Tapping machine

A technology of tapping machine and body, applied in the field of tapping machine, can solve the problems of shortening the service life, affecting the service life and machining accuracy, insufficient moving speed, etc., and achieving the effects of prolonging the service life, easy maintenance and improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

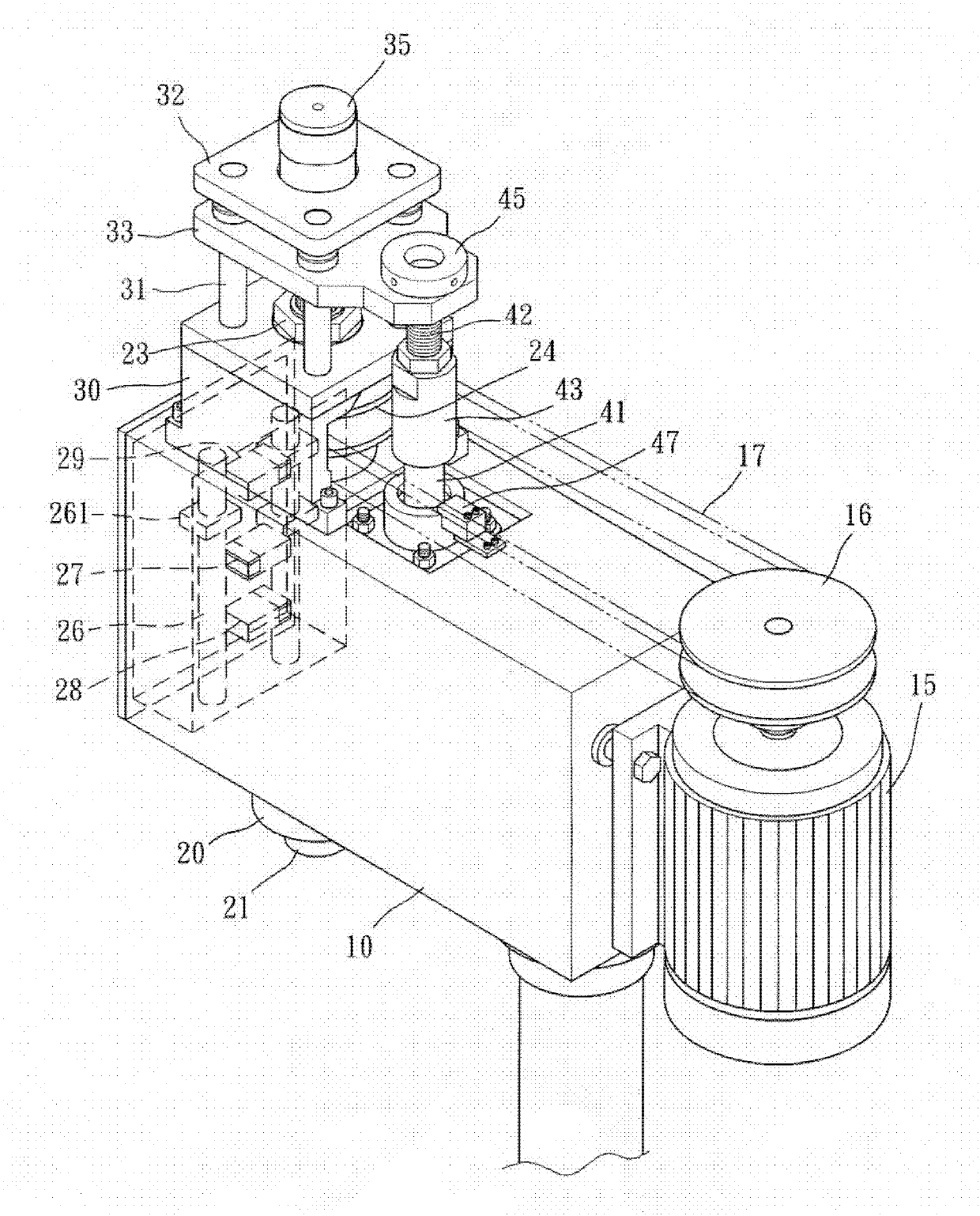

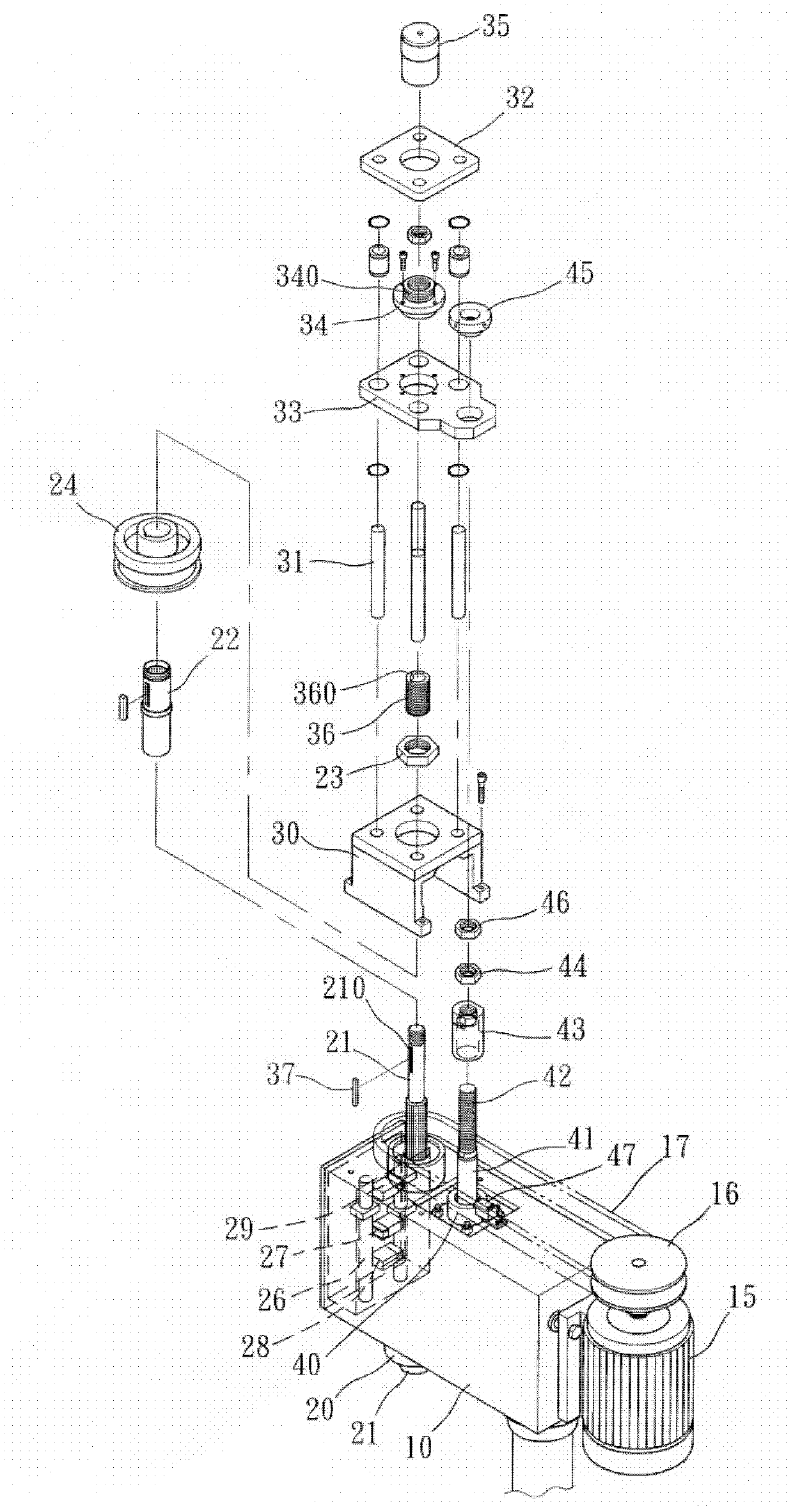

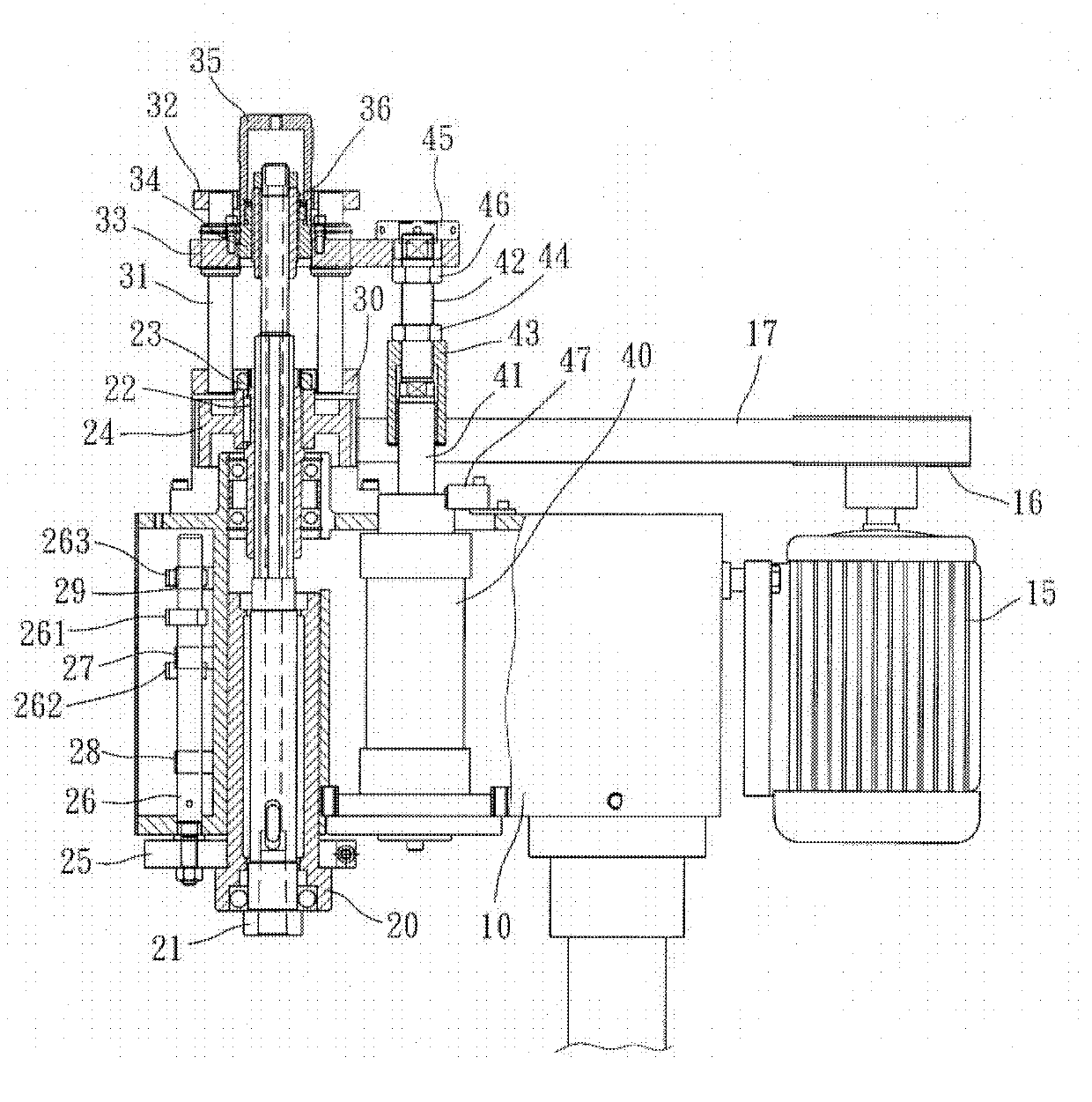

[0051] For the detailed composition of the tapping machine of the present invention, please refer to figure 1, figure 2 , Figure 3A and Figure 3B As shown, the tapping machine has a body 10, the body 10 is provided with a main shaft 20 that can move up and down, and the inner pivot of the main shaft 20 is provided with a rotating shaft 21 that can rotate and move synchronously, and one end of the body 10 is provided with a controllable The driving element 15 of rotating speed and steering, wherein the driving element 15 can be selected from servo motors and stepper motors that can control the rotating speed and steering. The output end of the driving element 15 has a pulley 16 for driving the aforementioned main shaft 20 through at least one belt 17 The axis of rotation 21;

[0052] The middle section of the rotating shaft 21 of the main shaft 20 is provided with a shaft sleeve 22 pivotally arranged on the body 10, wherein the inner edge of the shaft sleeve 22 forms an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com