Preparation method of silicate fluorescent composite material with layered structure

A layered silicate, composite material technology, applied in the field of material chemistry, can solve the problems of quenching, broadened fluorescence, emission spectrum shift, etc., to achieve the effect of improving fluorescence performance and fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

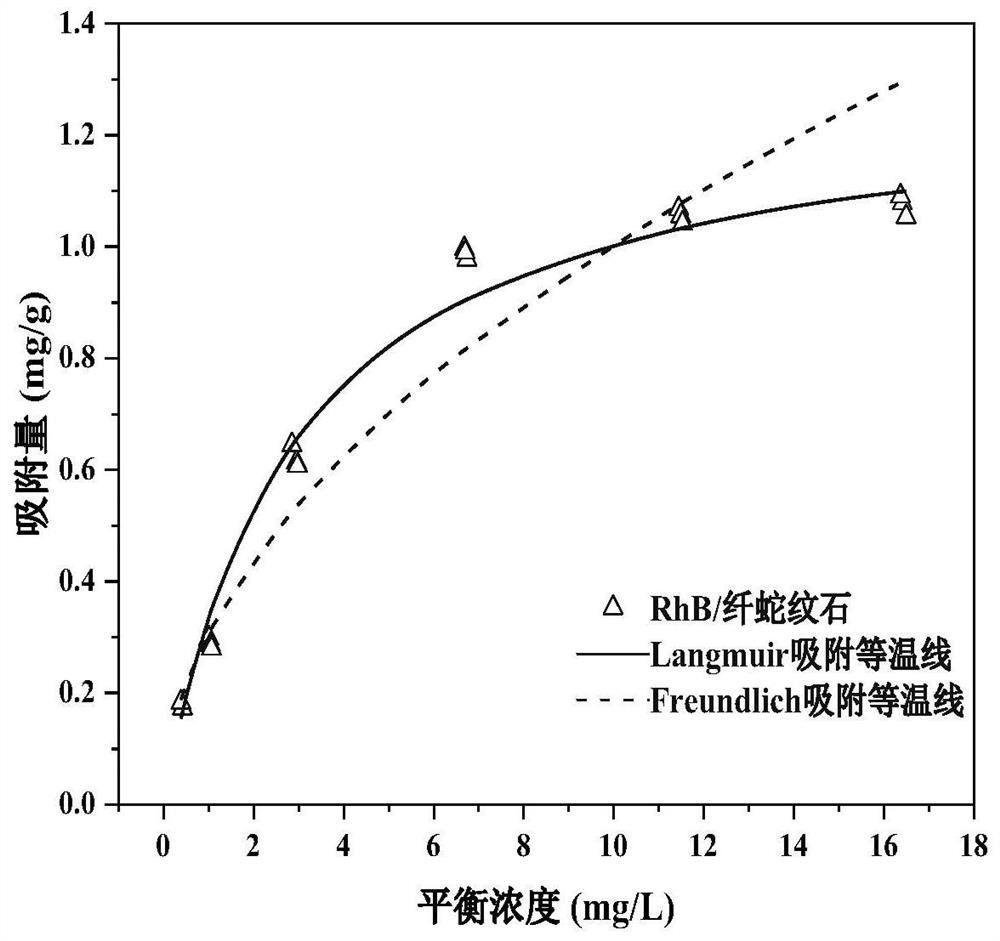

[0055] The chrysotile samples were first sieved, then ground, sieved with 200 mesh, and rhodamine B aqueous solutions with different concentrations were prepared.

[0056] Weigh 0.1 g of 200 mesh halloysite and add it to 30 mL of rhodamine B aqueous solution.

[0057] After shaking for 5 hours, it was taken out, centrifugally filtered, and the solid matter was dried to obtain a powdery composite material. Take the filtrate supernatant, measure its absorbance, and calculate the adsorption amount of the composite material.

[0058] The thermodynamic adsorption curves of different initial concentrations of RhB (1mg / L-about 17mg / L) and chrysotile are as follows: figure 1 shown.

Embodiment 2

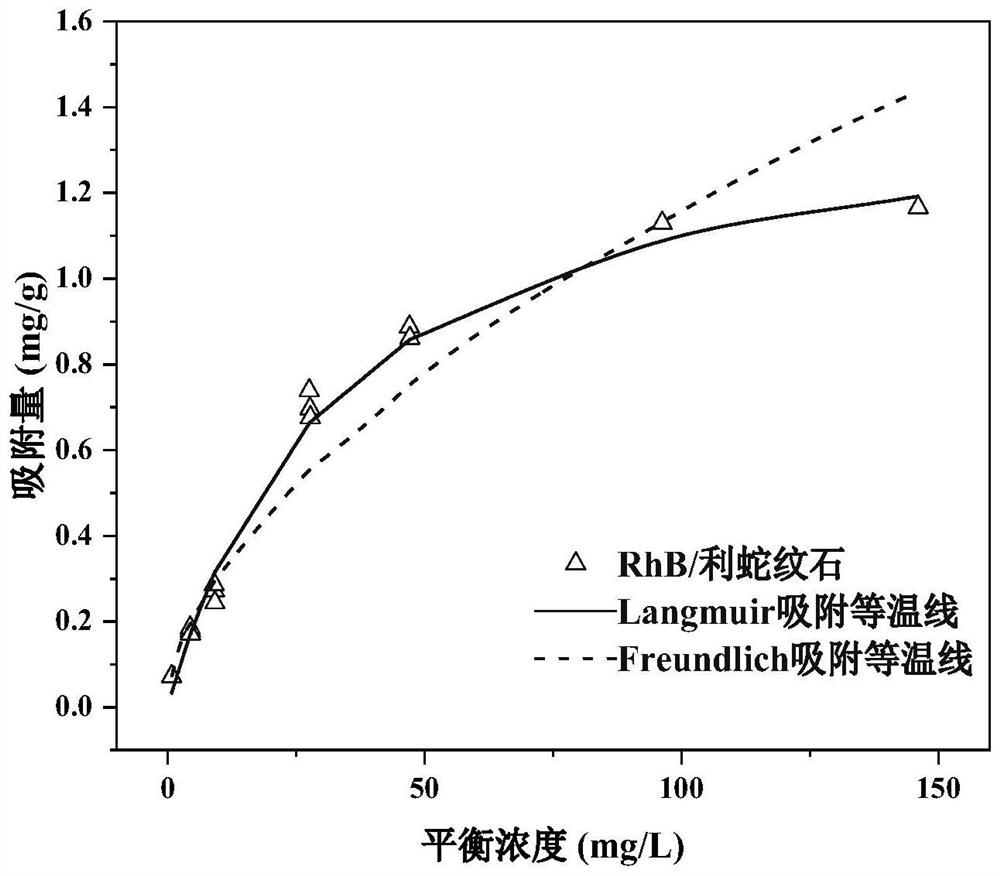

[0060] The lizardite samples were first sieved and ground, sieved with 200 mesh, and rhodamine B aqueous solutions with different concentrations were prepared.

[0061] Weigh 0.1 g of 200 mesh halloysite and add it to 30 mL of rhodamine B aqueous solution.

[0062] After shaking for 5 hours, it was taken out, centrifugally filtered, and the solid matter was dried to obtain a powdery composite material. Take the filtrate supernatant, measure its absorbance, and calculate the adsorption amount of the composite material.

[0063] The thermodynamic adsorption curves of different initial concentrations of RhB (1mg / L-about 150mg / L) and lizardite are as follows: figure 2 as shown,

Embodiment 3

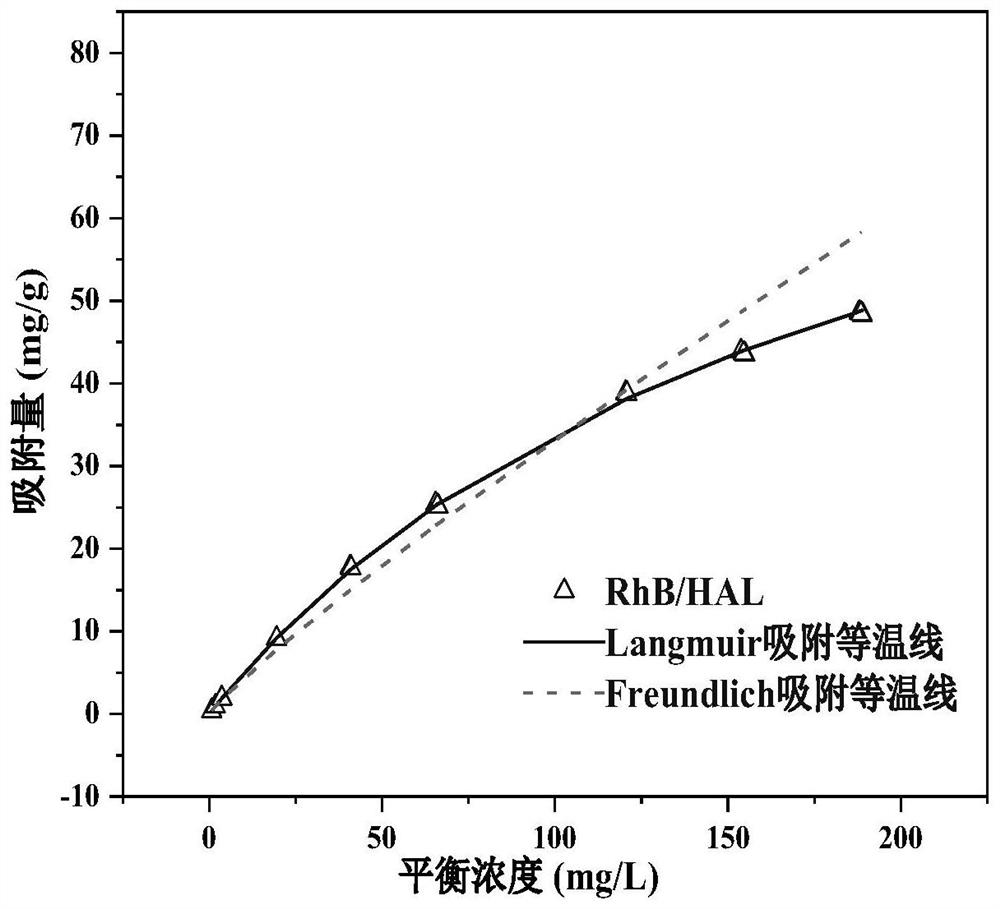

[0065] The halloysite sample was first sieved, then ground, sieved with 200 mesh, and rhodamine B aqueous solutions with different concentrations were prepared.

[0066] Weigh 0.1 g of 200 mesh halloysite and add it to 30 mL of rhodamine B aqueous solution.

[0067] After shaking for 5 hours, it was taken out, centrifugally filtered, and the solid matter was dried to obtain a powdery composite material. Take the filtrate supernatant, measure its absorbance, and calculate the adsorption amount of the composite material.

[0068] The thermodynamic adsorption curves of different initial concentrations of RhB (1mg / L-about 200mg / L) and halloysite are as follows: image 3 as shown,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com