Oxygen-containing lanthanum sulfate thin film and preparation method thereof by layer-by-layer self assembly of nanosheets

A layer-by-layer self-assembly and lanthanum sulfate technology, applied in the field of material science, can solve the problems of low film-forming speed, inappropriateness, and uncontrollable film thickness, etc., and achieve the effect of high film-forming quality and fast film-forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

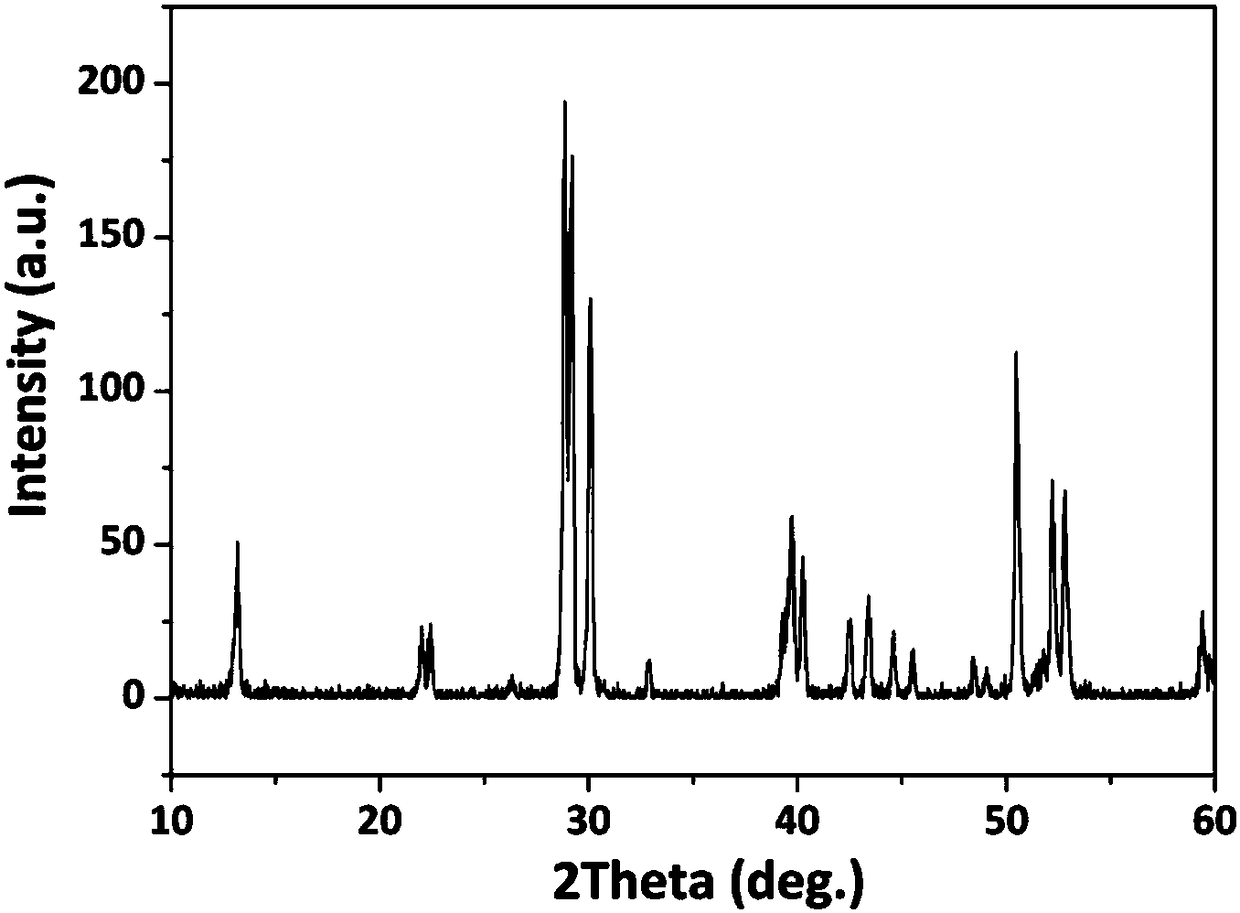

Embodiment 1

[0042] An oxygen-containing lanthanum sulfate film, the film thickness is 5-10nm; the composition of the oxygen-containing lanthanum sulfate film is La 2 o 2 SO 4 , wherein, according to the molar ratio of elements, La: O: S=2:6:1;

[0043] A method for preparing nano-sheet layer self-assembly of lanthanum oxysulfate film, comprising the following steps:

[0044] (1) Prepare the solution

[0045] Lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) Mix well in deionized water to prepare La 3+ Lanthanum nitrate (La(NO) with a concentration of 0.03mol / L 3 ) 3 ) solution;

[0046] (2) ammonium sulfate particles ((NH 4 ) 2 SO 4 ) is dissolved in the prepared lanthanum nitrate solution and stirred for 10 minutes. When the solution is transparent and clear, the ammonium sulfate particles are fully dissolved to obtain a mixed solution of lanthanum nitrate and ammonium sulfate; wherein, the prepared lanthanum nitrate and sulfate In the mixed solution of ammonium, by molar ...

Embodiment 2

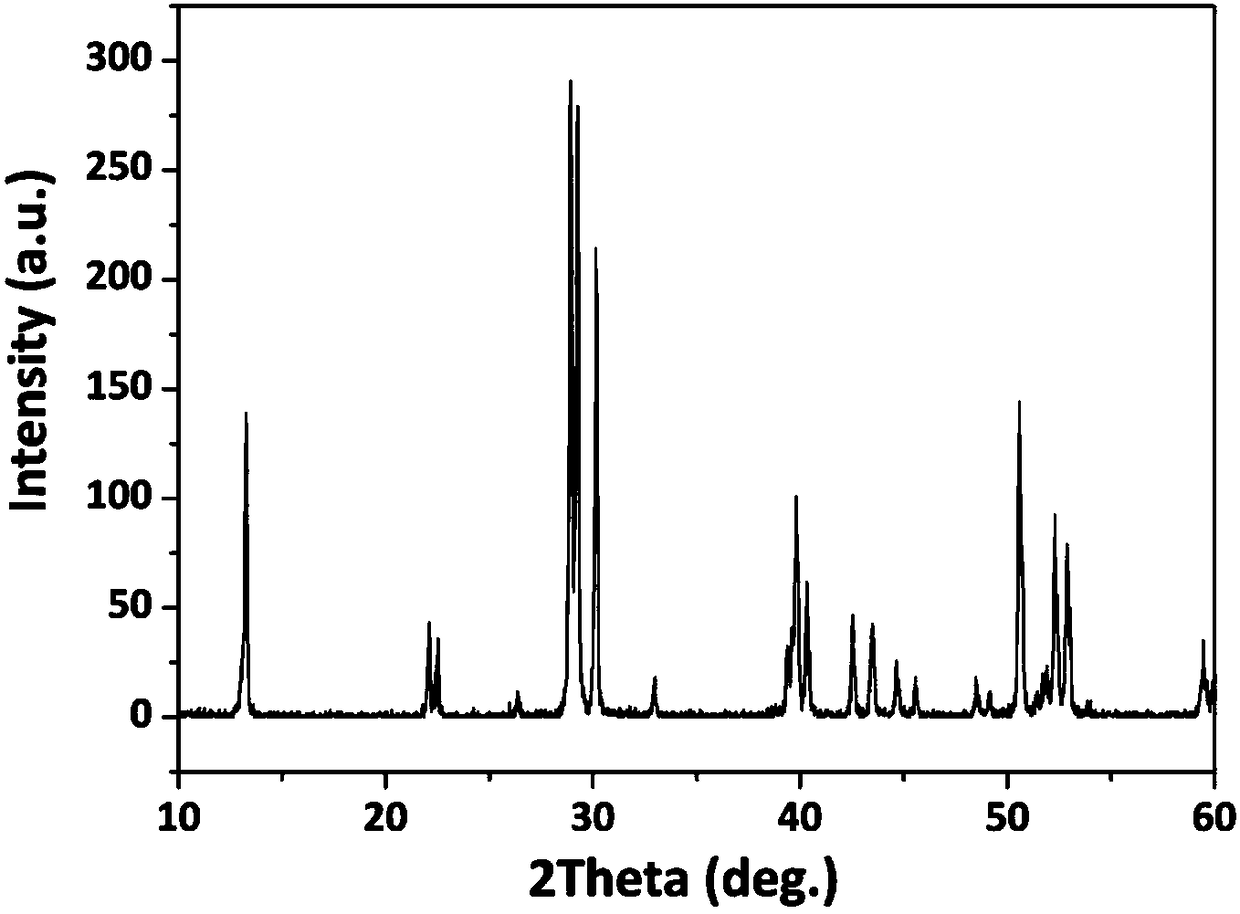

[0059] An oxygen-containing lanthanum sulfate film, the film thickness is 40-50nm; the composition of the oxygen-containing lanthanum sulfate film is (La, Eu) 2 o 2 SO 4 , wherein, by element molar ratio, (La+Eu):O:S=2:6:1; by molar ratio, La:Eu=17:3.

[0060] A method for preparing nano-sheet self-assembly of lanthanum oxysulfate thin films, comprising the following steps:

[0061] (1) Prepare the solution

[0062] Lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) Mix well in deionized water to prepare La 3+ Lanthanum nitrate (La(NO) with a concentration of 0.20mol / L 3 ) 3 ) solution;

[0063] Europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O) Mix well in deionized water and prepare Eu 3+ Europium nitrate (Eu(NO 3 ) 3 ) solution;

[0064] (2) Mix the prepared lanthanum nitrate solution with the prepared europium nitrate solution to obtain a mixed solution of lanthanum nitrate and europium nitrate; wherein, by molar ratio, lanthanum nitrate: europium nitrate=17...

Embodiment 3

[0077] An oxygen-containing lanthanum sulfate film, the film thickness is 20-30nm; the composition of the oxygen-containing lanthanum sulfate film is (La, Eu) 2 o 2 SO 4 , wherein, by element molar ratio, (La+Eu):O:S=2:6:1; by molar ratio, La:Eu=9:1.

[0078] A method for preparing nano-sheet self-assembly of lanthanum oxysulfate thin films, comprising the following steps:

[0079] (1) Prepare the solution

[0080] Lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) Mix well in deionized water to prepare La 3+ Lanthanum nitrate (La(NO) with a concentration of 0.10mol / L 3 ) 3 ) solution;

[0081] Europium nitrate hexahydrate (Eu(NO 3 ) 3 ·6H 2 O) Mix well in deionized water and prepare Eu 3+ Europium nitrate (Eu(NO 3 ) 3 ) solution;

[0082] (2) Mix the prepared lanthanum nitrate solution with the prepared europium nitrate solution to obtain a mixed solution of lanthanum nitrate and europium nitrate; wherein, by molar ratio, lanthanum nitrate: europium nitrate=9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com