Simple rich-lean separation device arranged in W-flame boiler

A technology of thick-thin separation and thick-thin separator, which is applied in the field of thick-thin separation devices, can solve the problems of many parts, large space occupation, complex structure, etc., and achieve the effect of fewer parts, saving space and prolonging the stroke in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

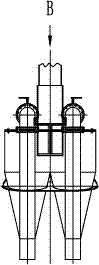

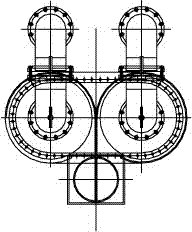

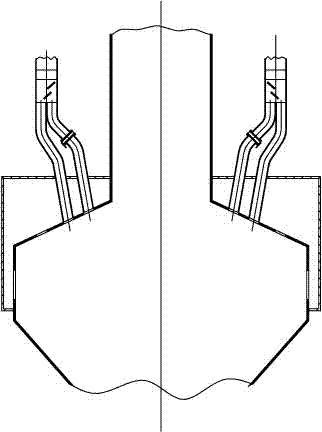

[0009] Specific implementation mode one: combine Figure 6-Figure 8 Describe this embodiment mode, a thick-lean separation device arranged in a W flame boiler in this embodiment includes a primary air pipe 2, a pulverized coal thick-lean separator 3, an exhaust gas pipeline 7, an exhaust gas baffle plate 12, and a concentrated coal dust main pipeline 4. Coal powder equalizer 14 and two concentrated coal powder pipelines 5, the lower end of the primary air pipeline 2 communicates with the upper end of the coal powder concentration separator 3, and the exhaust gas baffle 12 is installed on the exhaust gas pipeline 7, so that The thick-thin separation device also includes a thick-thin separation plate 13, and the thick-thin separation plate 13 is fixedly installed on the inner wall of the pulverized coal thick-lean separator 3, and the upper end of the exhaust gas pipeline 7 and the upper end of the thick pulverized coal main pipeline 4 are connected with the coal The lower end o...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 6 and Figure 8 To describe this embodiment, the shade separation plate 13 of this embodiment is a triangular blunt body or a semicircular blunt body. Such setting reduces the abrasion of the pulverized coal on the thick-thin separation plate 13 . Other components and connections are the same as those in the first embodiment.

[0011] Working principle: The pulverized coal airflow enters the pulverized coal concentration separator 3 from the primary air duct 2, and the pulverized coal particles collide with the concentration separation plate 13. Due to the large inertia of the pulverized coal particles, the pulverized coal is concentrated to the concentration separation plate after the collision On the inner wall of the pulverized coal concentration separator 3 opposite to 13, the air inertia is very small, and the concentration separation plate 13 has little influence on the velocity direction of the air, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com