Preparation method of luminescent material based on rare earth phosphate

A technology of rare earth phosphates and luminescent materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of limiting the application of rare earth phosphates, achieve good biocompatibility and water solubility, easy preparation, and low price effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

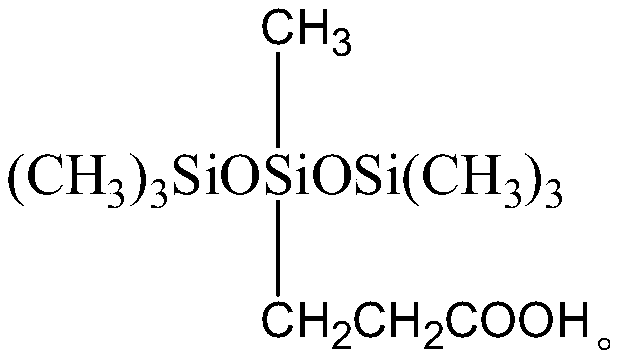

[0035] Preparation of silicone ligands:

[0036] S1. Under the protection of nitrogen, add 50g of hexamethyldisiloxane into 100g of saturated sodium bicarbonate solution, cool to 5°C, add 20g of methyldichlorosilane dropwise, keep the temperature for 2 hours, and then let the reaction solution stand for stratification , the upper organic phase was washed with a saturated sodium bicarbonate solution until the pH was equal to 6, and then washed with deionized water until neutral to obtain a product one;

[0037] S2. Cool product one to 5°C, add 5g of concentrated sulfuric acid, heat to 60°C and react for 5h, carry out liquid separation and rectification separation treatment on the obtained reaction liquid, collect fractions at 139-145°C, and obtain product two;

[0038] S3. Under the protection of nitrogen, 2 g of chloroplatinic acid and 60 g of acrylic acid were added to the product two, and the temperature was raised to 80° C. for 4 hours to obtain the modified organosilicon l...

Embodiment 2

[0040] Preparation of silicone ligands:

[0041] S1. Under the protection of nitrogen, add 50g of hexamethyldisiloxane into 150g of saturated sodium bicarbonate solution, cool to 5°C, add 15g of methyldichlorosilane dropwise, keep the temperature for 2 hours, and then let the reaction solution stand for stratification , the upper organic phase was washed with a saturated sodium bicarbonate solution until the pH was equal to 6, and then washed with deionized water until neutral to obtain a product one;

[0042] S2. Cool product 1 to 5°C, add 8g of concentrated sulfuric acid, heat to 60°C for 5 hours, and conduct liquid separation and rectification separation of the obtained reaction solution, collect fractions at 139-145°C to obtain product 2;

[0043] S3. Under the protection of nitrogen, 3 g of chloroplatinic acid and 70 g of acrylic acid were added to the product two, and the temperature was raised to 80° C. for 4 hours to obtain the modified organosilicon ligand B.

Embodiment 3

[0045] (1) Take 10gY 2 o 3 and 10gTb 4 o 7 Add 5 mL of 2 mol / L nitric acid solution and 0.5 mL of hydrogen peroxide to two beakers respectively, heat under stirring until the solids in the beakers are completely dissolved, continue heating to evaporate water, stop heating when crystals are precipitated in the beaker, and put The beaker was naturally cooled to room temperature, and dried to precipitate crystals to obtain Y(NO 3 ) 3 and Tb(NO 3 ) 3 ;

[0046] (2) Set Y(NO 3 ) 3 and Tb(NO 3 ) 3 Add in absolute ethanol at a molar ratio of Y and Tb of 95:5, and disperse ultrasonically for 30 minutes to obtain solution 1 with n(Y+Tb) of 0.06mol / L;

[0047] (3) Add 5 g of modified organosilicon ligand A and 25 g of nano-silicon dioxide into 500 mL of absolute ethanol, ultrasonically disperse for 30 min, and then react at room temperature for 3-5 h under stirring to obtain solution 2;

[0048] (4) Add 4mL phosphoric acid and 20mL deionized water to 100mL solution 1 under s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com