Patents

Literature

45results about How to "Easy to replace parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

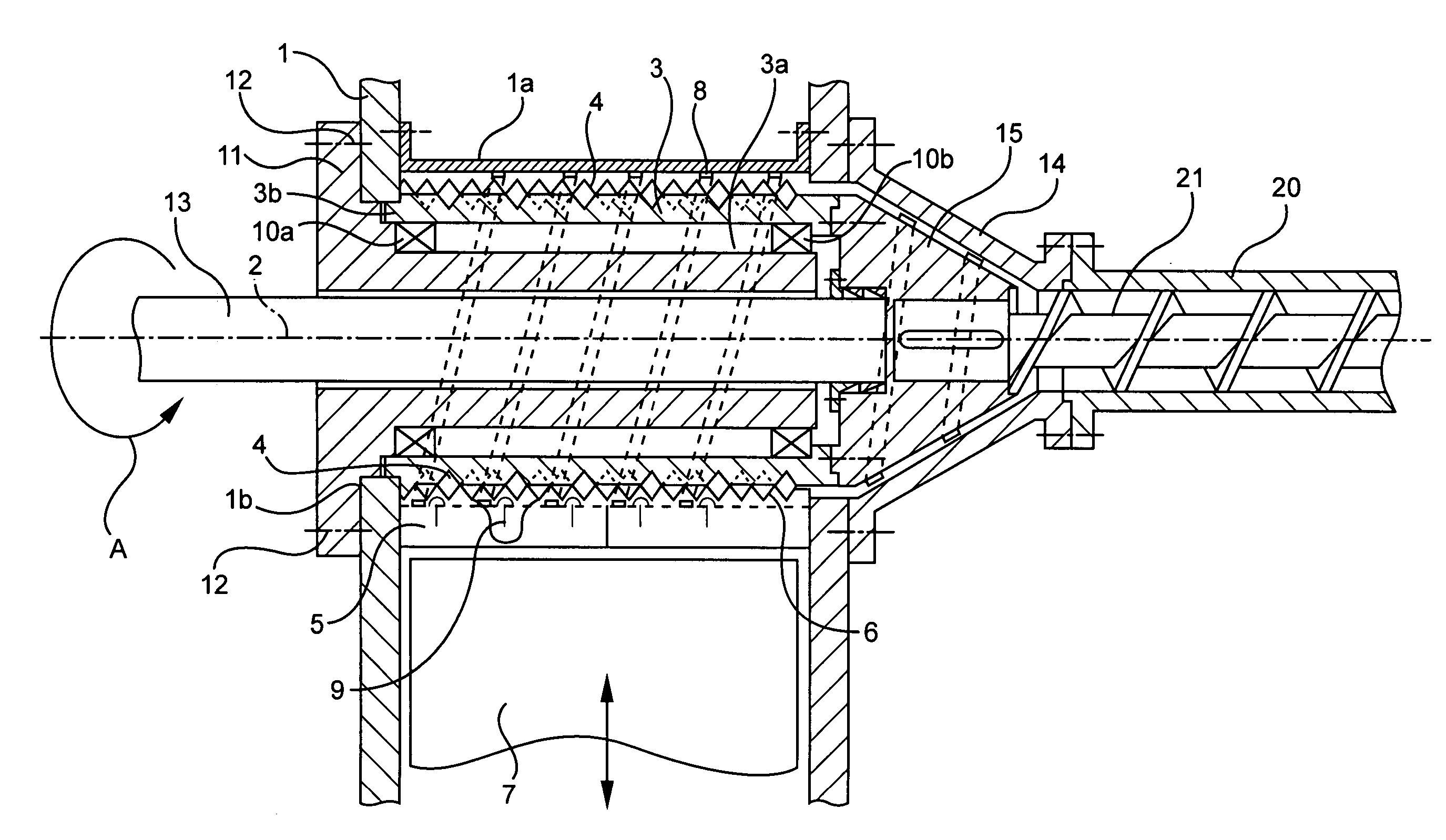

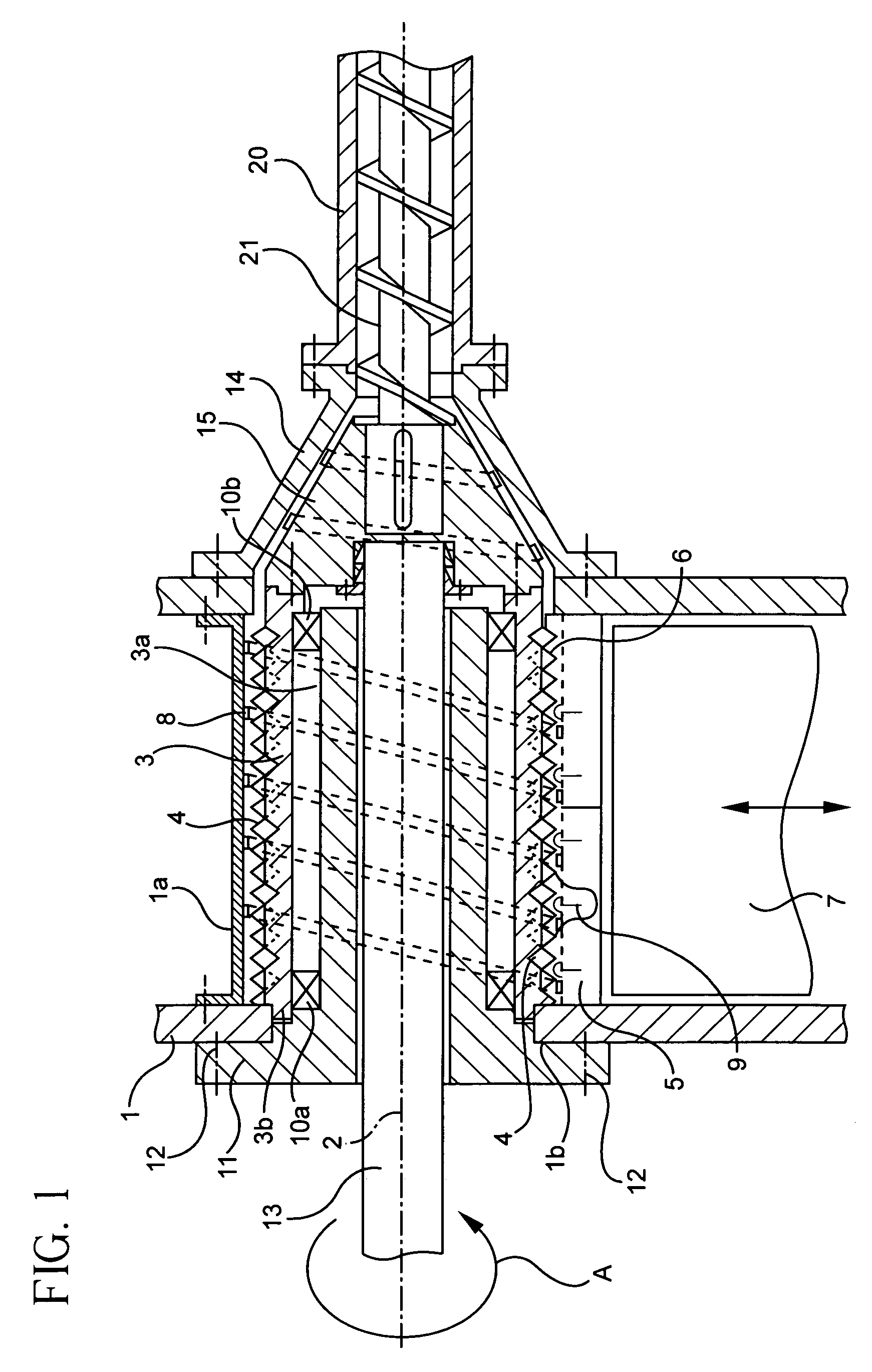

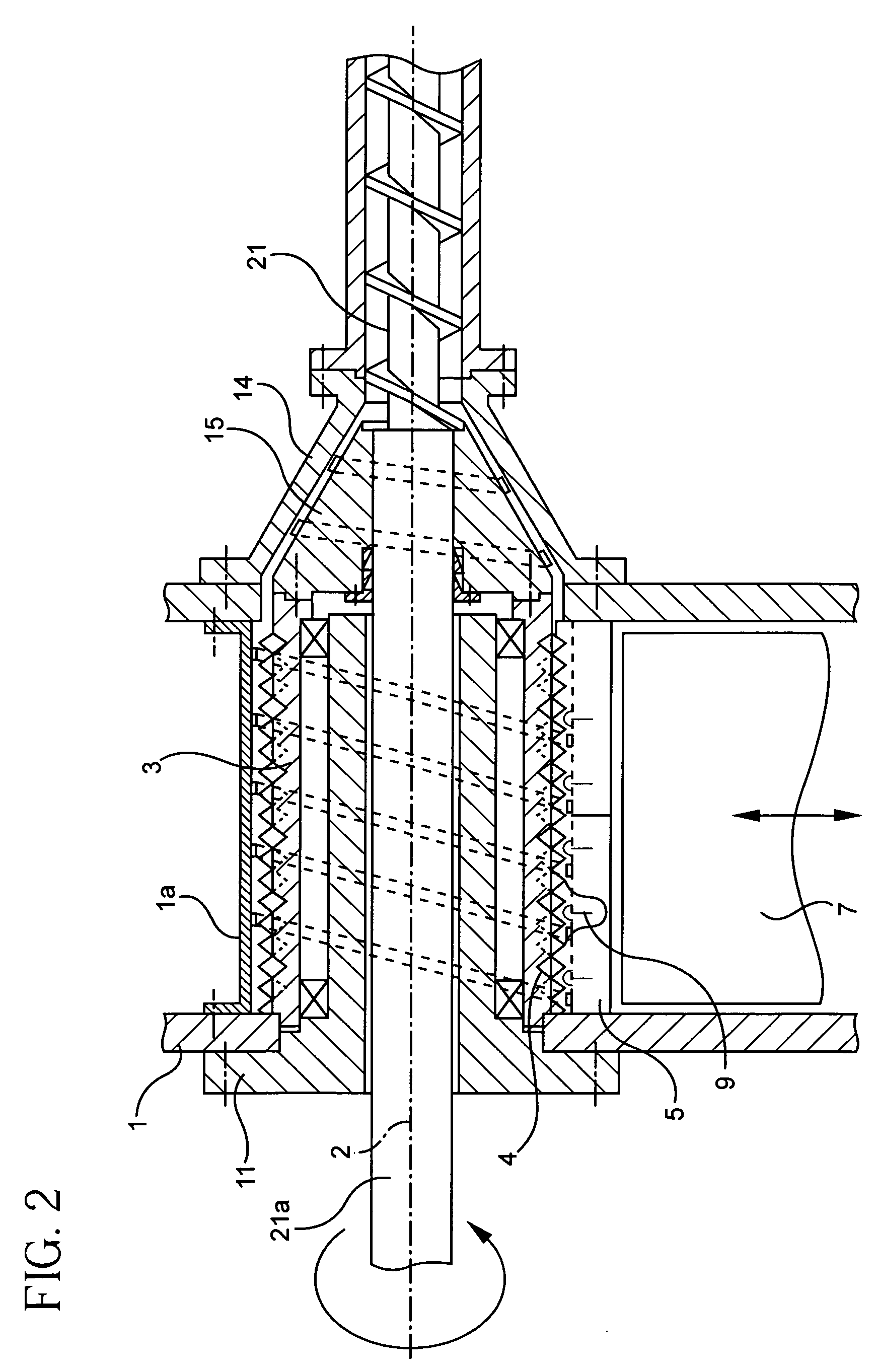

Iontophoresis device

InactiveUS20050070840A1Improve performanceImprove convenienceElectrotherapyPharmaceutical delivery mechanismMembrane bodiesIon-exchange membranes

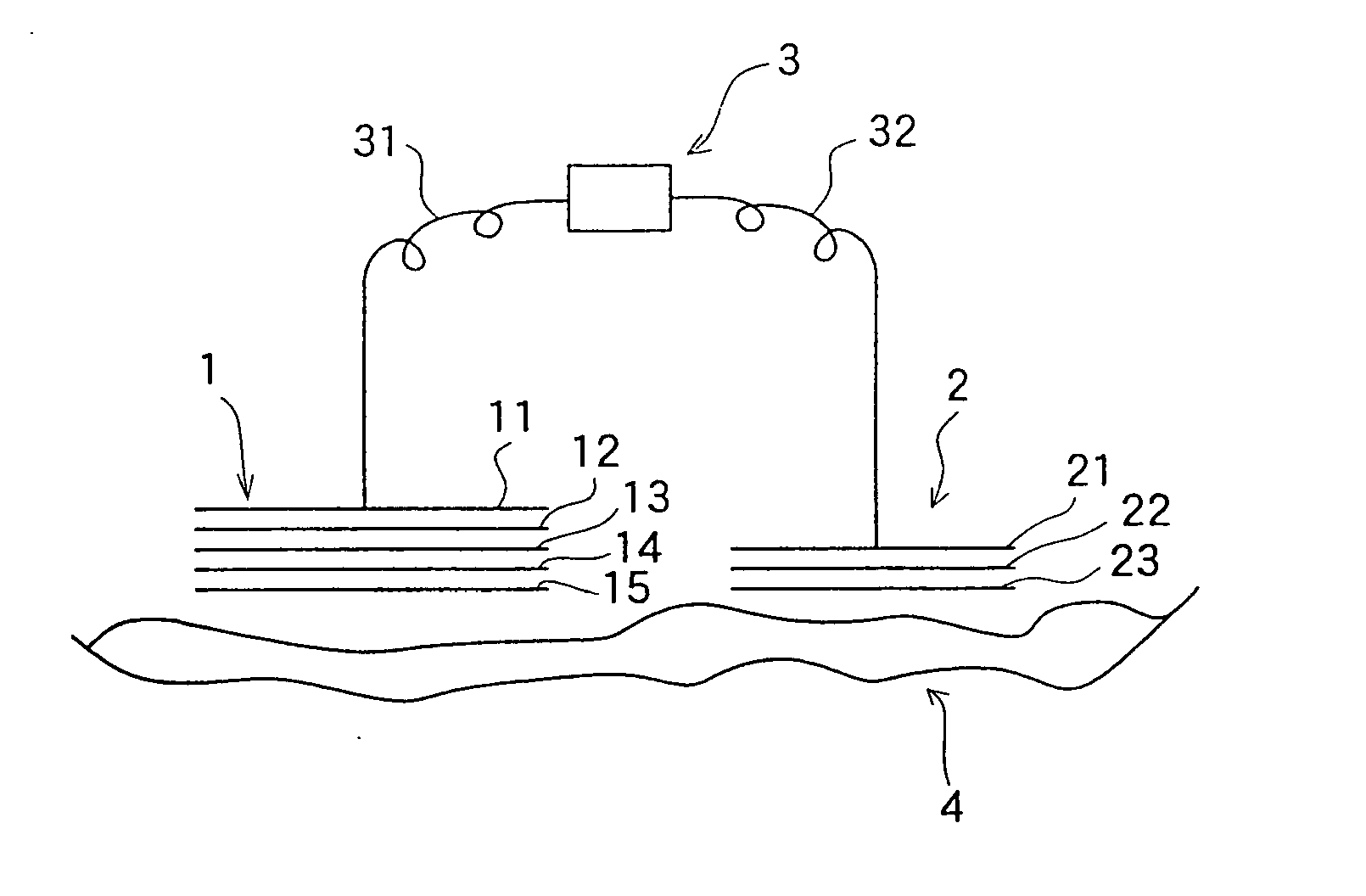

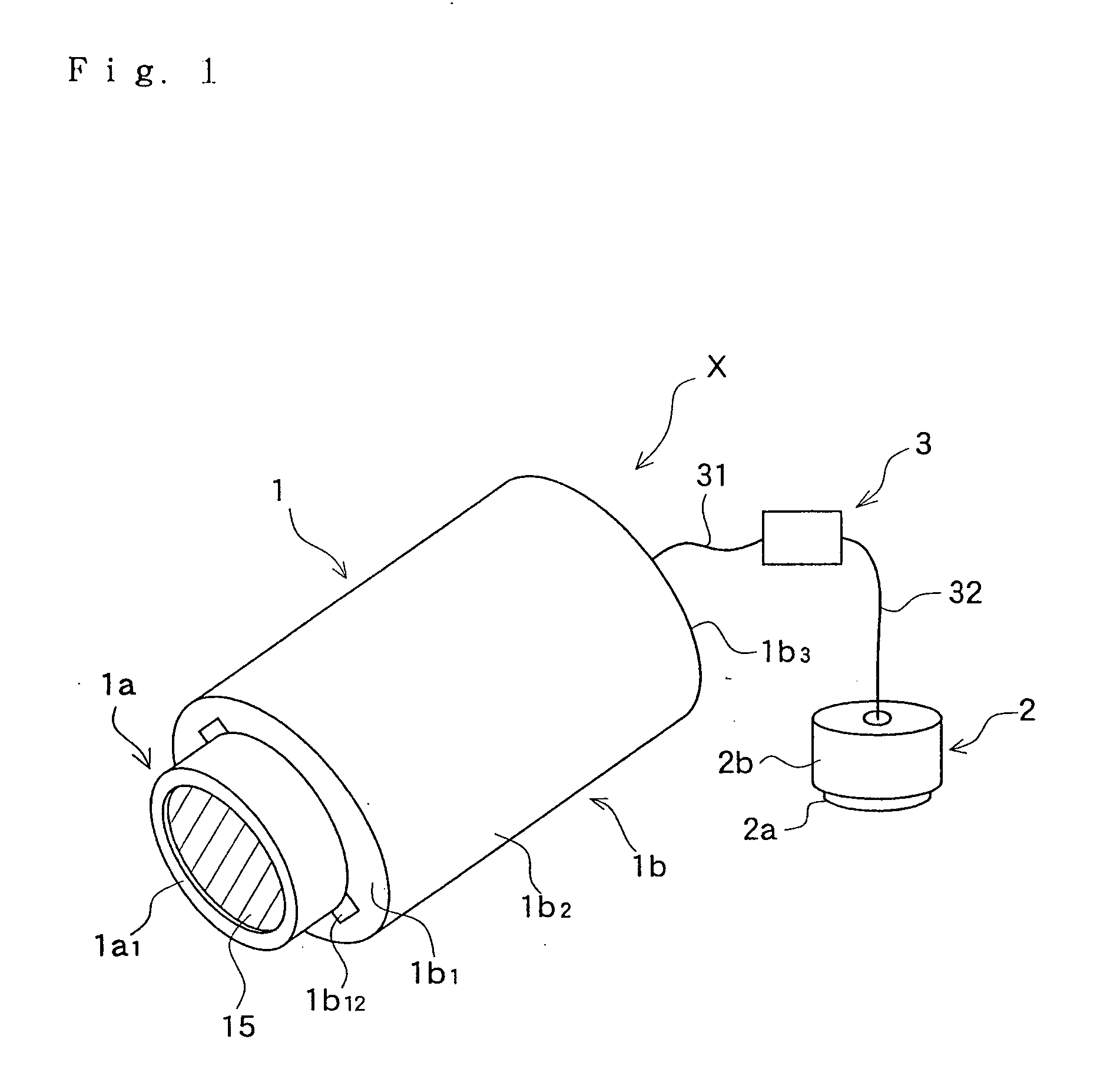

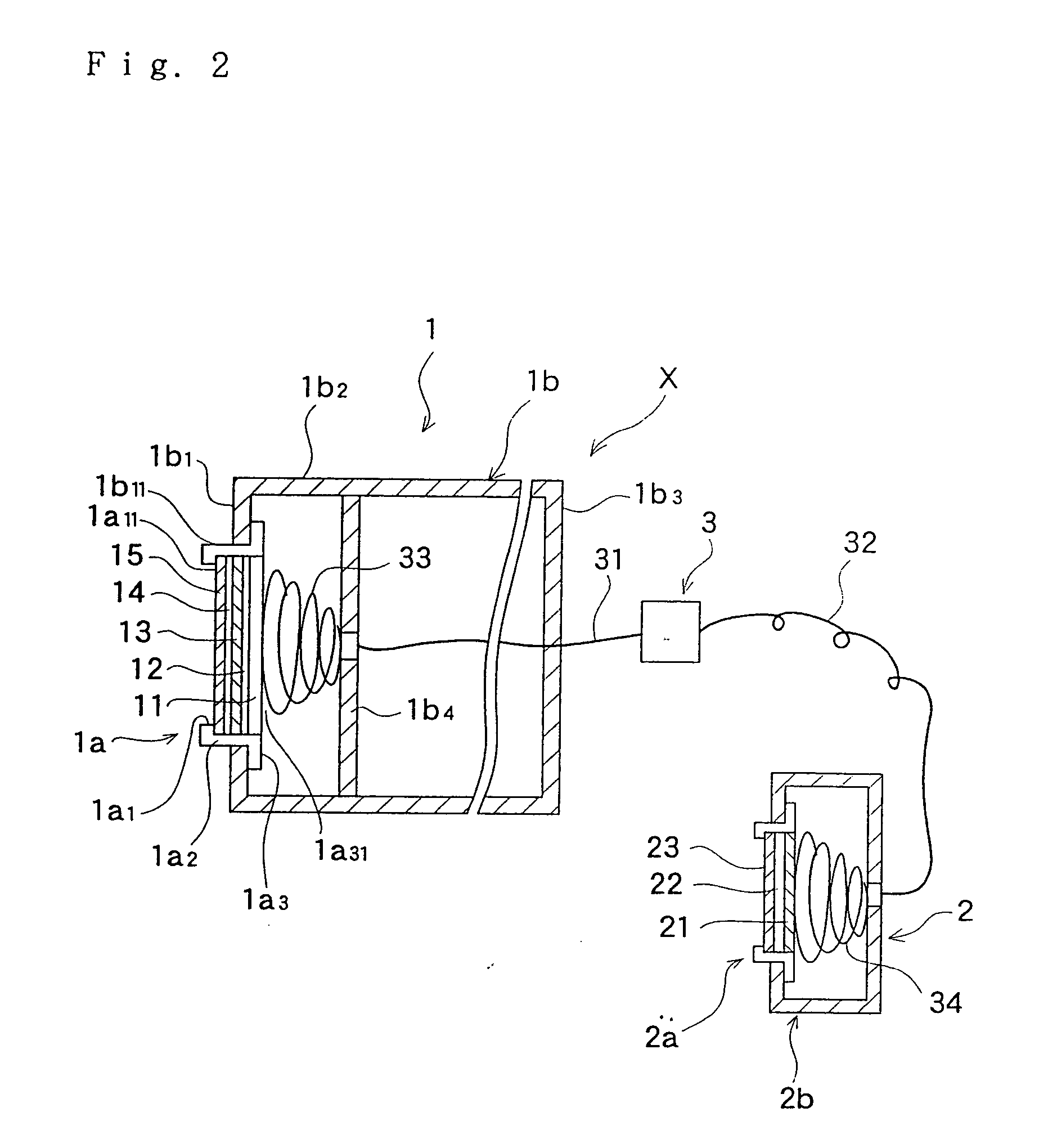

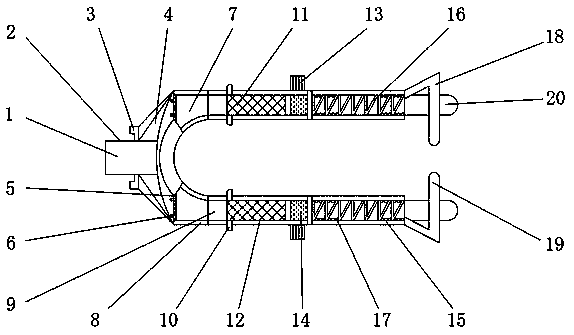

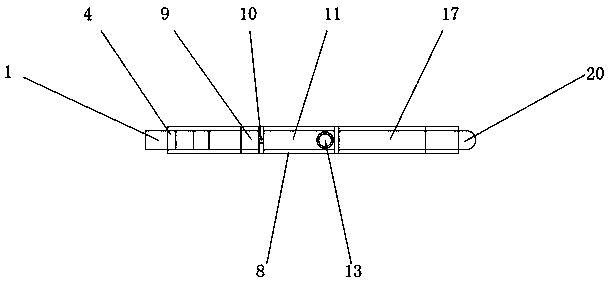

An iontophoresis device useful for administering an ionic drug by iontophoresis has an iontophoresis electrode section (active electrode section) and a ground electrode section (inactive electrode section) both of which are to be connected to a power source. The iontophoresis device includes elements (members) of both of the electrode sections are all formed of membrane bodies, and includes ion exchange membranes different in ion selectivity, one being selective to ions of the same species as charged ions of the ionic drug and the other to ions different in species from the charged ions of the ionic drug that are arranged in the iontophoresis electrode section, and at least an ion exchange membrane selective to ions opposite to the charged ions of the ionic drug is arranged in the ground electrode section. The iontophoresis device can administer the ionic drug stably over a long period of time at high transport efficiency.

Owner:TITI ELLEBEAU INC

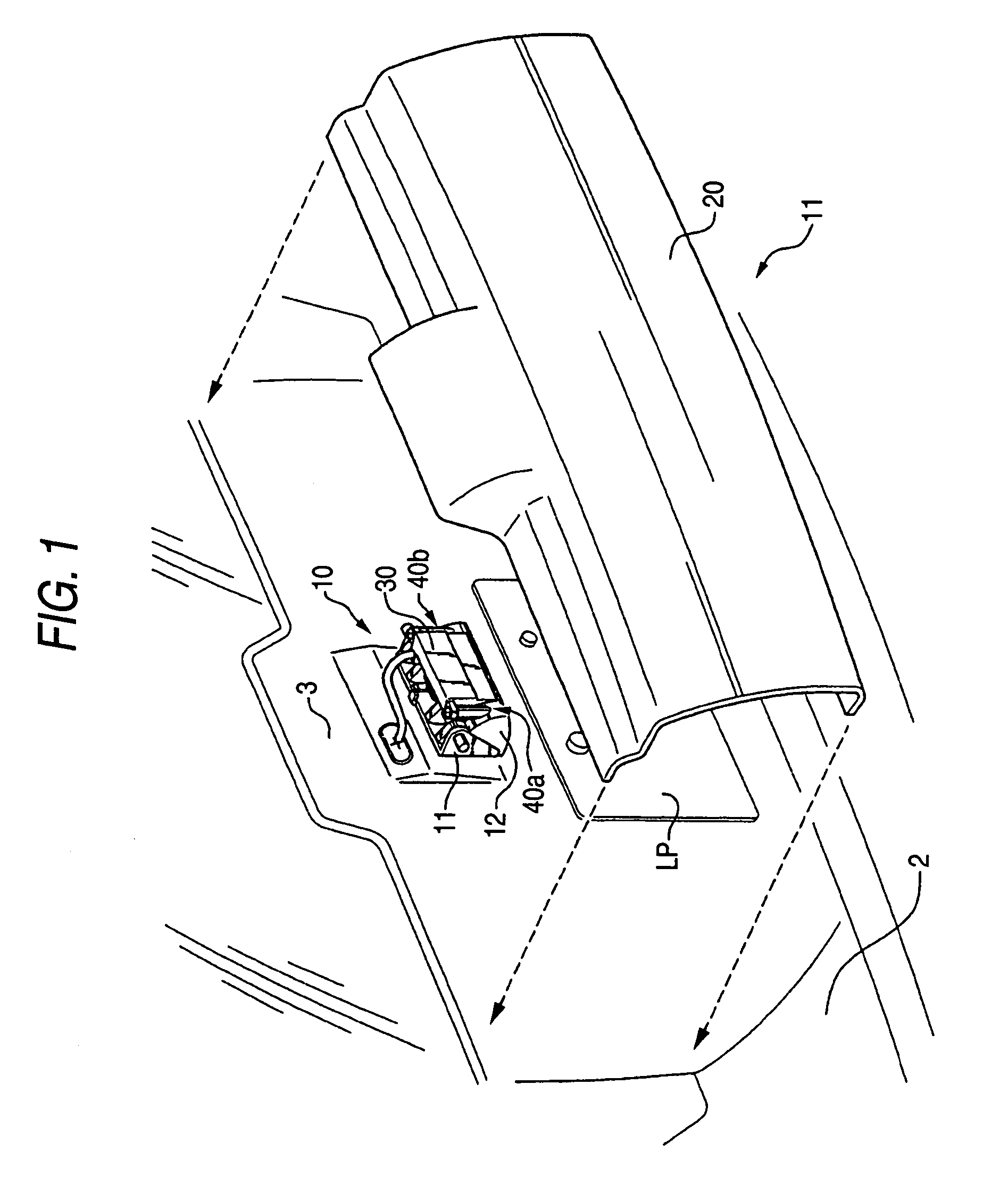

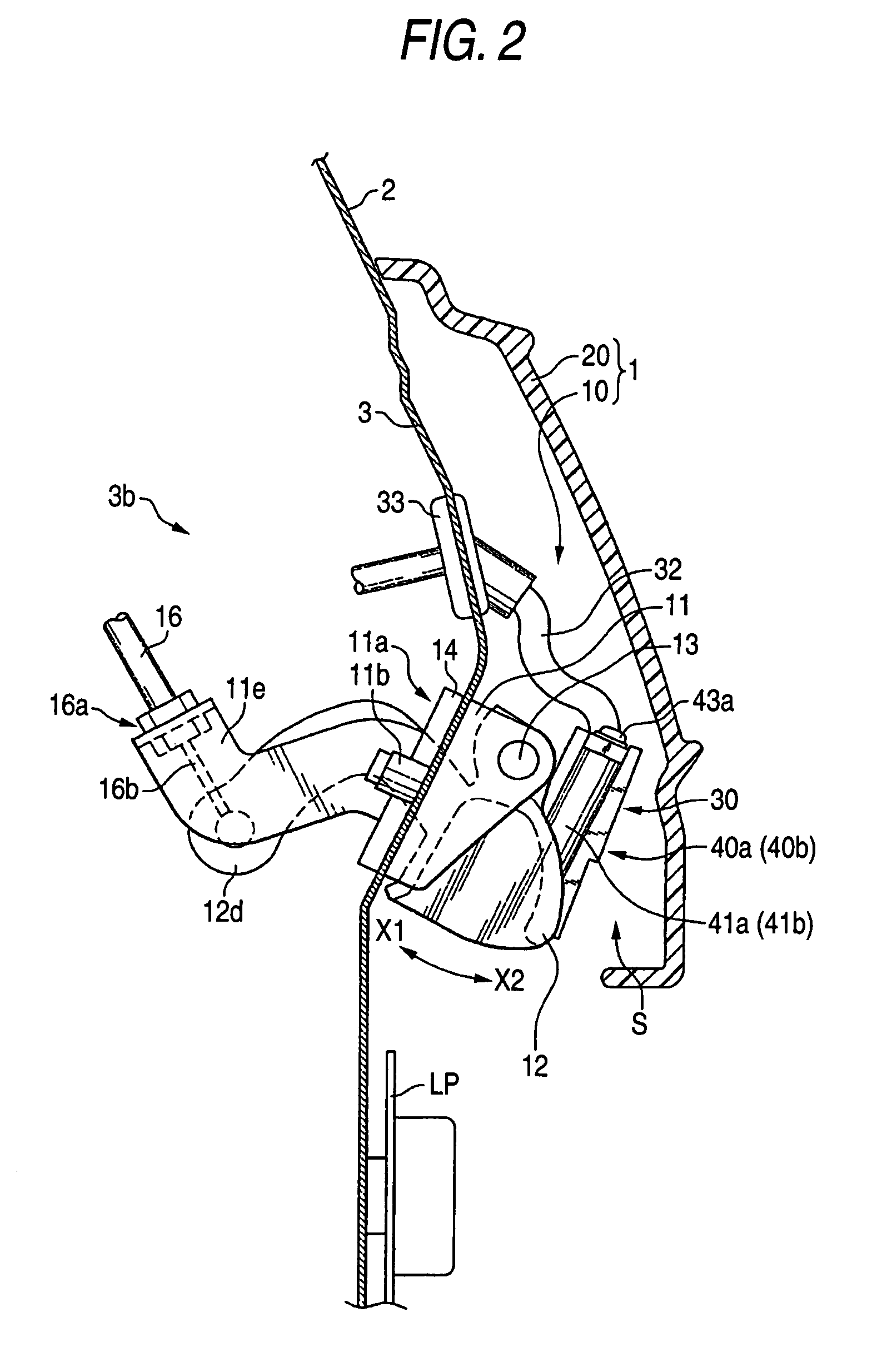

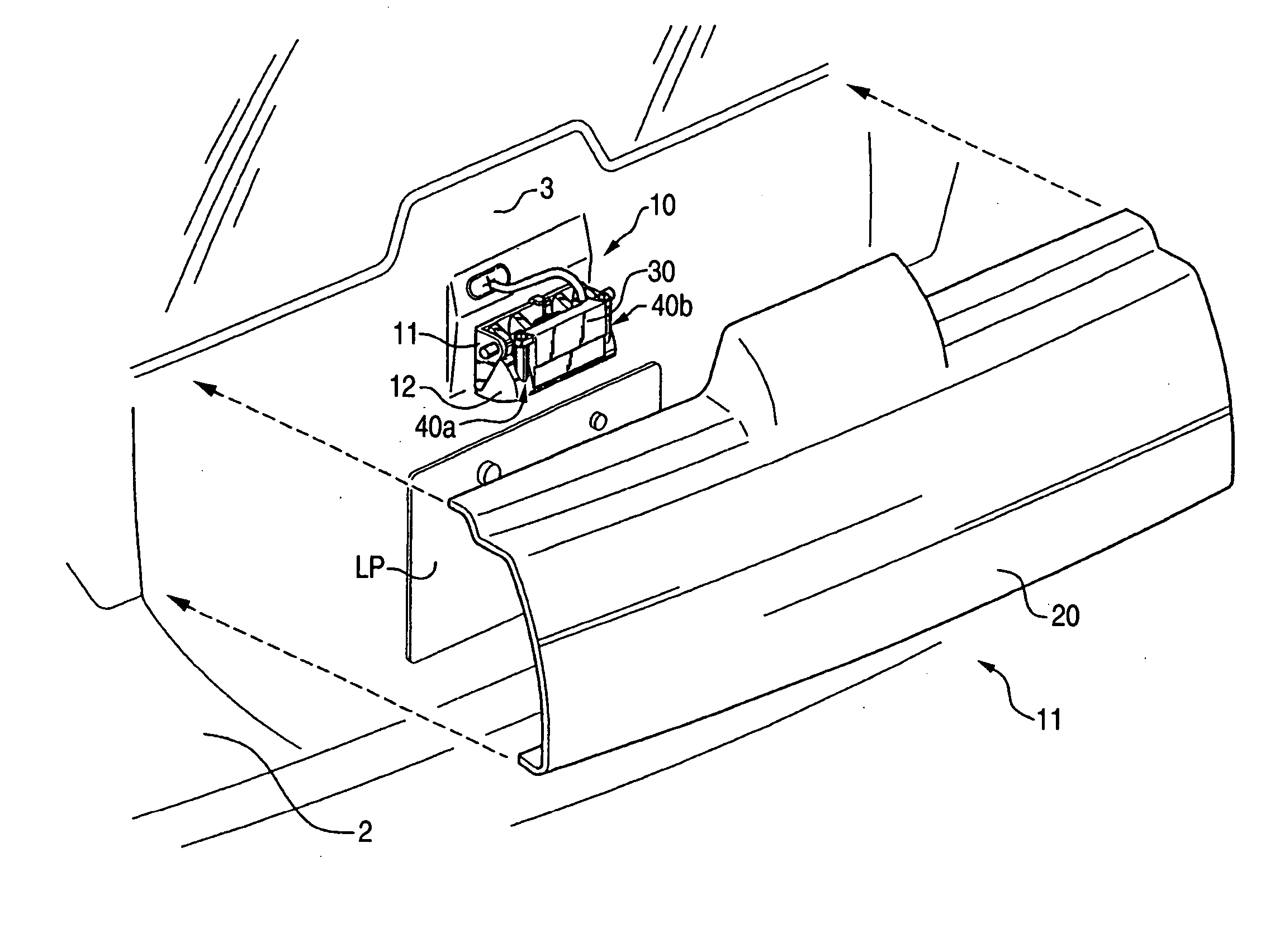

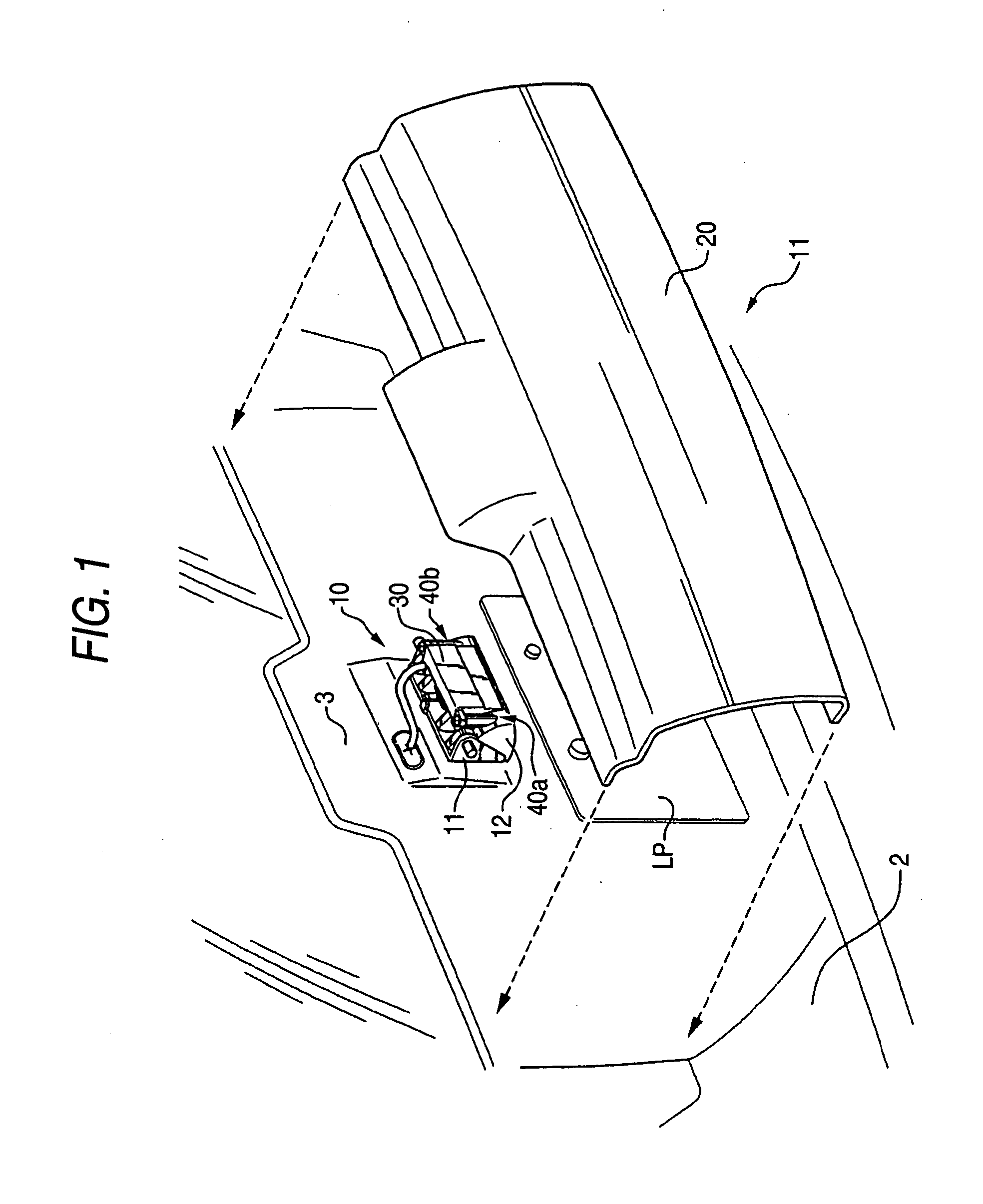

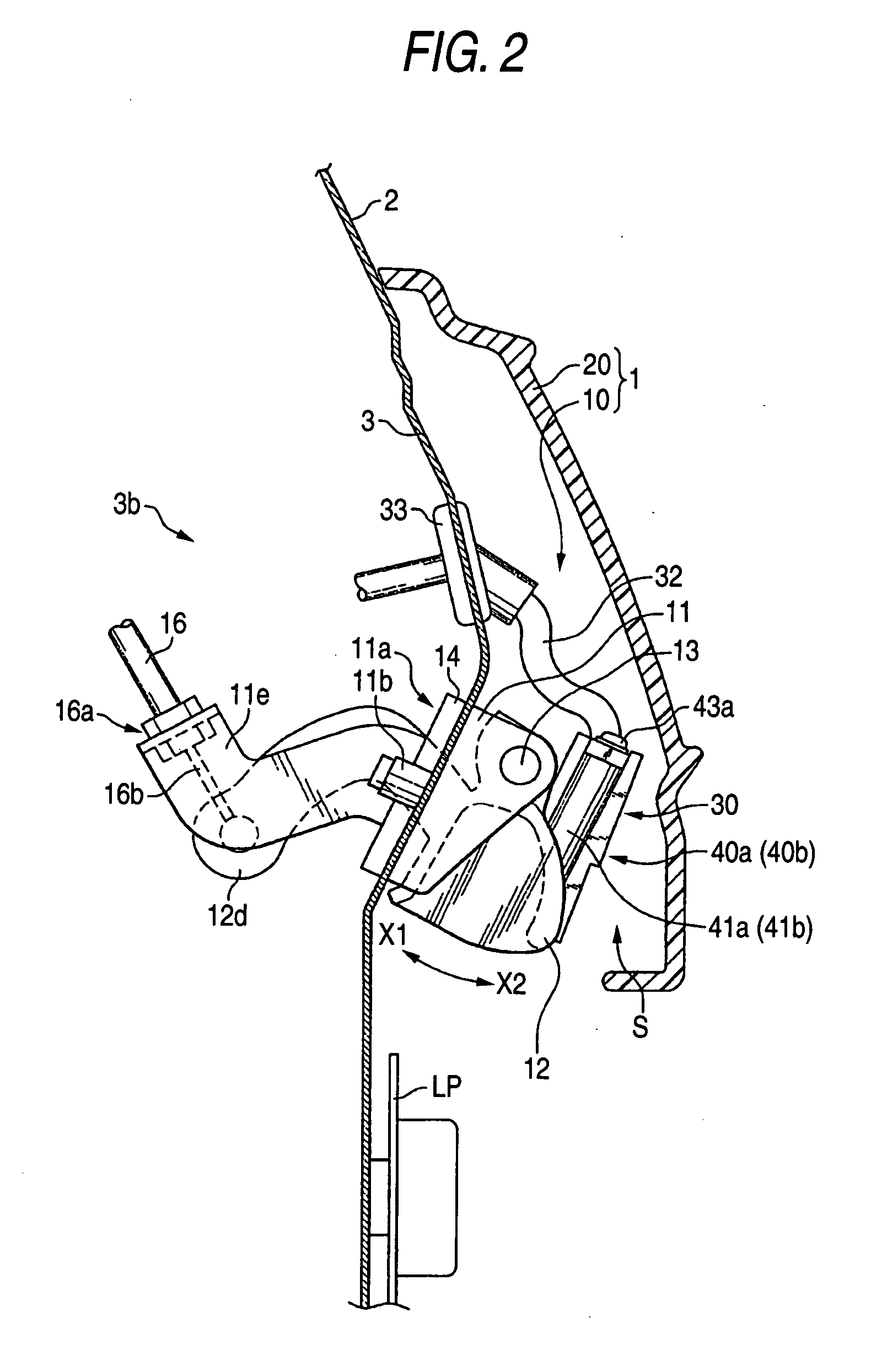

Door handle apparatus

InactiveUS7062945B2Easy constructionLow costWing handlesDoors/windowsBack doorElectrical and Electronics engineering

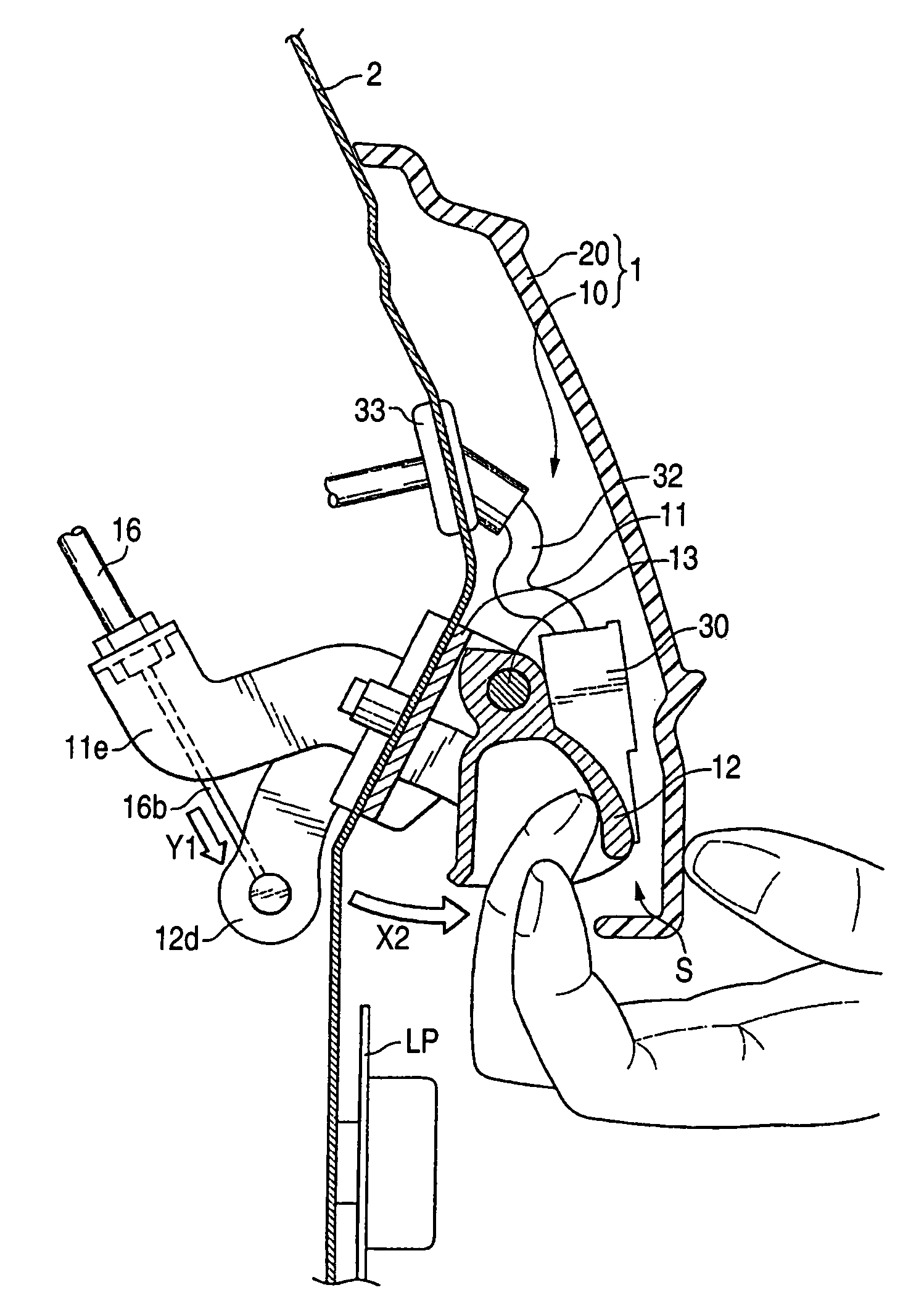

A door handle apparatus having a door handle 12 which is provided on a back door of an automobile in such a manner as to oscillate freely and a cover member 20 for covering the door handle 12, wherein a detection sensor 30 for detecting the approach of an operator toward the door handle 12 is provided between the door handle 12 and the cover member 20.

Owner:HONDA MOTOR CO LTD

Door handle apparatus

InactiveUS20050057050A1Easy constructionLow costBurglar alarm by openingWing handlesEngineeringBack door

A door handle apparatus having a door handle 12 which is provided on a back door of an automobile in such a manner as to oscillate freely and a cover member 20 for covering the door handle 12, wherein a detection sensor 30 for detecting the approach of an operator toward the door handle 12 is provided between the door handle 12 and the cover member 20.

Owner:HONDA MOTOR CO LTD

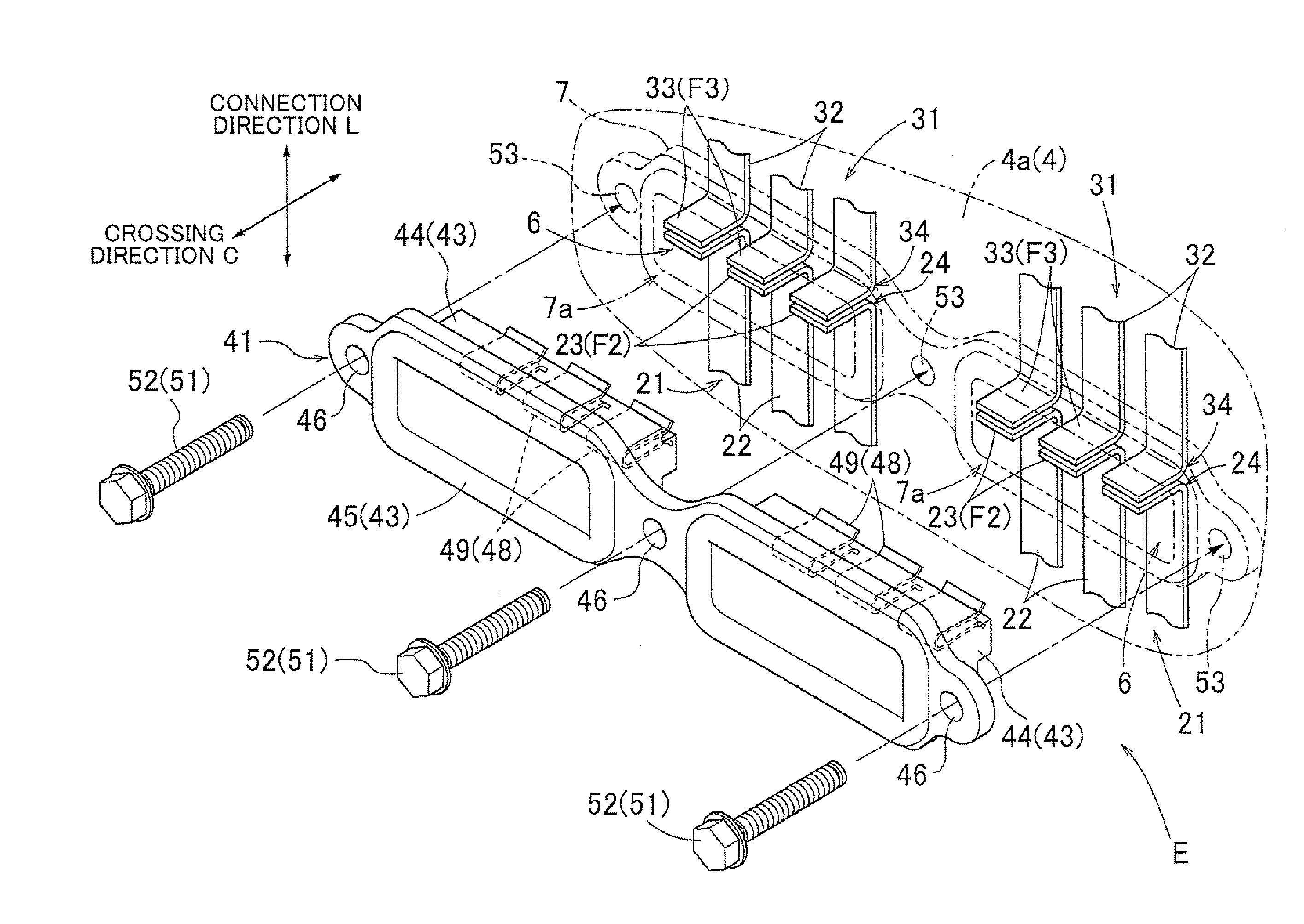

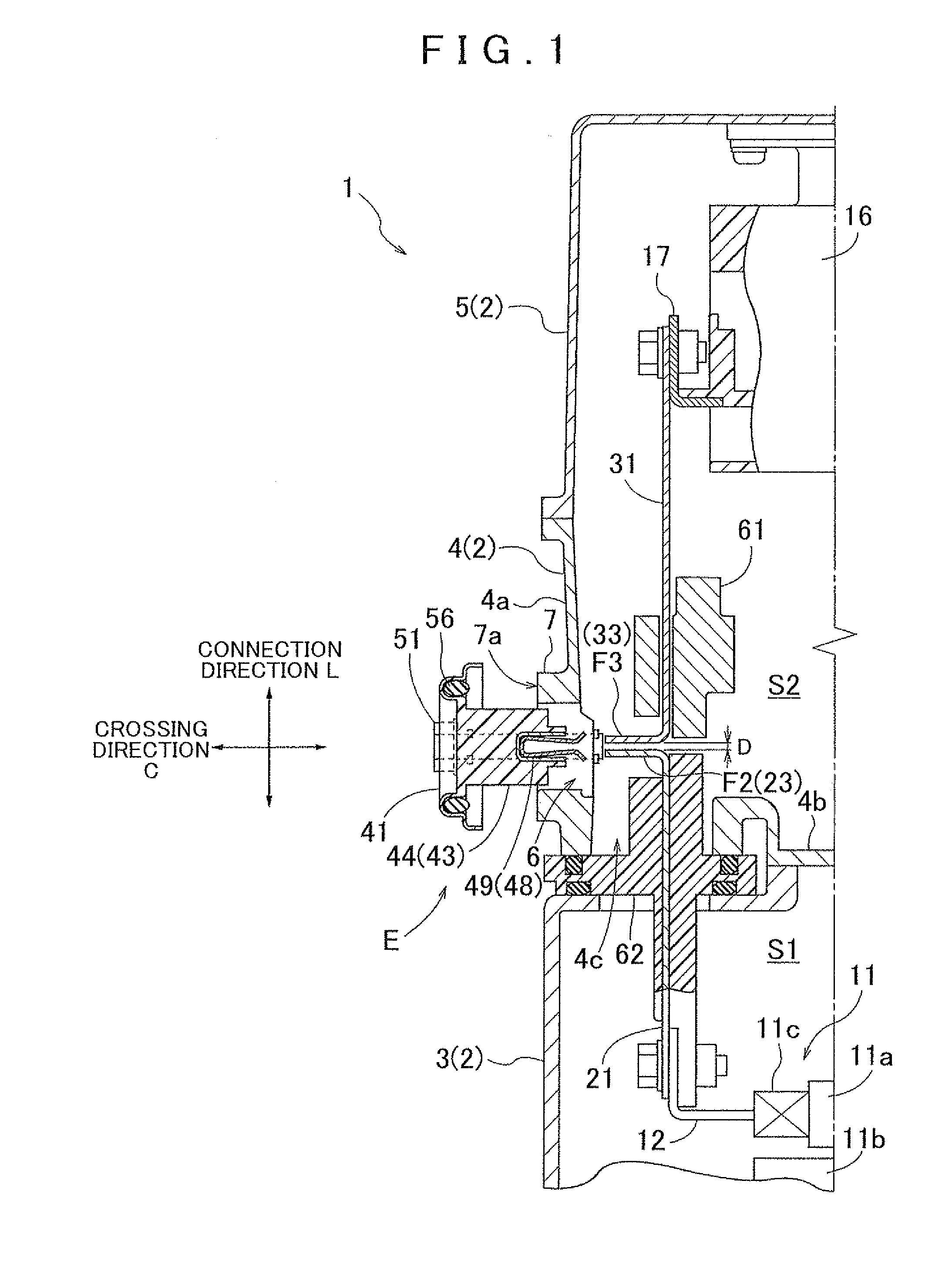

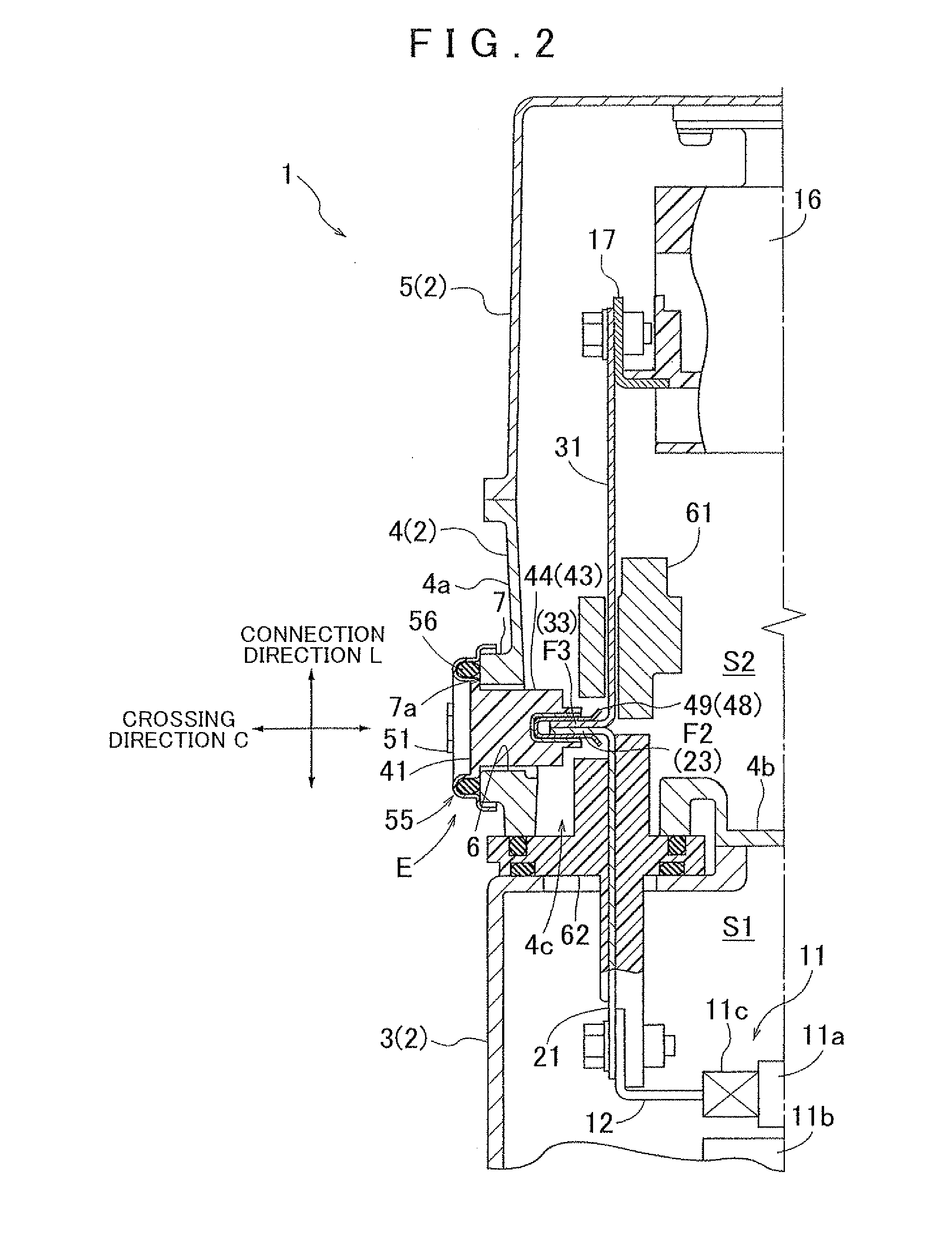

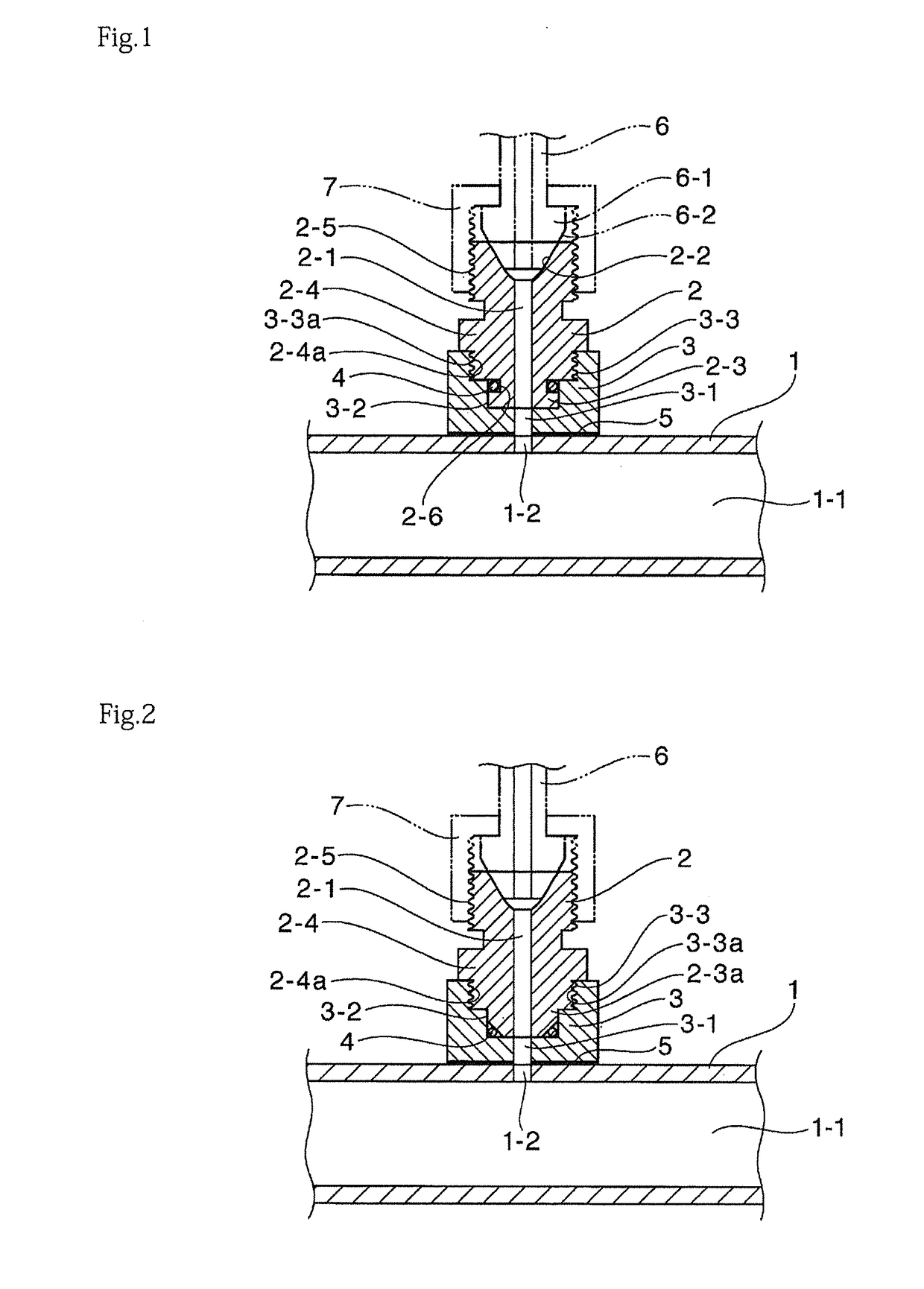

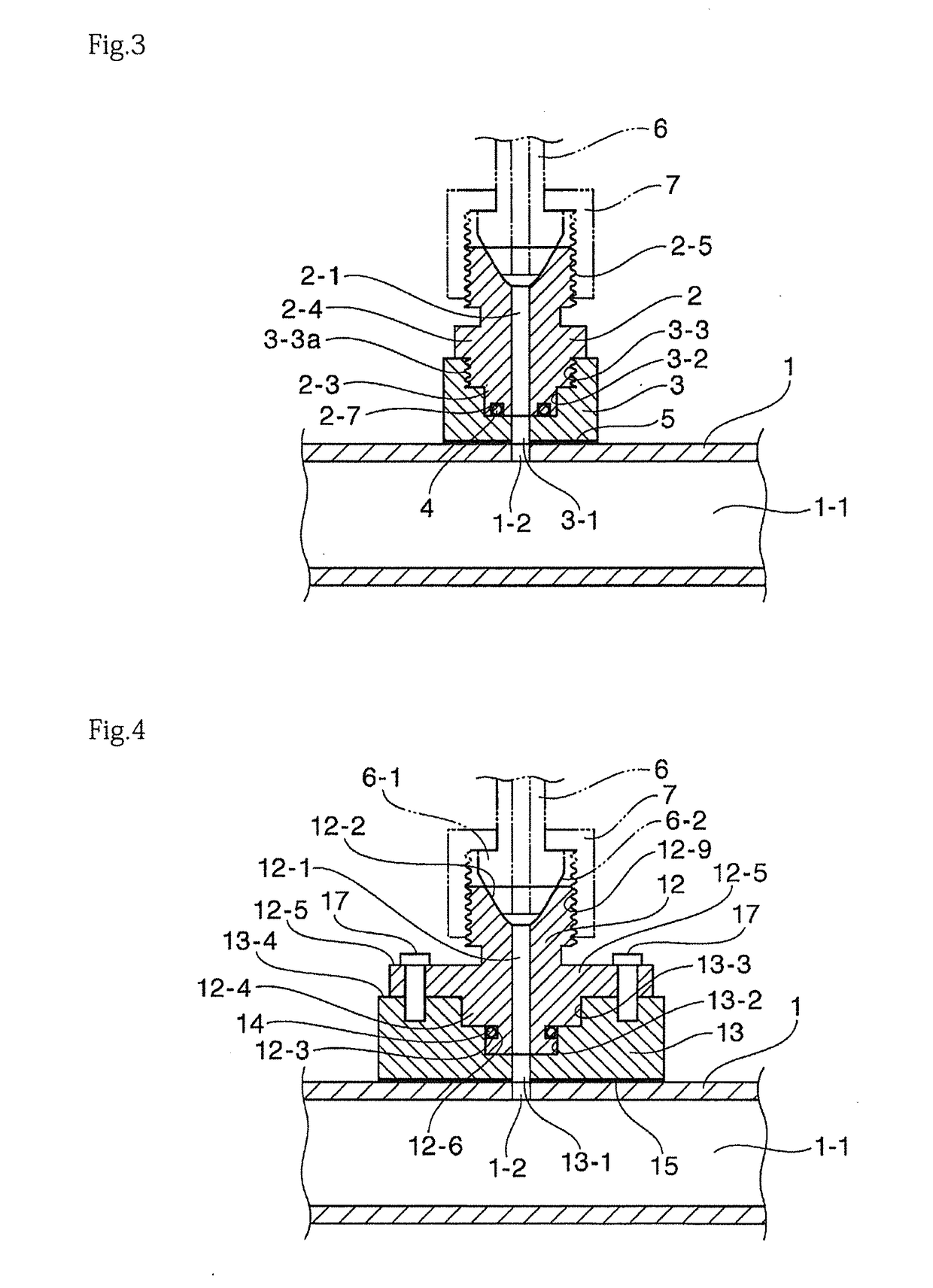

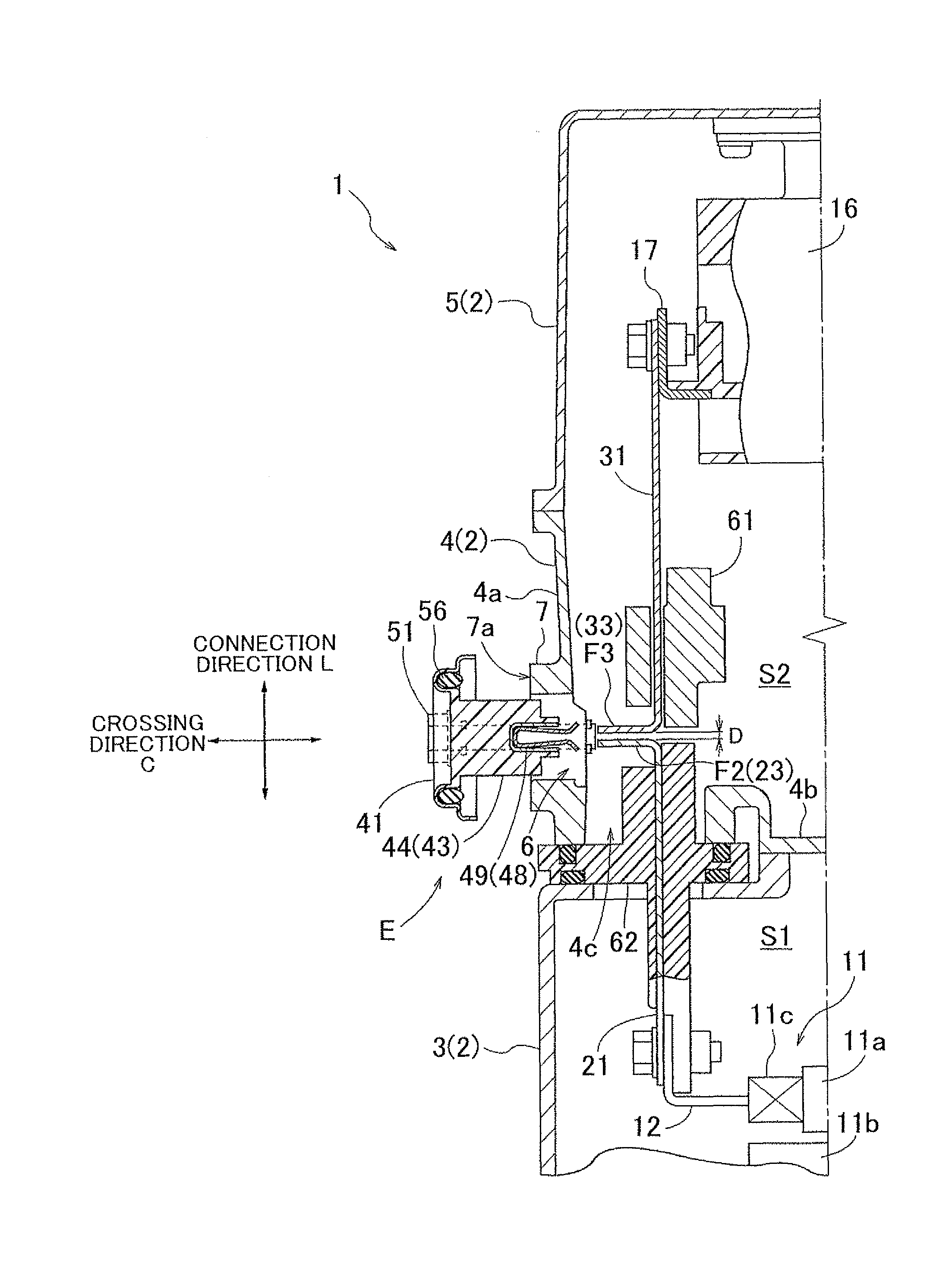

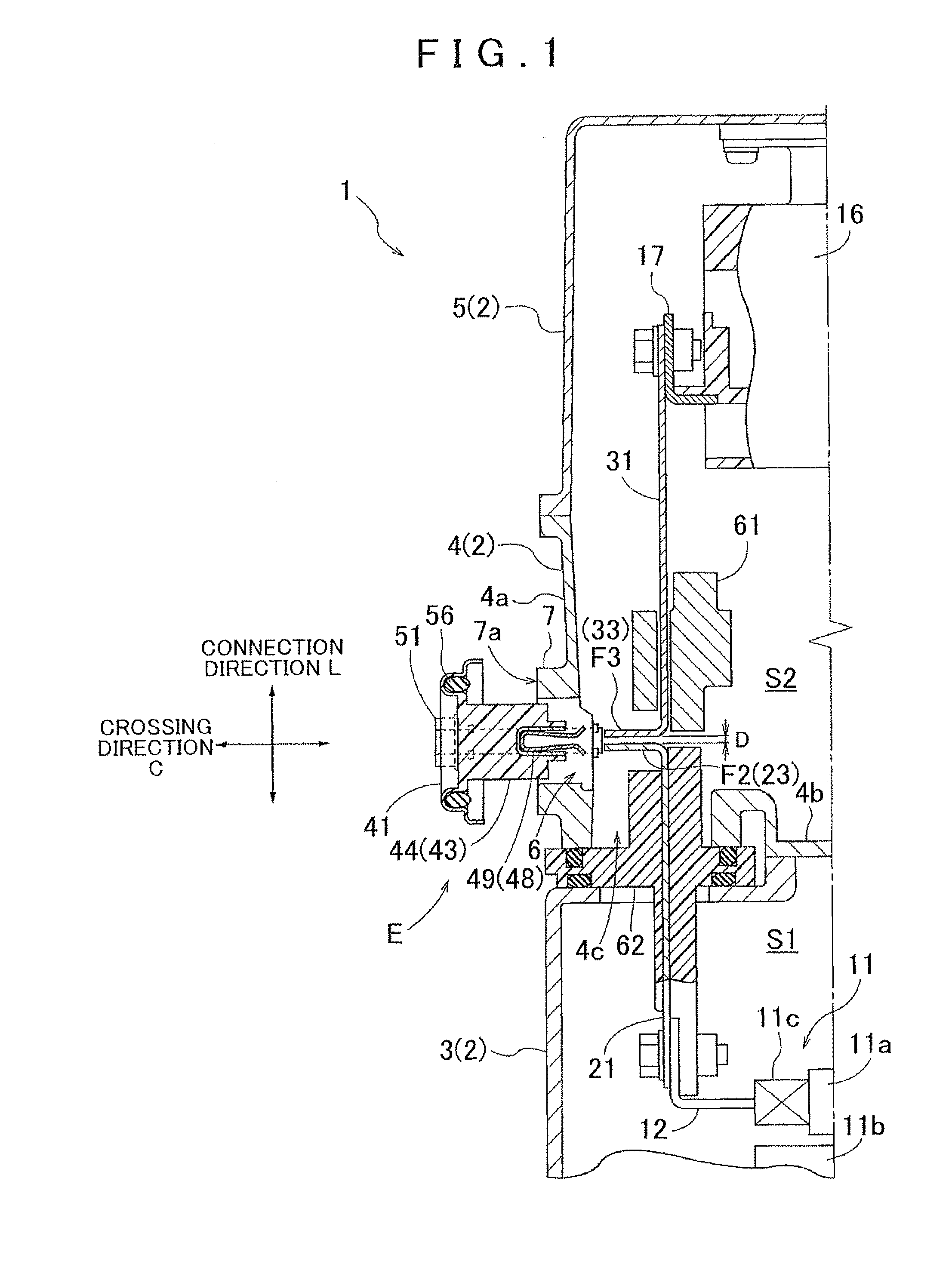

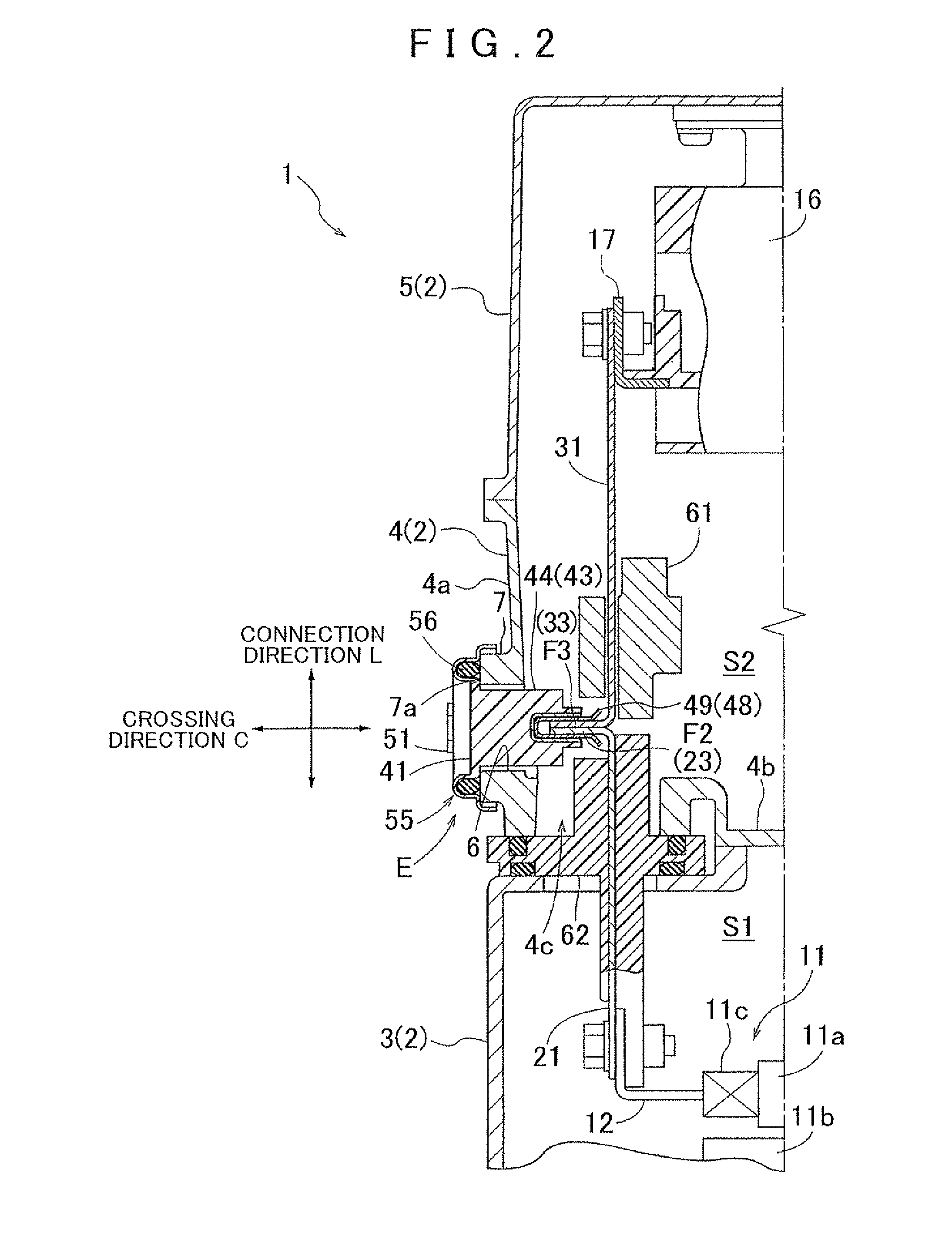

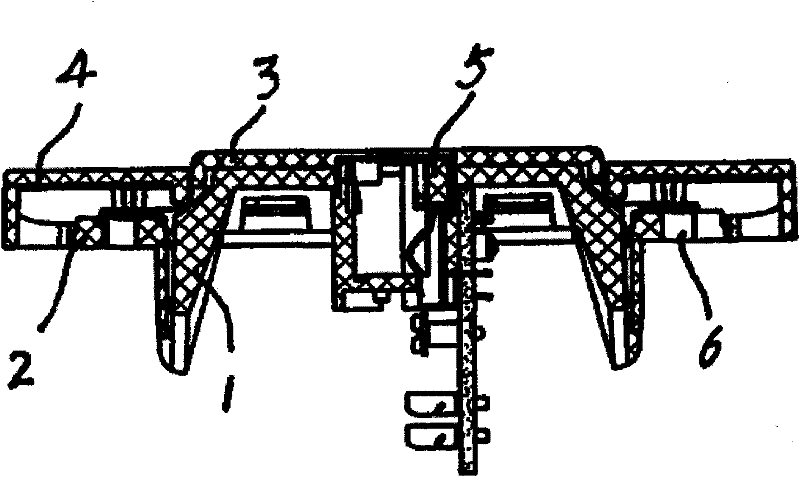

Electrical connection device

InactiveUS20110065298A1Low costEasy to replace partsAssociation with control/drive circuitsWindingsElectricityEngineering

The present invention relates to an electrical connection device that connects a rotating electrical machine and an inverter within a housing. The electrical connection device is configured with a first bus bar connected to a terminal of the rotating electrical machine such that the first bus bar that is insulated from the housing, and a second bus bar that is connected to a terminal of the inverter device such that the second bus bar is also insulated from the housing. An insulating connection member is configured to connect the first bus bar and the second bus bar. The first bus bar and second bus bar are housed within the housing such that they face each other to form a gap between them. The connection member is configured to pass through a wall of the housing so as to electrically connect the first and second bus bars.

Owner:AISIN AW CO LTD

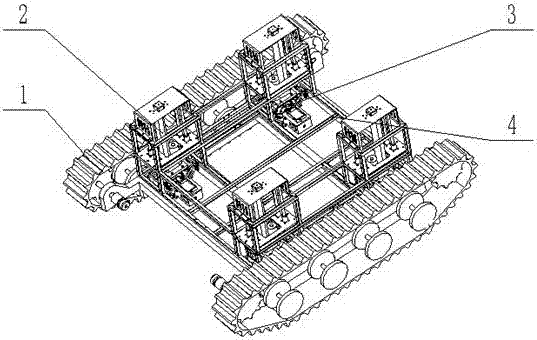

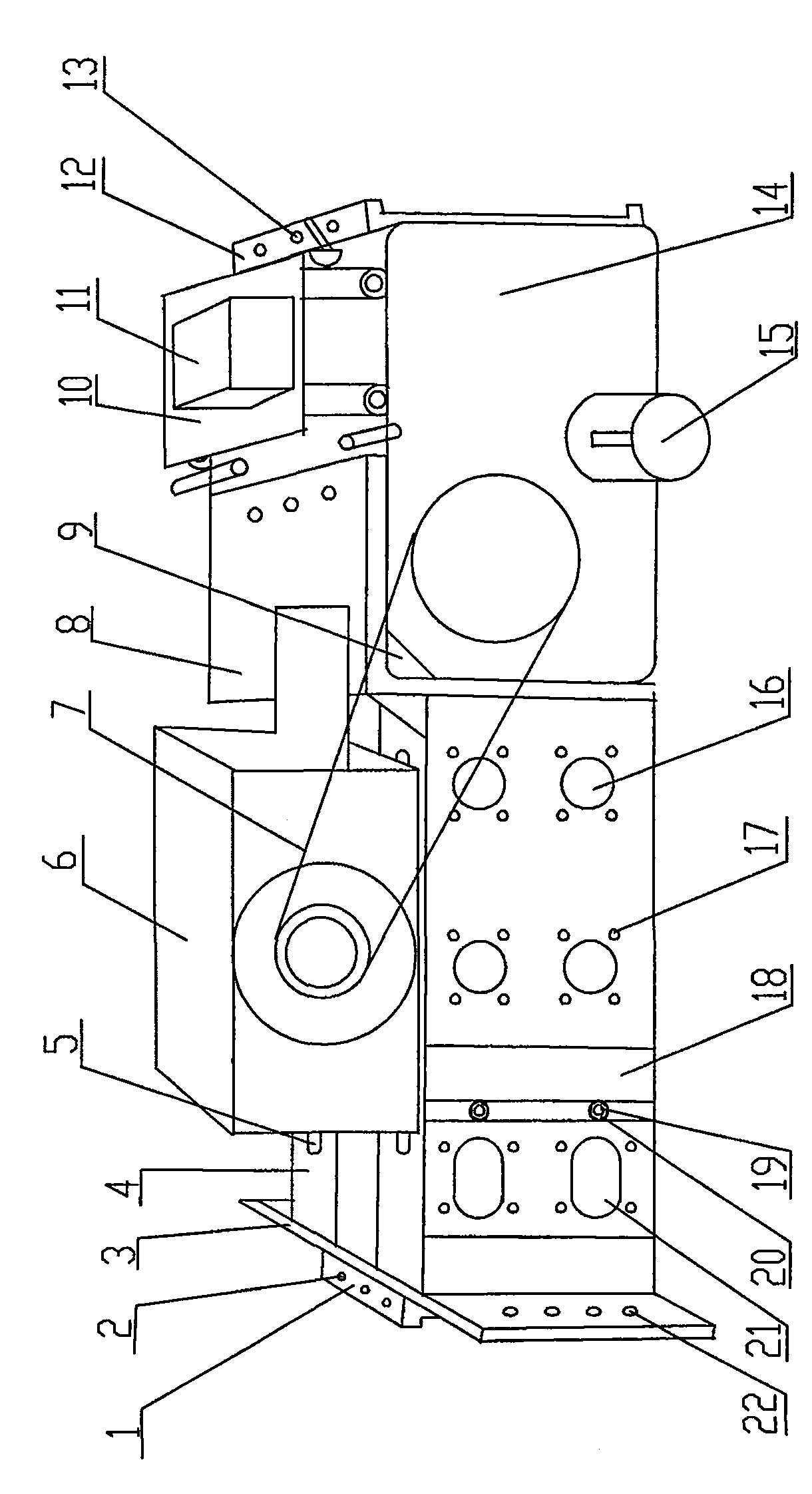

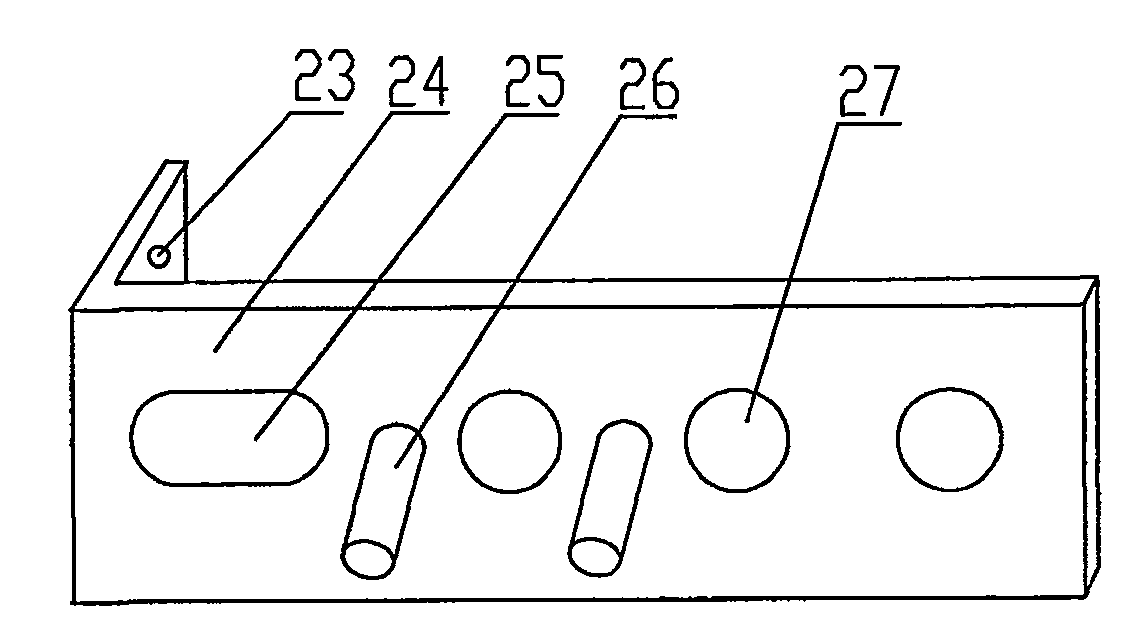

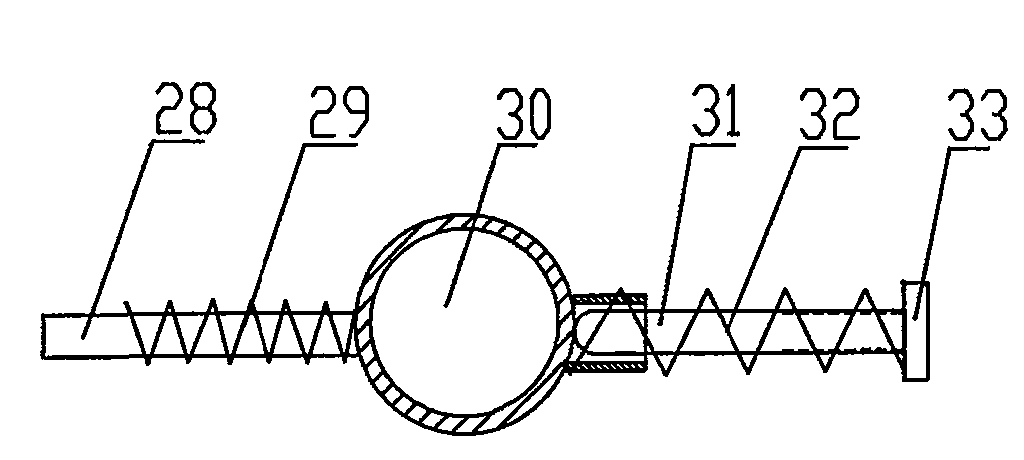

Wheel-track composite type chassis structure

PendingCN107140042ASimple structureEasy to replace partsEndless track vehiclesTerrainRolling chassis

The invention discloses a wheel-track composite type chassis structure. The wheel-track composite type chassis structure comprises a caterpillar baseboard, four electric push rod lifting mechanisms, four Mecanum mobile mechanisms and an omnibearing mobile platform frame, the omnibearing mobile platform frame is fixed to the wheel-track chassis baseboard, push rod top ends of the four electric push rod lifting mechanisms are fixed to the omnibearing mobile platform frame separately, the four Mecanum mobile mechanisms are fixedly connected with the four electric push rod lifting mechanisms, and by extending and retracting electric push rods, the Mecanum mobile mechanisms are in contact with and leave the ground. The wheel-track composite type chassis structure is flexible to move, convenient to operate and reliable to run, and the adaptability to complex terrains is high.

Owner:NANJING UNIV OF SCI & TECH

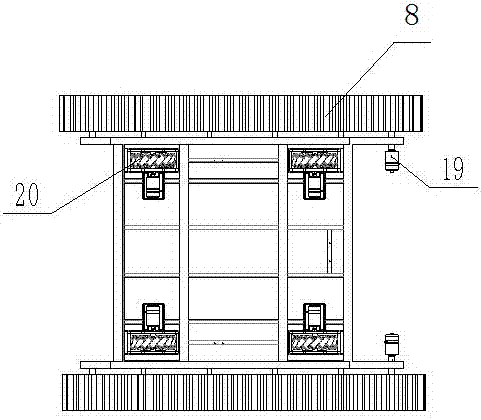

Household garbage pulverizer

The invention discloses a household garbage pulverizer. The household garbage pulverizer comprises a base. A plurality of damping columns are arranged on the upper side of the base. A supporting plate is arranged at the upper ends of the damping columns. Damping springs are arranged on the outer sides of the damping columns. A shell is arranged on the upper side of the supporting plate. The shell is provided with a main hob cavity and two auxiliary hob cavities. Two main hob spindles are arranged in the main hob cavity and arranged along the middle portion of the shell in a vertically-parallel manner. Each auxiliary hob cavity is internally provided with an auxiliary hob spindle set. Each auxiliary hob spindle is provided with an auxiliary hob. A feeding pipe is arranged at the upper end of the right side of the shell. A feeding hopper is arranged at the other end of the feeding pipe. A scattering shaft is arranged in the feeding hopper and provided with a plurality of eccentric wheels. A second motor is arranged at the upper end of the shell. A disinfectant box is further arranged at the upper end of the shell. A plurality of spray heads arranged in the shell are arranged at the lower end of the disinfectant box. The household garbage pulverizer is simple in structure, convenient to use, good in pulverizing effect, long in service life, not prone to blockage and capable of conducting disinfection.

Owner:SUQIAN HUAIHAI TECH SERVICES

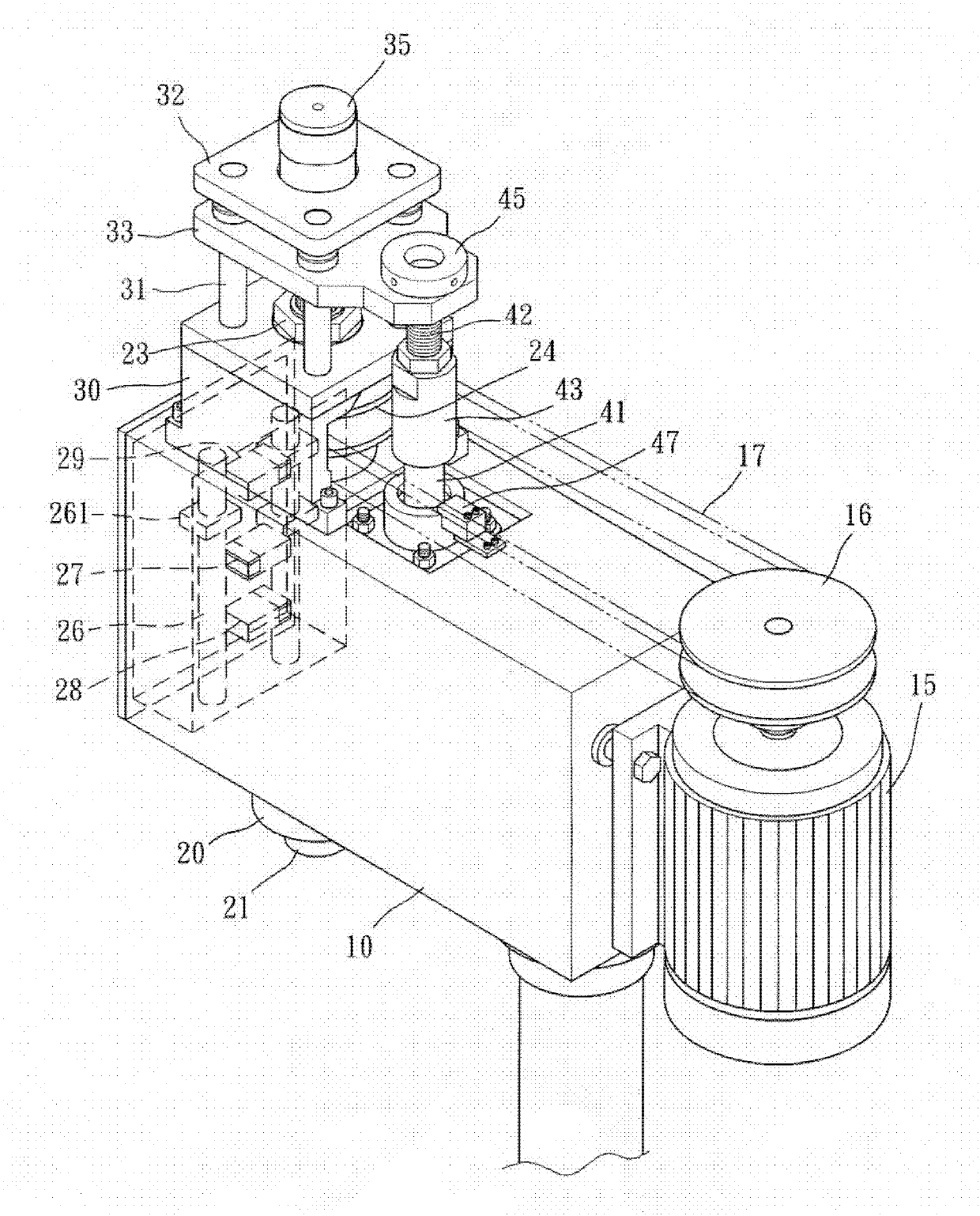

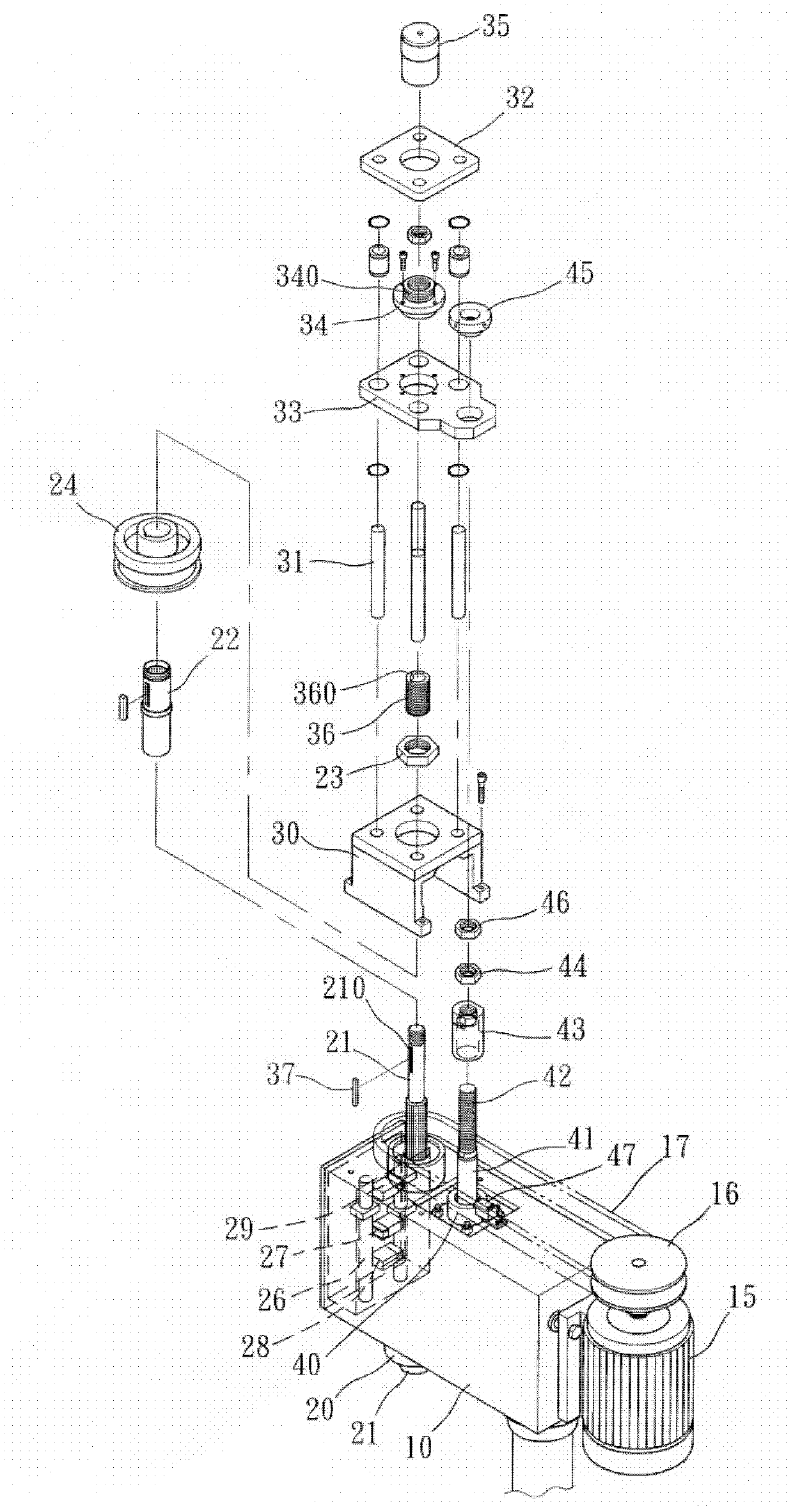

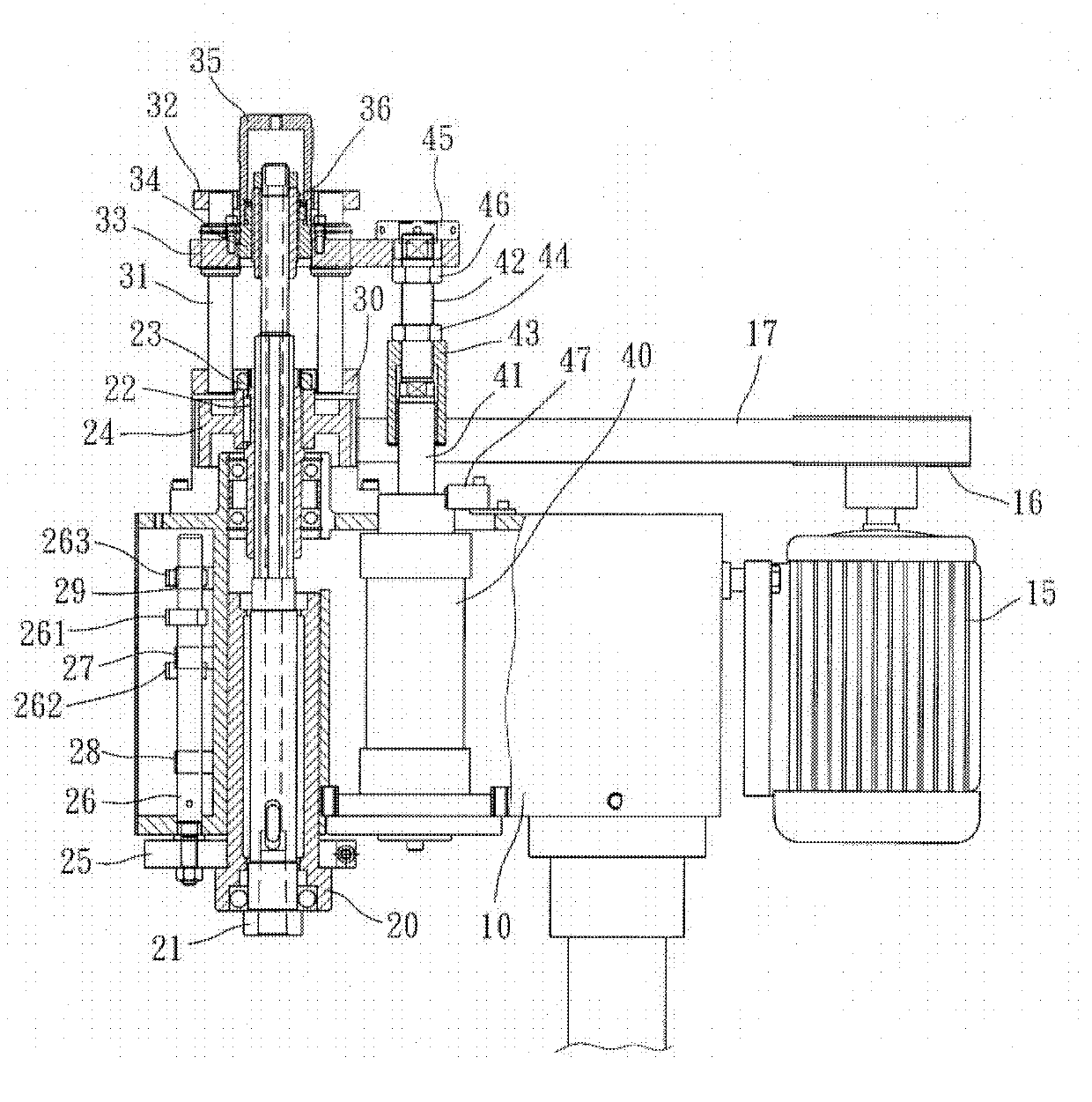

Tapping machine

A tapping machine is provided with a machine body, the machine body is provided with a main shaft capable of up-down movement, a rotary shaft capable of rotation and synchronous movement is pivoted in the main shaft, one end of the machine body is provided with a driving element capable of controlling rotation speed and rotation direction; a rotary shaft middle section of the main shaft is provided with a shaft sleeve pivoted on the machine body; the machine body is provided with a fixed seat for going-through of an upper end of the rotary shaft corresponding to the upper part of the main shaft; a cylinder body is disposed in the machine body, and the cylinder body is provided with a telescopic rod capable of rising and falling due to gas pressure or oil pressure source. The tapping machine is easy to disassemble, relative components are exposed, maintenance, component change and detachment assembly of the tapping machine are facilitated, stability and accuracy of action are improved, service lifetime is prolonged, rapid movement can be performed, movement time of knife feeding and retracting idle running can be shortened, unnecessary abrasion is reduced, and machining accuracy is ensured.

Owner:SHANGHAI LIANG LIH MACHINERY & ELECTRIC CO LTD

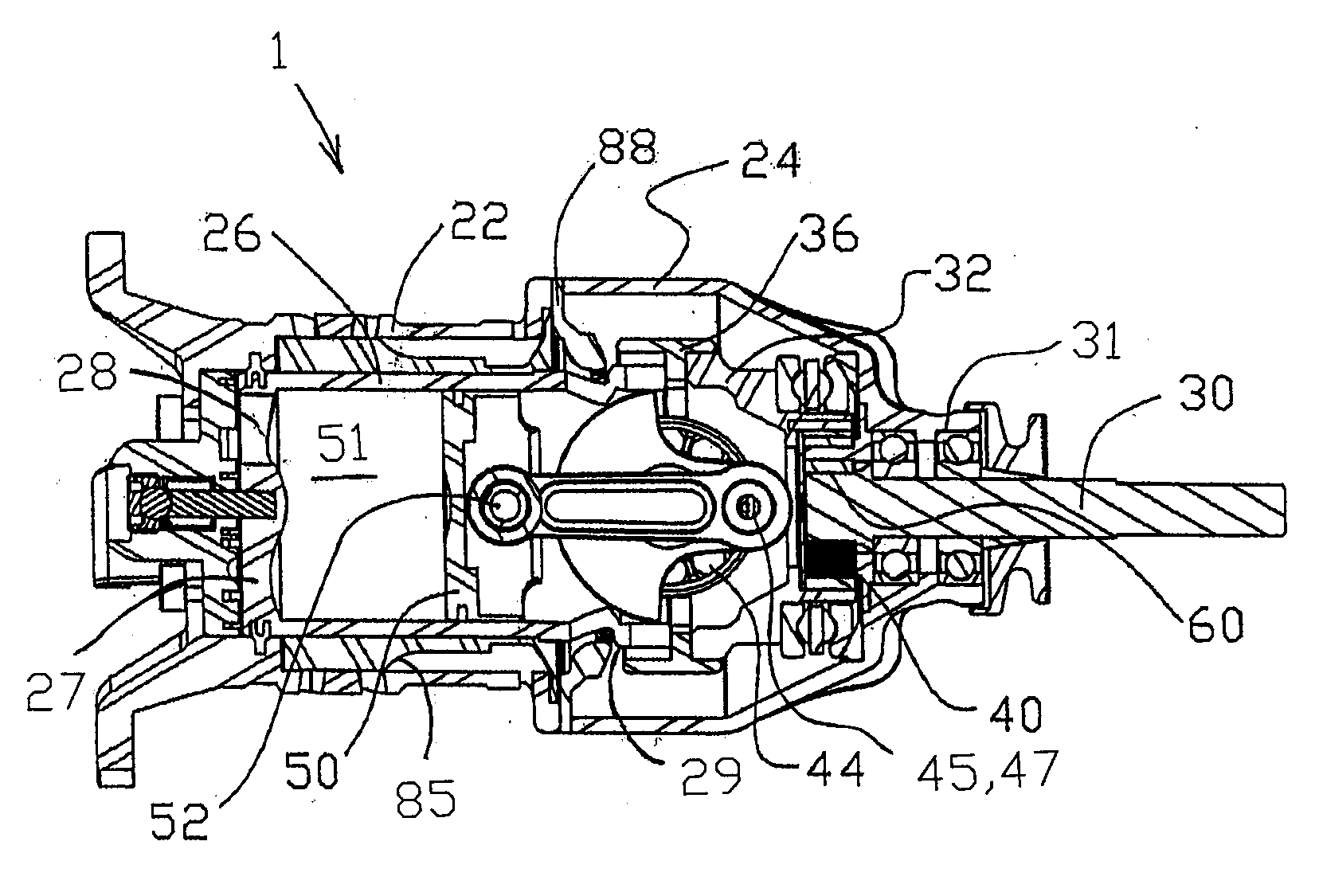

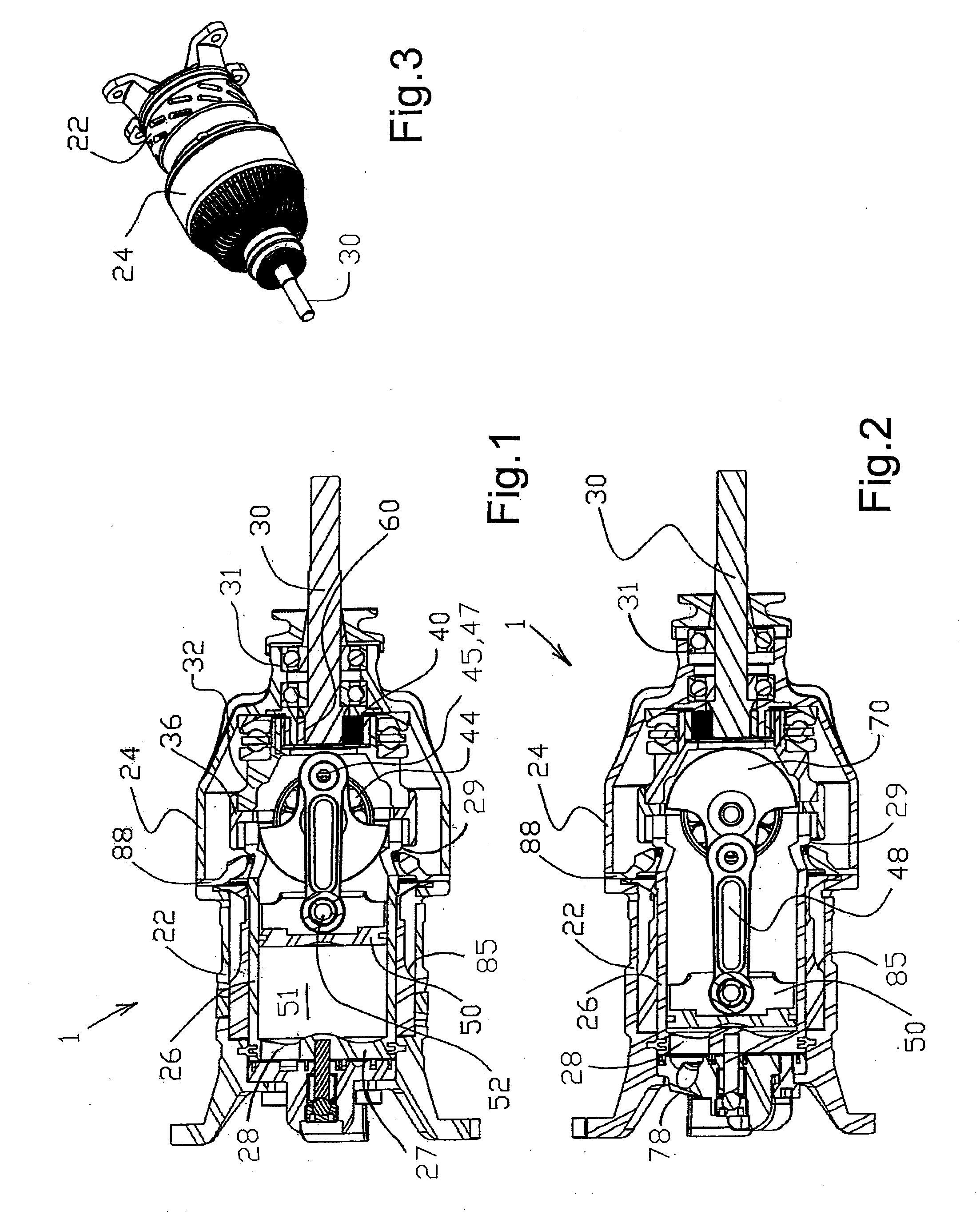

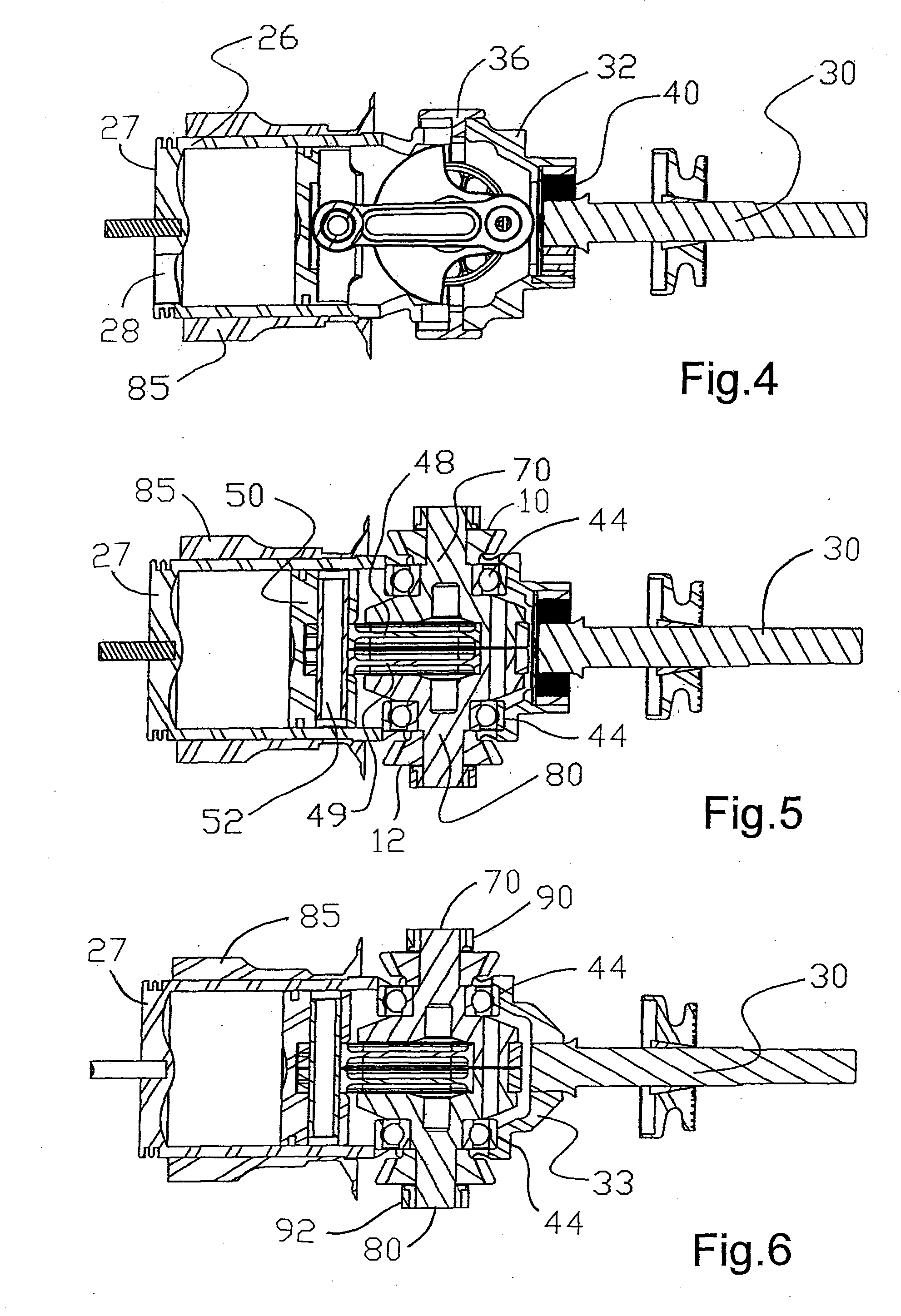

Rotary Engine

InactiveUS20100108034A1Competitive and affordable priceReduce manufacturing costInternal combustion piston enginesReciprocating piston enginesCombustionRotary engine

A rotary engine (1) is characterised by a driven output shaft (30) powered by internal combustion carried out in a cylinder (26) to drive a piston (50) and crankshafts (70, 80) carrying contra-rotating drive gears (10, 12) meshing with a fixed gear ring (88), rotation of the gears (10, 12) transmitting rotary motion to the piston (50) and the cylinder (26), the gear cage base (32), gears (10, 12) and to the output shaft (30). The contra-rotation of the gears (10, 12) on the respective crankshaft (70, 80) provides for a balanced power transmission.

Owner:MARBAW INT NICKEL CORP

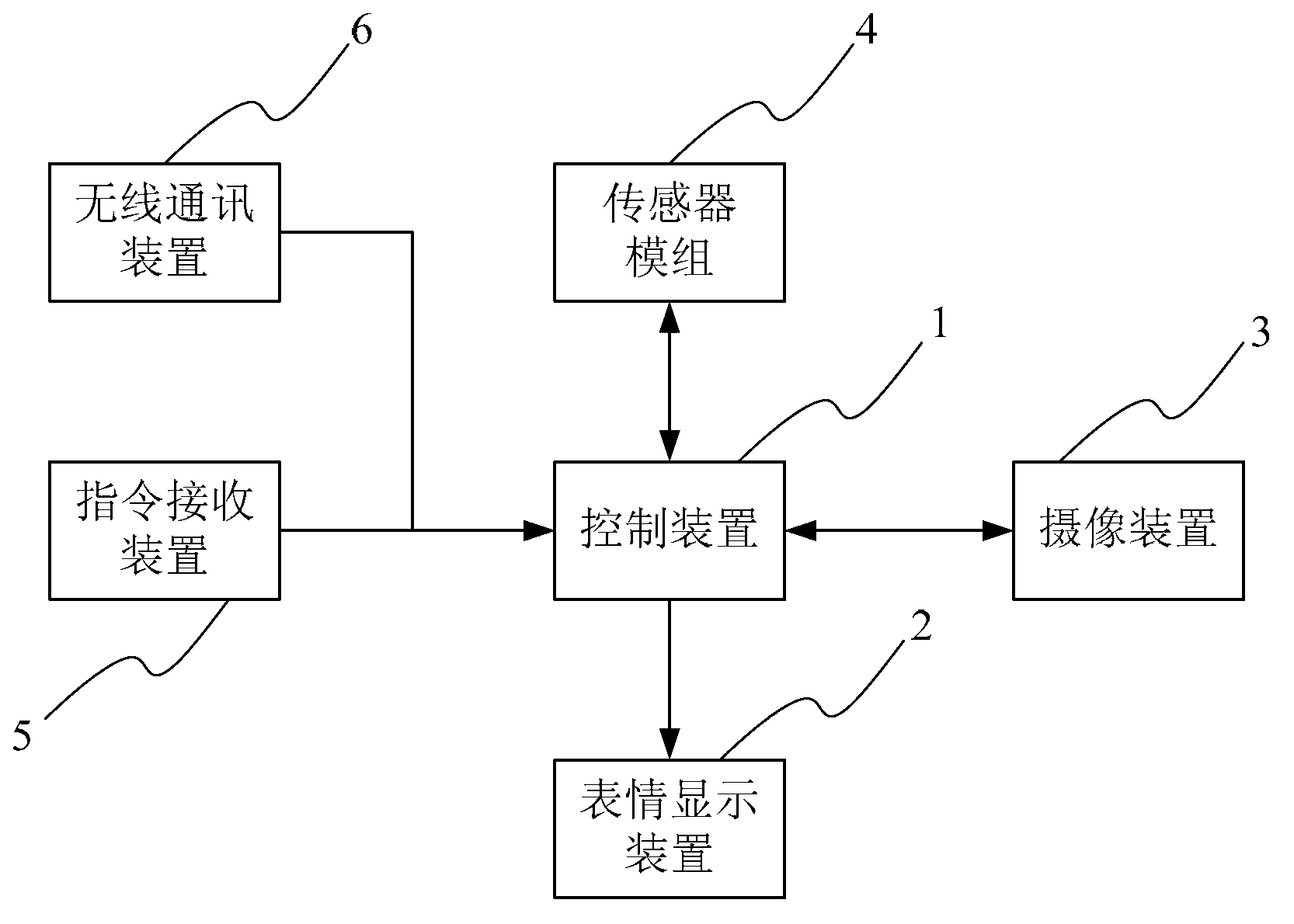

Domestic service robot

The invention discloses a domestic service robot which comprises a body, a head and four limbs. The head is detachably connected with the body. All limbs are detachably connected with the body. The domestic service robot further comprises a control device. The head comprises an expression display. The control device is used for generating a control signal including an expression display signal. The expression display is used for displaying expressions according to the control signal. The domestic service robot is simple in structure, parts of the robot are convenient to replace, and the domestic service robot is convenient to operate, can simulate various expressions according to different control commands, and is vivid and lively.

Owner:SHANGHAI XPARTNER ROBOTICS

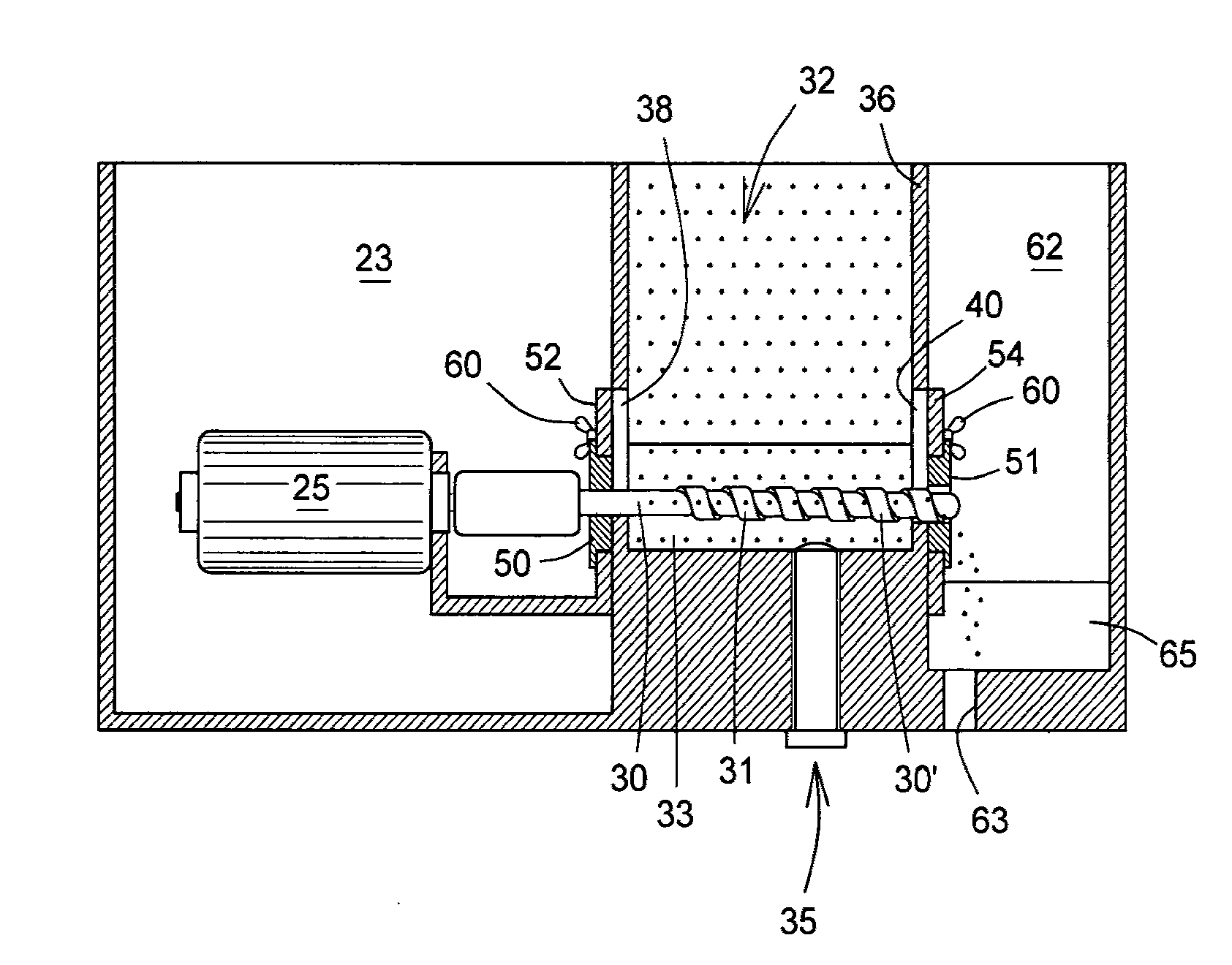

Device for the comminution of materials

InactiveUS7077344B2Reduce wearEasy maintenanceGrain huskingGrain polishingSynthetic materialsPack material

A device for compacting loosely packed materials, in particular synthetic materials, comprises a shredder / conveyor rotor body arranged in a casing and drivable with the rotation around an axis of rotation and a consecutively arranged extruder with an extruder screw that is arranged rotatably and coaxially to the shredder / conveyor rotor body. Materials supplied to the shredder / conveyor rotor body are conveyed to the extruder screw, whereby they optionally are shredded. According to the invention, the shredder / conveyor rotor body is configured as a hollow body open at the front side opposite the extruder and has at least one rotary bearing in its interior, which rotary bearing rests on an abutment body projecting from the open front side into the interior of the shredder / conveyor rotor body.

Owner:STARLINGER & CO GMBH

Fuel rail for gasoline direct-injection engine

InactiveUS20170260946A1Convenience to workLow costFuel injection apparatusMachines/enginesGasoline direct injectionHardness

Provided is a fuel rail for a gasoline direct-injection engine, characterized in that a branch connector is attached to a main pipe through a recessed connection member, the recessed connection member is secured to the main pipe by brazing or welding, the branch connector is recess-projection fitted to the recessed connection member and is detachably fastened thereto by a thread fastening mechanism or by a bolt fastening mechanism, and an O-ring provided between the recessed connection member and the branch connector is tightened by an axial force created by fastening of the branch connector to thereby create a seal between the recessed connection member and the branch connector; and a hardness of the branch connector is set to be lower than that of the branch pipe facing the branch connector.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

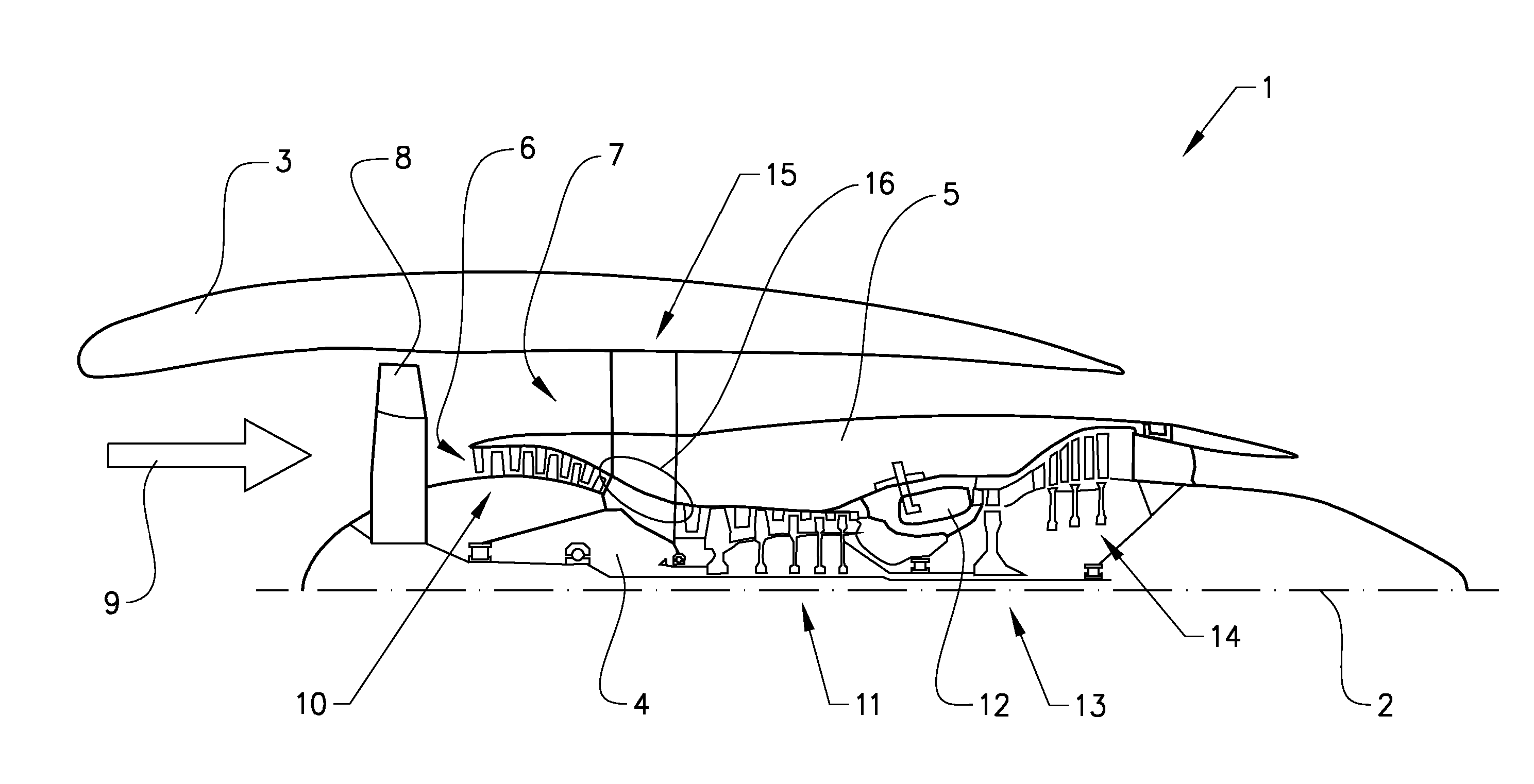

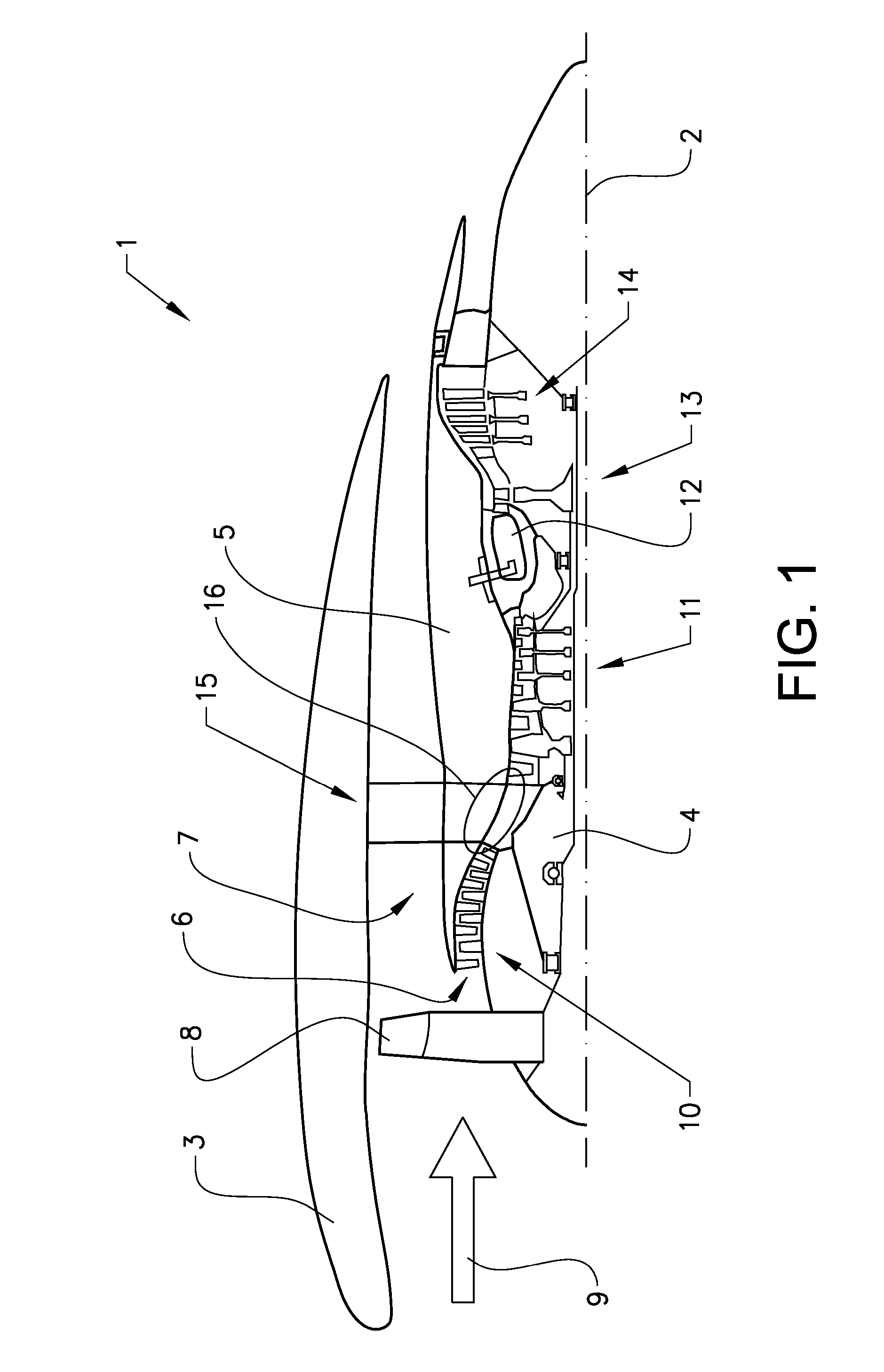

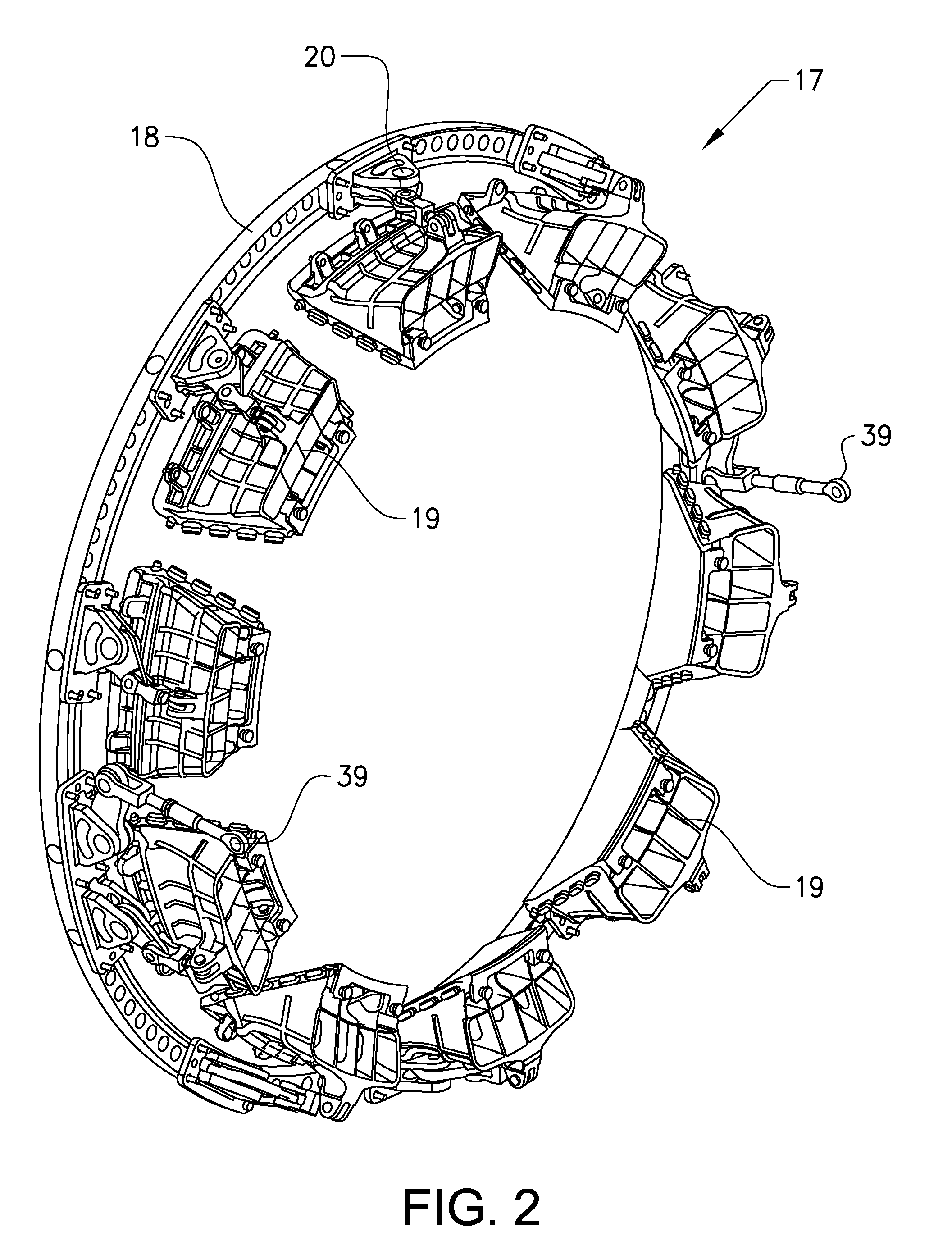

Device for moving at least one moveable element in a gas turbine

ActiveUS20070080262A1Decreasing lever distanceReduce tensionControlling membersEngine fuctionsEngineeringGas turbines

The invention relates to a device (20) for moving at least one moveable element (19) in a gas turbine engine (1) between a first and a second position. The device includes a linkage (21) that connects a pivotable annular member (18) with the moveable element (19) in such a way that the movement of the moveable element (19) between the two positions is accomplished when the annular member (18) is pivoted. The linkage (21) has a link member (22) connected to the moveable element (19) via a first articulation joint (23). The device also has a support member (24) that supports the link member (22) at a distance from the first articulation joint.

Owner:GKN AEROSPACE SWEDEN AB

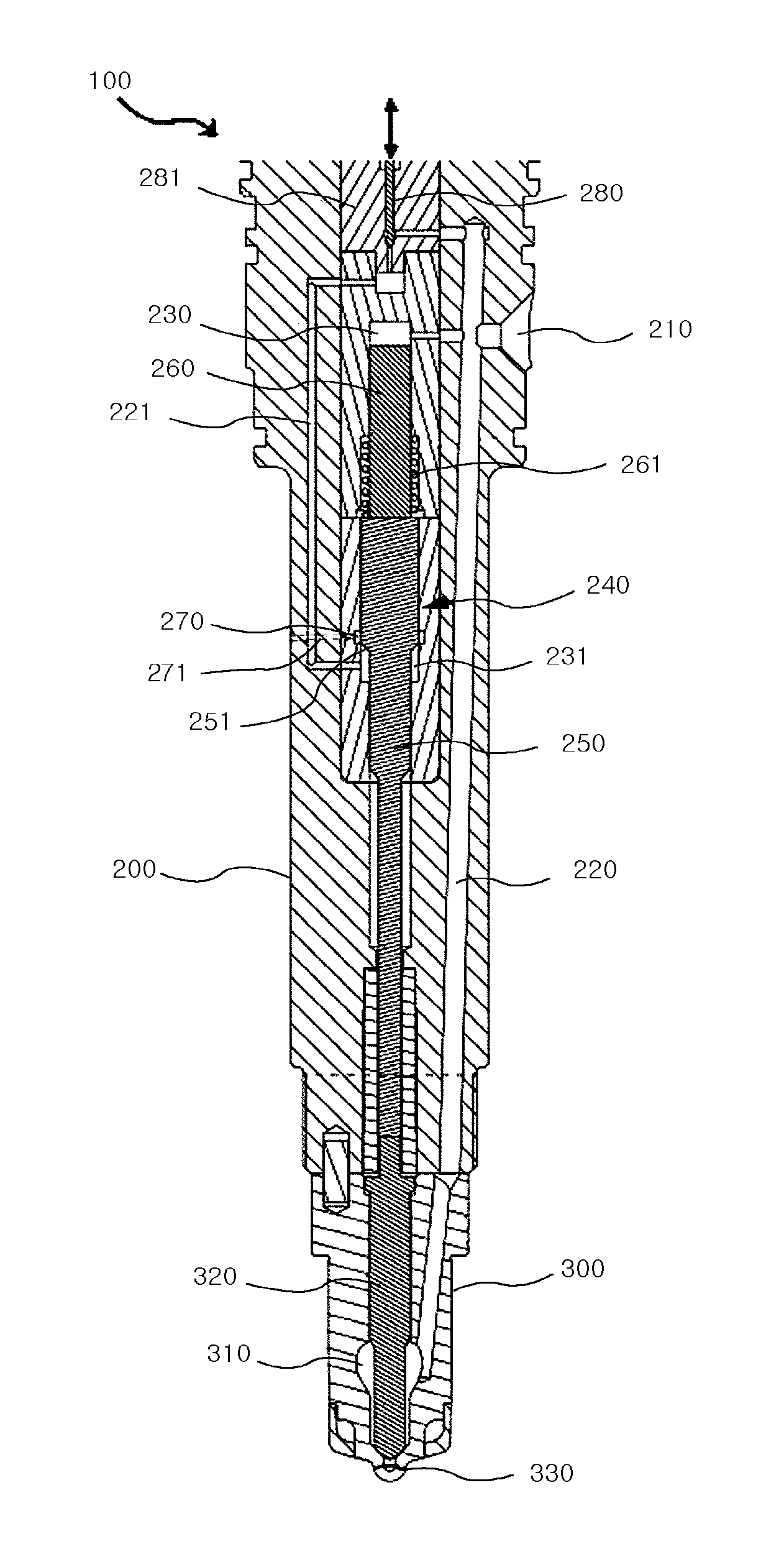

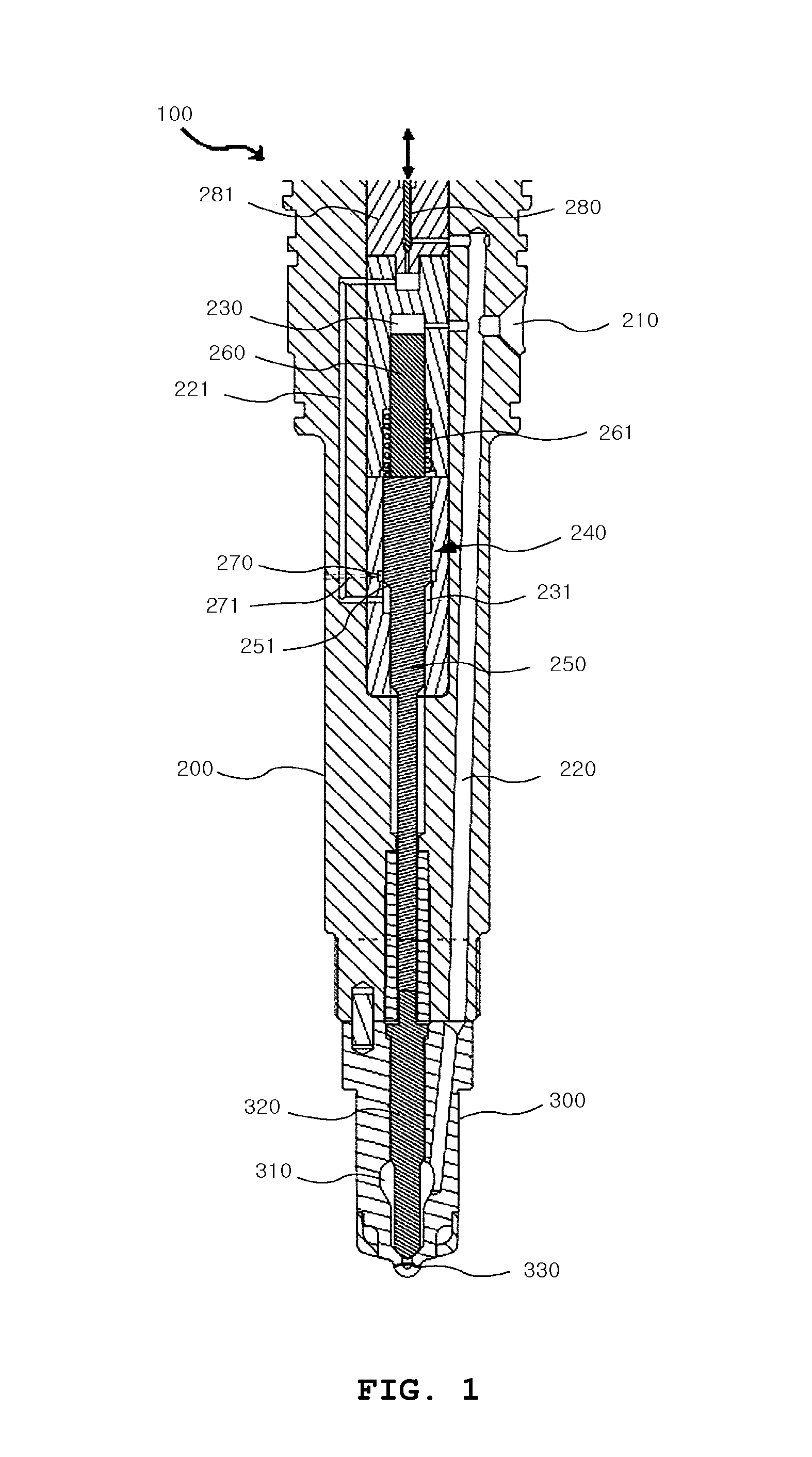

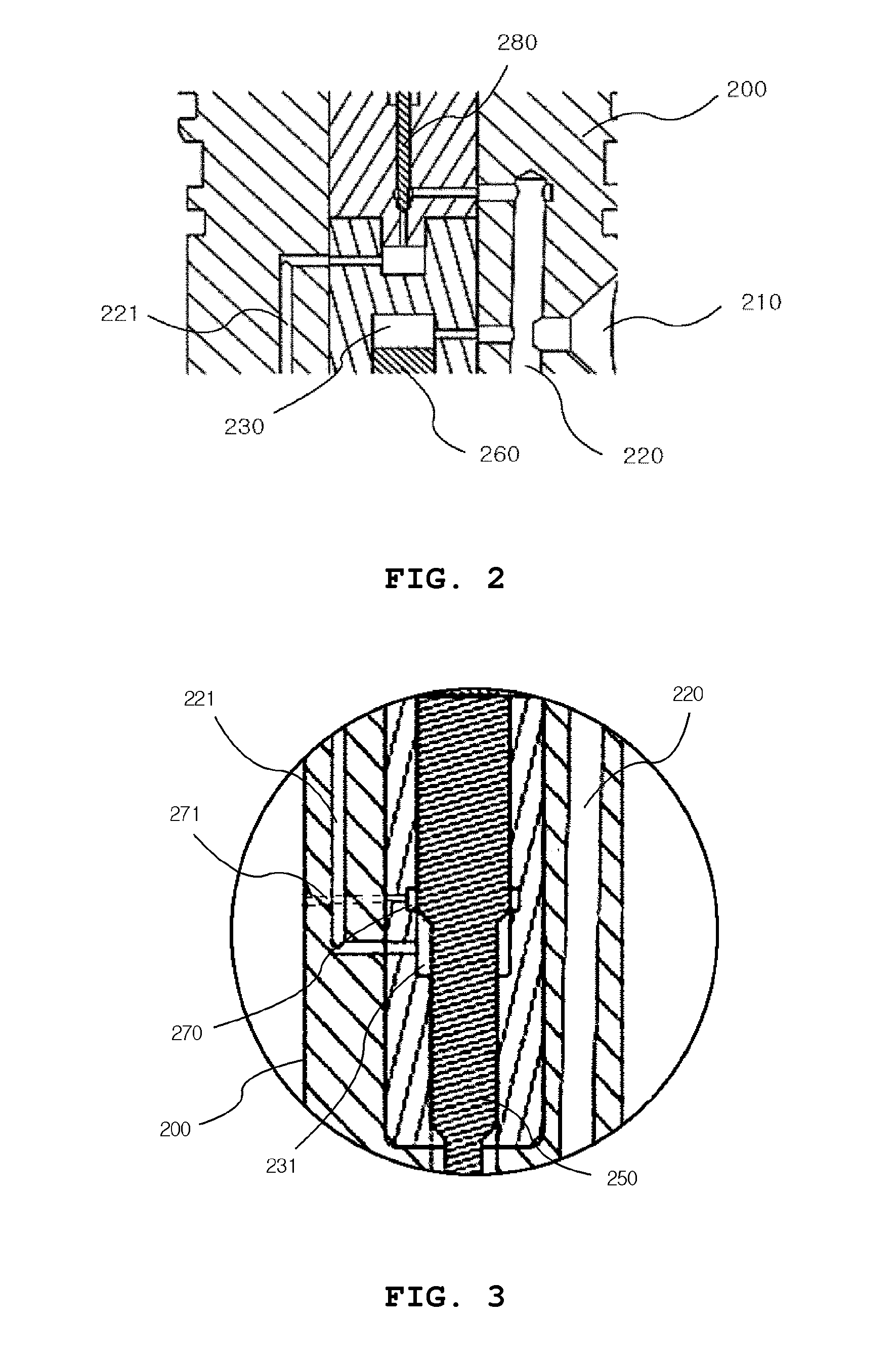

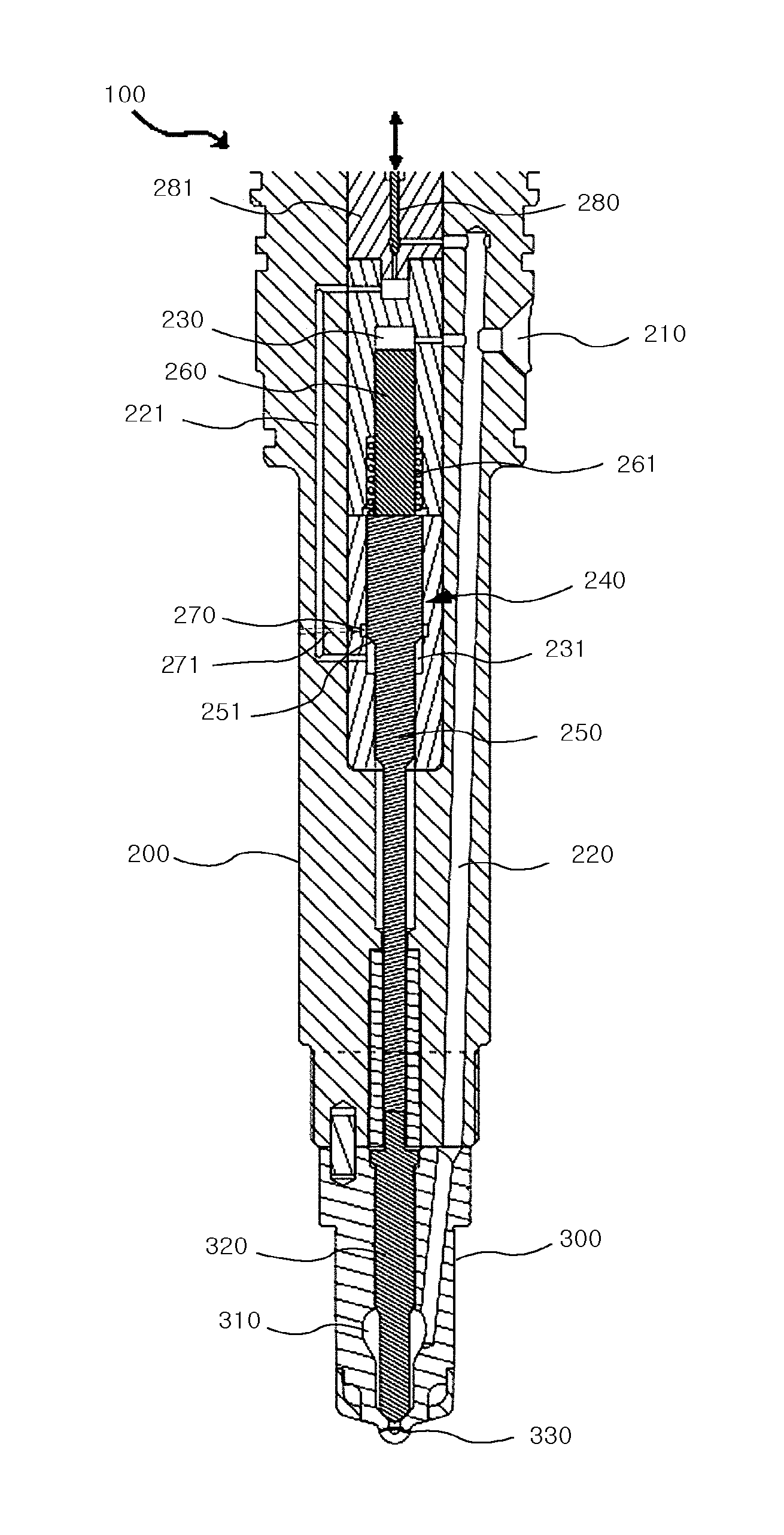

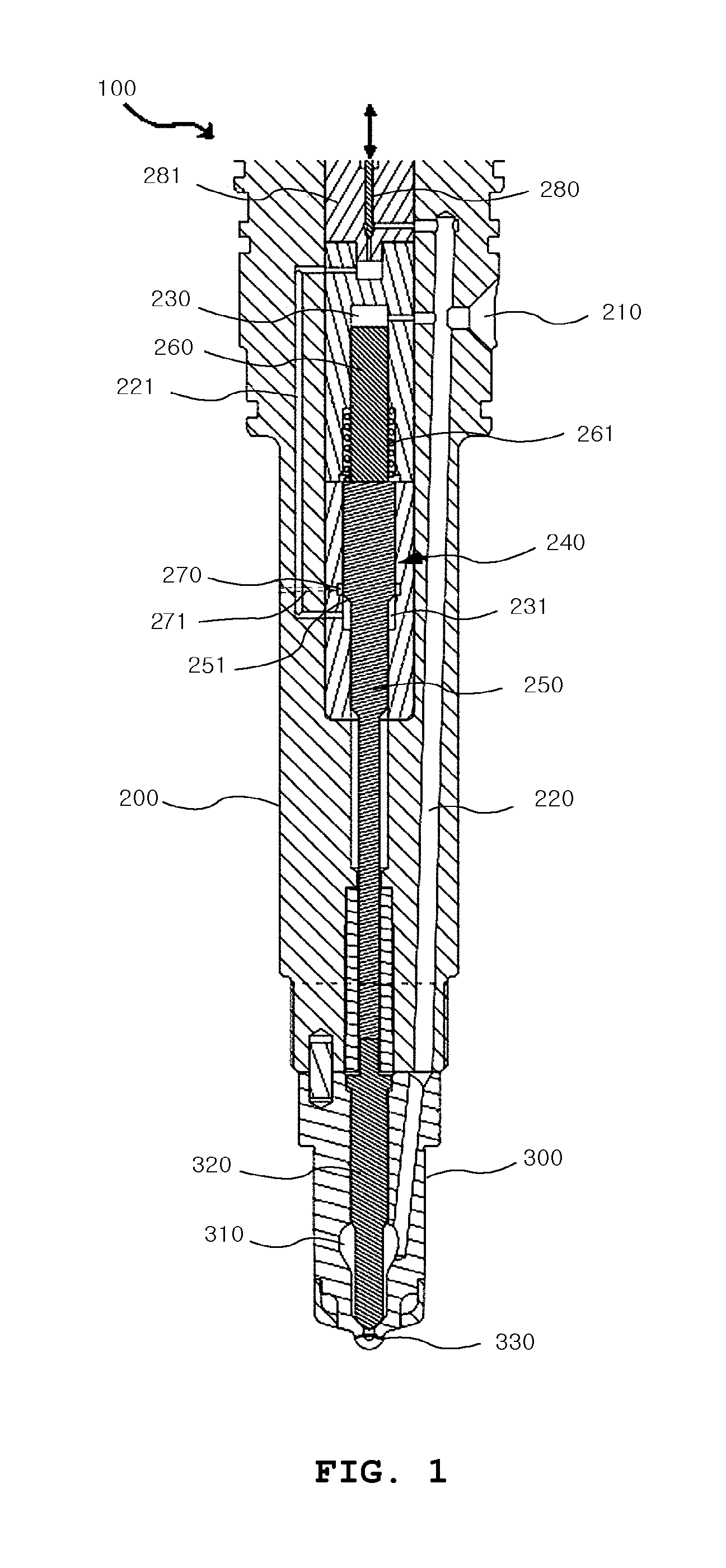

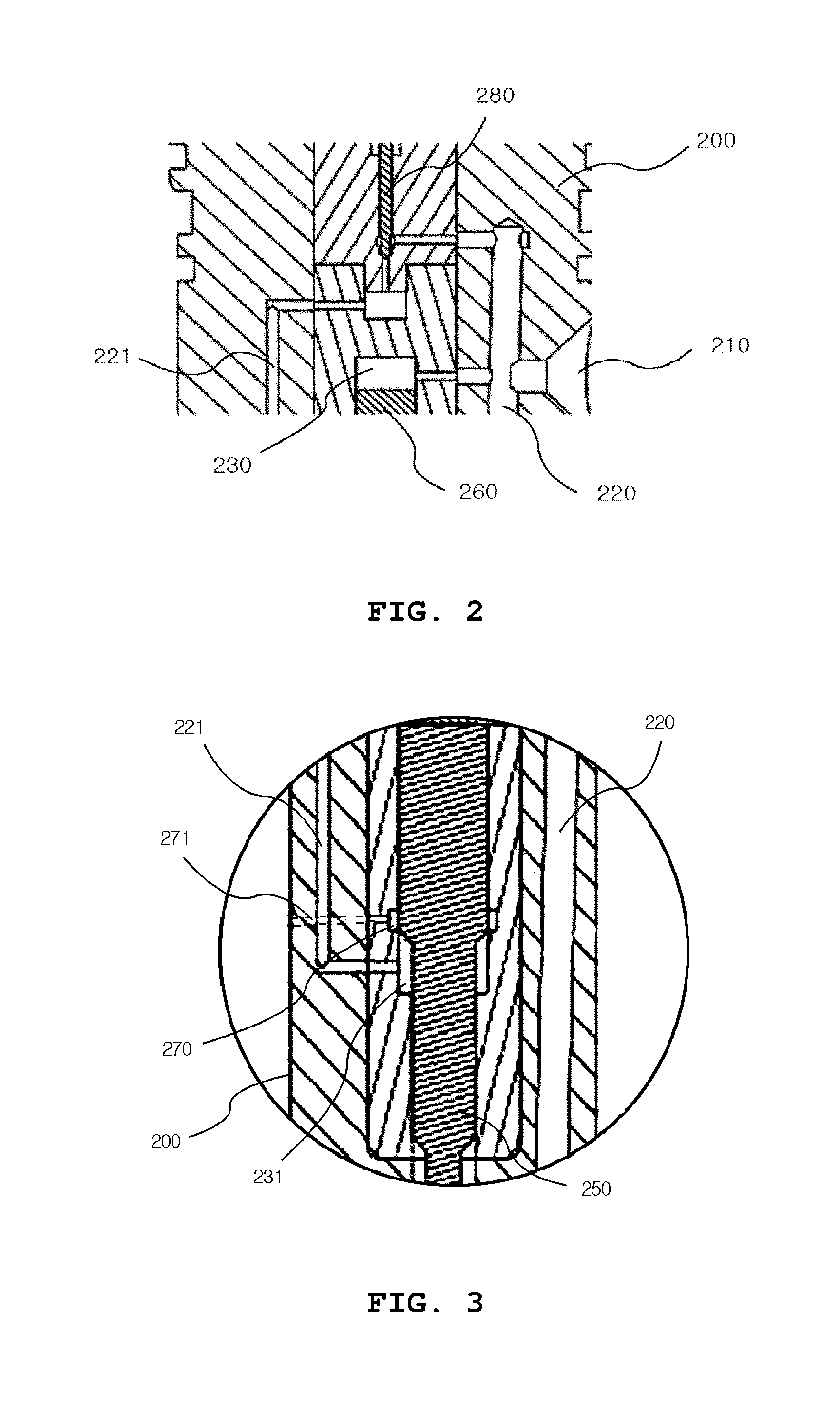

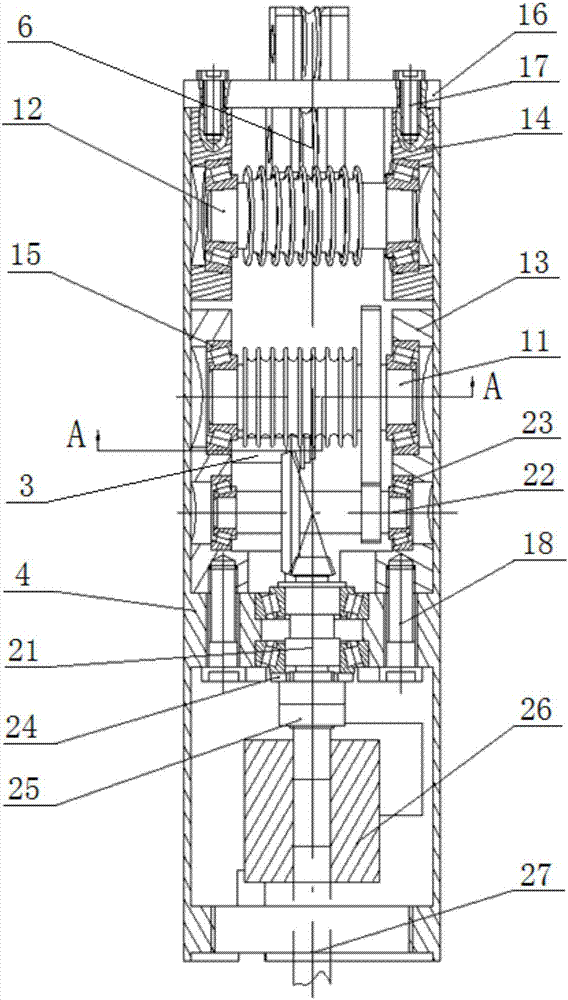

Electronic control fuel injection valve

ActiveUS20130332048A1Limiting fuel injectionEasy to replace partsElectrical controlDigital data processing detailsMachine partsControl signal

An electronically controlled fuel injection valve can control the time to inject fuel and the amount of fuel to be injected in response to a control signal independently from the operating condition of an engine unlike a traditional mechanical fuel injection valve. The electronically controlled fuel injection valve employs a control method for fuel injection that increases the force of lifting up a cutoff needle of an injection controller by delivering high-pressure fuel to a lower pressure chamber via a control needle, thereby rapidly controlling fuel injection, has a simple structure making it easy to assemble, replace and precisely machine parts, and has a simple flow path structure which facilitates fabrication.

Owner:HYUNDAI HEAVY IND CO LTD

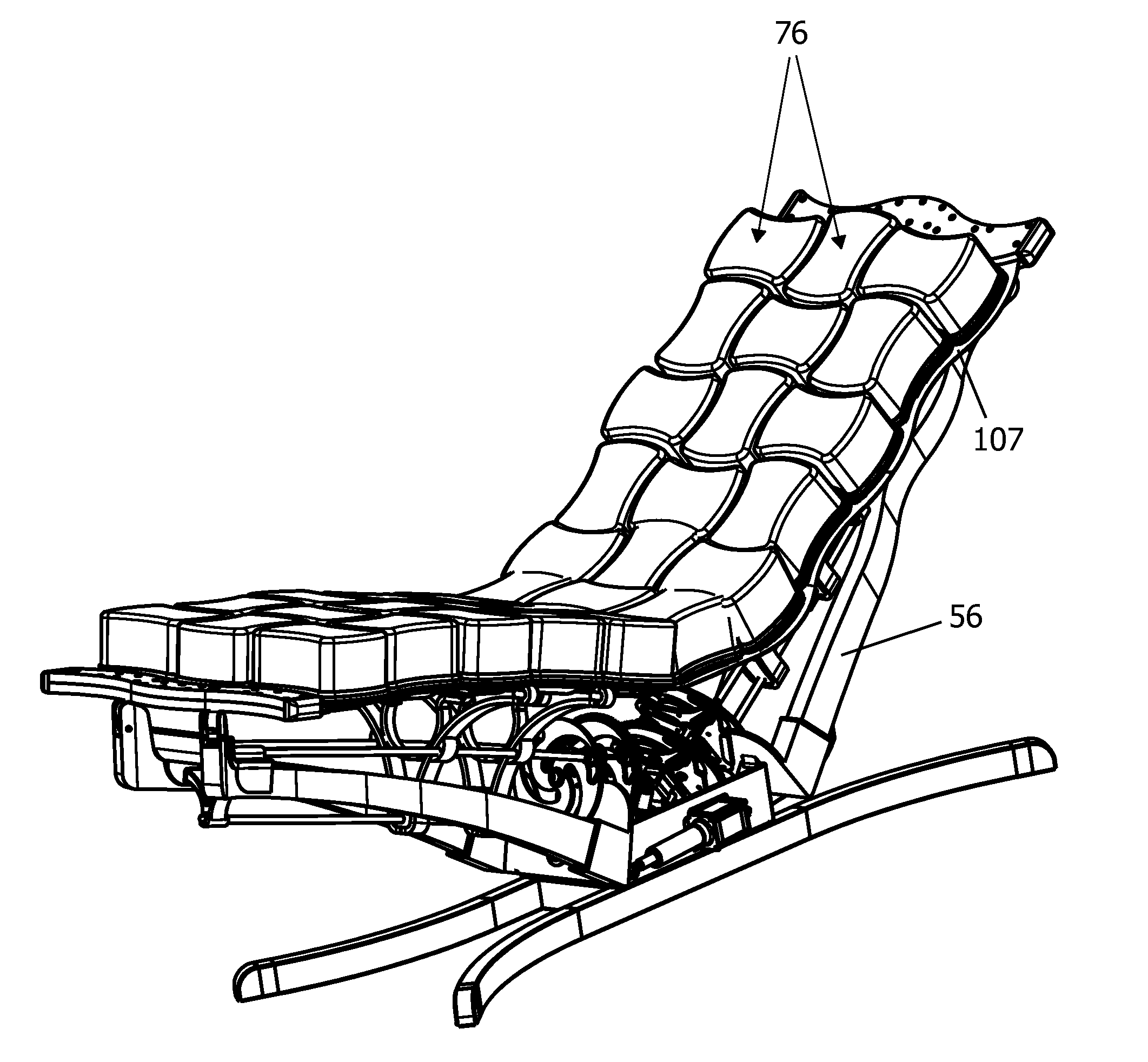

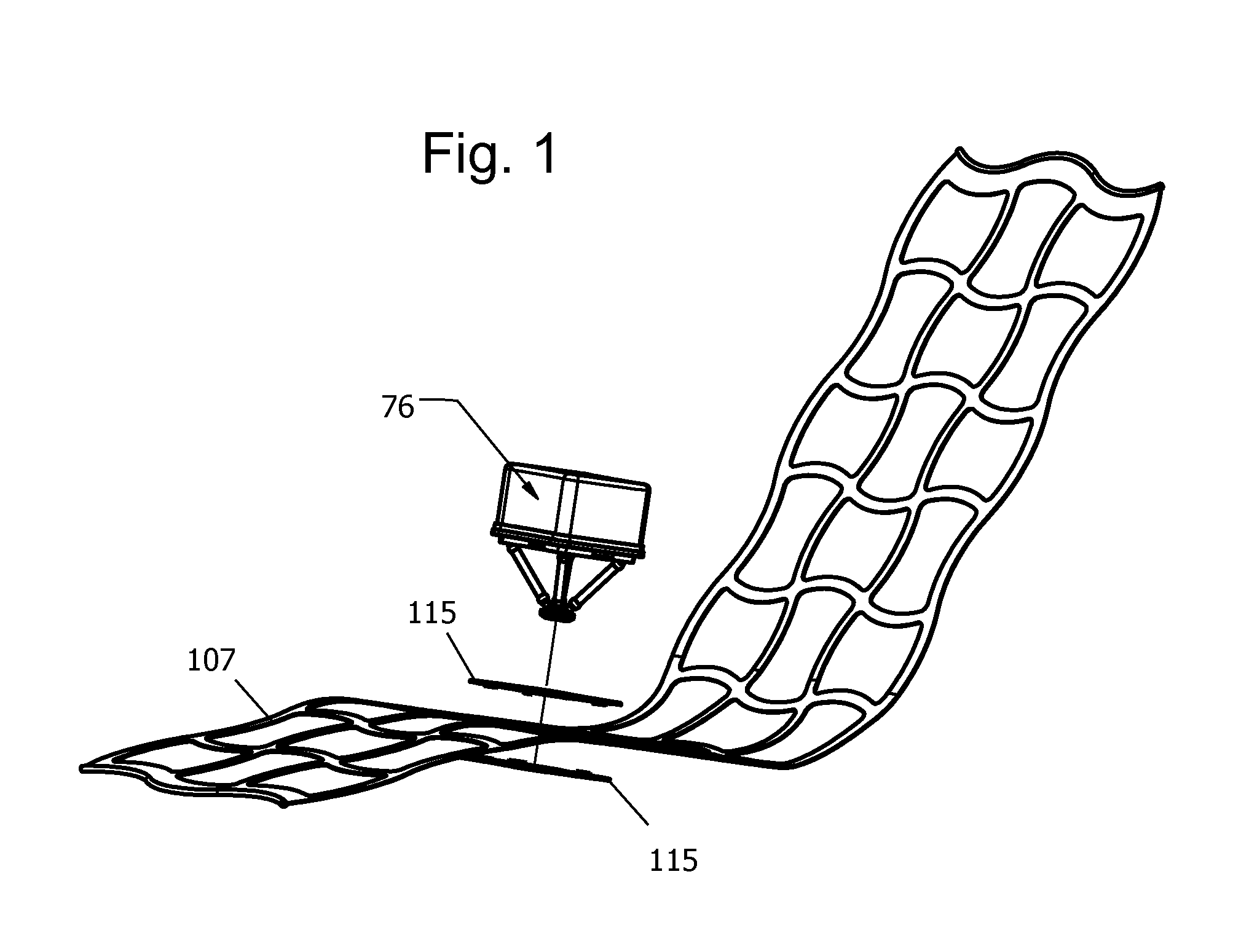

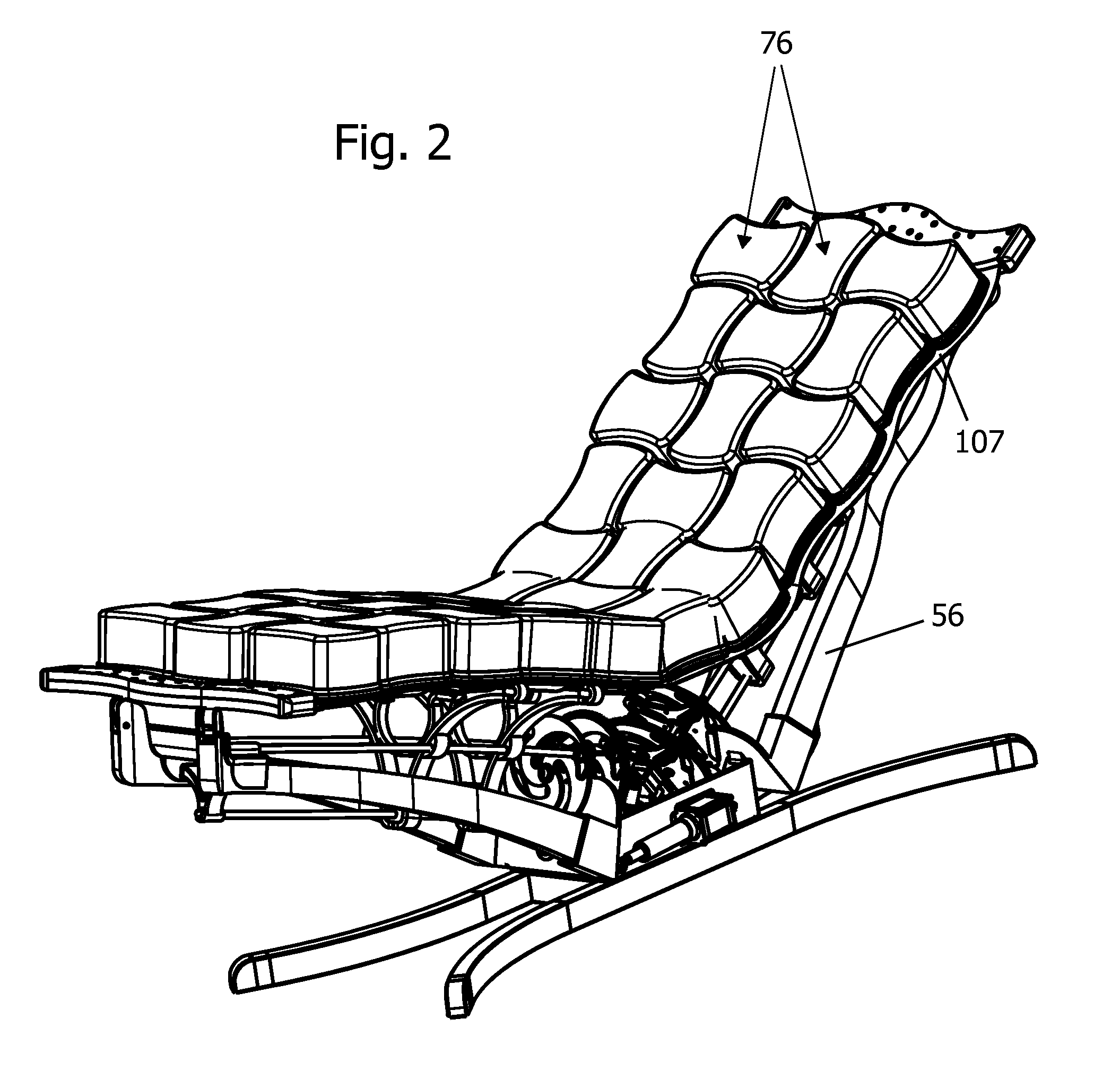

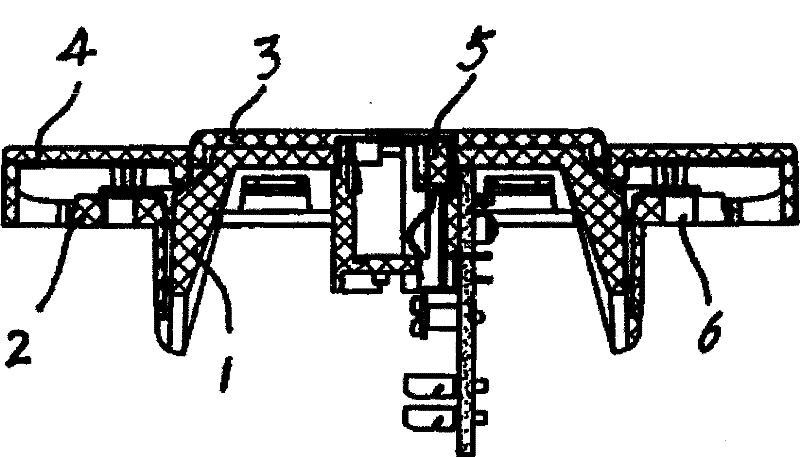

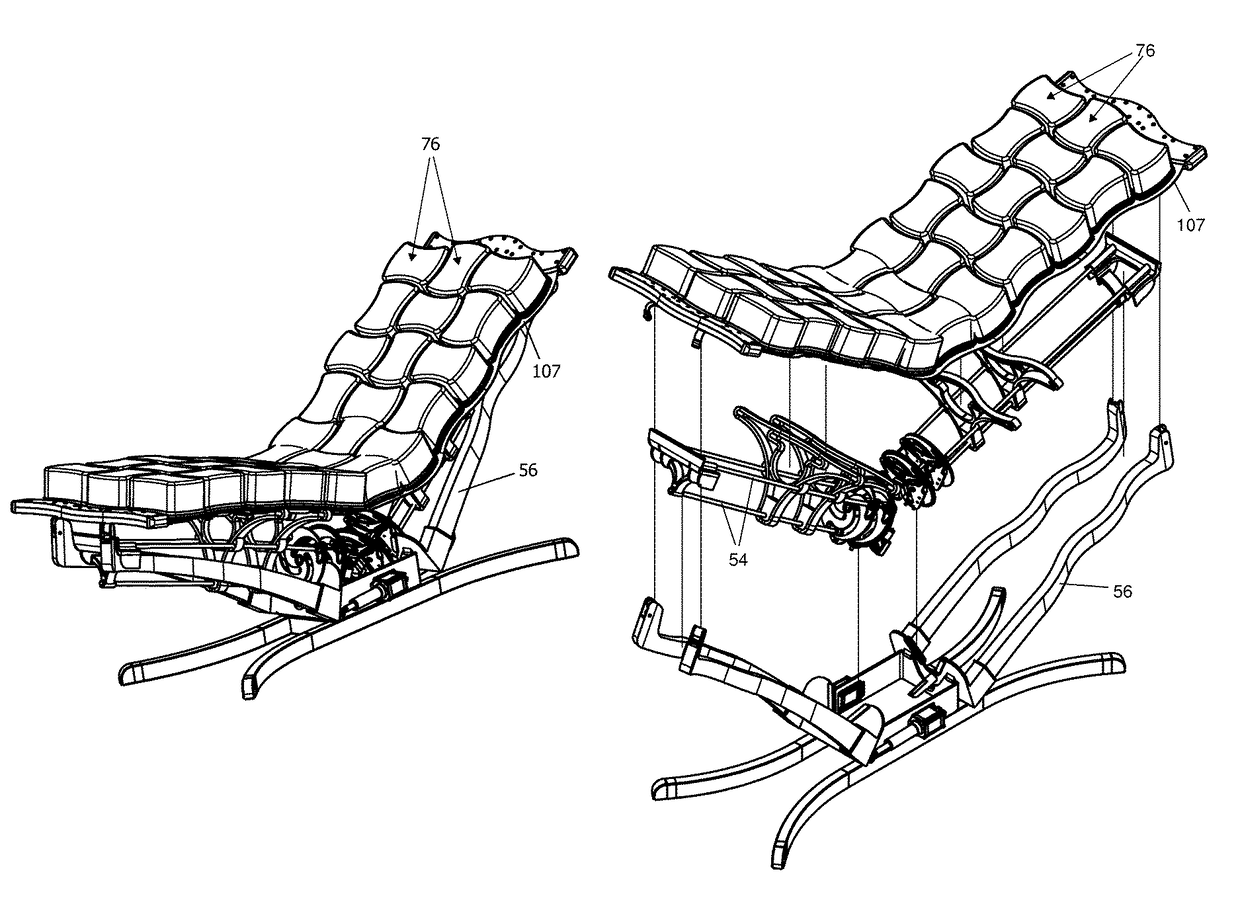

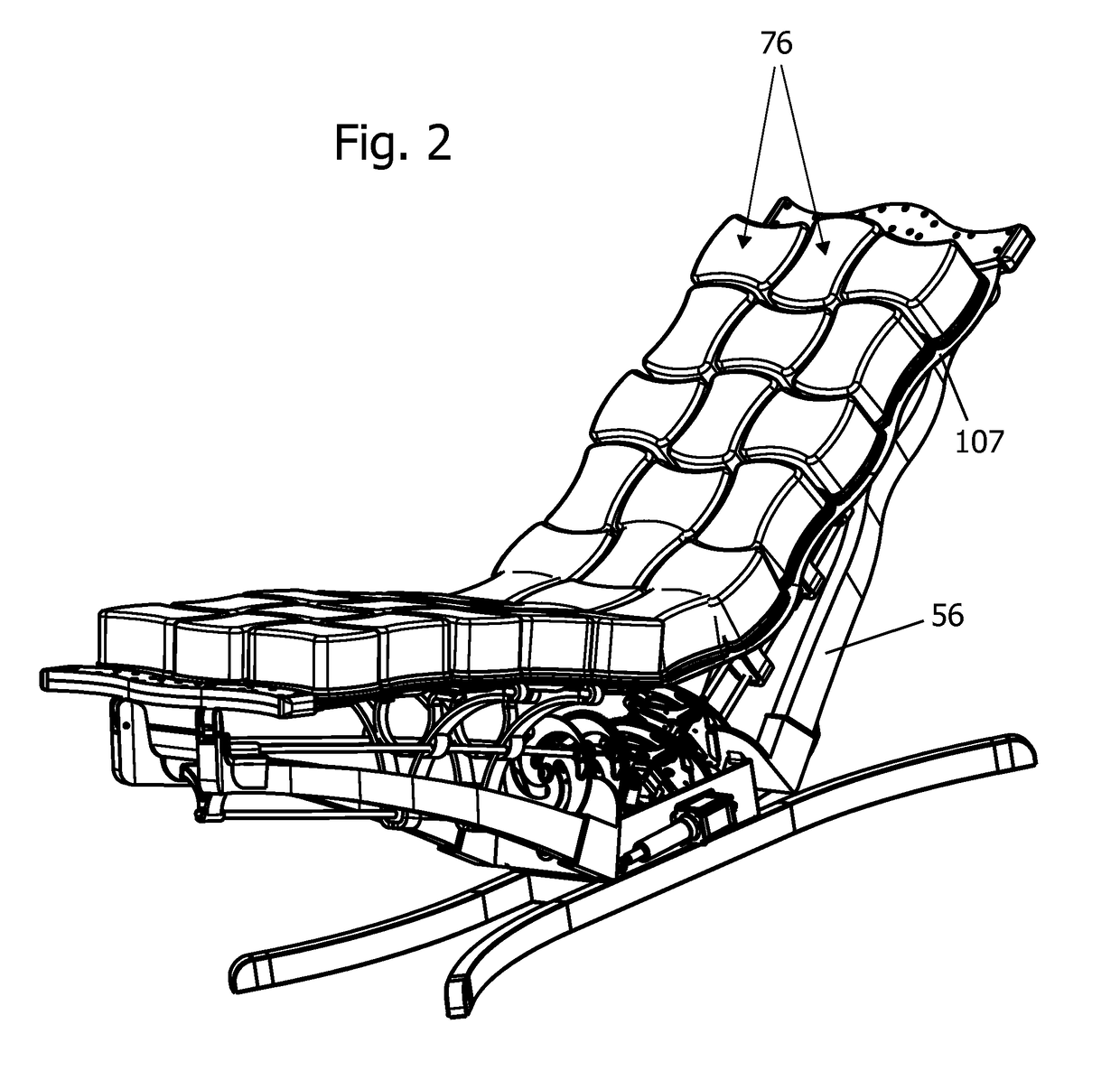

Multi layered modular support system for lounge and other applications

ActiveUS20160353893A1Great and less resistanceEasy to adjustDismountable chairsSpring mattressesSupporting systemComputer module

A lounge having a matrix mat and a plurality of modules capable of being inserted into the matrix mat. The lounge may include a frame configured as a rigid frame, a modular frame, and combinations thereof. The modular frame may further include a tri-cable suspension. The tri-cable suspension may be attached to a dilator retractor mechanism. The modules may be a mushroom cap module, a spider spring module, a web module, a lighting module, an electronics module, and combinations thereof.

Owner:MOLENDA DONALD J

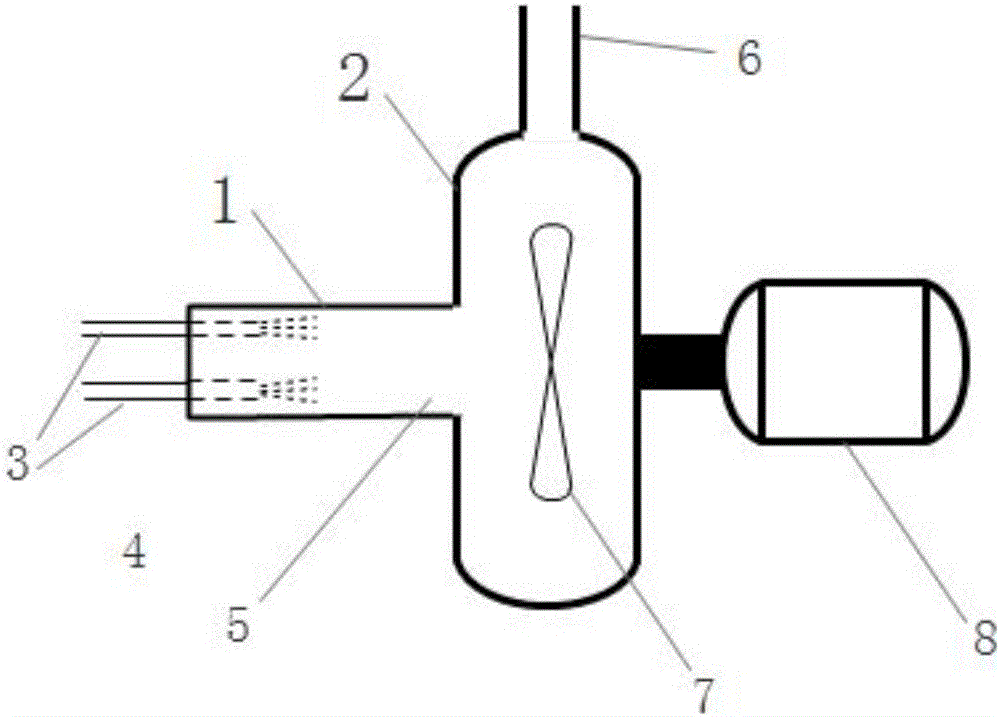

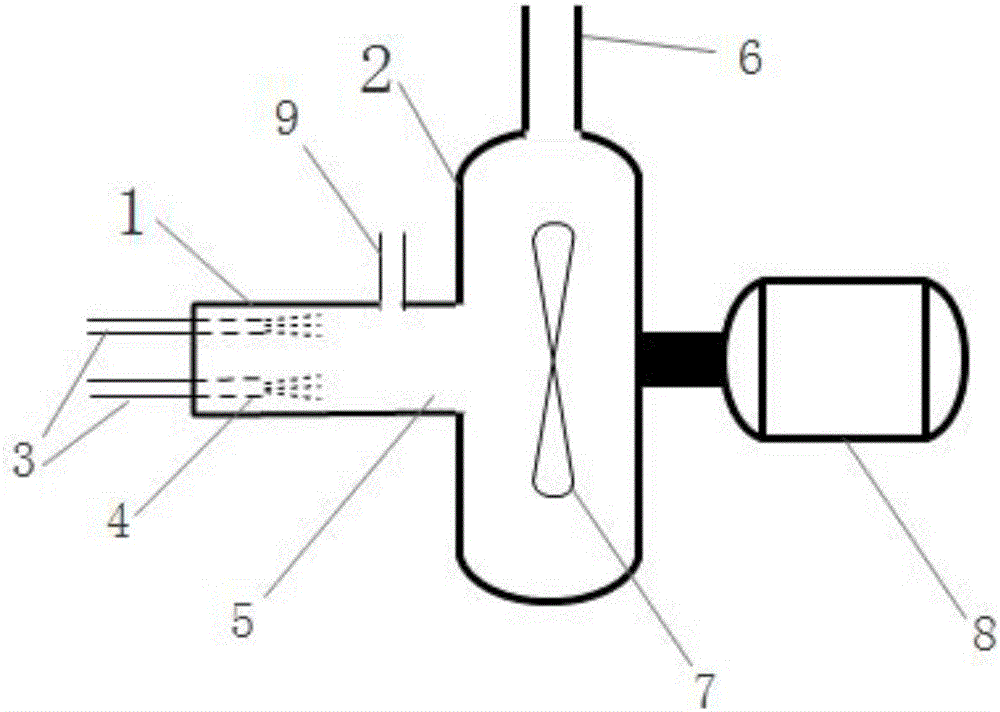

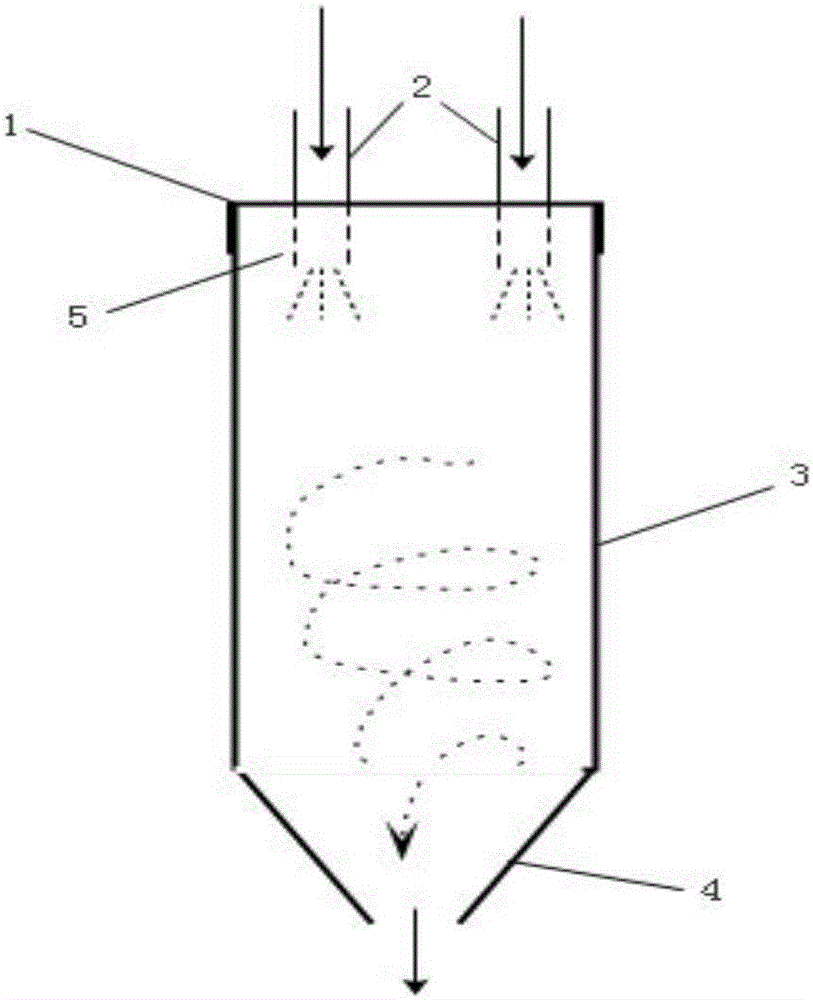

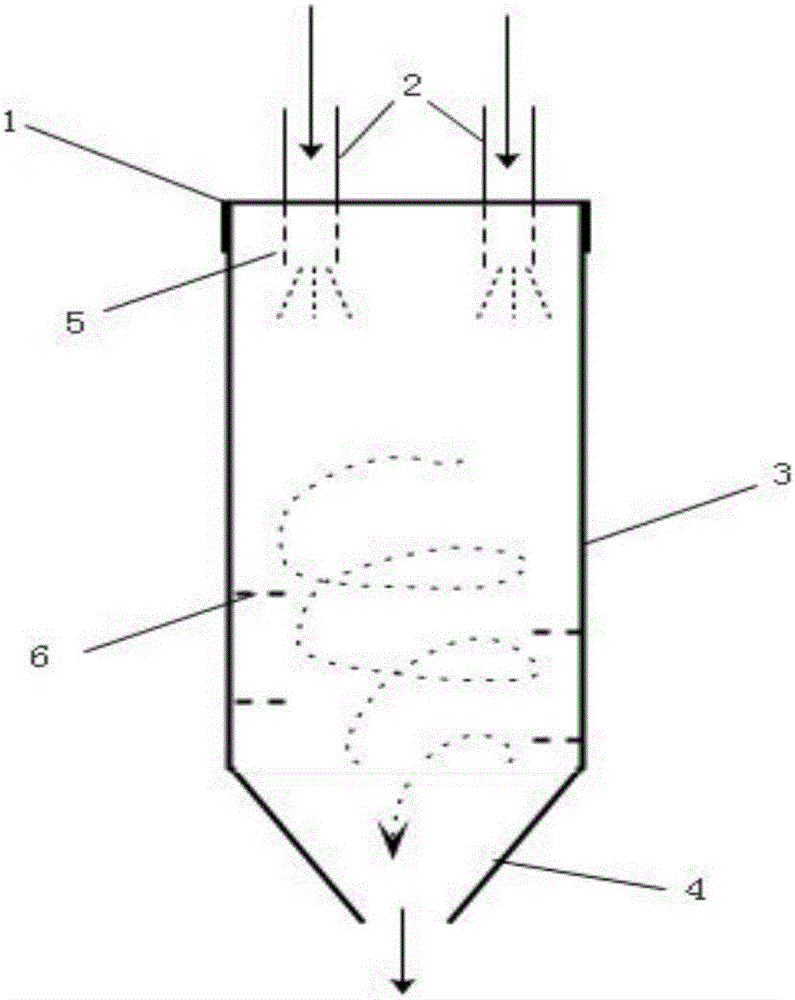

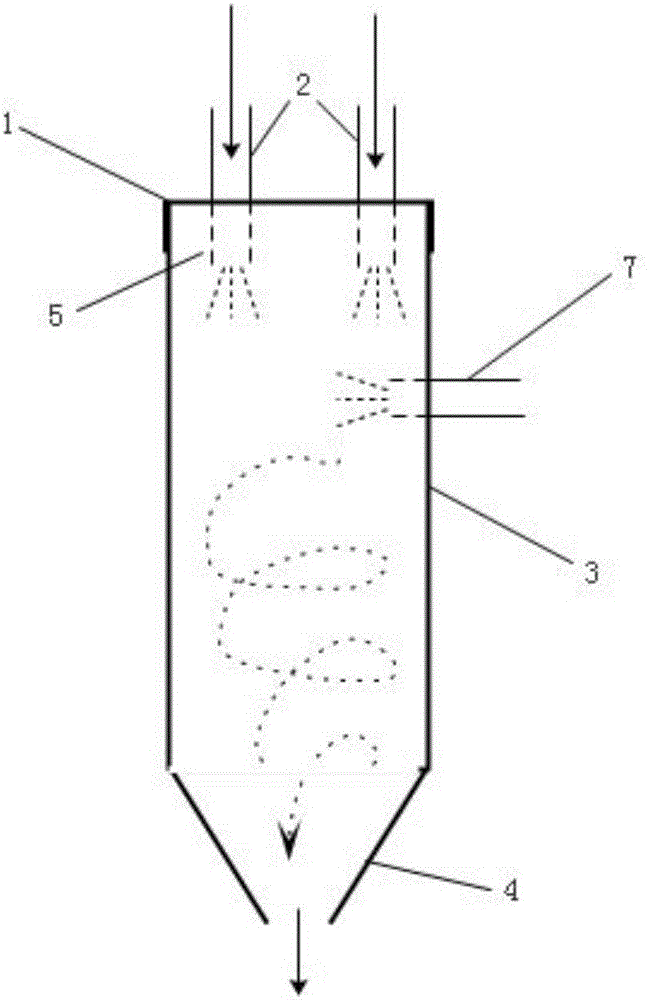

Chemical device and method for preparing ultra-fine rare earth compound through device

The invention provides a chemical device and a method for preparing an ultra-fine rare earth compound through the device. The device comprises a feeding unit (1) and a stirring unit (2), the stirring unit (2) is provided with an airtight cavity provided with an inlet (5) and an outlet (6), and a stirring impeller (7) is disposed in the cavity; the feeding unit (1) is tubular, one end of the feeding unit is a feeding end, and the other end of the feeding unit is connected with the inlet (5) of the stirring unit (2). The feeding unit (1) is provided with at least two feed inlets (3), and the tail end of each feed inlet (3) is provided with a nozzle (4). Rare earth feed liquid and a precipitator enter the feeding unit from different feed inlets (3) and the nozzles (4) of the feeding unit (1), are stirred by the stirring impeller (7) at high speed, react with each other and then are sprayed out through the outlet (6). The obtained slurry is filtered, washed, dried or fired, and the ultra-fine rare earth compound is obtained. The device is small and simple in structure, convenient to manufacture and use, easy to clean and capable of being used for preparing the ultra-fine rare earth compound with D50 smaller than or equal to 1 micrometer, and parts are easy to replace.

Owner:QIANDONG RARE EARTH GRP

Electronically controlled fuel injection valve

ActiveUS9181893B2Limiting fuel injectionEasy to replace partsElectrical controlDigital data processing detailsMachine partsControl signal

An electronically controlled fuel injection valve can control the time to inject fuel and the amount of fuel to be injected in response to a control signal independently from the operating condition of an engine unlike a traditional mechanical fuel injection valve. The electronically controlled fuel injection valve employs a control method for fuel injection that increases the force of lifting up a cutoff needle of an injection controller by delivering high-pressure fuel to a lower pressure chamber via a control needle, thereby rapidly controlling fuel injection, has a simple structure making it easy to assemble, replace and precisely machine parts, and has a simple flow path structure which facilitates fabrication.

Owner:HYUNDAI HEAVY IND CO LTD

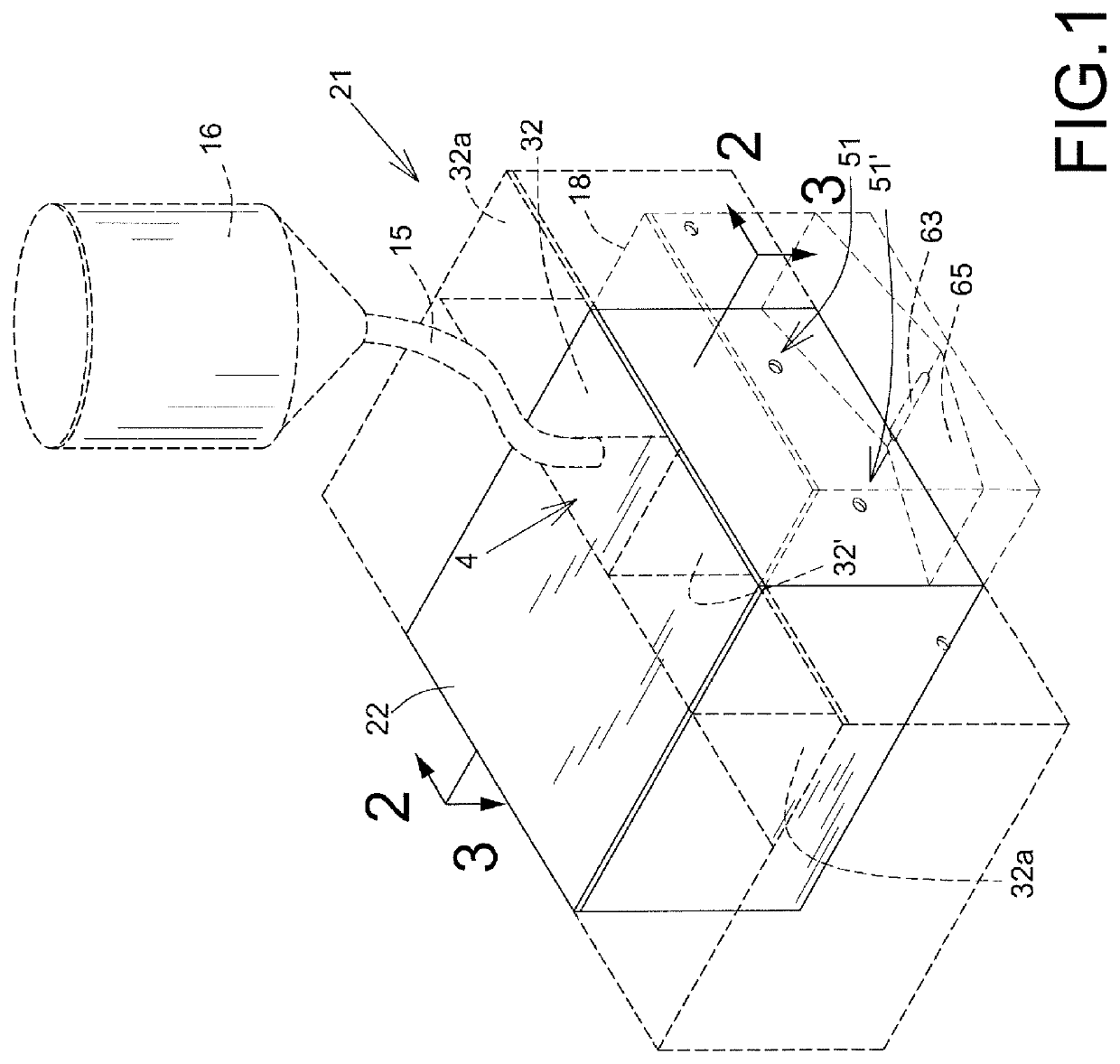

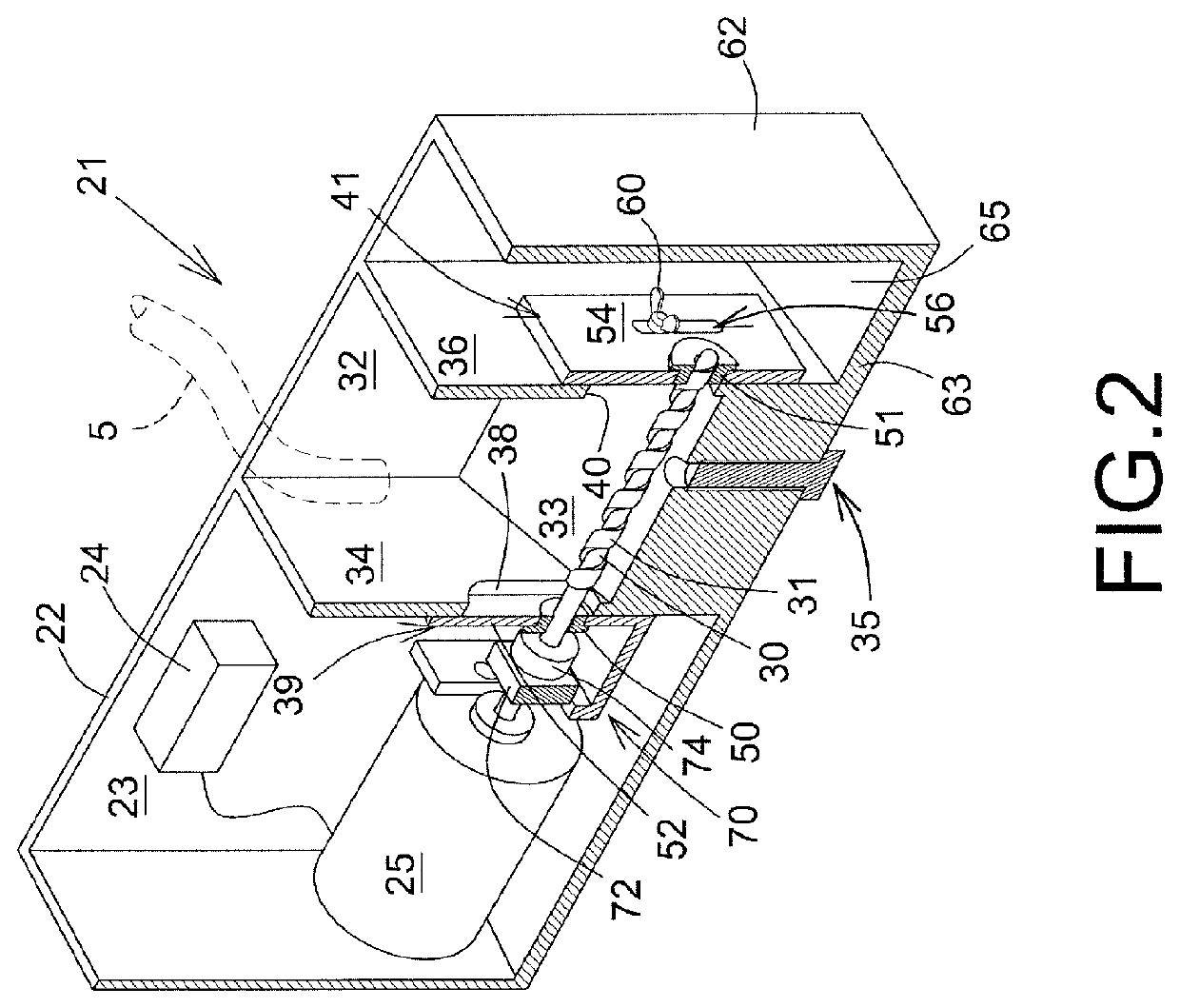

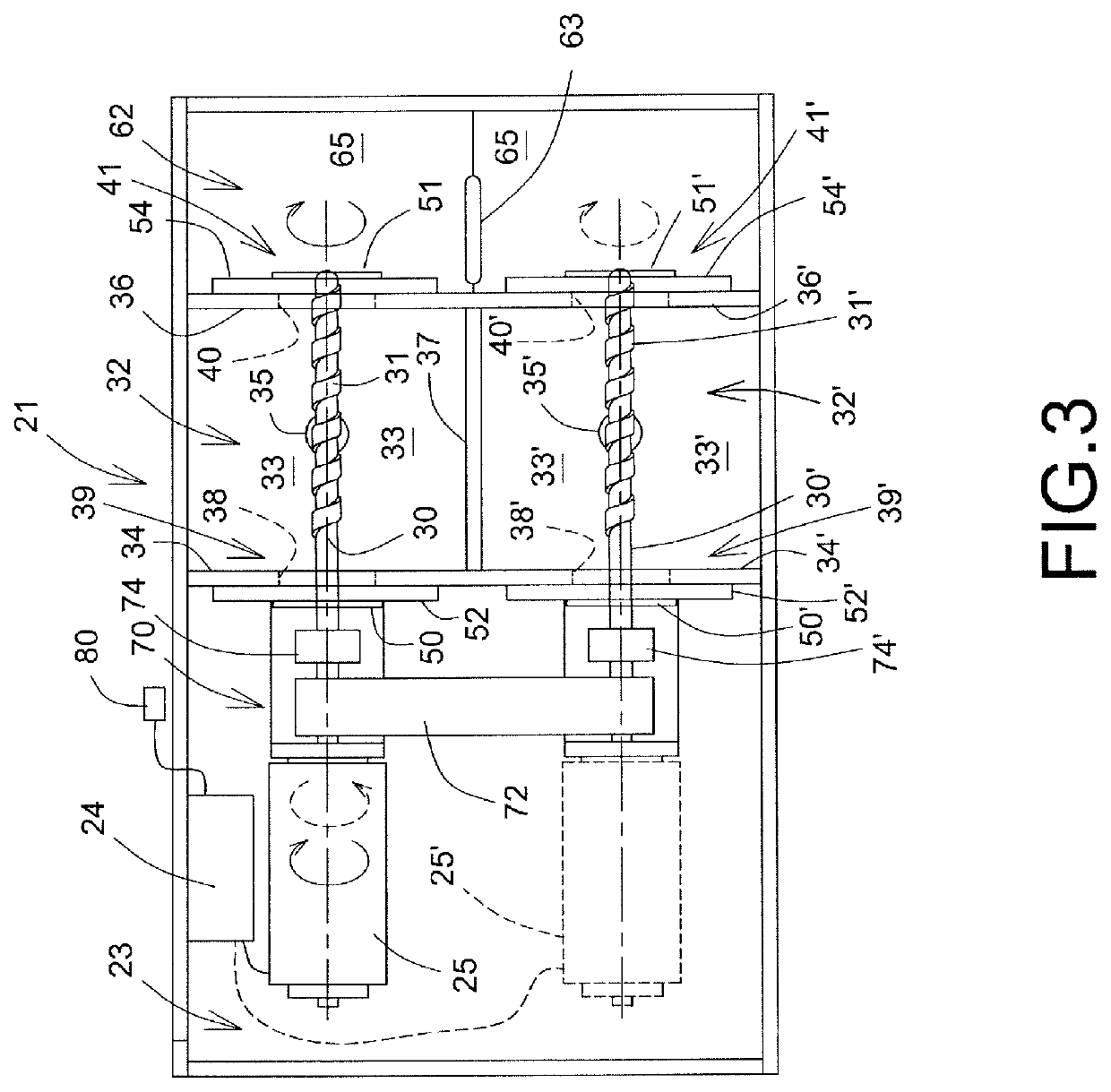

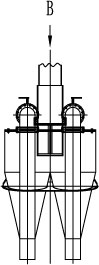

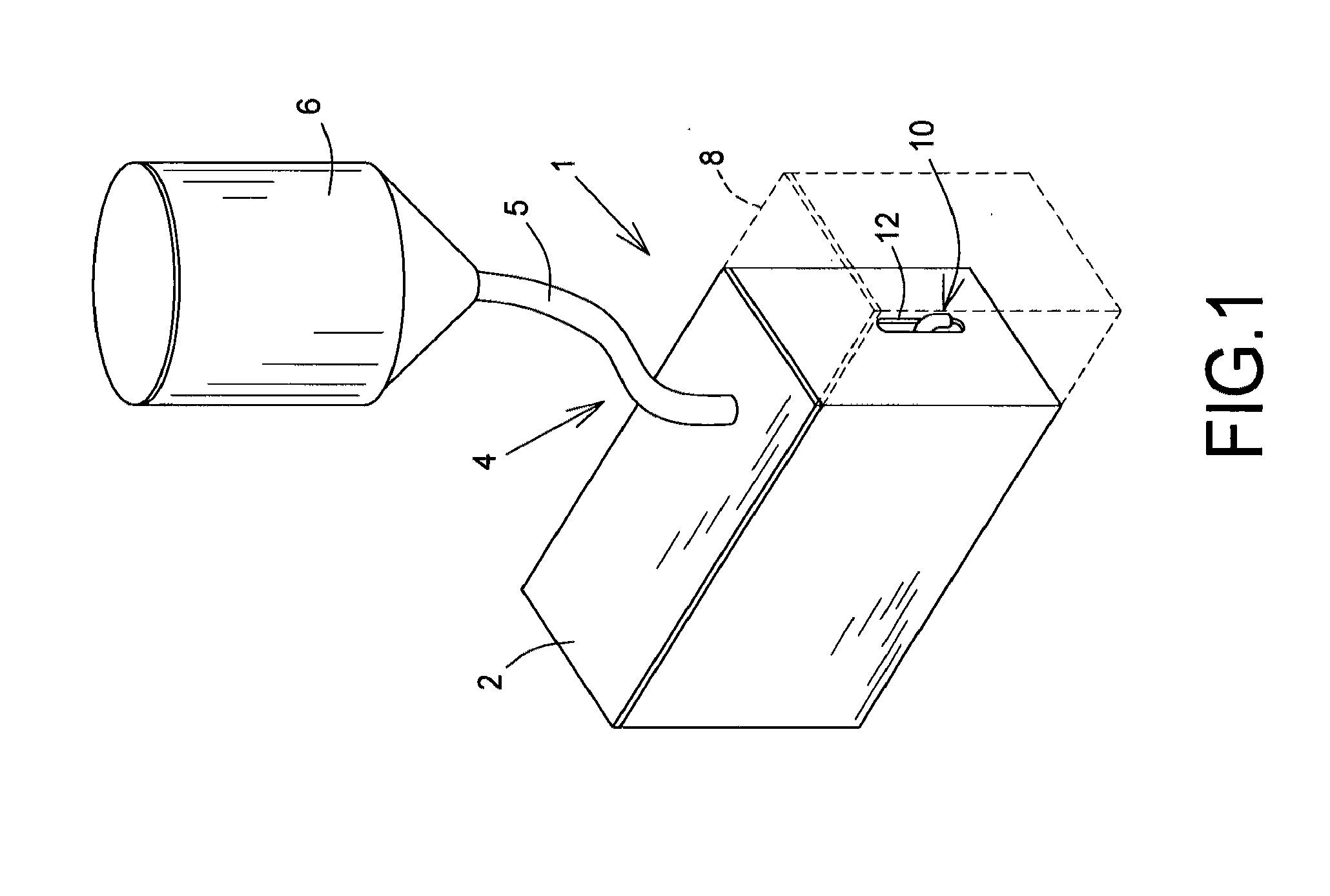

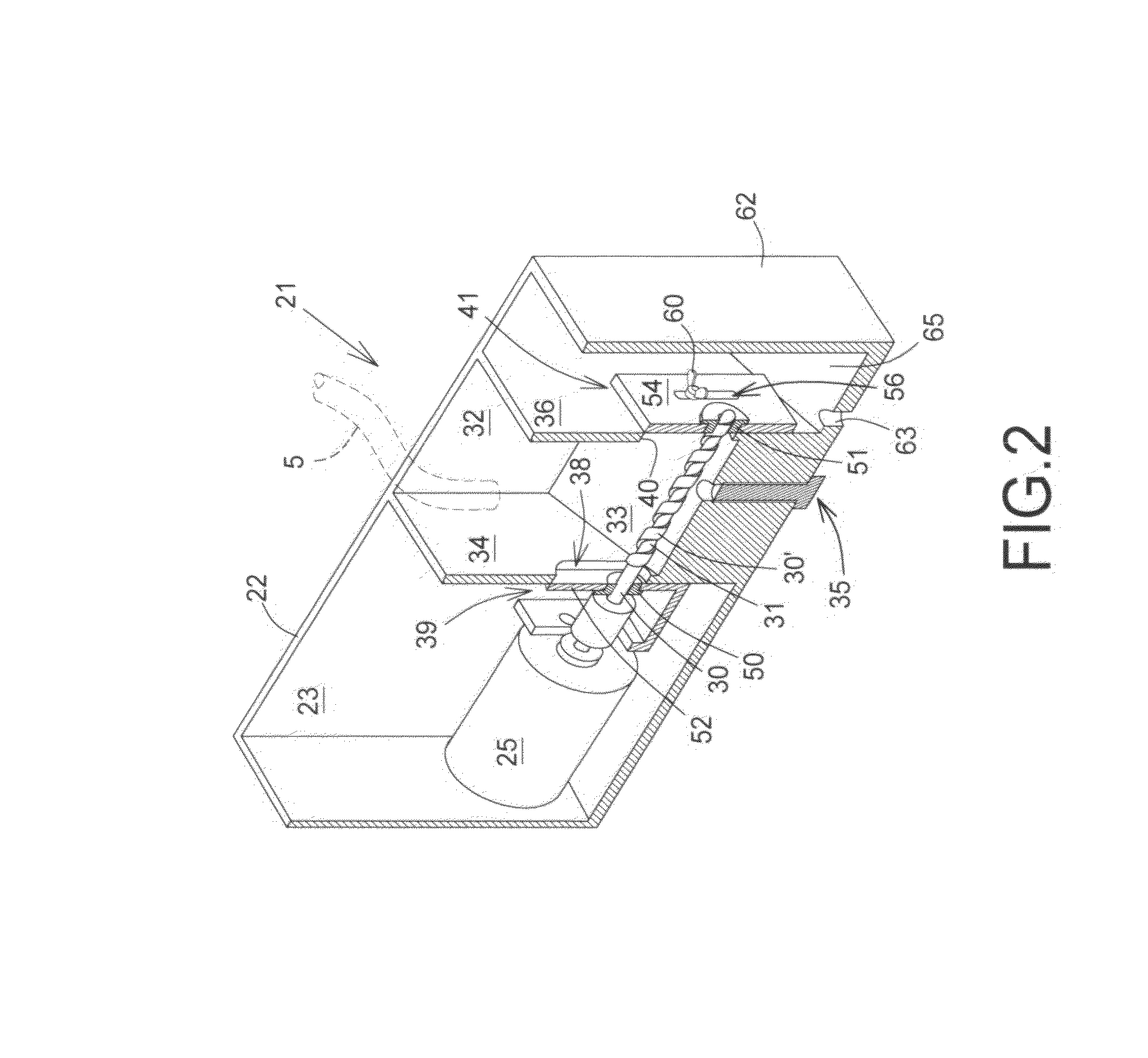

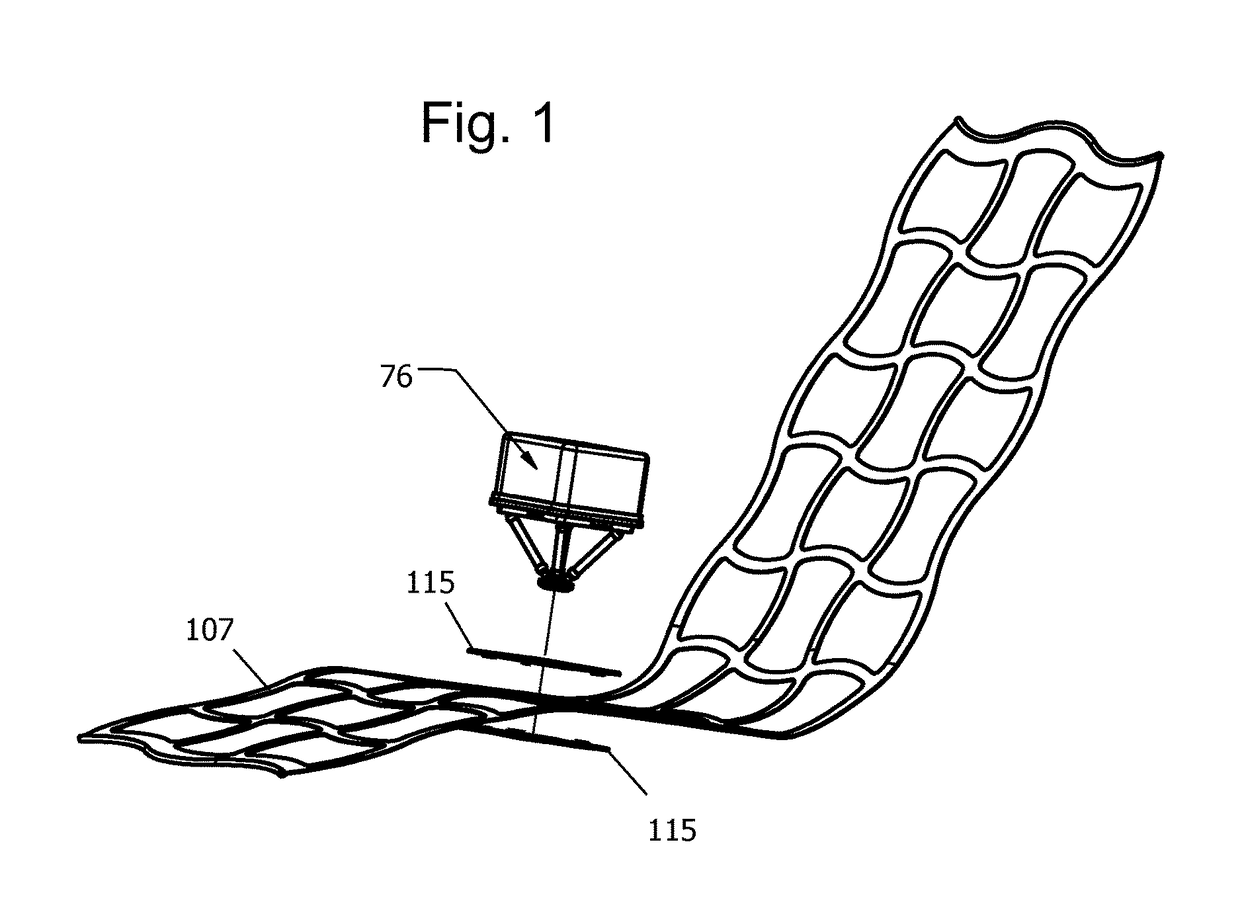

Multi-reservoir feeding apparatus

ActiveUS10940446B2Simple construction operationEasy to replace partsControl using synchronised pumpsFlow mixersEngineeringMechanical engineering

A multi-reservoir feeding / dosing apparatus for the delivery of at least two substances in discrete form includes first and second conveying elements in which the discharge end thereof are a close fit in a discharge bushing thereby to ensure that the correct dosage of each substance is discharged on a consistent basis. Each conveying element is in its respective reservoir. At least one motor drives both conveying elements, with each rotational direction of the motor actuating a corresponding one of the conveying elements.

Owner:CAVADISTRIB

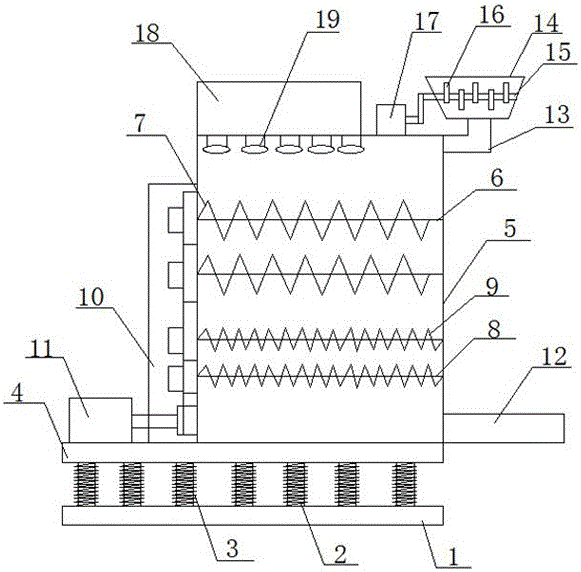

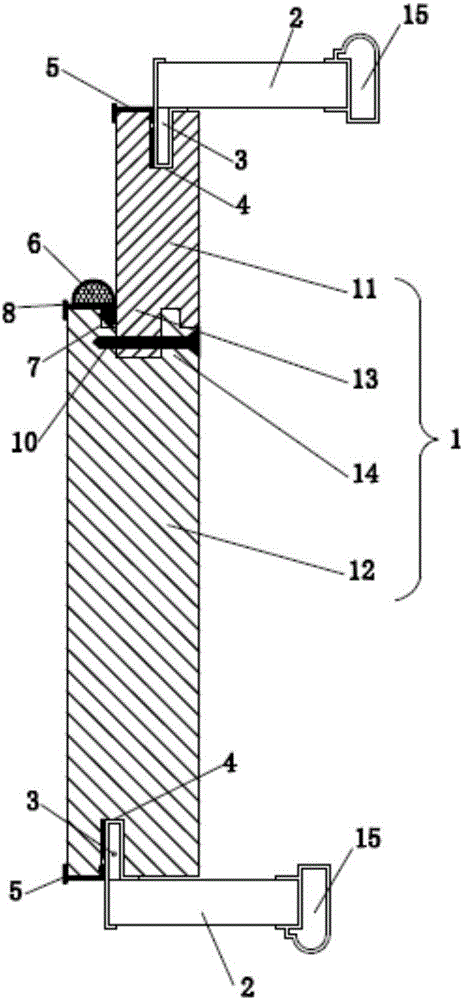

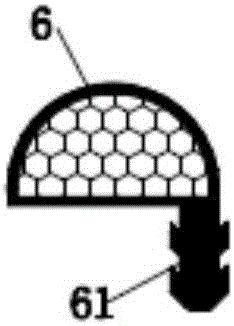

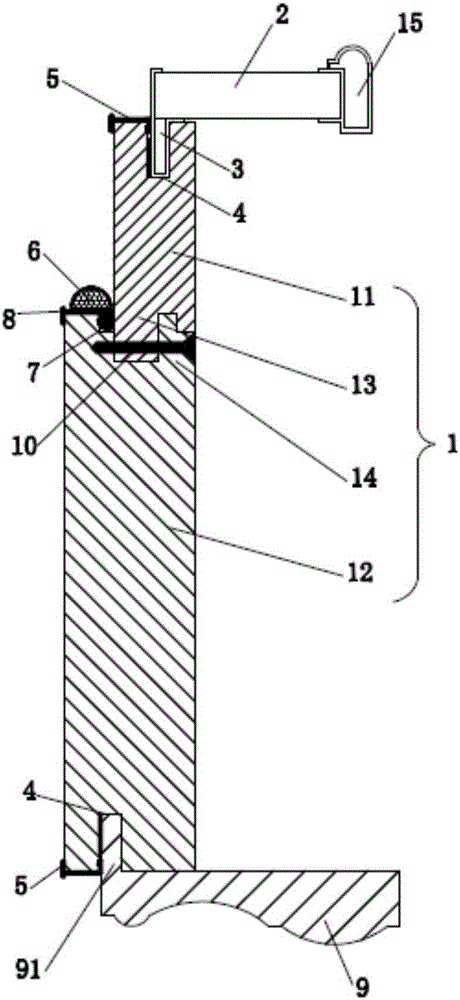

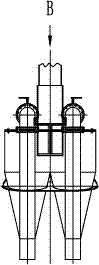

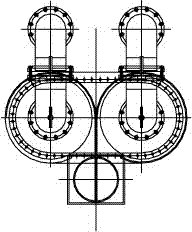

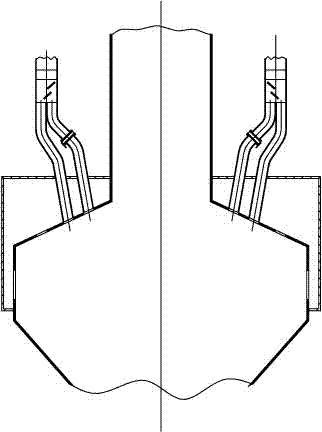

Simple rich-lean separation device arranged in W-flame boiler

ActiveCN101797562AImprove the effect of shade separationExtend furnace strokeGas current separationCoal pipelineEngineering

The invention discloses a simple rich-lean separation device arranged in a W-flame boiler, relates to the rich-lean separation device arranged in the W-flame boiler and solves the problems that the conventional rich-lean separation device for the W-flame boiler has a plurality of components and a complex structure and occupies a large space. In the simple rich-lean separation device, a rich-lean separation plate (13) is fixedly arranged on the inner wall of a pulverized coal rich-lean separator (3); the upper end of an exhaust gas pipeline (7) and the upper end of a master dense pulverized coal pipeline (4) are both communicated with the lower end of the pulverized coal rich-lean separator (3); the exhaust gas pipeline (7) is positioned under the rich-lean separation plate (13); the master dense pulverized coal pipeline (4) is communicated with a pulverized coal equal divider (14); the lower end of the pulverized coal equal divider (14) is provided with dense pulverized coal pipelines (5); and the pulverized coal equal divider (14) is communicated with two dense pulverized coal pipelines (5). The device has a simple structure, saves the space, improves the reliability and spatial adaptability of a system and is applied in the technical field of burning of the W-type flame boiler.

Owner:HARBIN INST OF TECH

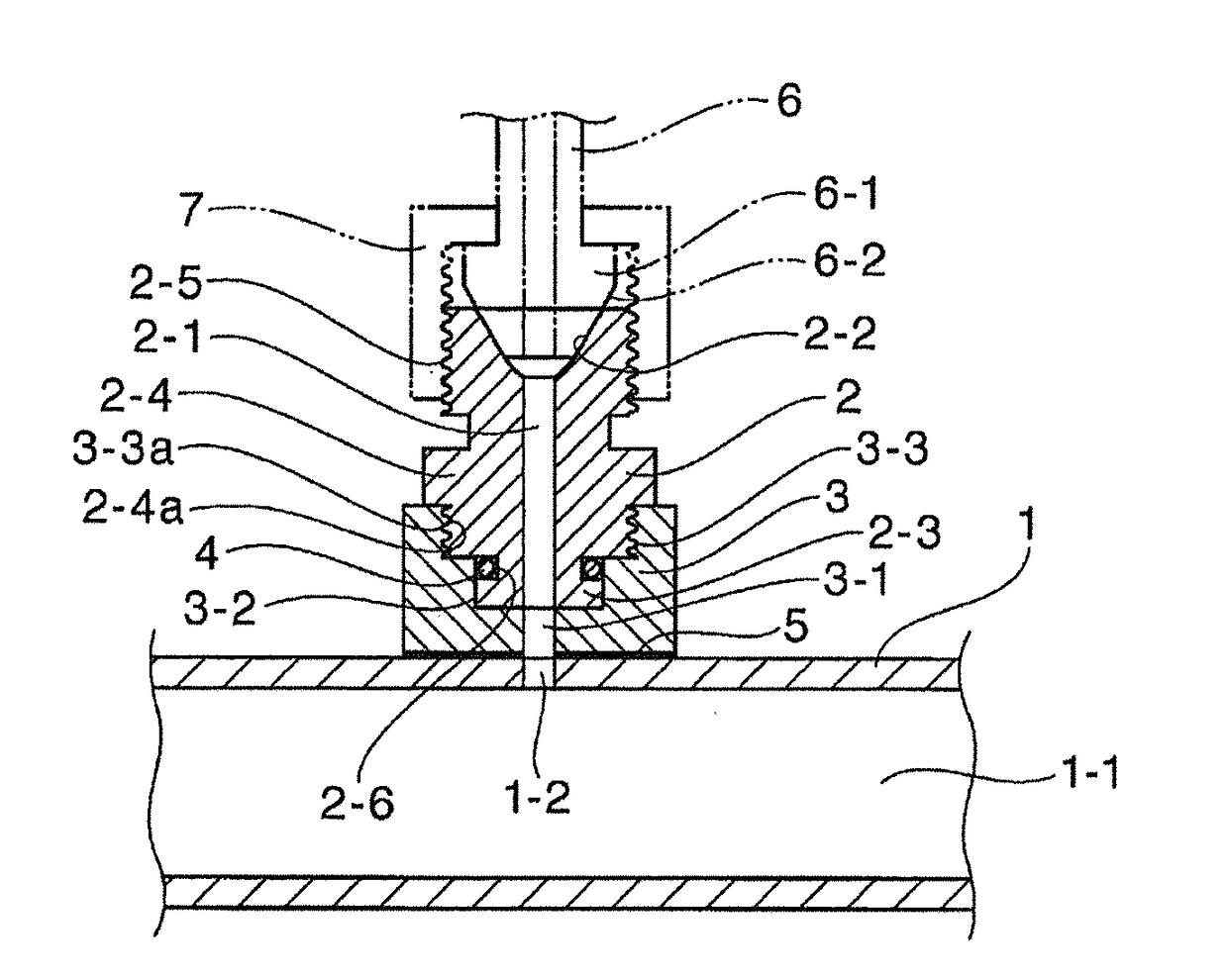

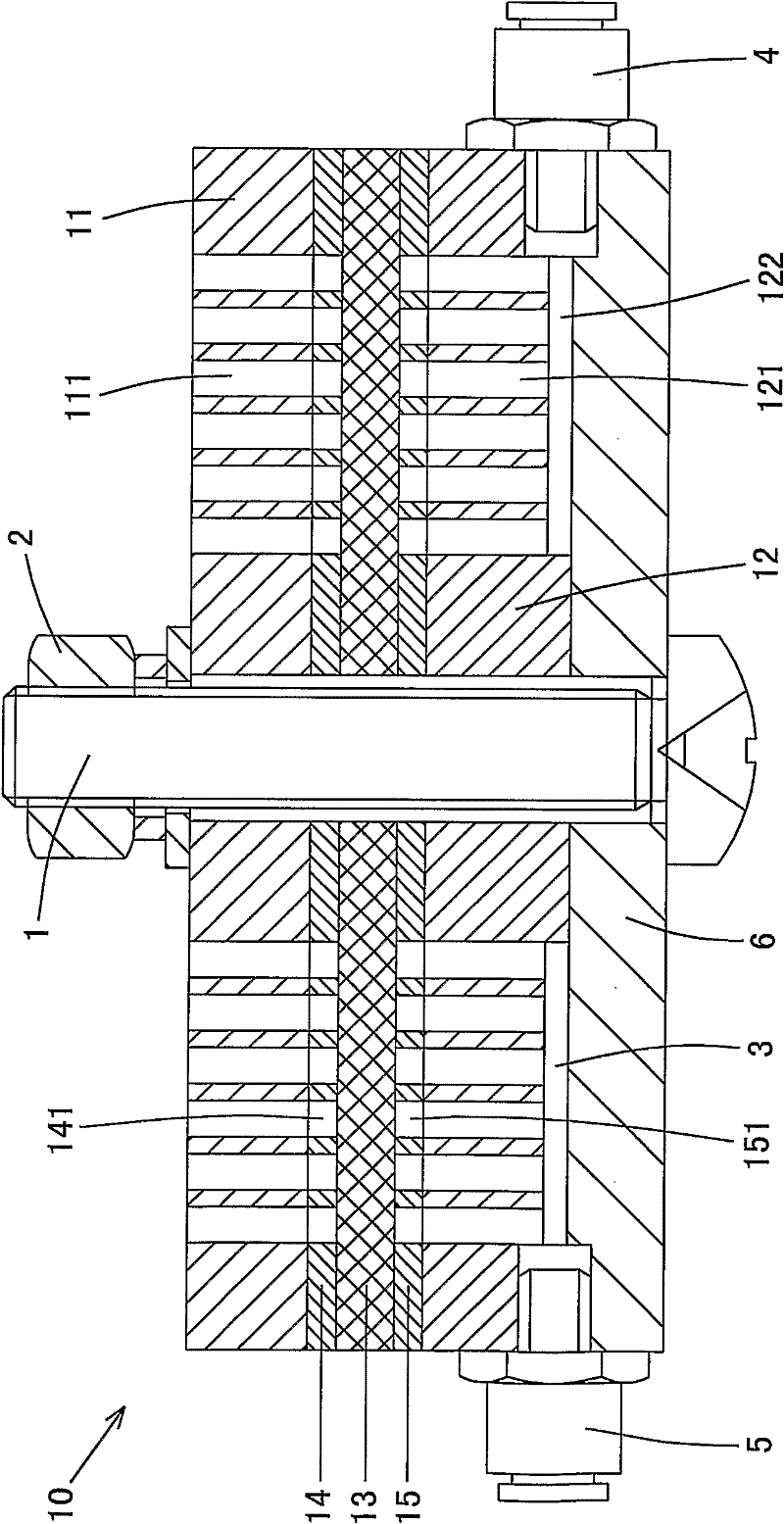

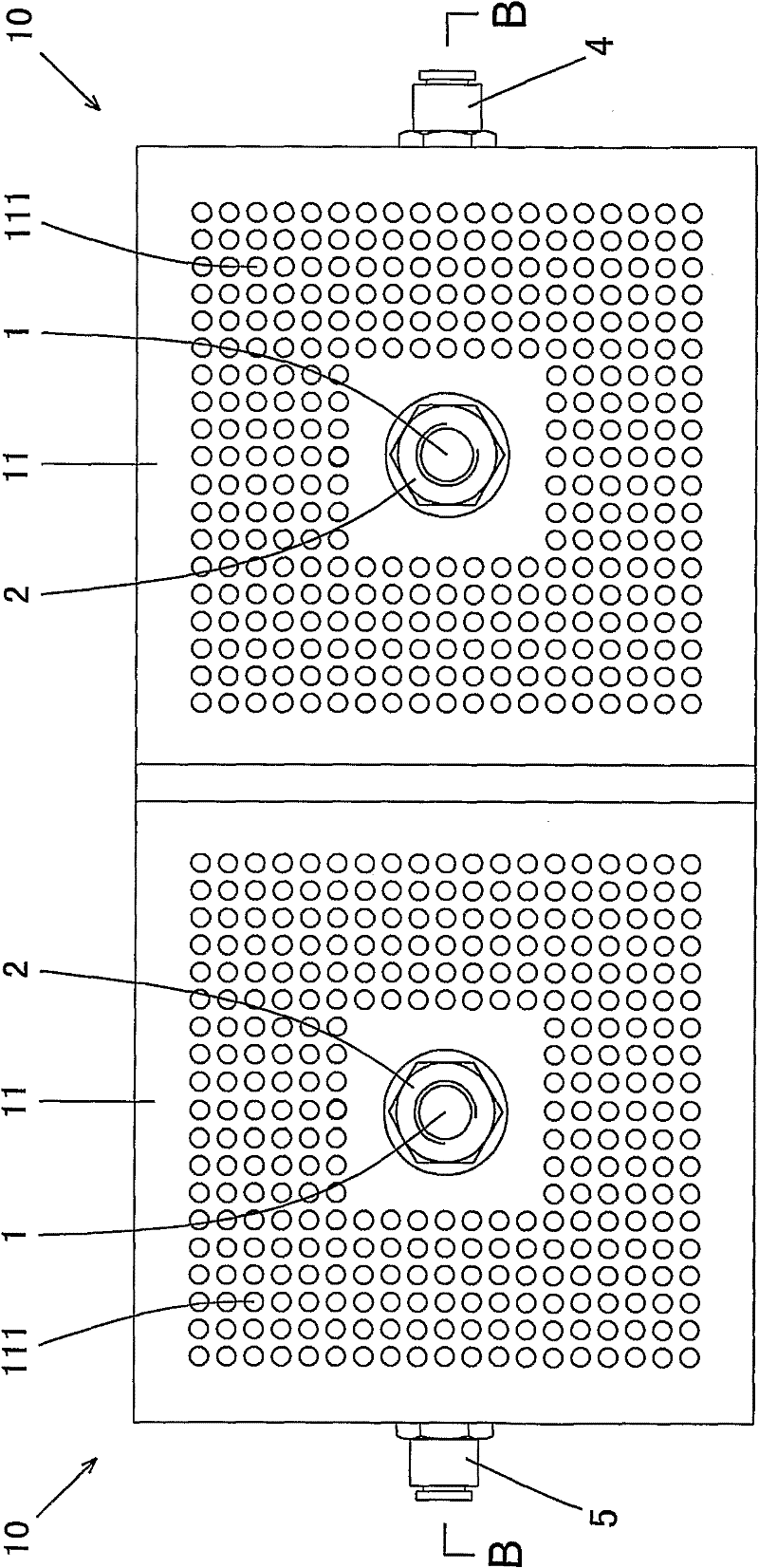

Electrical connection device

InactiveUS7972157B2Simple and safe mannerEasy to replace partsAssociation with control/drive circuitsWindingsElectricityElectrical connection

The present invention relates to an electrical connection device that connects a rotating electrical machine and an inverter within a housing. The electrical connection device is configured with a first bus bar connected to a terminal of the rotating electrical machine such that the first bus bar that is insulated from the housing, and a second bus bar that is connected to a terminal of the inverter device such that the second bus bar is also insulated from the housing. An insulating connection member is configured to connect the first bus bar and the second bus bar. The first bus bar and second bus bar are housed within the housing such that they face each other to form a gap between them. The connection member is configured to pass through a wall of the housing so as to electrically connect the first and second bus bars.

Owner:AISIN AW CO LTD

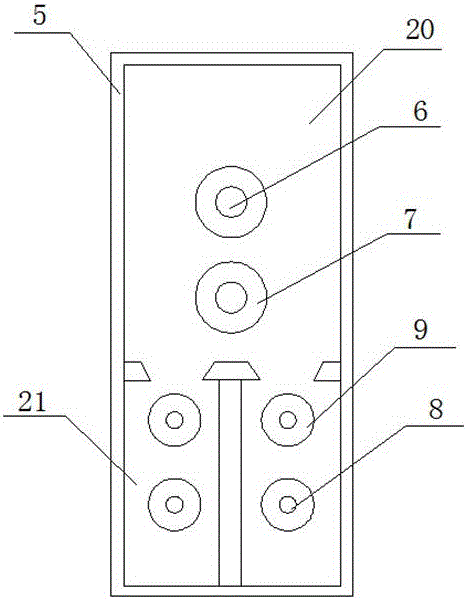

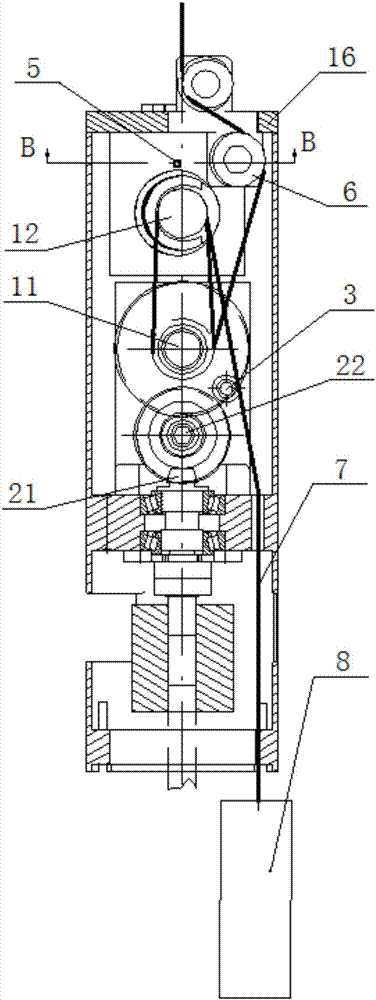

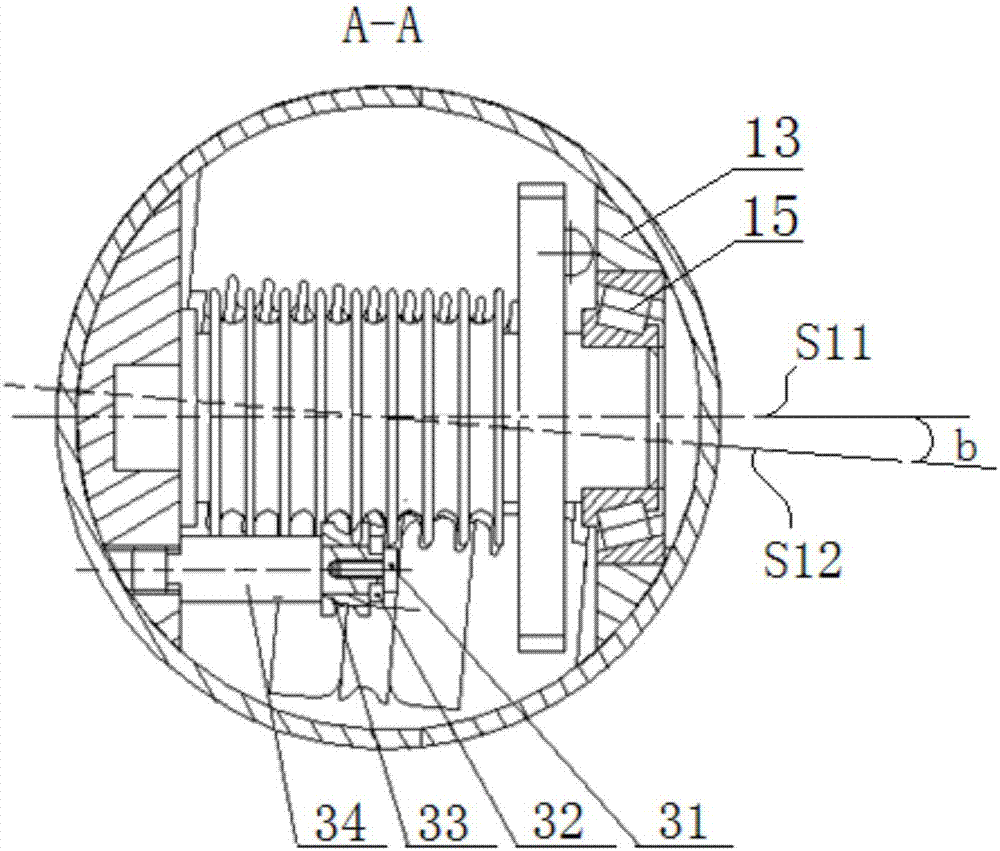

Force reduction mechanism of winch

PendingCN108002261ACompact structureOptimize space utilizationWinding mechanismsGearing detailsWheel and axleGear drive

The invention discloses a force reduction mechanism of a winch. The force reduction mechanism of the winch is composed of an upper guide wheel assembly, a lower guide wheel assembly, a shell, an uppercover plate, a driving bevel gear shaft, a transmission gear shaft, a lower grooved wheel shaft and an upper grooved wheel shaft, wherein the driving bevel gear shaft, the transmission gear shaft, the lower grooved wheel shaft and the upper grooved wheel shaft are sequentially arranged in the shell from bottom to top and integrally machined. The middle of the driving bevel gear shaft is installedon the annular inner edge of the shell. A driving bevel gear at one end of the driving bevel gear shaft is engaged with a driven bevel gear in the middle of the transmission bevel gear shaft, and theother end of the driving bevel gear shaft is connected with a power source. A driving straight gear at the end of the transmission gear shaft is engaged with a driven straight gear at the end of thelower grooved wheel shaft. Gear grooves are formed in the middle section of the lower grooved wheel shaft and the middle section of the upper grooved wheel shaft in parallel. The upper guide wheel assembly is installed on the upper cover plate to guide in a cable along the center line of the shell and then guide the cable to the lower grooved wheel shaft; and the lower guide wheel assembly is installed below the lower grooved wheel shaft and used for guiding the cable out from the upper grooved wheel shaft to a position away from a gear drive pair. The force reduction mechanism of the winch isof a long and thin structure and small in size and can provide a large load.

Owner:JILIN UNIV

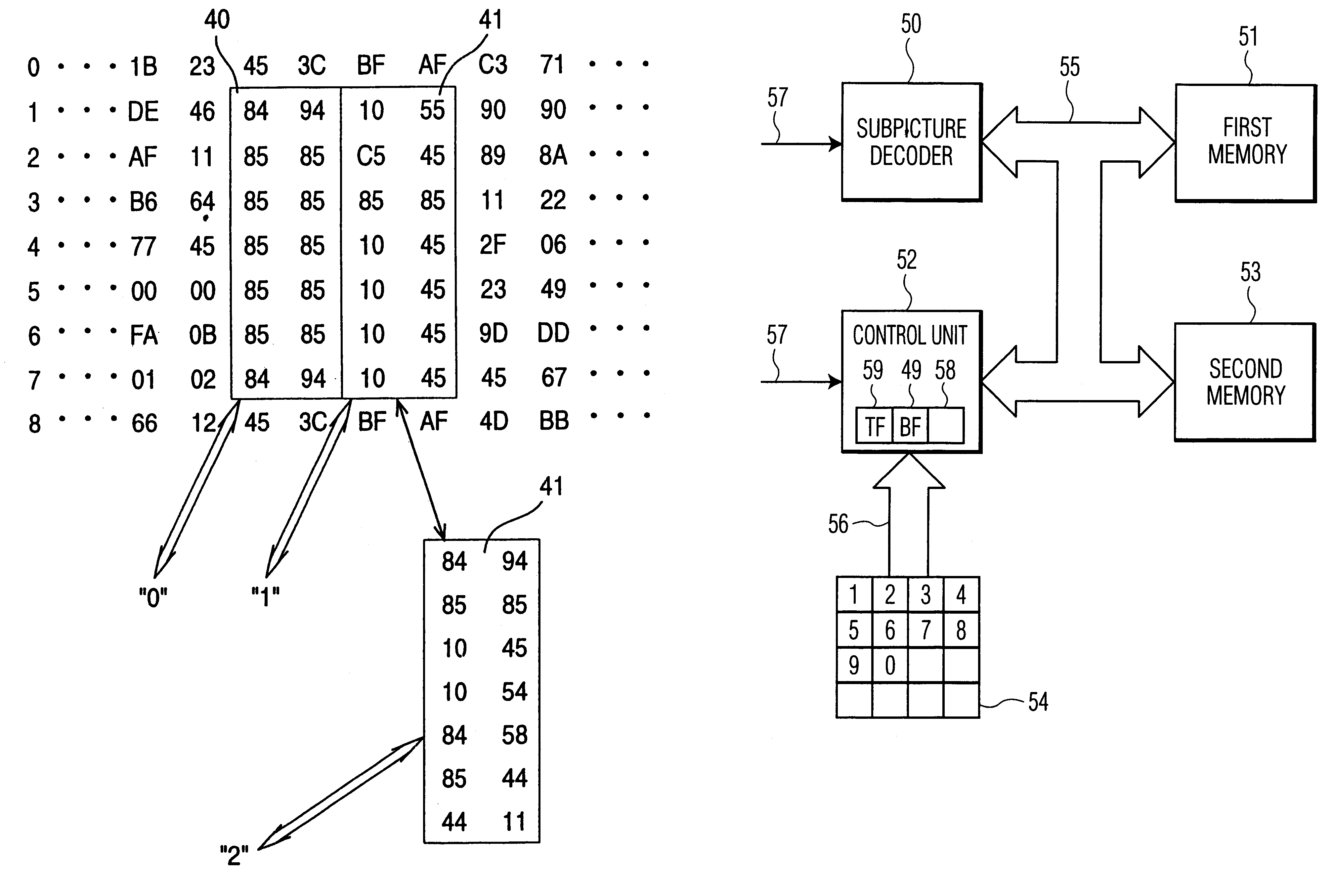

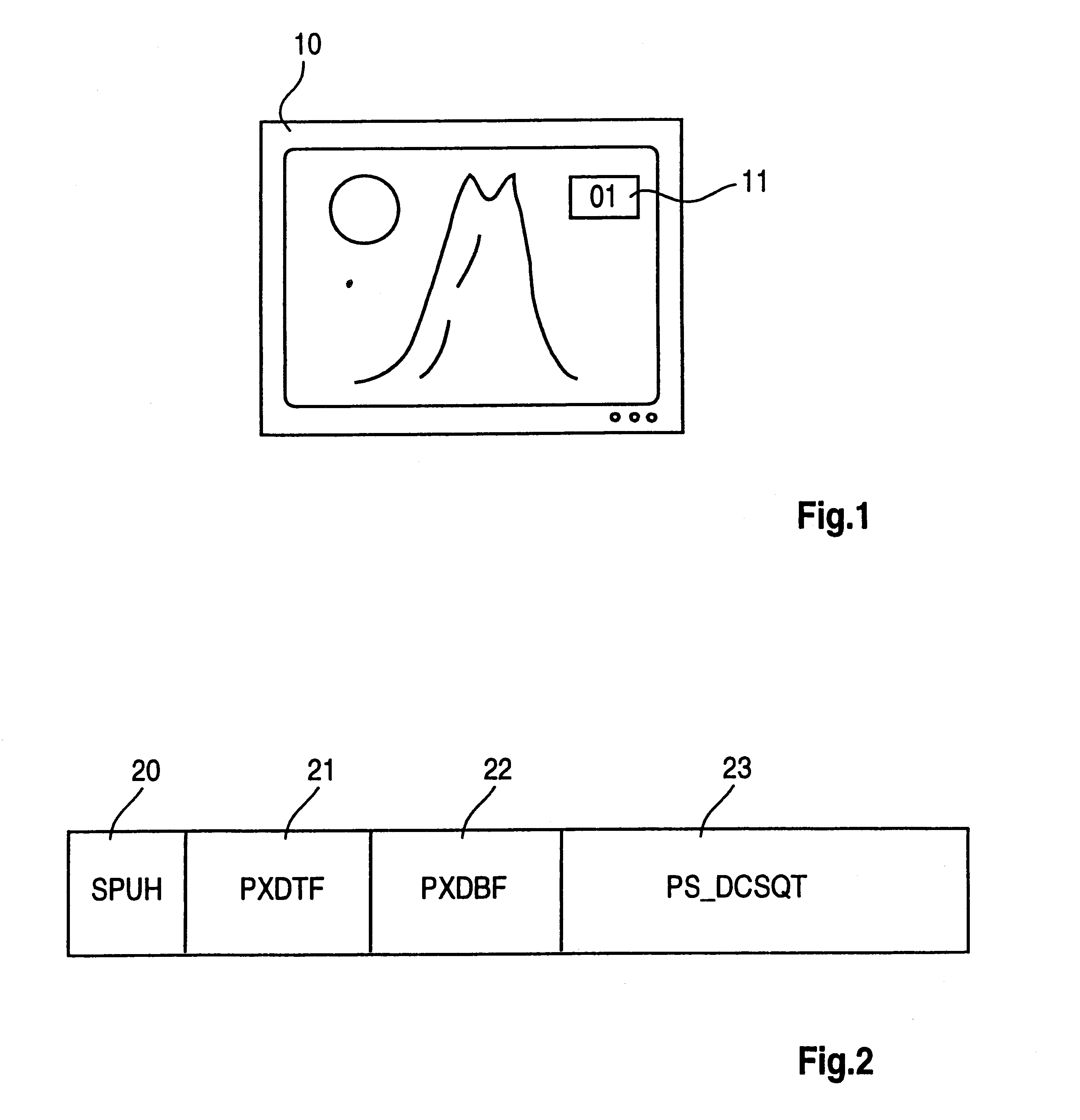

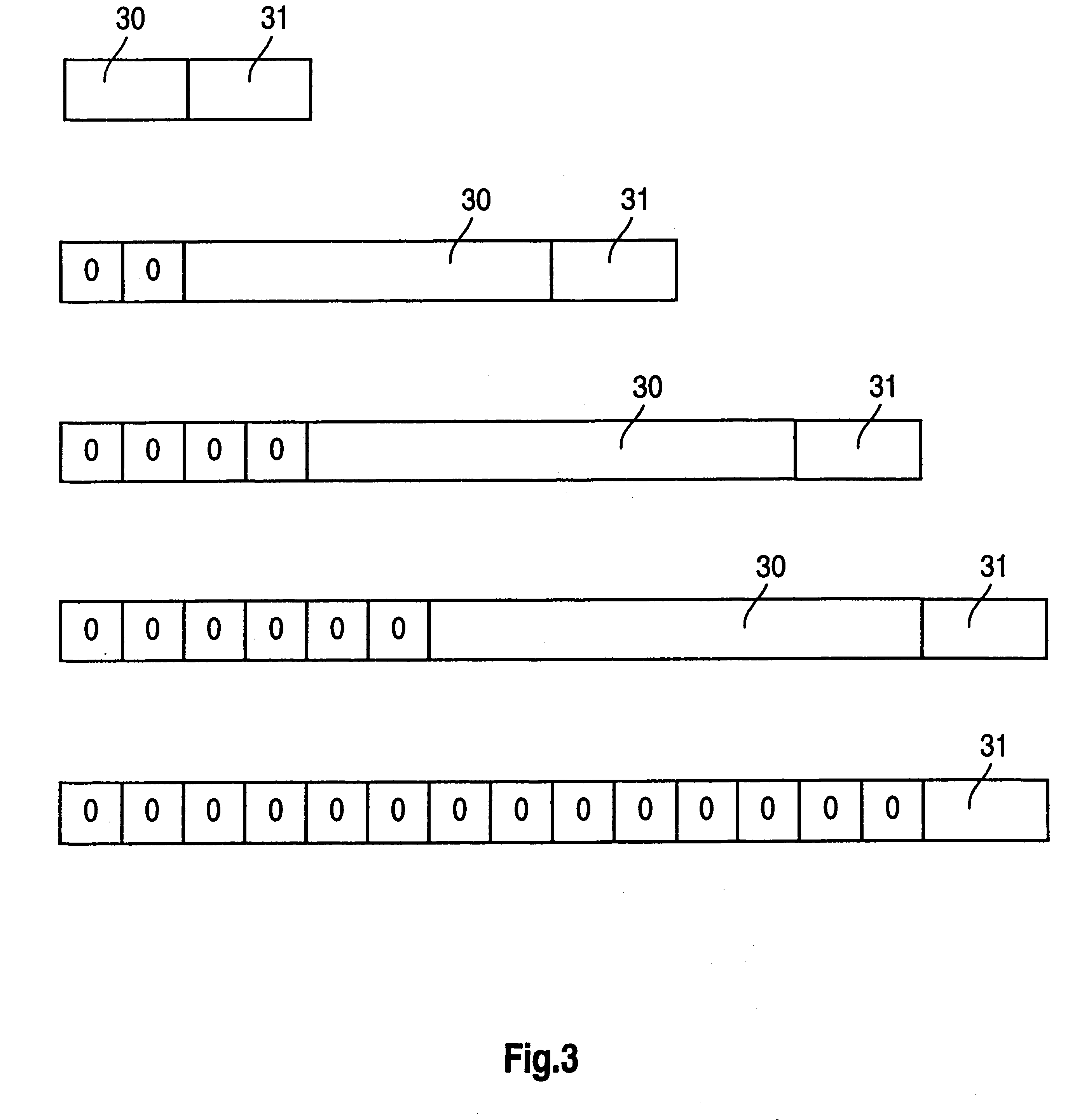

Method for replacing parts of a digitally coded picture, and device for carrying out the method

InactiveUS6233021B1Easy to replace partsConflict and incorrect displayTelevision system detailsPulse modulation television signal transmissionSoftware engineeringByte

A method for replacing parts of a digitally coded picture (11) is proposed. The digitally coded picture (11) may correspond to a sub-picture which is displayed on the screen of a television set (10). In the method, each line of the picture (11) is run length-coded. The replaceable parts of a line of the picture are run length-coded separately. The part which replaces the replaceable, original part of a line of the picture (11) is run length-coded in such a way that it has the same number of data units (data bytes) as the original part of this line of the picture (11). The replacement of the data for the run length coding words is carried out in a memory device (51). The replacement is possible in a simple manner by virtue of the fact that the original part of a line of the picture and the new part of the line of the picture have the same number of data units. Moreover, a device for carrying out the method is also proposed.

Owner:DEUTSCHE THOMSON-BRANDT GMBH

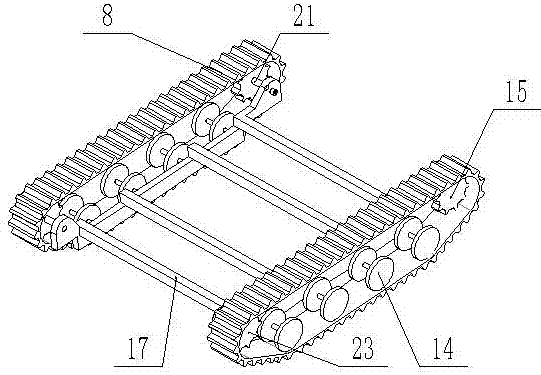

Agricultural remote control crawler multifunctional vehicle

InactiveCN100569576CEasy to replace partsEasy maintenanceJet propulsion mountingEndless track vehiclesDrive wheelVehicle frame

Owner:祝恩波

Reaction device and method for preparing superfine rare earth compound through same

InactiveCN106362657AReduce volumeEasy to useRare earth metal sulfatesRare earth metal chloridesRare earthEngineering

Owner:QIANDONG RARE EARTH GRP

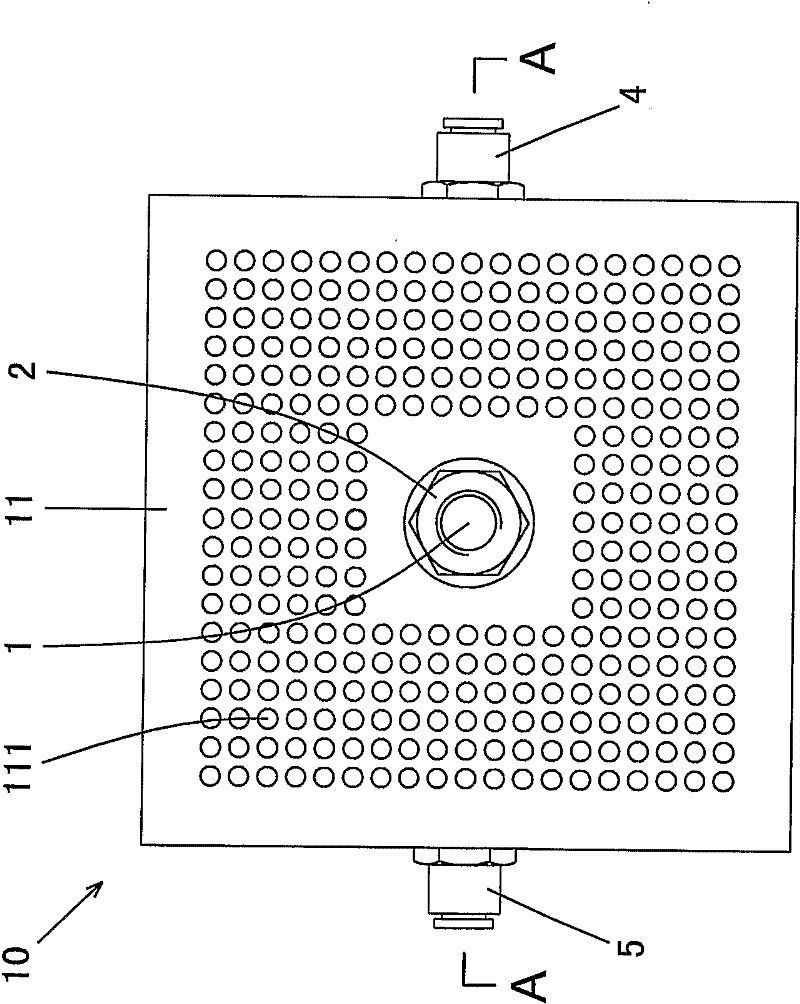

Fuel cell

InactiveCN101485020BSimple structureEasy to assemble and disassembleSolid electrolyte fuel cellsFuel cell detailsFuel cellsMiniaturization

A fuel cell which comprises at least one battery unit. The battery unit comprises positive and negative electrode fluid guide plates and membrane electrodes. The membrane electrodes are disposed between the positive and negative electrode fluid guide plates, wherein a bolt hole is disposed on the non-periphery area of the positive and negative electrode fluid guide plates correspondingly. A fastening bolt is disposed in the bolt hole. A positive conductive plate is interposed between the positive fluid guide and the membrane electrode of the battery unit and a negative conductive plate is interposed between the negative fluid guide and the membrane electrode of the battery unit. A bolt hole is disposed on the positive and negative conductive plates and membrane electrodes correspondingly.A fastening bolt is disposed in the bolt hole. A fluid guide hole is provided on the positive fluid guide plate and the positive conductive plate respectively to connect the air. A fluid guide hole is provided on the negative fluid guide plate and the negative conductive plate respectively to connect the fuel room. The structure of the fuel cell of the invention is simple, the inner resistance islittle, the output power is large, the disassembly and maintenance is convenient, the miniaturization is easy, multi-type voltage and current can be outputted and the operation is convenient.

Owner:GOLDEN ENERGY FUEL CELL

Dosing apparatus

InactiveUS20120145746A1Easy constructionEasy to operateRacksMovable measuring chambersEngineeringDiscrete form

A dosing apparatus for the delivery of a substance in discrete form comprises a conveying element in which the discharge end thereof is a close fit in a discharge bushing thereby to ensure that the correct dosage of substance is discharged on a consistent basis.

Owner:CAVADISTRIB

Combined door frame

ActiveCN106088923AEasy to replace partsSimple processingWindow/door framesEngineeringElectrical and Electronics engineering

Owner:付晗

Suspension front fork of one-armed bicycle

InactiveCN108791645AEasy to replaceEasy to replace partsSteering deviceAxle suspensionsRubber ringEngineering

The invention discloses a suspension fork of a one-armed bicycle. The suspension fork of the one-armed bicycle includes concave tabling grooves, hinges, dustproof rubber rings, anti-skid lugs, and external connecting triangular frames. The hinges are installed on the right sides of the concave tabling grooves, the dustproof rubber rings are installed on the right sides of the hinges, and the external connecting triangular frames are installed on the right sides of the anti-skid lugs. The structure is scientific and reasonable, the use is safe and convenient, and the concave tabling grooves enable connecting pieces to be more compact during connection. Part Replacement and maintenance are convenient by the hinges. Only the dustproof rubber rings can avoid dust, soil and other impurities from entering the sleeves, and the anti-skid lugs can reduce the shocking pressure when being shocked, and indirectly increase the recovery time of damping springs, so that suspension body feeling of thefront fork is better during shocking. The external connecting triangular frames can decompose and offset the pressure generated when shocking.

Owner:王鼎兴

Wall socket convenient in mounting and demounting

InactiveCN102544859AEasy to replace partsEasy to install and maintainCoupling device detailsEngineeringMechanical engineering

Owner:徐新东

Multi layered modular support system for lounge and other applications

ActiveUS9848709B2Great and less resistanceEasy to adjustSpring mattressesStoolsModularityEngineering

A lounge having a matrix mat and a plurality of modules capable of being inserted into the matrix mat. The lounge may include a frame configured as a rigid frame, a modular frame, and combinations thereof. The modular frame may further include a tri-cable suspension. The tri-cable suspension may be attached to a dilator retractor mechanism. The modules may be a mushroom cap module, a spider spring module, a web module, a lighting module, an electronics module, and combinations thereof.

Owner:MOLENDA DONALD J

Simple rich-lean separation device arranged in W-flame boiler

ActiveCN101797562BImprove the effect of shade separationExtend furnace strokeGas current separationCoal pipelineEngineering

The invention discloses a rich-lean separation device arranged in a W-flame boiler, relates to the rich-lean separation device arranged in the W-flame boiler and solves the problems that the conventional rich-lean separation device for the W-flame boiler has a plurality of components and a complex structure and occupies a large space. In the simple rich-lean separation device, a rich-lean separation plate (13) is fixedly arranged on the inner wall of a pulverized coal rich-lean separator (3); the upper end of an exhaust gas pipeline (7) and the upper end of a master dense pulverized coal pipeline (4) are both communicated with the lower end of the pulverized coal rich-lean separator (3); the exhaust gas pipeline (7) is positioned under the rich-lean separation plate (13); the master dense pulverized coal pipeline (4) is communicated with a pulverized coal equal divider (14); the lower end of the pulverized coal equal divider (14) is provided with dense pulverized coal pipelines(5); and the pulverized coal equal divider (14) is communicated with two dense pulverized coal pipelines (5). The device has a simple structure, saves the space, improves the reliability and spatial adaptability of a system and is applied in the technical field of burning of the W-type flame boiler.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com