Reaction device and method for preparing superfine rare earth compound through same

A rare earth compound and reaction device technology, applied in rare earth metal compounds, rare earth metal halides, rare earth metal chlorides, etc., can solve the problems of time-consuming installation and replacement of components, insufficient particle size distribution, and difficult control, and achieve replacement. The effect of convenient parts and cleaning, centralized distribution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

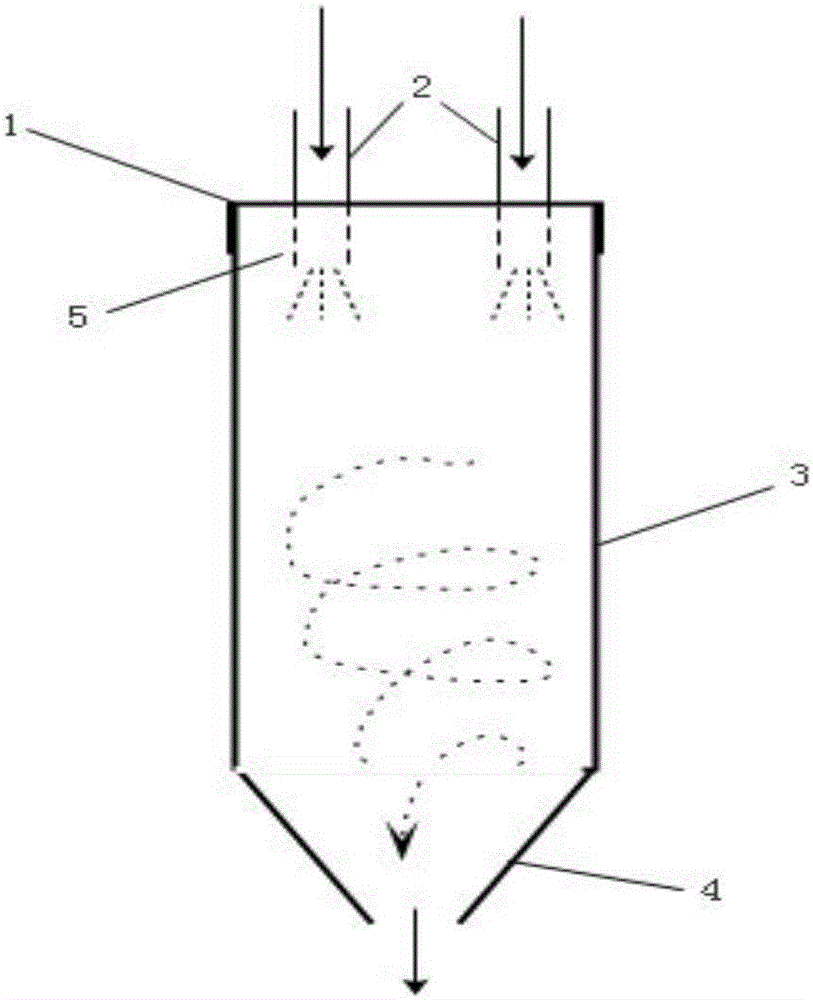

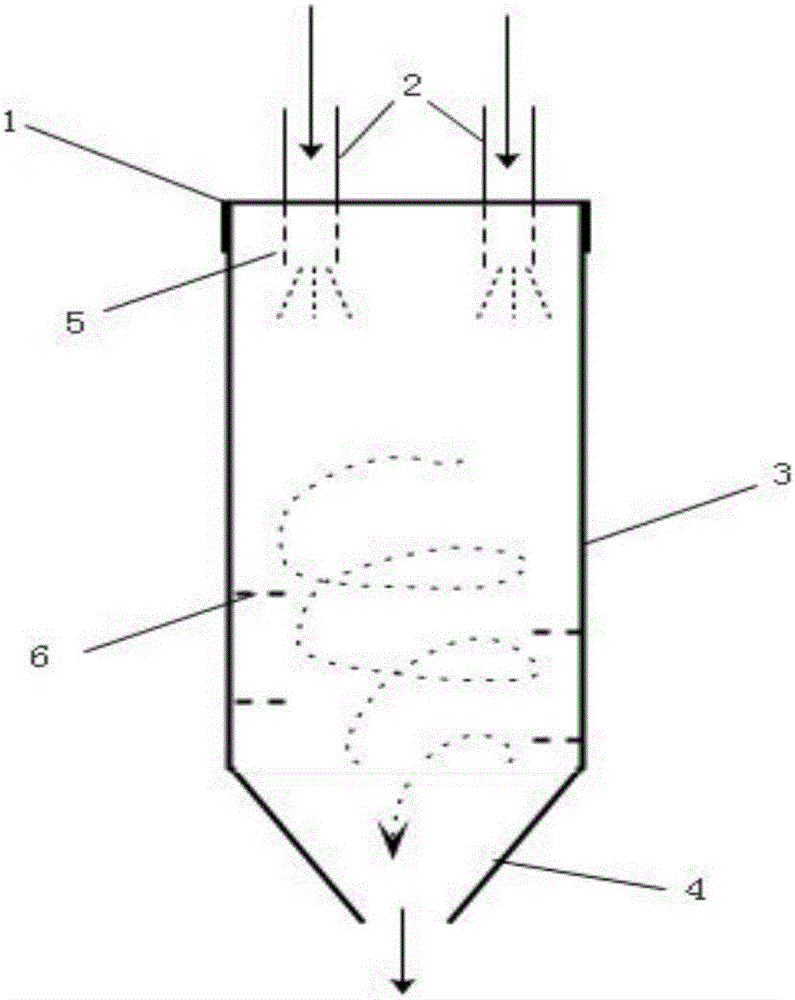

[0031] as attached figure 1 Shown, be a kind of reaction device of the present invention, comprise end cover 1, feed pipe 2, cylinder 3, feed outlet 4 and nozzle 5; Described feed pipe 2 is 2, passes through end cover 1 and extends Into the cylinder 3, the outlet end of each feed pipe 2 is equipped with a nozzle 5, one end of the cylinder 3 is connected to the end cover 1, and the other end is connected to the conical discharge port 4, and the cylinder 3 is connected to the end cover 1 and the discharge port. 4 are thread mouth connection.

[0032] According to the process requirements, the cylinder 3 is designed to have a diameter of 50mm and a length of 1000mm; the length of the discharge port 4 is 50mm, and its outlet diameter is 5mm; the nozzle 5 is spiral and connected with a threaded mouth, and the device is used for emulsification. The effect is good.

Embodiment 2

[0034] as attached figure 1 Shown, be a kind of reaction device of the present invention, comprise end cover 1, feed pipe 2, cylinder 3, feed outlet 4 and nozzle 5; Described feed pipe 2 is 2, passes through end cover 1 and extends Into the cylinder 3, the outlet end of each feed pipe 2 is equipped with a nozzle 5, one end of the cylinder 3 is connected to the end cover 1, and the other end is connected to the conical discharge port 4, and the cylinder 3 is connected to the end cover 1 and the discharge port. 4 are flange connections.

[0035] According to the process requirements, the cylinder 3 is designed to have a diameter of 200mm and a length of 200mm; the length of the discharge port 4 is 200mm, and its outlet diameter is 160mm; the nozzle 5 is in the shape of a shower and has a silk mouth, and the device is used for the precipitation reaction of rare earth compounds. Rare earth compounds with particle size D50≤1μm can be prepared.

Embodiment 3

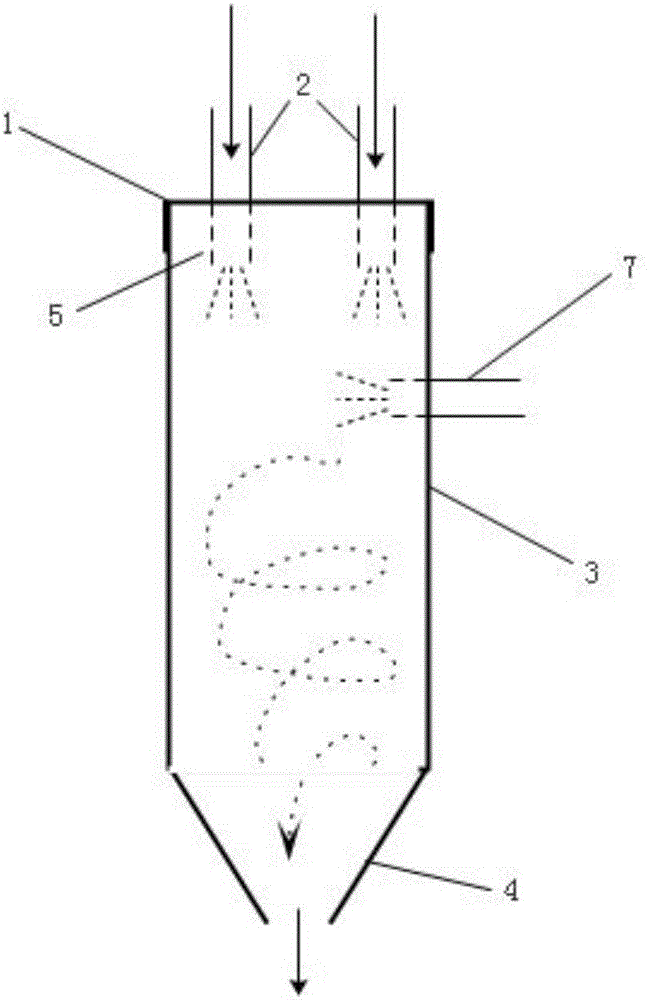

[0037] as attached image 3 As shown, it is a reaction device of the present invention, comprising an end cap 1, a feed pipe 2, a cylinder 3, a discharge port 4 and a nozzle 5; there are 3 feed pipes 2, of which 2 feed pipes 2 go through the end cover 1 and extend into the cylinder 3, and the other feed pipe 2 passes through the wall of the cylinder 3 and extends into the cylinder 3, the outlet end of each feed pipe 2 is equipped with a nozzle 5, and one end of the cylinder 3 It is connected with the end cover 1, and the other end is connected with the conical discharge port 4, and the cylinder 3 is connected with the end cover 1 and the discharge port 4 by ferrules.

[0038] According to the process requirements, the cylinder 3 is designed to have a diameter of 100mm and a length of 500mm; the length of the discharge port 4 is 100mm, and its outlet diameter is 50mm; the nozzle 5 adopts a hollow cone and is connected by a ferrule. The mixture of rare earth extractants works v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com