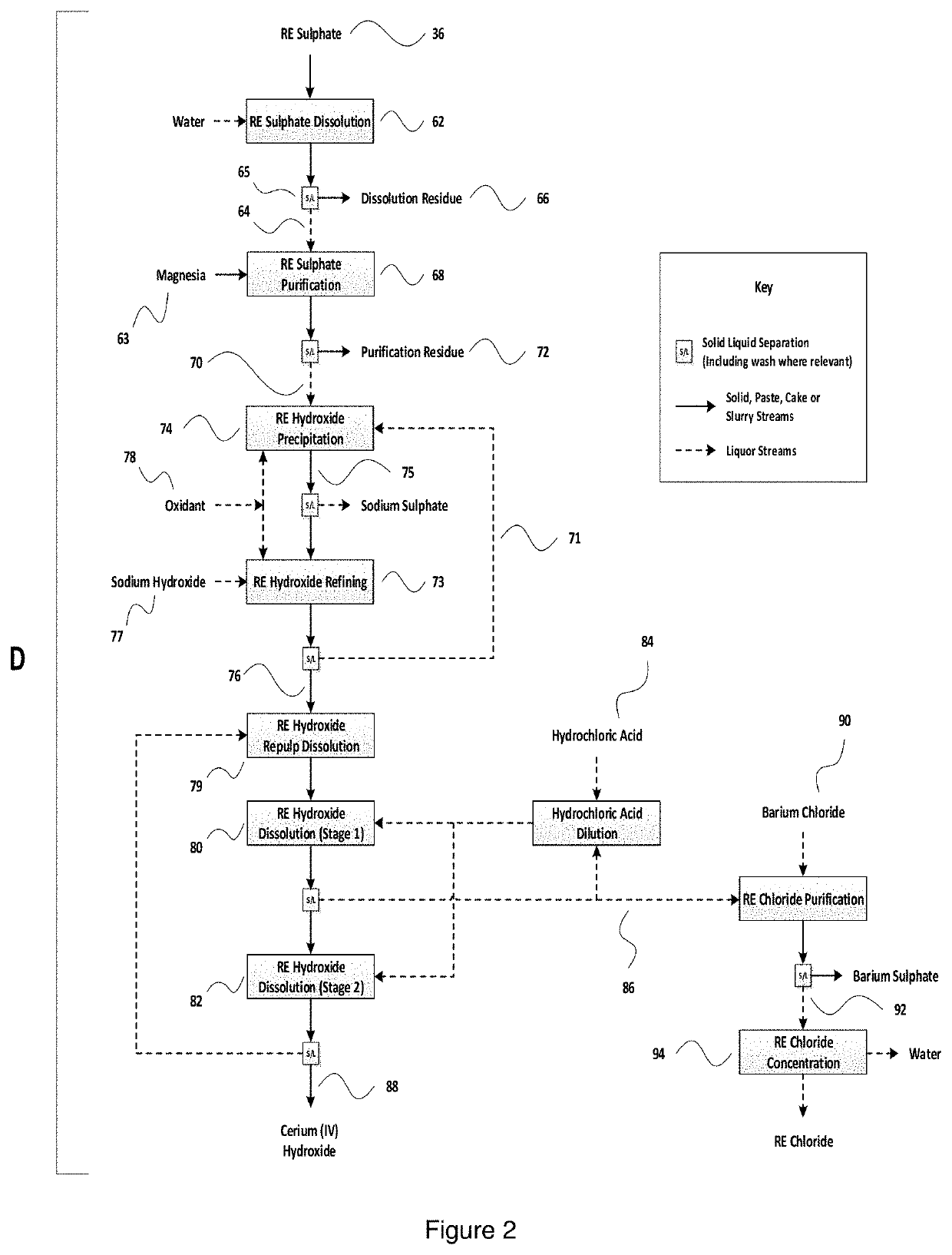

Process for the recovery of rare earths

PendingUS20210140012A1Maximise precipitationMinimising co-precipitationRare earth metal sulfatesRare earth metal chloridesPropanolSimple Organic Compounds

A method for the precipitation of rare earth sulphate, the method including subjecting a crude rare earth sulphate solution to precipitation in the presence of a water soluble, volatile, organic compound to produce a rare earth sulphate precipitate and an acidic supernatant. The organic compound is preferably selected from the group consisting of methanol, ethanol, iso-propanol, tert-butanol, acetone or mixtures thereof, and is preferably methanol. Preferably, the organic compound is used in the precipitation at a weight ratio of between 0.25:1 to 1.5:1, and preferably 0.5:to 1.25:1, with the crude sulphate solution.

Owner:ARAFURA RESOURCES

Pollution-free preparation method of ceric sulfate

The invention belongs to the field of preparation of inorganic chemistry, in particular to a pollution-free preparation method of ceric sulfate. The preparation method comprises the following steps: dissolving cerium chloride crystals in deionized water; adding strong alkali into the mixture; after full reaction, carrying out aging, suction filtration and cleaning; adding the obtained filter cakesinto dilute sulfuric acid; heating the mixture to react till the filter cakes are fully dissolved; carrying out cooling, crystallizing and suction filtration; and filtering the filter cakes to obtainsaffron yellow high quality ceric sulfate.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Europium sulfate decomposition method

InactiveCN105776309AChemically stableGood water solubilityRare earth metal sulfatesLanthanide oxides/hydroxidesFiltrationSulfate

An europium sulfate decomposition method is characterized in that europium sulfate is added to a hydrochloric acid solution according to the 1: (2-6): (1-0.5) mass ratio of the europium sulfate to the hydrochloric acid solution to hydrogen peroxide, and stirring is performed for 10-30 minutes; then the hydrogen peroxide is added, and stirring is performed for 1-5 hours; finally, water is added for dilution according to the (0.5-4):1 mass ratio of the water to the hydrochloric acid solution, filtration is performed, filter residues are returned for re-decomposition treatment, and filtrate is used for crude europium preparation. The europium sulfate decomposition method adopts the hydrogen peroxide to decompose the europium sulfate in the hydrochloric acid solution, replaces a traditional nitric acid or alkali heating decomposition process, reduces the energy consumption and is simple in operation and low in cost.

Owner:GUANGDONG INST OF RARE METALS

Oxygen-containing lanthanum sulfate thin film and its nanosheet layer-by-layer self-assembly preparation method

ActiveCN108217711BSave rare earth resourcesControl thicknessRare earth metal sulfatesNanotechnologyLayer by layer self assemblyOxygen

Owner:BOHAI UNIV

A method for processing low-grade fluorite ore containing rare earth

ActiveCN109371239BReduce energy consumptionReduce consumptionRare earth metal sulfatesHydrogen fluorideSlagCerium

The invention relates to a method for treating rare-earth-containing low-grade fluorite minerals, and belongs to the field of hydrometallurgy. The rare-earth-containing low-grade fluorite minerals areused as a target, and provides a method for performing program temperature control segmented slurry decomposition treatment by adopting an absolute excess sulfuric acid solution, a low-temperature section is controlled to preferentially decompose the fluorite minerals, then raising the temperature to decompose the rare earth minerals. The hydrofluoric acid is recycled from tail gas, the reacted acid leaching slag is leached with water to obtain the rare earth, neutralization and thorium removal are carried out to recover the rare earth and the gypsum which is reach the radioactive standard, and the acid leaching solution is used for circularly decomposing the new fluorite minerals after supplementing sulfuric acid. According to the method for treating rare-earth-containing low-grade fluorite minerals, CaF2 and fluorine-carbon cerium ore in the rare-earth-containing low-grade fluorite minerals reach a relatively high decomposition rate through the program temperature control slurryingreaction, the consumption of sulfuric acid is low, the purity of the hydrofluoric acid recovered from the tail gas is high, hydrofluoric acid, gypsum and a sulfuric acid rare-earth solution are obtained, the comprehensively utilize of fluorine, calcium and rare earth resources in the rare-earth-containing low-grade fluorite minerals is realized, The whole process has no three-waste pollution and is clean and environment-friendly.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Method for producing high-purity scandium oxide

ActiveUS10968112B2Efficiently obtainedRare earth metal sulfatesScandium oxides/hydroxidesOXALIC ACID DIHYDRATEOxalate

Provided is a method for obtaining high-purity scandium oxide efficiently from a solution containing scandium. The method for producing high-purity scandium oxide of the present invention has a first firing step S12 for subjecting a solution containing scandium to oxalation treatment using oxalic acid and firing the obtained crystals of scandium oxalate at a temperature of 400 to 600° C., inclusive, a dissolution step S13 for dissolving the scandium compound obtained by firing in one or more solutions selected from hydrochloric acid and nitric acid to obtain a solution, a reprecipitation step S14 for subjecting the solution to oxalation treatment using oxalic acid and generating a reprecipitate of scandium oxalate, and a second firing step S15 for firing the reprecipitate of obtained scandium oxalate to obtain scandium oxide.

Owner:SUMITOMO METAL MINING CO LTD

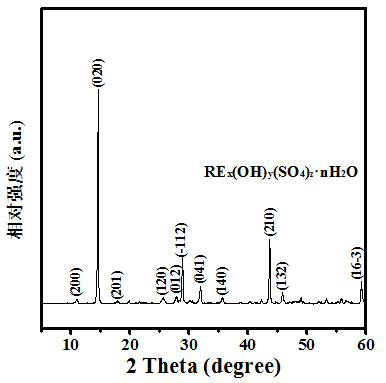

Synthesis and application of rare earth layered thermocatalytic material

ActiveCN112717957AMild reaction conditionsHigh yieldRare earth metal sulfatesOrganic chemistryAlcoholAromatization

The invention relates to synthesis and application of a rare earth layered thermocatalytic material, wherein the chemical formula of the rare earth rare earth layered thermocatalytic material is REx(OH)y(SO4)z.nH2O, RE represents rare earth elements, and x, y and z can be integers or fractions. According to the invention, the rare earth layered material has excellent stability and Lewis acidity; alcohol, aldehyde and phenol aromatic compounds are synthesized in one step from ethanol; the rare earth layered thermocatalytic material provided by the invention has excellent thermocatalytic performance, wherein the conversion rate of ethanol is close to 100%, the yield of an aldol condensation product reaches 52%, and the selectivity of aromatic compounds in the aldol condensation product is about 80%; and the ethanol involved in the process can be obtained by biomass fermentation, fossil energy consumption can be avoided, the reaction conditions are mild, and the yield of the target product is relatively high.

Owner:NANKAI UNIV

Method for recovering scandium

ActiveUS10570480B2Recovered conveniently and efficientlyRare earth metal sulfatesRare earth metal chloridesSulfatePhysical chemistry

The invention provides a method for recovering scandium from an acidic solution containing scandium. The method having [a] a precipitation step wherein sodium sulfate is added into the acidic solution containing scandium to obtain a precipitate of a scandium double sulfate; [b] a neutralization step wherein pure water is added to the precipitate of a scandium double sulfate to dissolve the precipitate of a scandium double sulfate therein, and scandium hydroxide is obtained by adding a neutralizing agent into the dissolution liquid; and [c] a re-dissolution step wherein an acid is added to the scandium hydroxide obtained in the neutralization step, so that a scandium dissolution after purification, in which the scandium hydroxide is dissolved, is obtained.

Owner:SUMITOMO METAL MINING CO LTD

A kind of preparation method of rare earth layered hydroxide nanosheet and sol thereof

InactiveCN108059182BSimple preparation processEasy to operateRare earth metal sulfatesNanotechnologyPhysical chemistryLanthanum nitrate

The invention relates to preparation methods of rare earth layered hydroxide nanosheets and rare earth layered hydroxide nanosheet sol. The preparation method of the nanosheets comprises the followingsteps: preparing a lanthanum nitrate solution with a corresponding concentration, dissolving ammonium sulfate particles into the lanthanum nitrate solution according to a proportion so as to form a mixed solution, adjusting the pH of the mixed solution to 6-10, and continuously stirring to obtain uniform suspension; carrying out a reaction to obtain a product, immediately carrying out centrifugalseparation on the product, and drying to obtain the rare earth layered hydroxide La2(OH)4SO4.nH2O nanosheets. The rare earth layered hydroxide nanosheet sol is prepared by putting the prepared nanosheets into a formamide solution, carrying out ultrasonic centrifugal treatment, and then taking the supernatant. According to the preparation method, the rare earth layered hydroxide La2(OH)4SO4.nH2O nanosheets can be prepared in one step by using an ice-bath method, so that the problem that in the prior art, the compounds cannot be prepared into single-layer nanosheets by using the conventional intercalation-stripping method can be solved; furthermore, the preparation methods are simple in process and convenient to operate, and can realize mass production; the corresponding nanosheet sol is good in stability and material-saving.

Owner:BOHAI UNIV

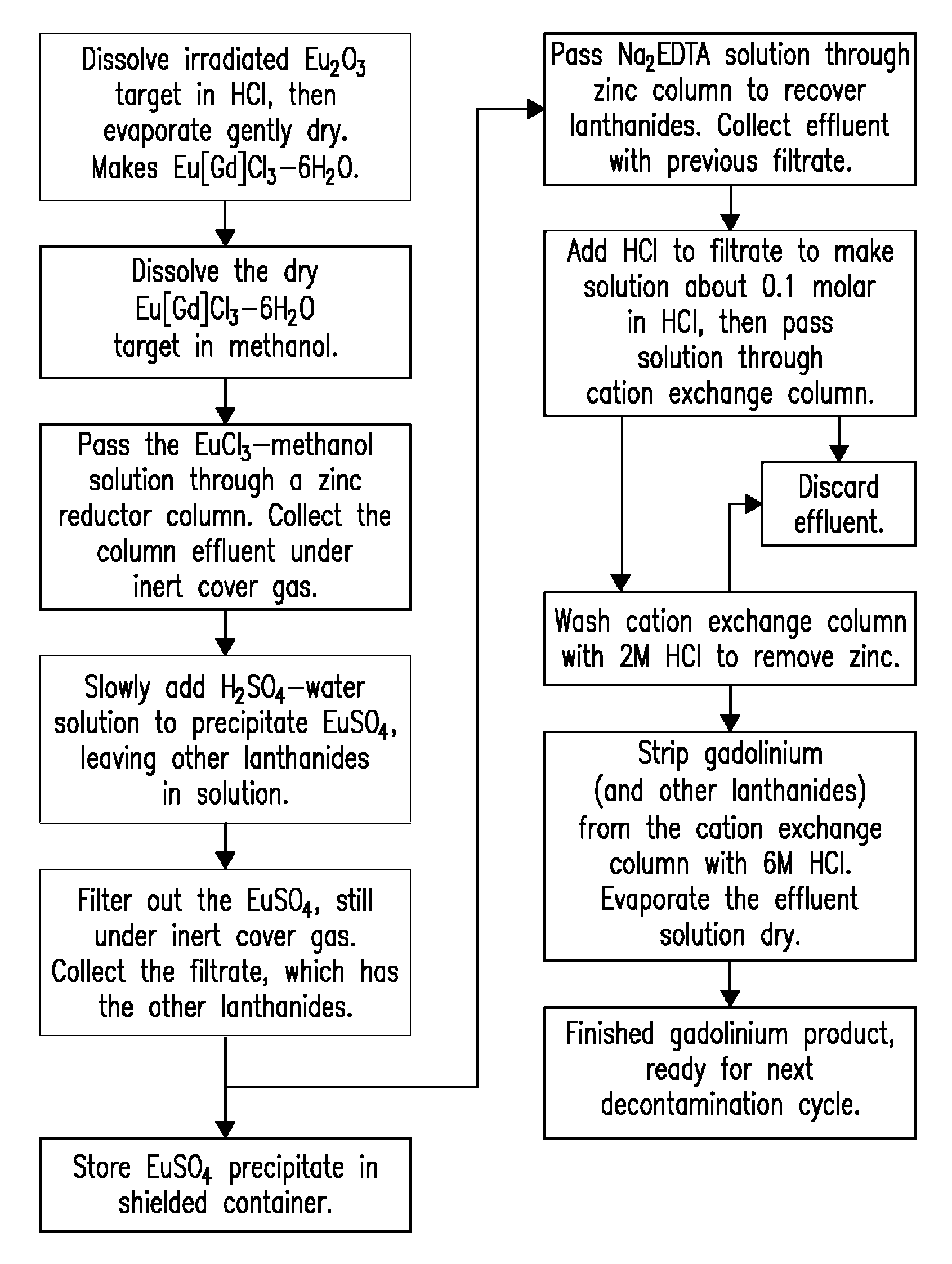

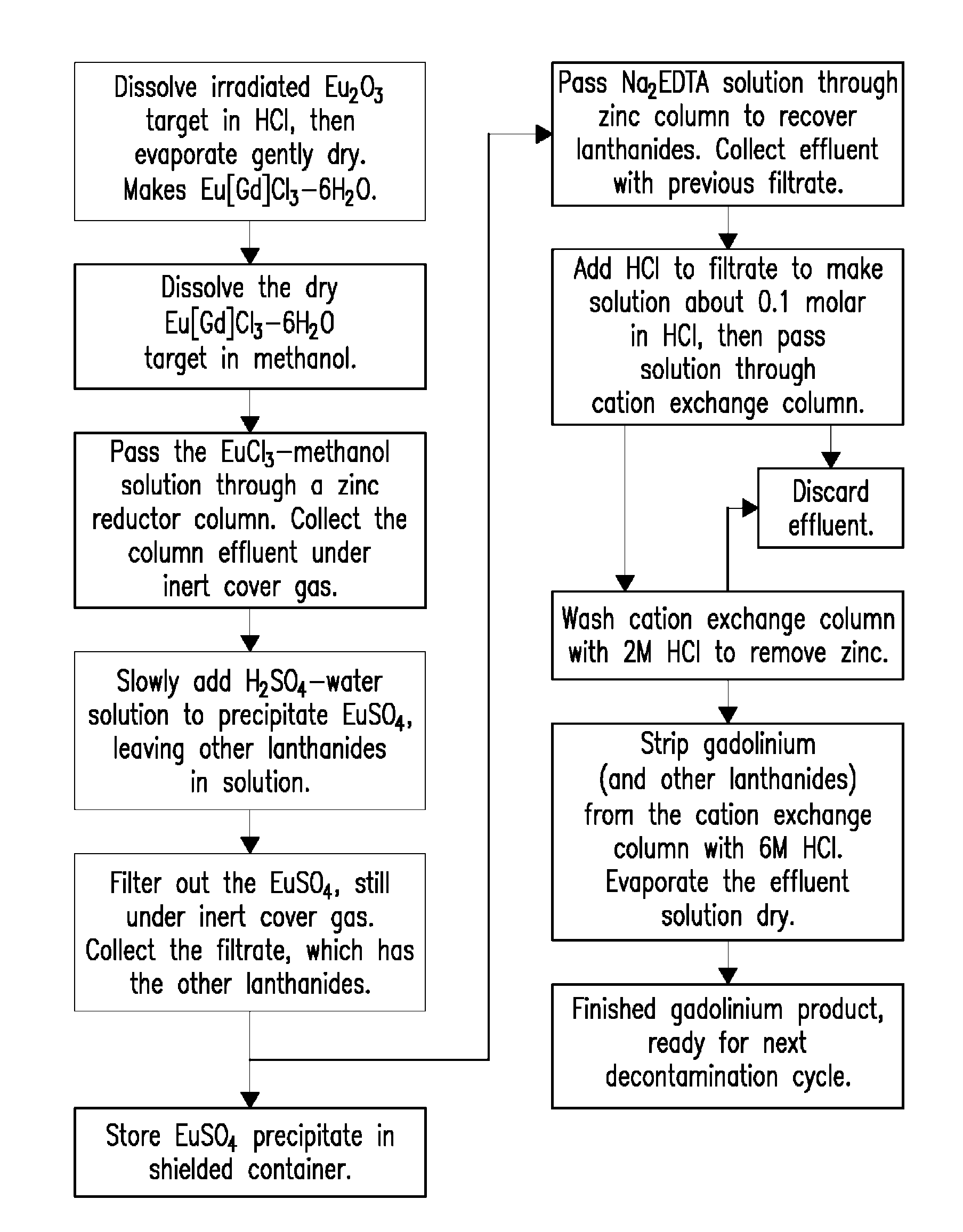

Purification process for 153Gd produced in natural europium targets

ActiveUS8425654B2Easy to manageLess of flammability hazardRare earth metal sulfatesRare earth metal chloridesReduction procedureProton

An alteration of the traditional zinc / zinc-amalgam reduction procedure which eliminates both the hazardous mercury and dangerous hydrogen gas generation. In order to avoid the presence of water and hydrated protons in the working solution, which can oxidize Eu2+ and cause hydrogen gas production, a process utilizing methanol as the process solvent is described. While methanol presents some flammability hazard in a radiological hot cell, it can be better managed and is less of a flammability hazard than hydrogen gas generation.

Owner:BATTELLE MEMORIAL INST

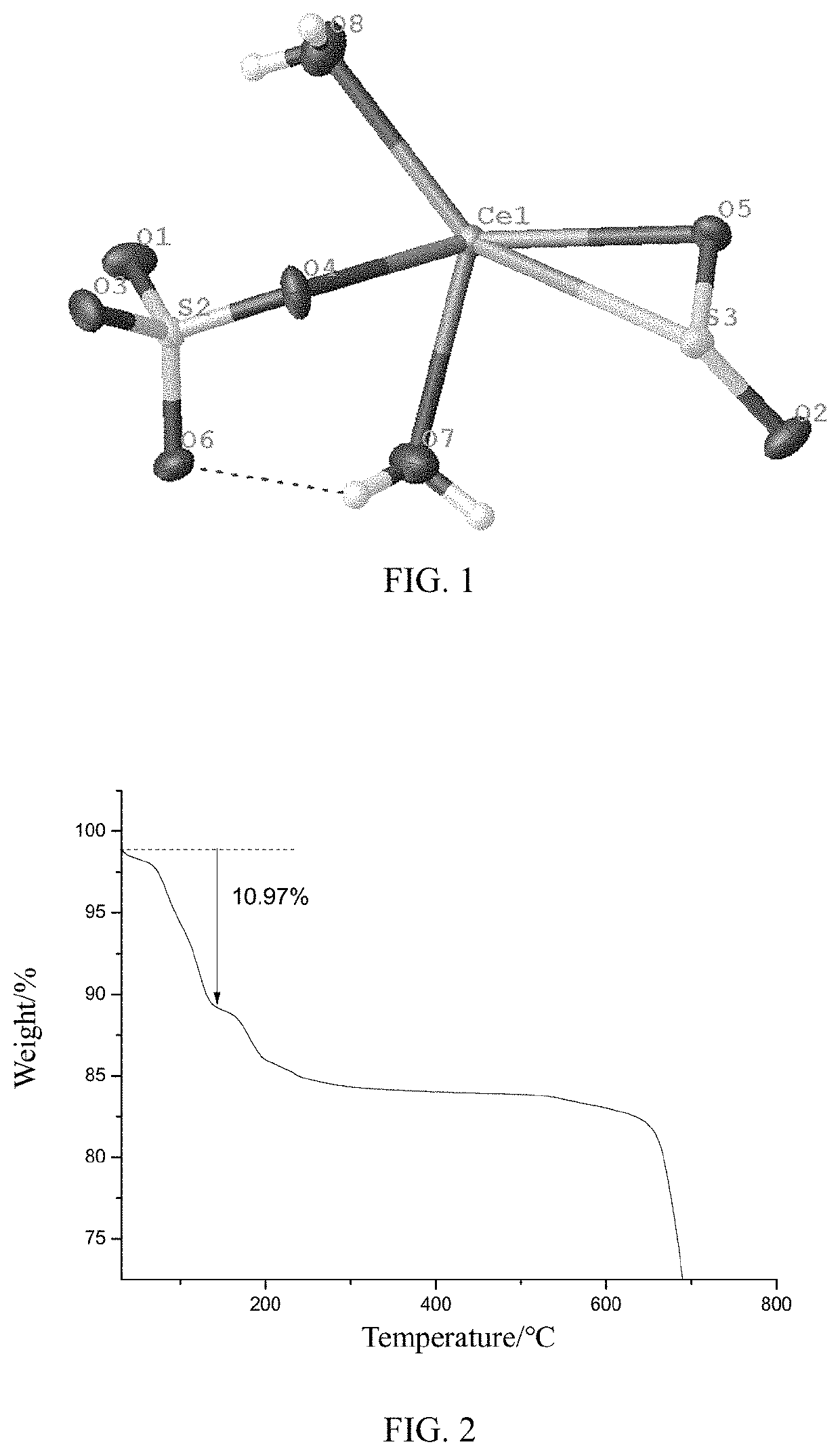

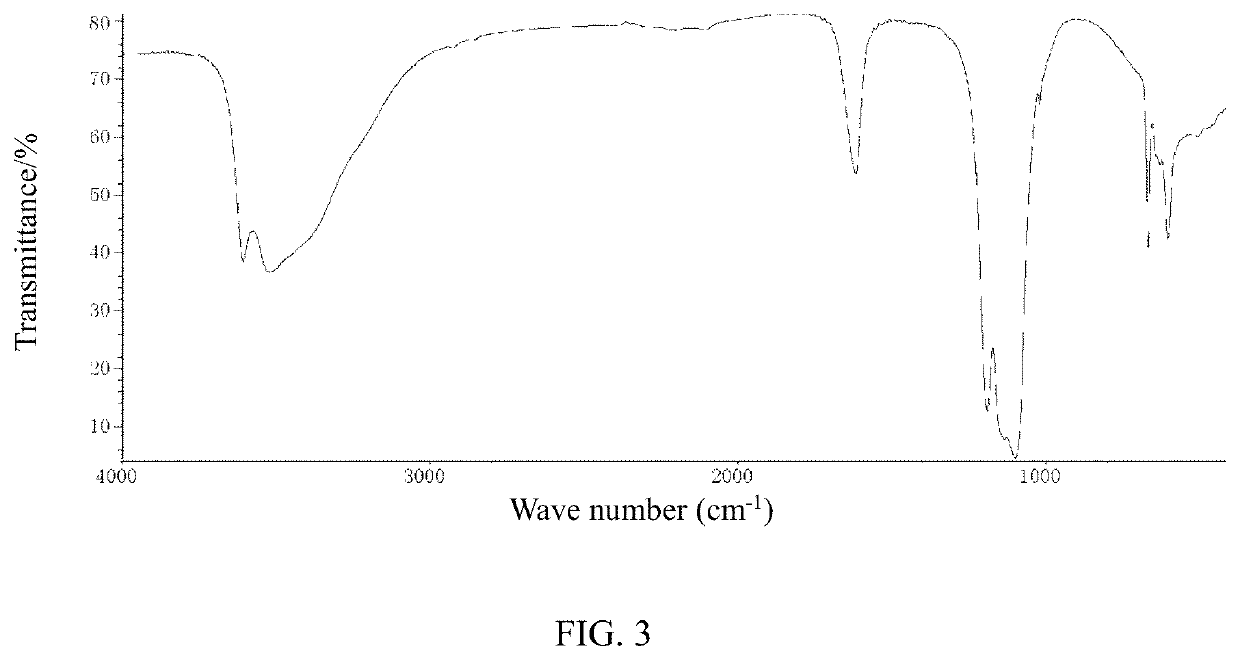

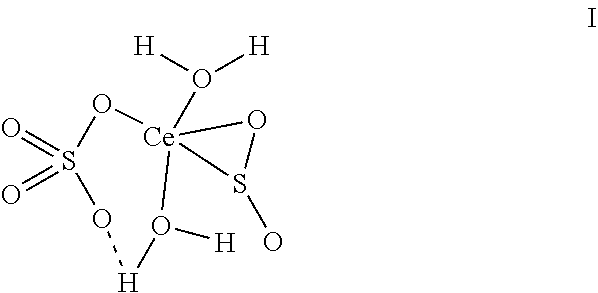

Cerium sulfate chelated sulfur dioxide, a preparation method and a use thereof

ActiveUS10899628B2Easy to judgeAvoid problemsRare earth metal sulfatesChemical analysis using titrationPhysical chemistrySulfur dioxide

Owner:SOUTH CHINA NORMAL UNIVERSITY

Rare earth sulfate salt and preparation method thereof

ActiveCN104445342BNo pollution in the processLow costRare earth metal sulfatesSolubilityCooking & baking

The invention discloses a rear-earth salt sulfate with good water solubility prepared through rear-earth salt sulfate. The rear-earth salt sulfate is characterized in that the rear-earth salt sulfate is powder-like odorless crystals in appearance, the chemical formula is RE2(SO4)3.nH2O, the rear-earth salt sulfate is dissolved in water and acid, the solution is clear, the solubility in water is decreased along with the increase of temperature, and the solubility in a sulfuric acid solution is decreased along with the increase of temperature. The preparation method comprises the following steps: adding rear-earth salt sulfate to the sulfuric acid solution for acid solubility, filtering and removing impurities, crystallization, rinsing and dehydration, and baking. The rear-earth salt sulfate is simple in technological process, low in acid soluble acidity, less in spent acid, less in equipment corrosion, free of environmental pollution, high in product yield and low in cost; the prepared rear-earth salt sulfate is good in water solubility.

Owner:YIYANG HONGYUAN RARE EARTH

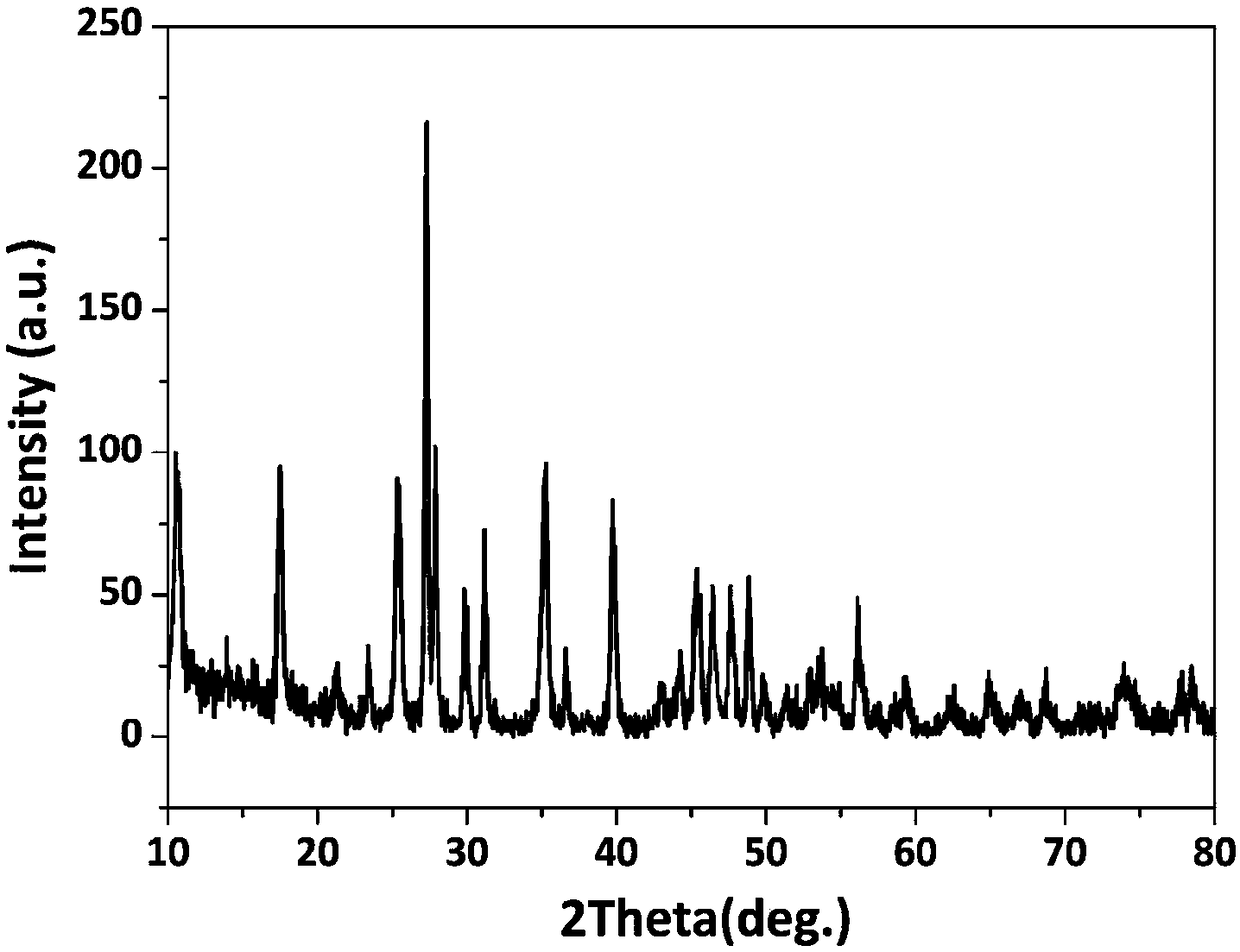

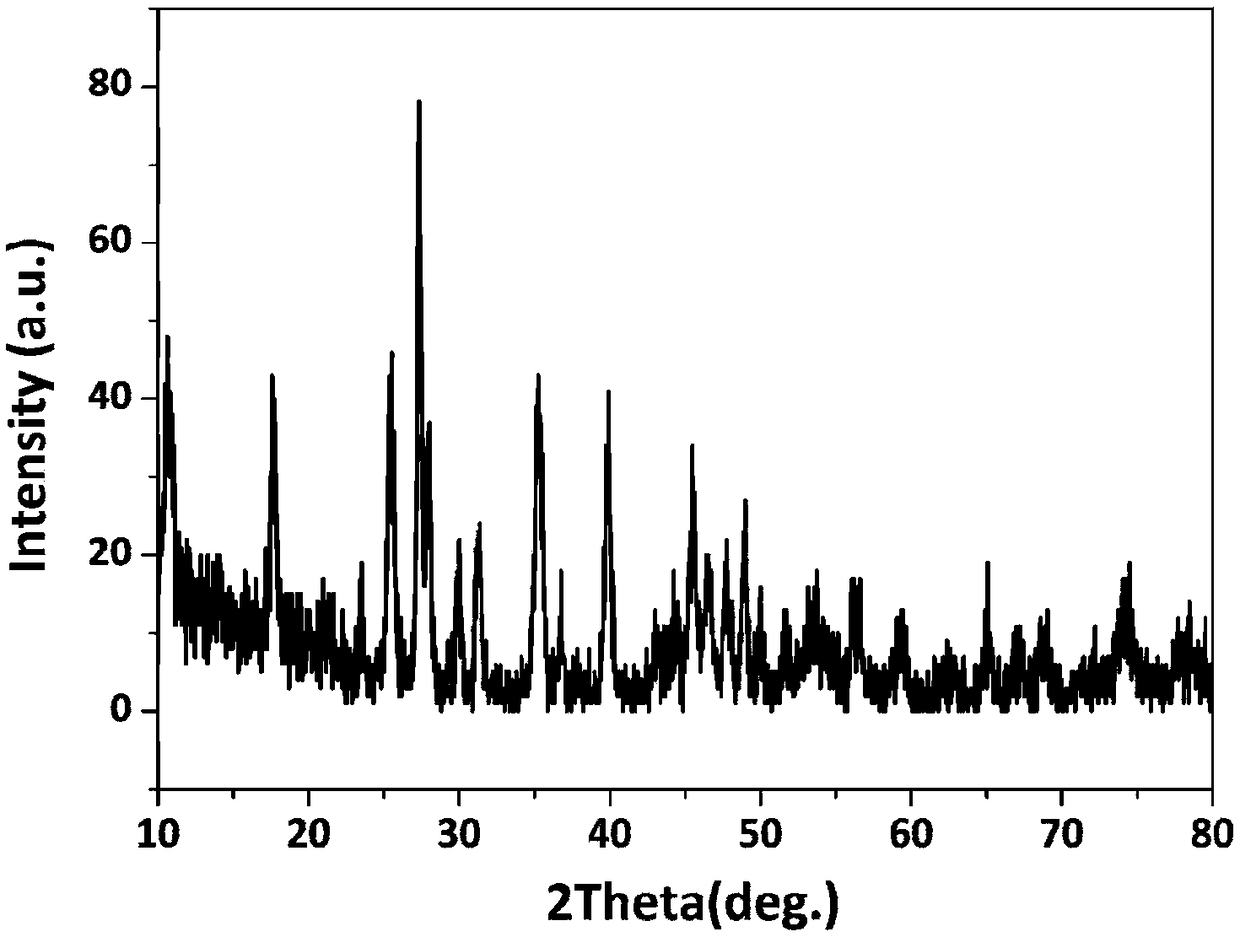

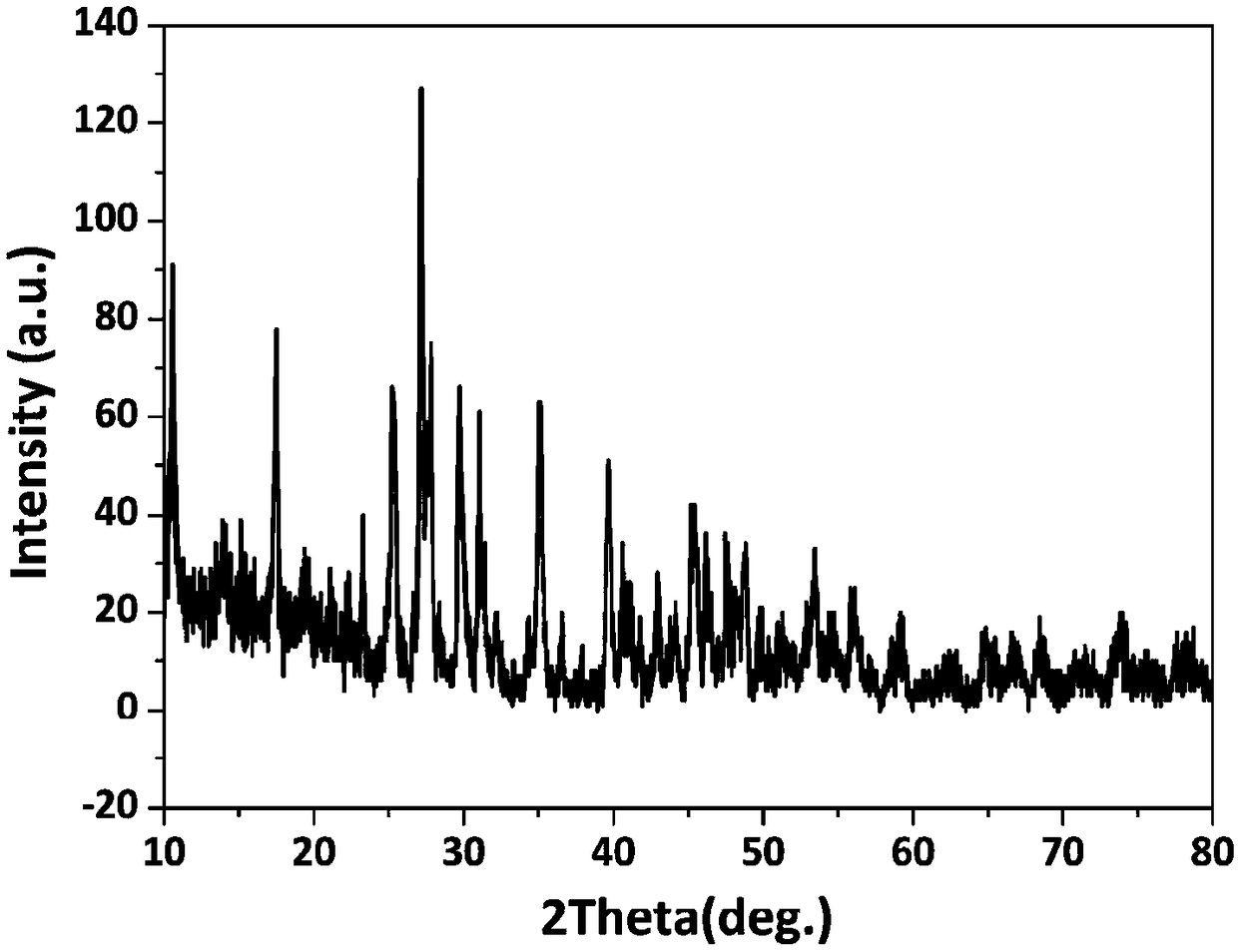

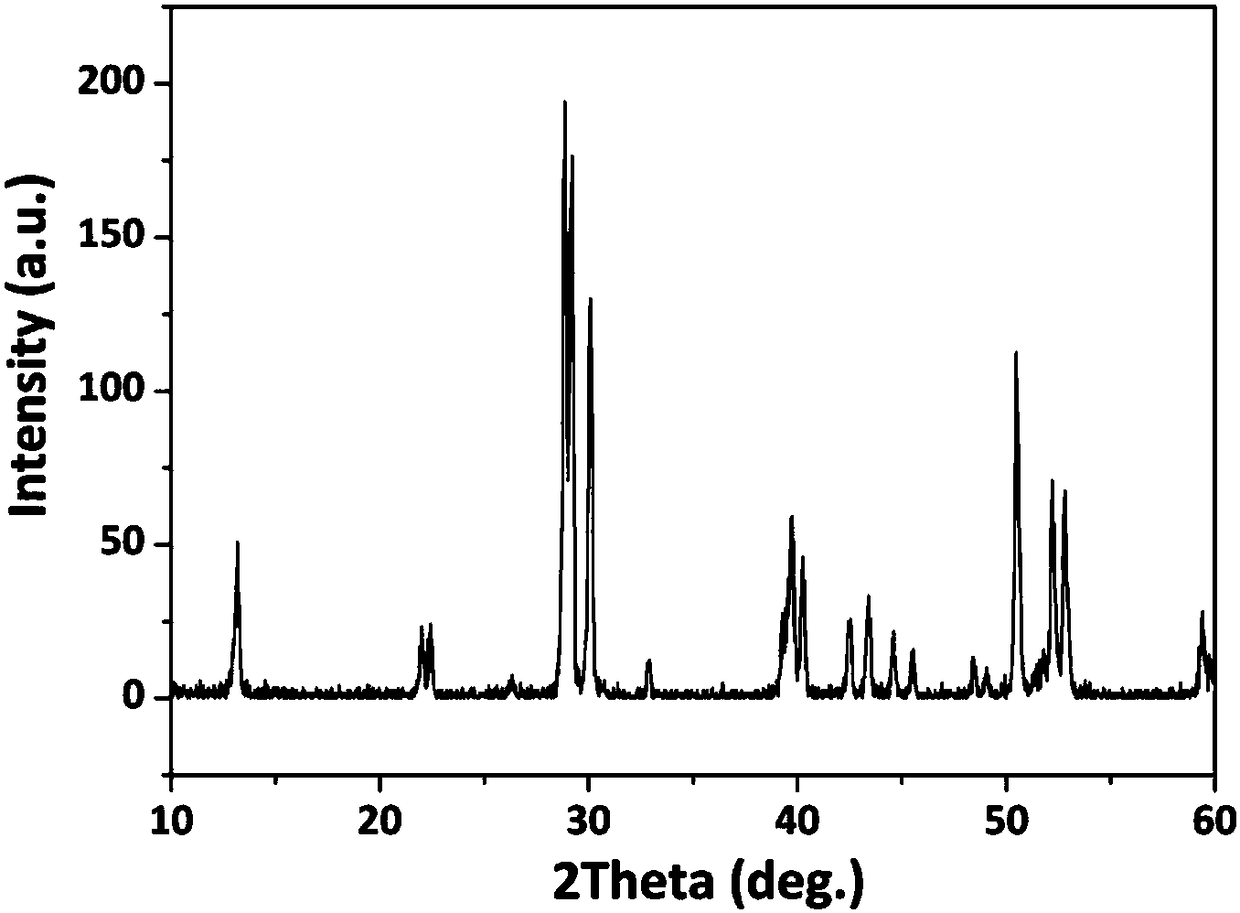

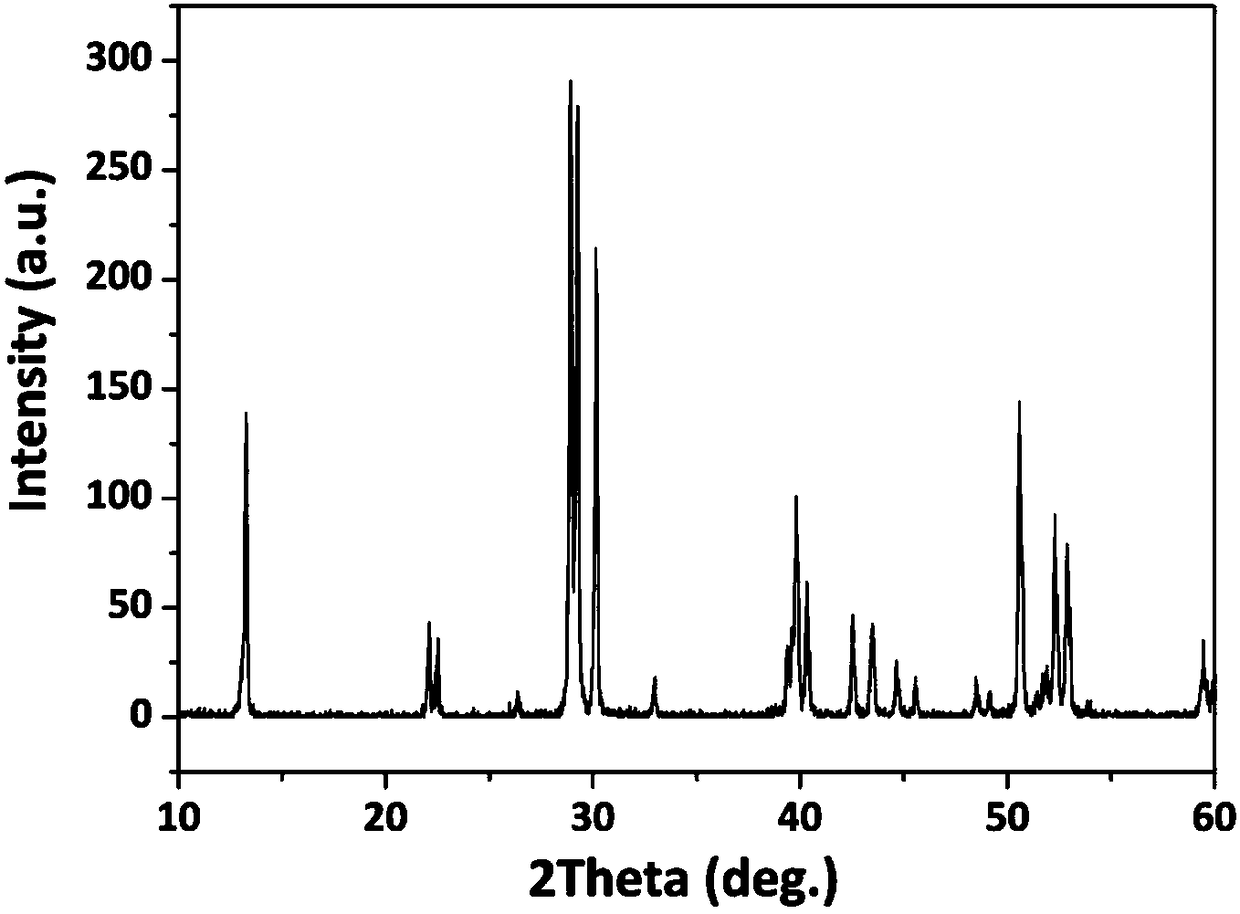

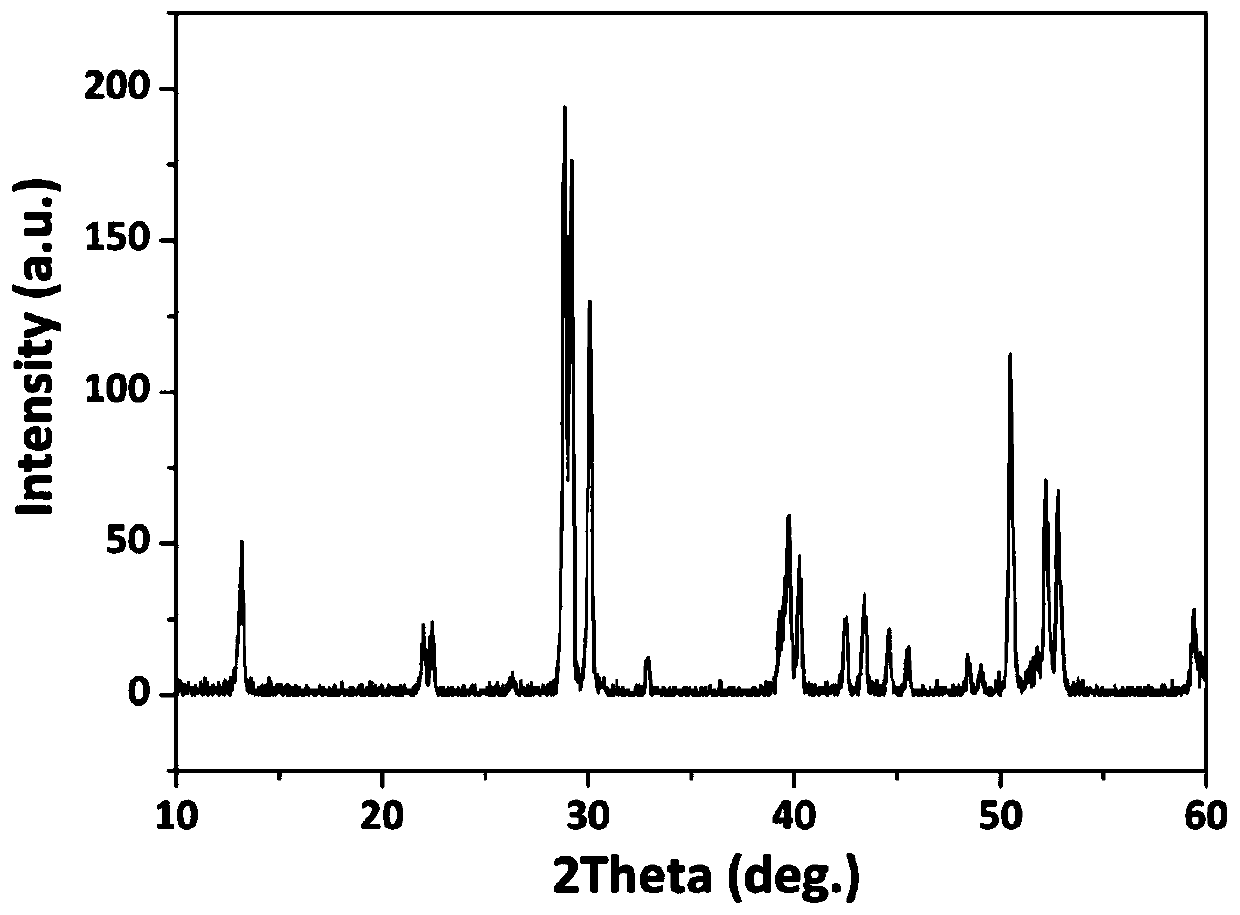

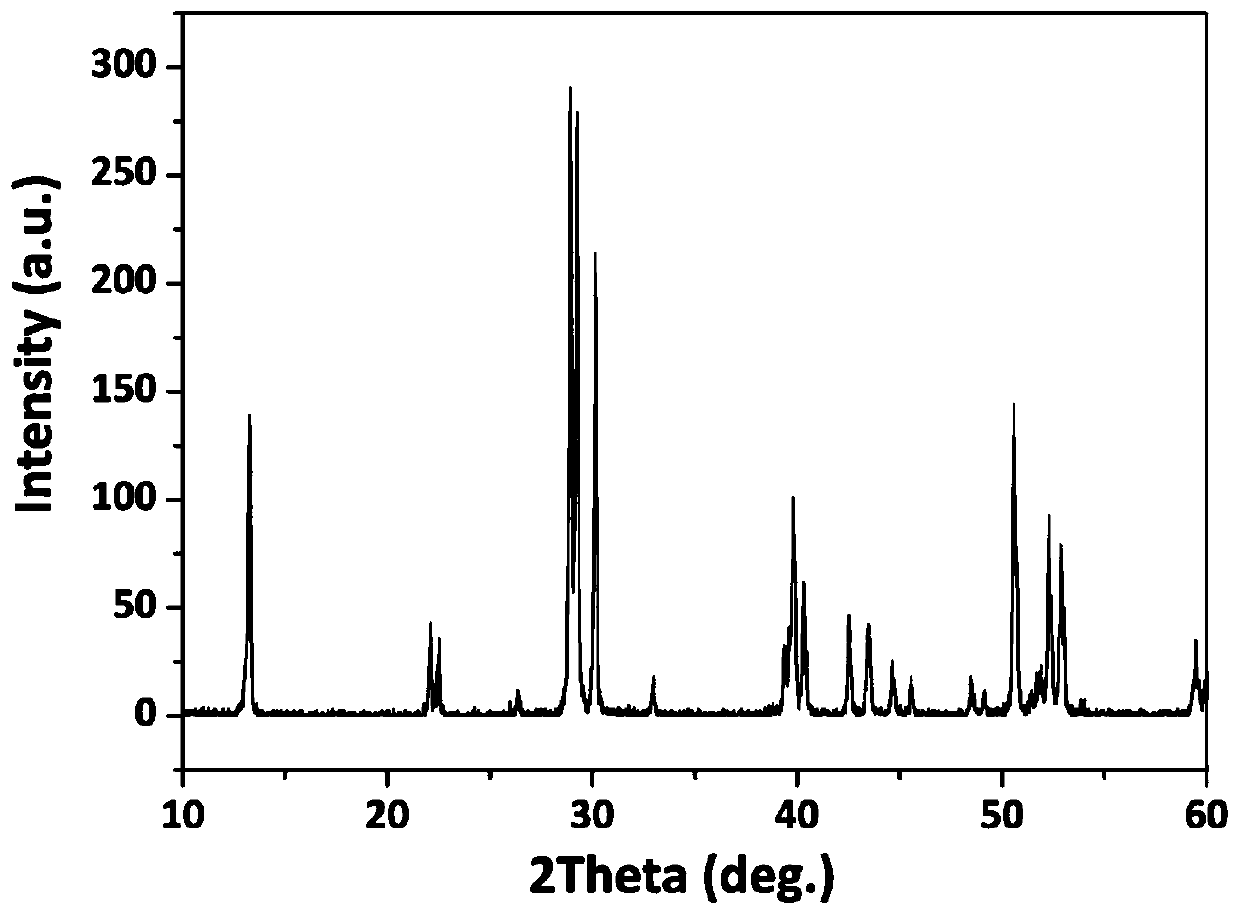

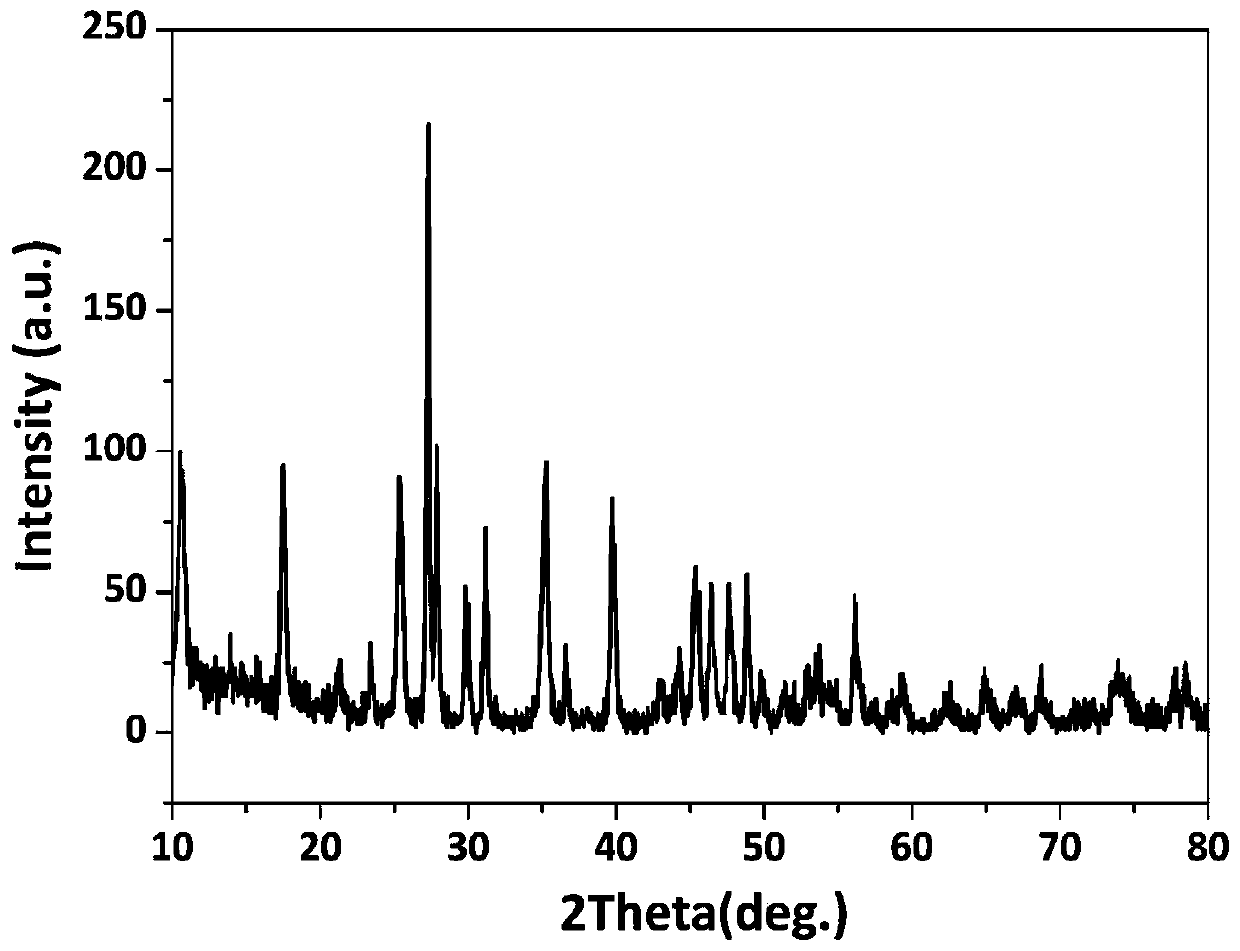

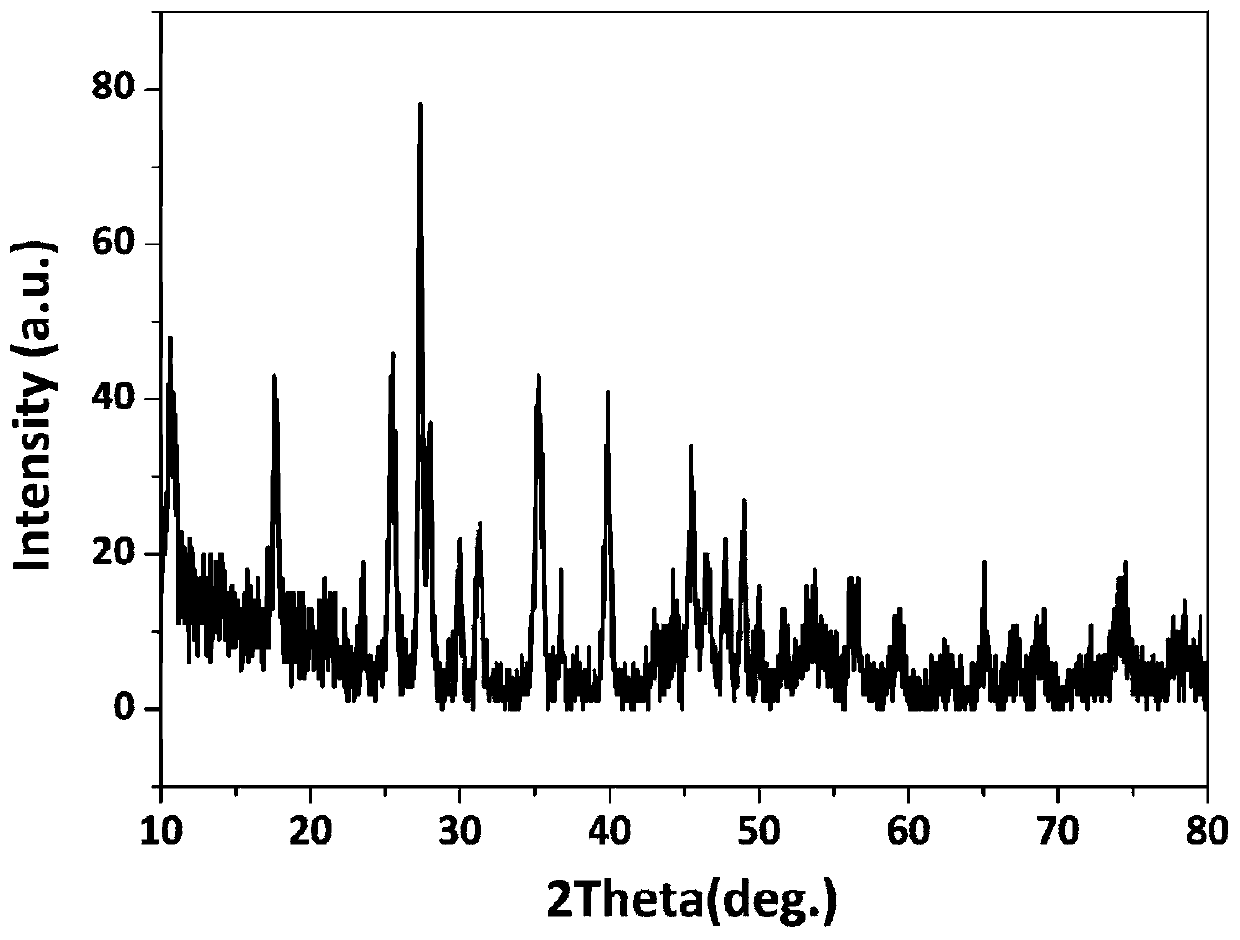

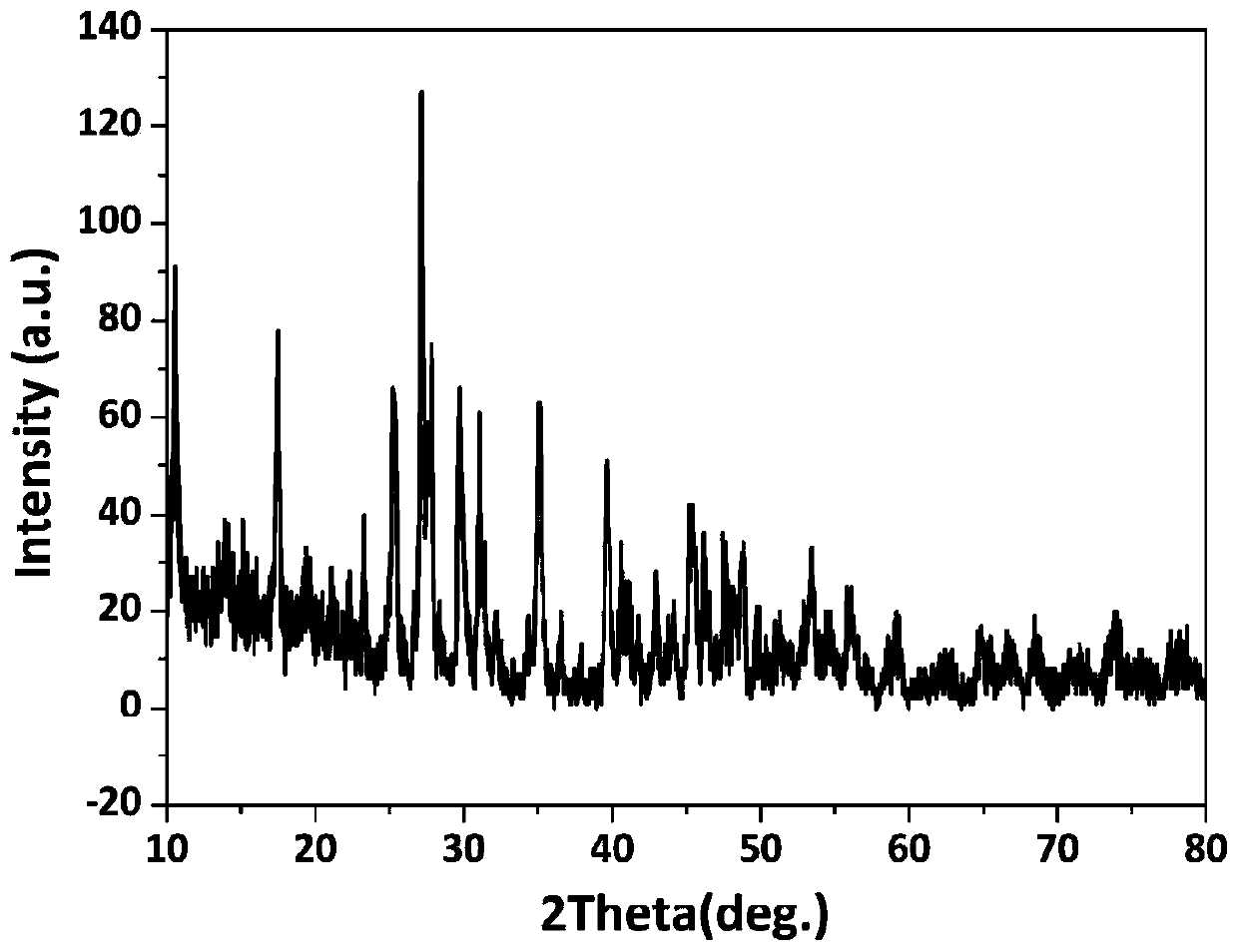

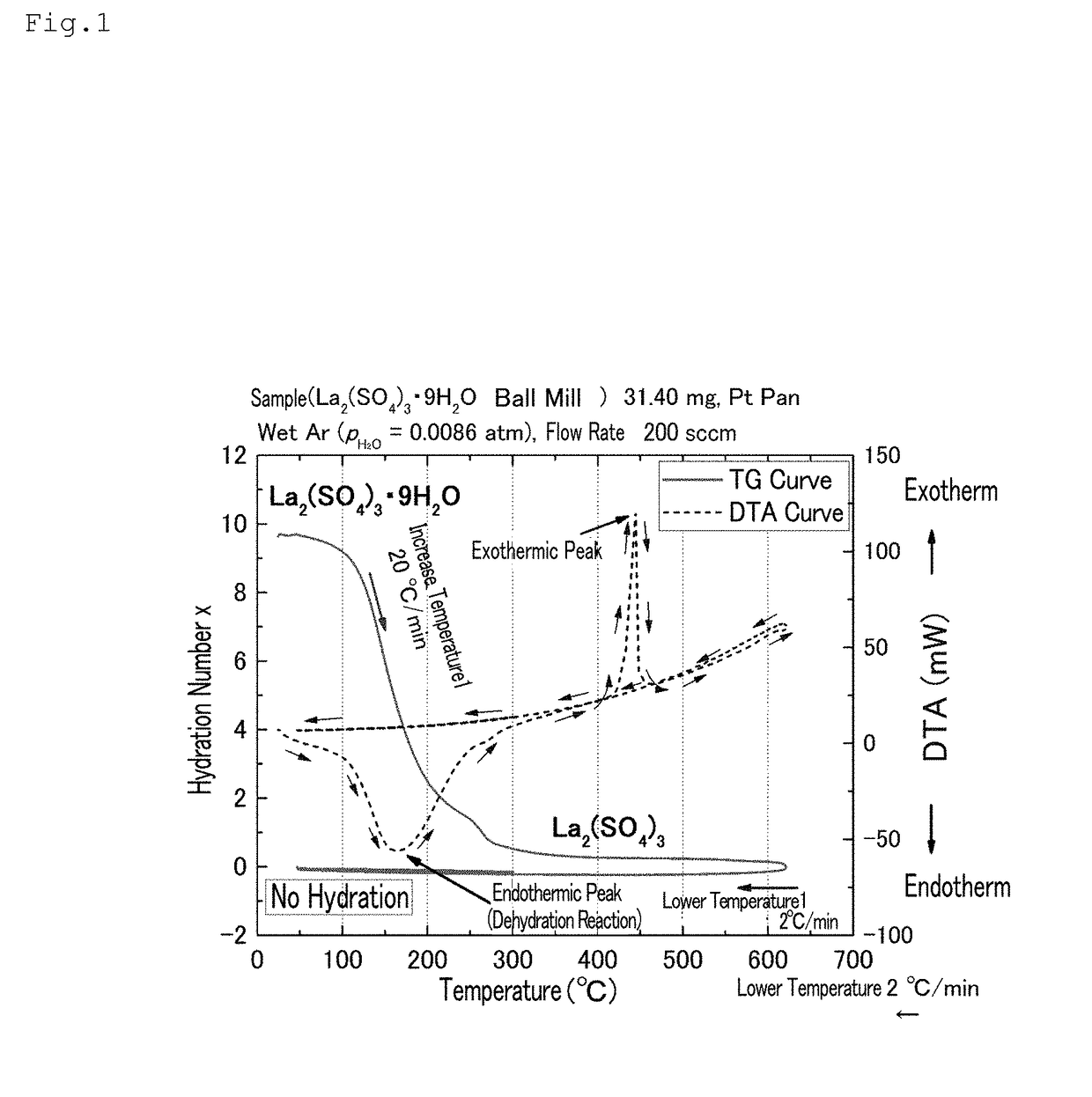

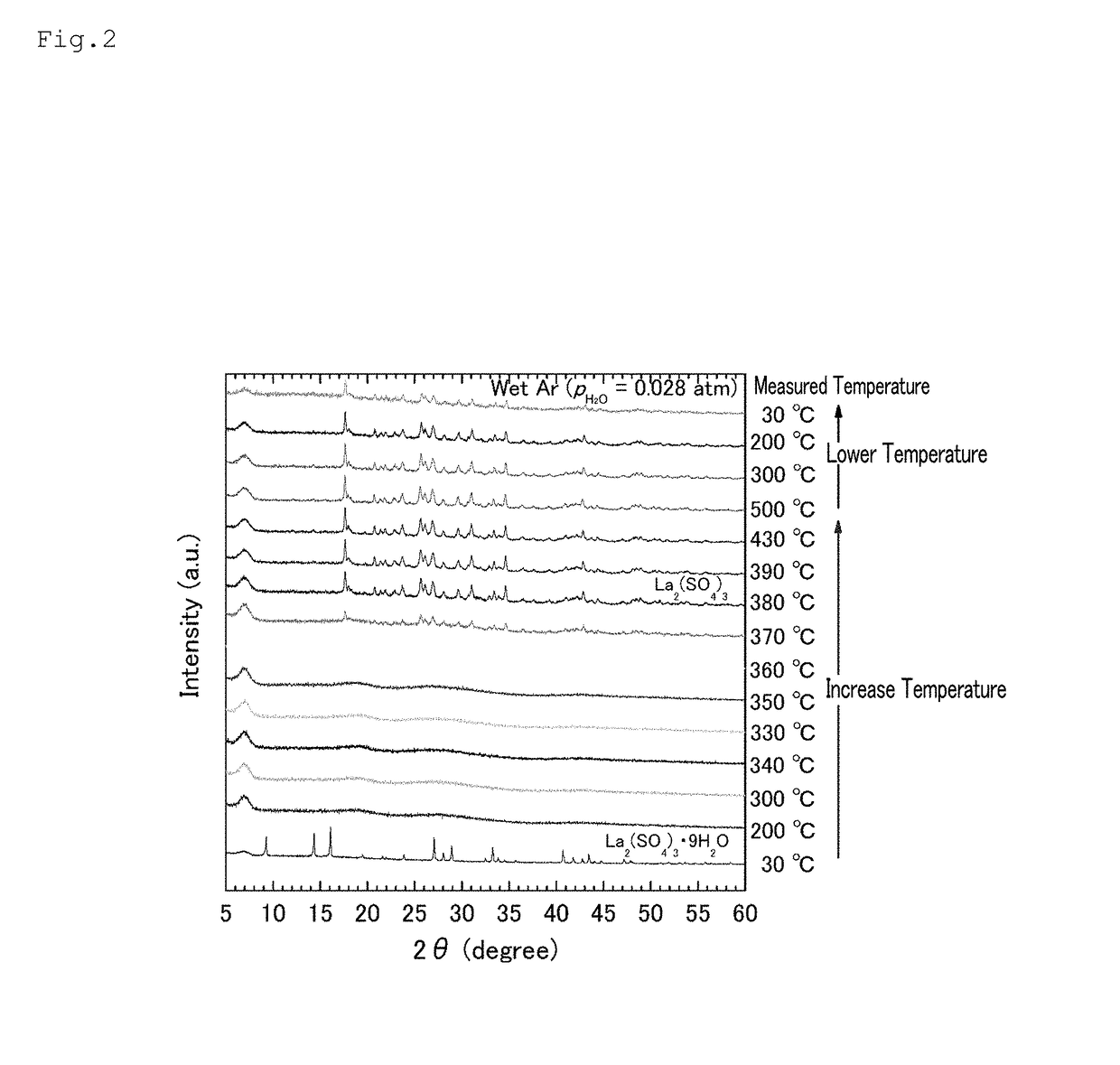

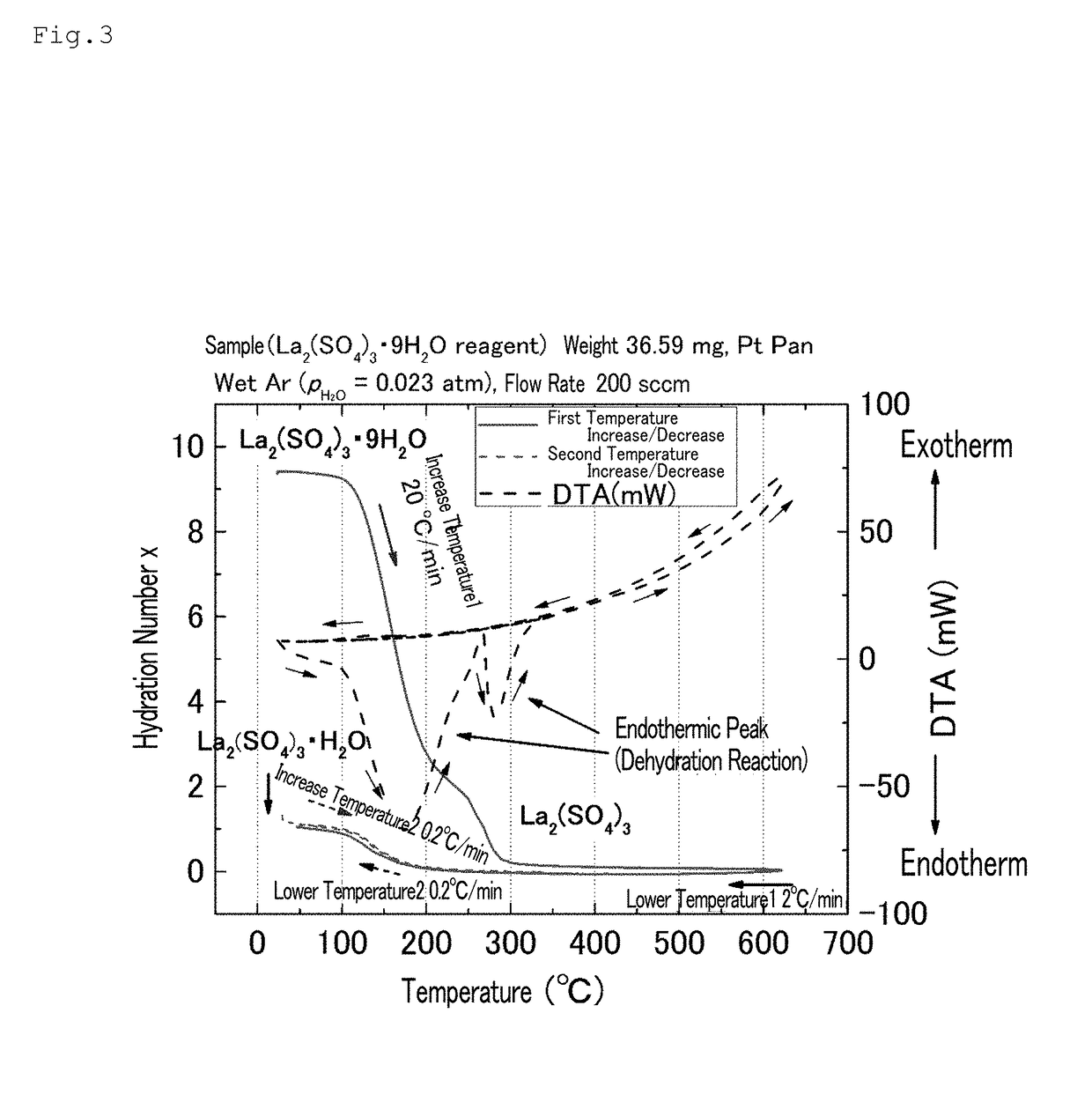

Hydrate of Rare Earth Metal Sulfate, Method for Producing Same, and Chemical Thermal Storage Material

InactiveUS20190002302A1Good reproducibilityReduce consumptionRare earth metal sulfatesHeat storage plantsX-rayRare earth

An object of the present invention is to provide an inexpensive and highly safe compound useful as a chemical heat storage material that ensures high reproducibility even in repeated reactions (having high repetition durability), and is capable of reversibly advancing heat storage and heat dissipation even in a relatively low temperature range. The present invention is a hydrate of a rare earth metal sulfate having characteristic peaks at specific diffraction angles (2θ) in an X-ray diffraction pattern, which is measured using a copper radioactive ray of λ=1.5418 Å passed through a monochromator.

Owner:KYOTO UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com