Pulverized coal concentrator, pulverized coal burner and pulverized coal boiler

A pulverized coal burner and concentrator technology, which is applied in the direction of burners, burners burning powder fuel, burning with multiple fuels, etc. It can solve the problems of increasing burner resistance, failing to achieve the concentration effect, and easy wear of the blade grid. problems, to achieve the effect of improving the separation effect of thick and thin, reducing the situation of mixing in advance, and enhancing the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

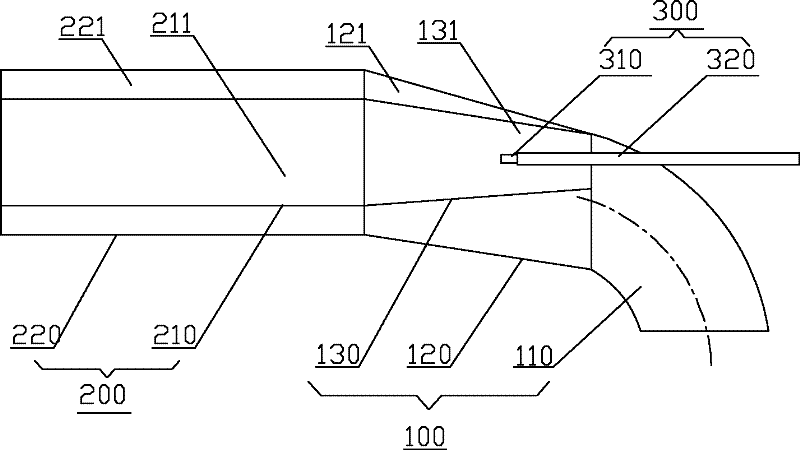

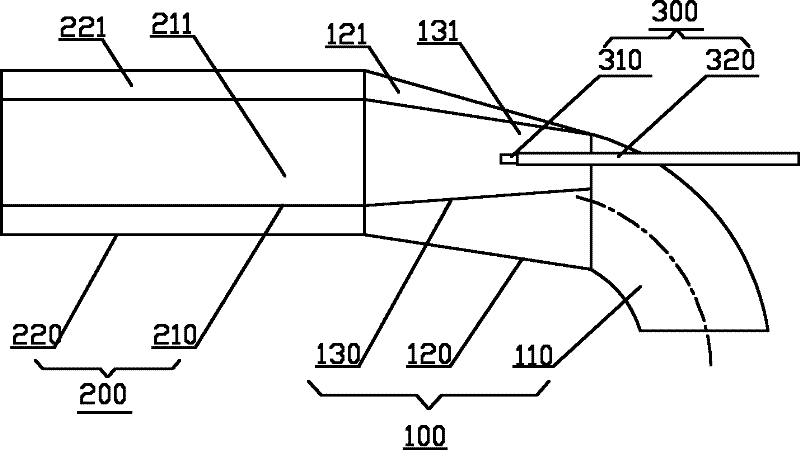

[0030] Please refer to figure 1 , which is a schematic structural view of a pulverized coal burner provided in Embodiment 1 of the present invention. The pulverized coal burner includes a double-layer cylinder 200 , a pulverized coal concentration section 100 , an ignition device 300 and other parts. The pulverized-coal concentration section 100 can separate the pulverized-coal airflow of the primary air from thick to thin to form a pulverized-phase dense-phase airflow and a pulverized-coal light-phase airflow. Used to ignite dense-phase pulverized coal gas stream.

[0031] The double-layer cylinder 200 includes a main body section 220 and a partition 210 located in the main body section 220; the partition board 210 extends along the coal powder flow direction, and divides the inside of the main body section 220 into a dense phase pulverized coal channel 211 and a light phase pulverized coal channel 221. In this example, the main body section 220 and the partition plate 210 ...

Embodiment 2

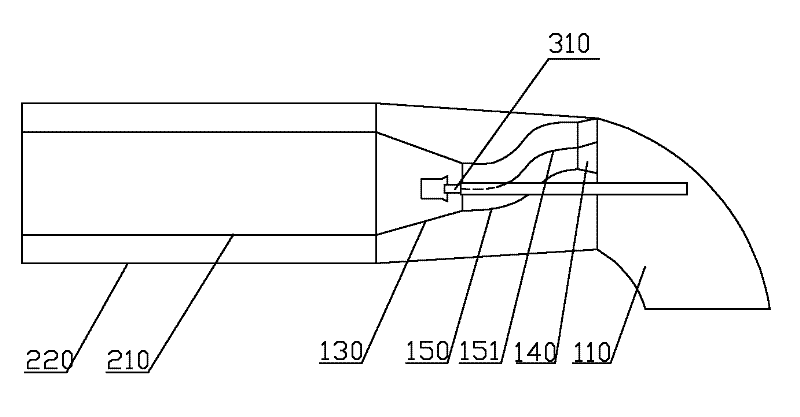

[0038] Please refer to figure 2 , which is a schematic structural diagram of the pulverized coal burner provided in Embodiment 2 of the present invention. Compared with embodiment one, in embodiment two, the pulverized coal concentrator in the pulverized coal concentrating section also comprises the shrinkage cavity section 140 of the flow cross section of the front end greater than the flow section of the rear end, and the shrinkage cavity section 140 rear end and as inner The front ends of the tapered barrel section 130 of the barrel are connected, and the front end is opposite to the part of the rear end of the elbow 110 which is biased toward the outer arc. Since the flow section at the front end of the shrinkage cavity section 140 is larger than the flow section at the rear end, the shrinkage cavity section 140 can produce an equal flow effect on the dense-phase pulverized-coal airflow, so that the pulverized coal in the dense-phase pulverized-coal airflow is distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com