Patents

Literature

84results about How to "Save rare earth resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process-saving manufacturing method of sintered Nd-Fe-B series magnet

ActiveCN102956337ASave rare earth resourcesSimplify the manufacturing processInorganic material magnetismInductances/transformers/magnets manufactureHydrogen pressureRare earth

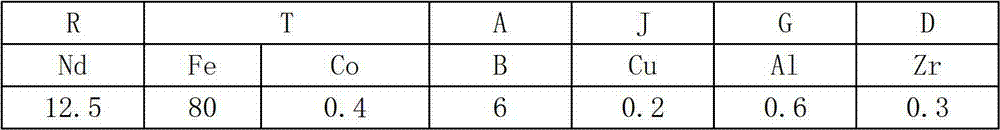

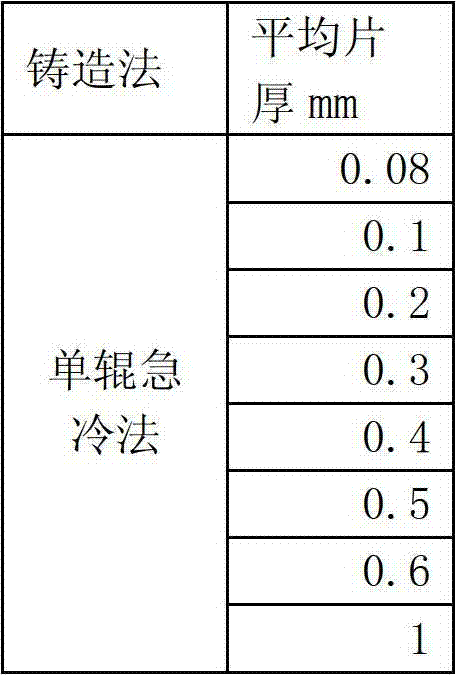

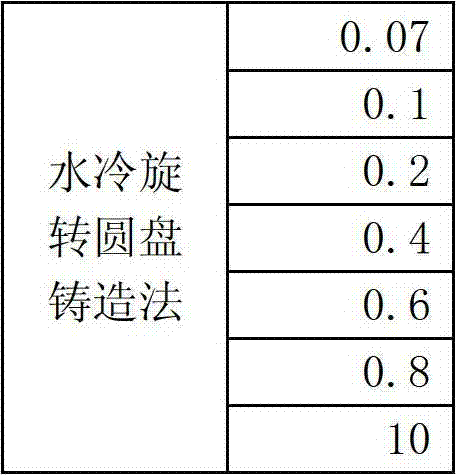

The invention discloses a process-saving manufacturing method of a sintered Nd-Fe-B series magnet. In a process of manufacturing the Nd-Fe-B series sintered magnet with oxygen content being below 2,500 ppm in the sintered magnet, a lamellar alloy raw material obtained by processes before a hydrogen demolishment pulverization process and with average thickness of 0.1-0.5 mm is used in a hydrogen demolishment pulverization process; hydrogen demolishment pulverization of not more than 24 hours is kept under the hydrogen pressure being above 0.01 MPa and below 1 MPa; then air stream pulverization is not performed; forming is directly performed by using a magnetic field forming method; and sintering is performed at the temperature of 900-1,140 DEG C under vacuum or in inert gas. The method realizes that the air stream pulverization process can be omitted to fulfill the aims of effectively utilizing precious rare earth resources, simplifying processes and performing low-cost production, and in addition, an oxidation effect which cannot be avoided in the air stream pulverization method in any way can also be prevented, so that the process is substantially a non-oxidative process, and large-scale manufacturing of ultrahigh-performance magnet is made possible.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

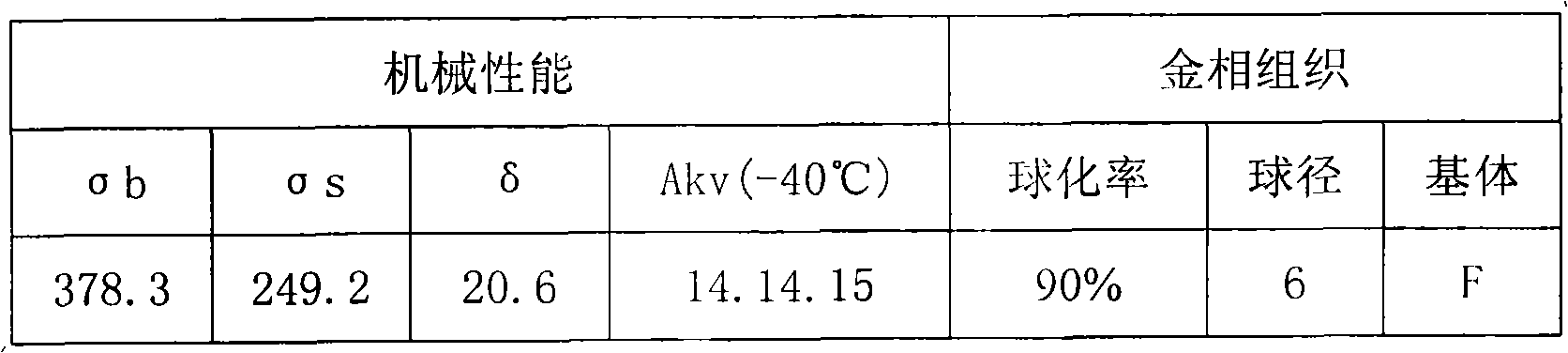

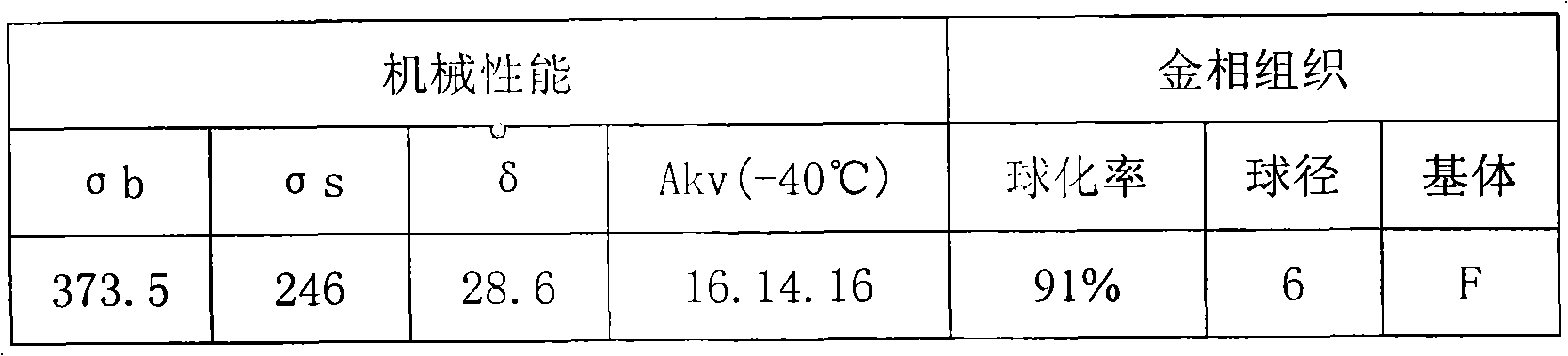

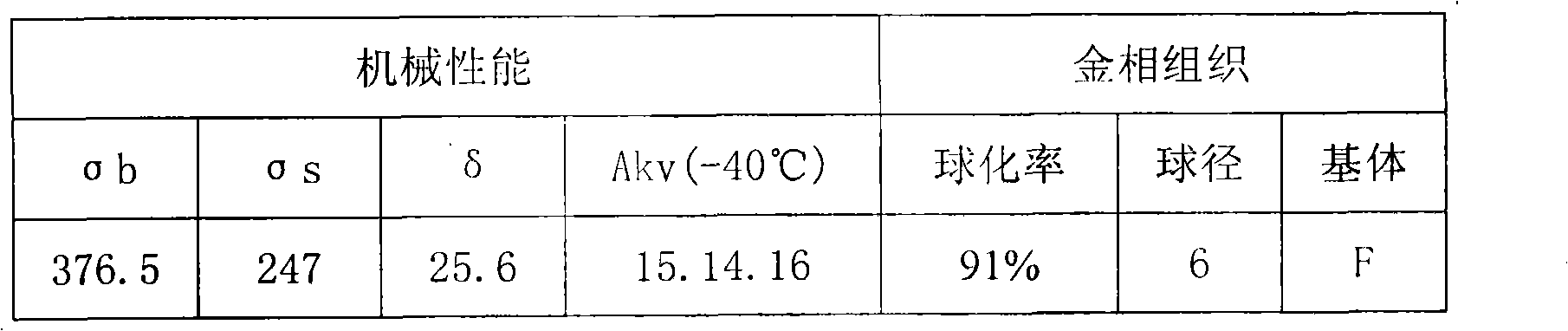

Ferrite ductile iron used at low temperature and manufacturing method thereof

ActiveCN102634723AEasy to controlSolve the problem of impuritiesProcess efficiency improvementChemical compositionFerrosilicon

The invention discloses chemical compositions of ferrite ductile iron used at low temperature and a manufacturing method of the ferrite ductile iron, determines the range of the chemical compositions of the ferrite ductile iron used at low temperature being minus 40 DEG C and provides a quality standard for the production of qualified and stable ductile iron workpieces. The manufacturing method comprises the steps of adopting pure iron, a carburant and silicon iron as raw materials, synthesizing and melting the raw materials in an electric furnace, conducting spheroidization on the raw materials by utilizing a low-rare-earth spheroidizing agent, and producing the ferrite ductile iron by adopting a combined inoculation method. According to the method, the purity of molten iron is improved stably, and the difficulties of high phosphorus, sulphur, titanium, other imputies and interference elements contents in the molten iron, large fluctuation and instability are solved. According to the method, a novel technical scheme is provided for the production of ferrite ductile iron workpiece which contains small, circular and smooth ductile iron and does not contain cementite and iron phosphide eutectic basically, the ferrite ductile iron can meet the demands of high-performance ferrite ductile iron workpiece in electrical industry, high-speed rail industry and the like, the dependence on imported products can be broken; and the running safety of nuclear power and the high-speed rail can be improved substantially.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

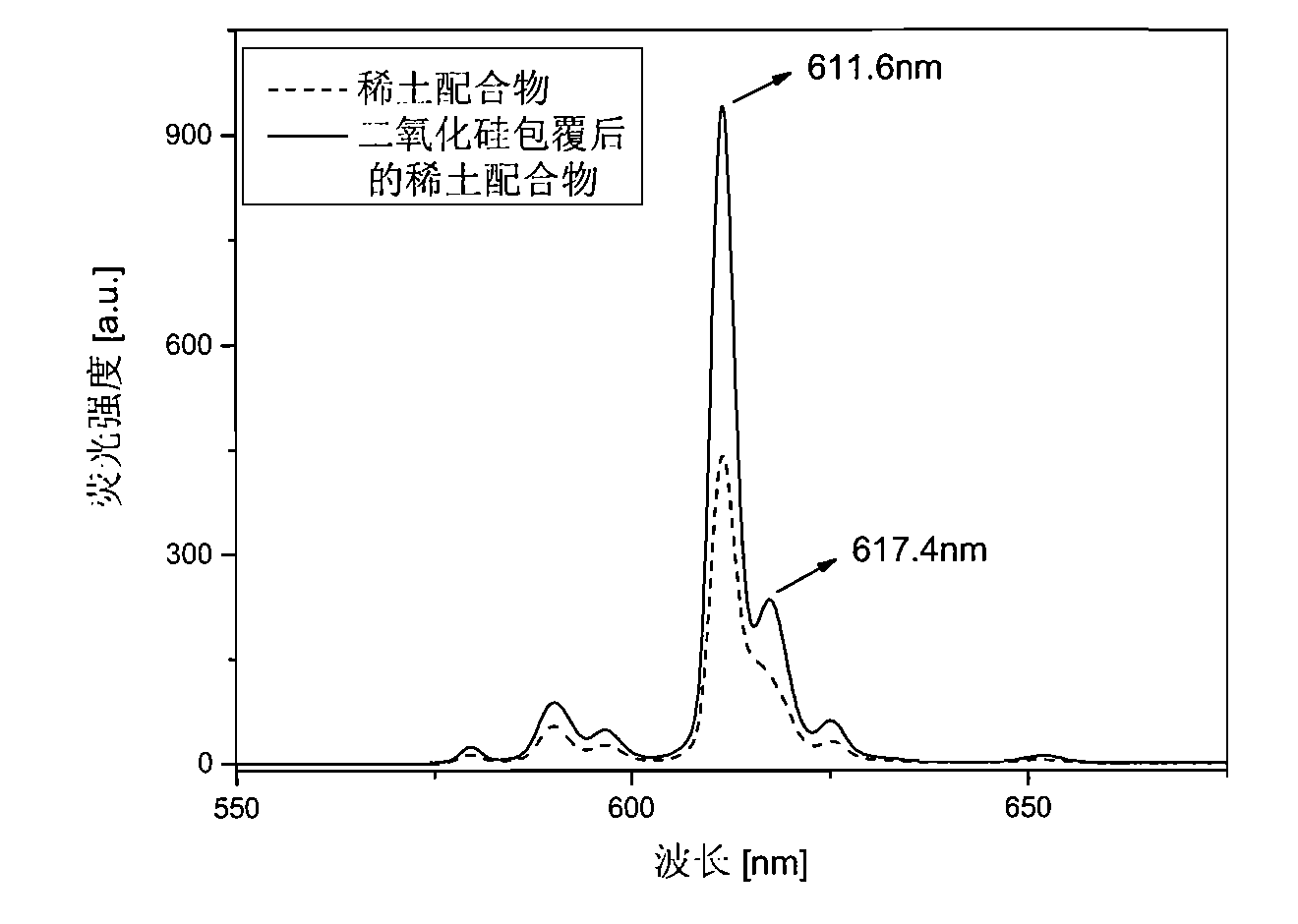

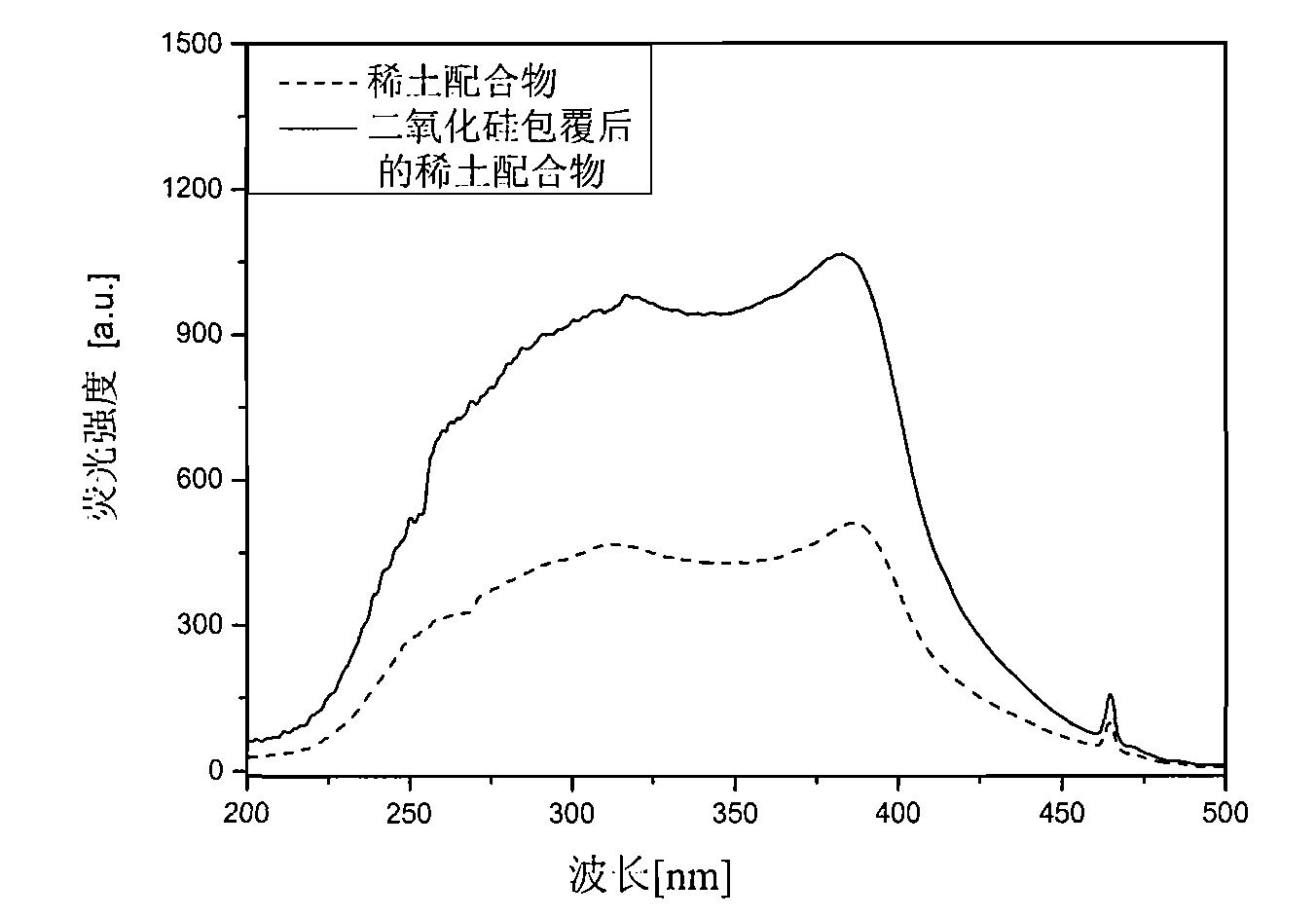

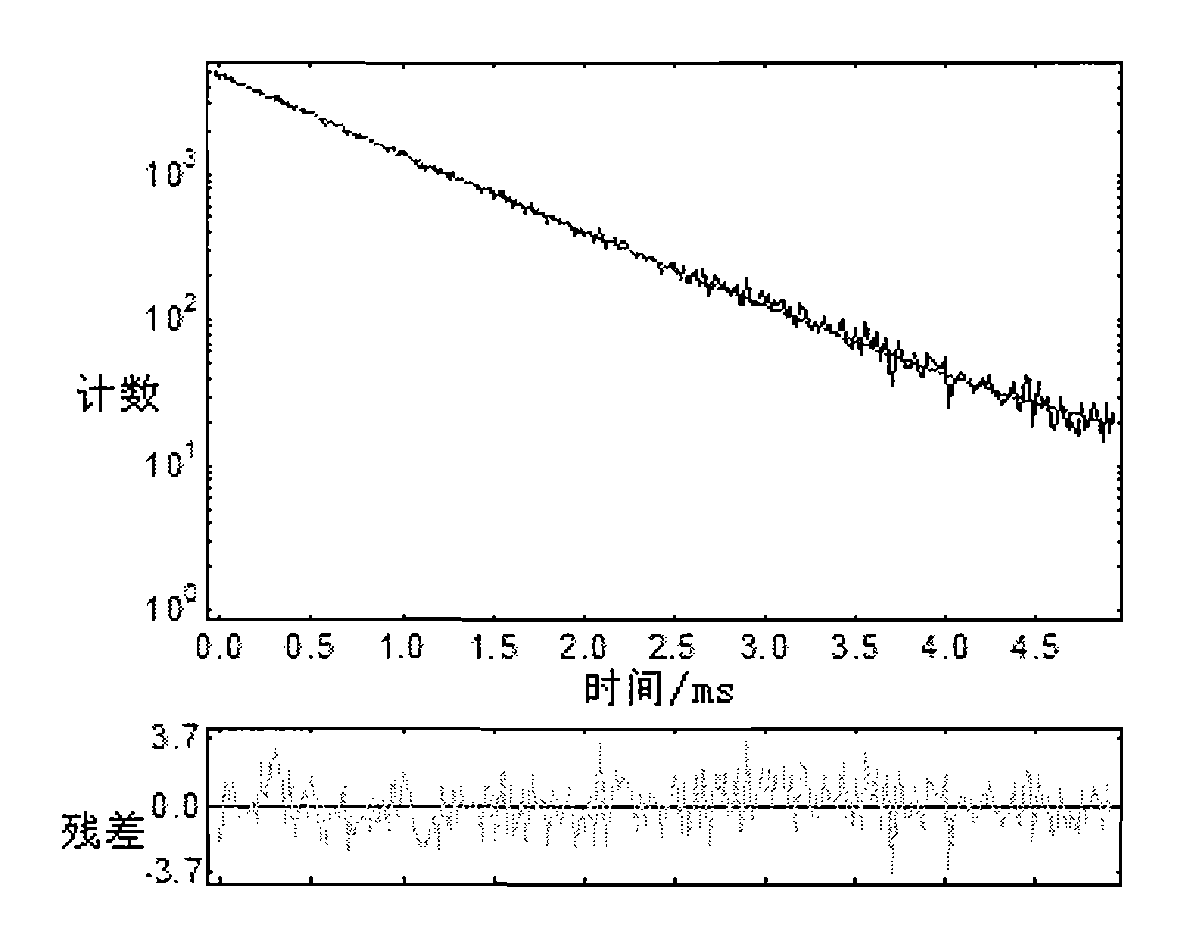

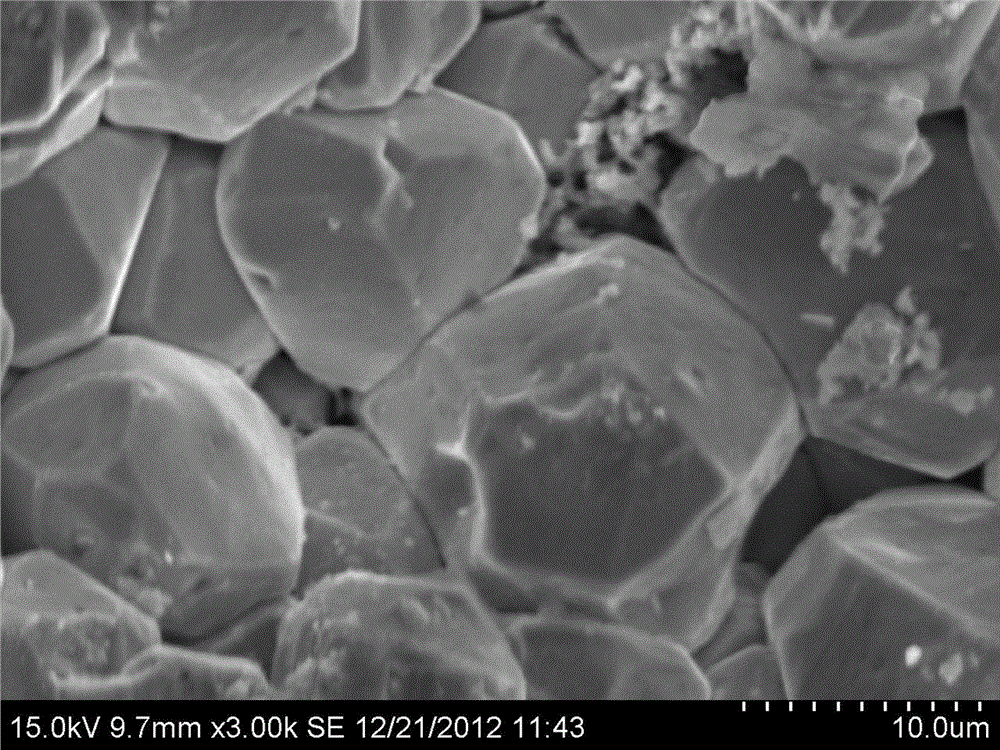

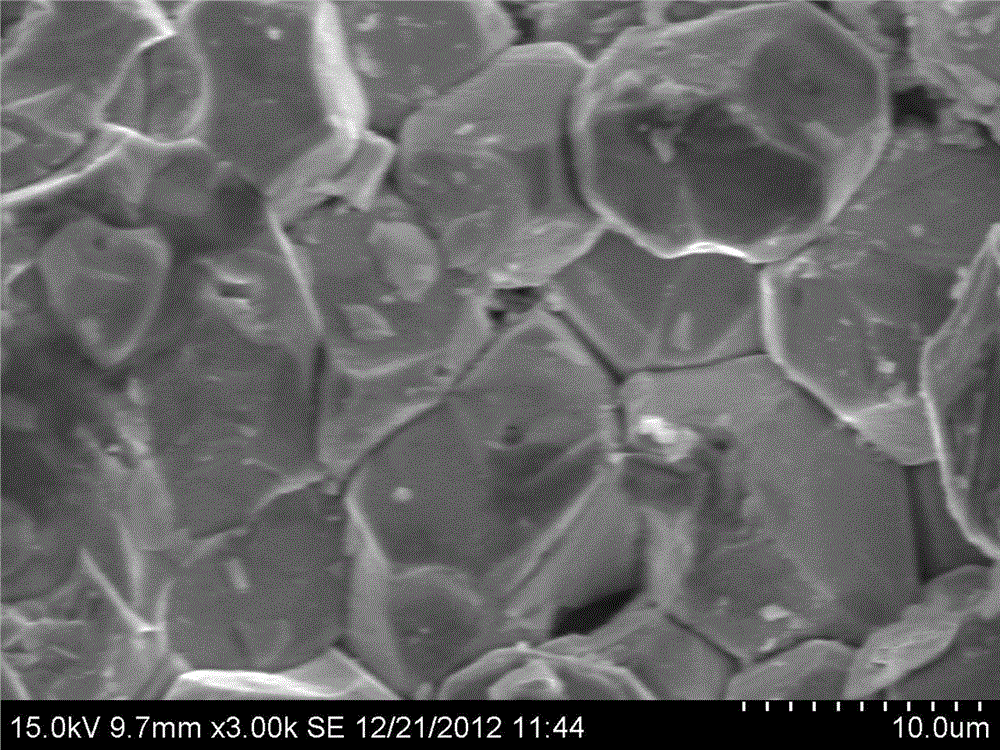

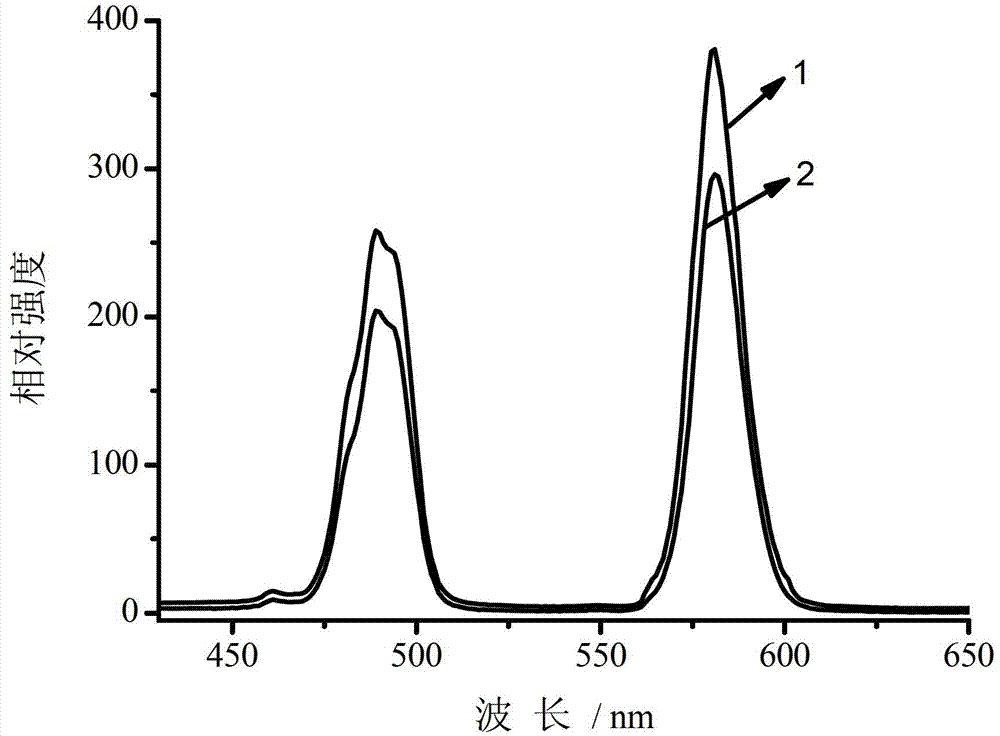

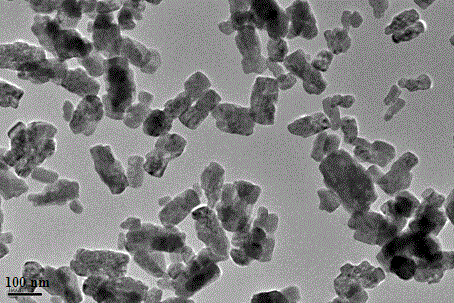

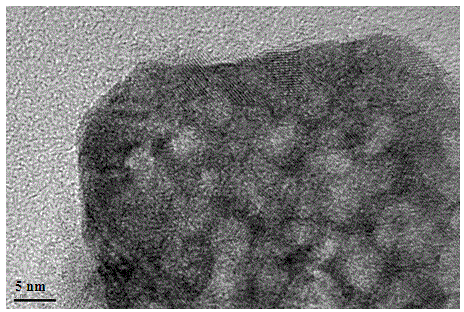

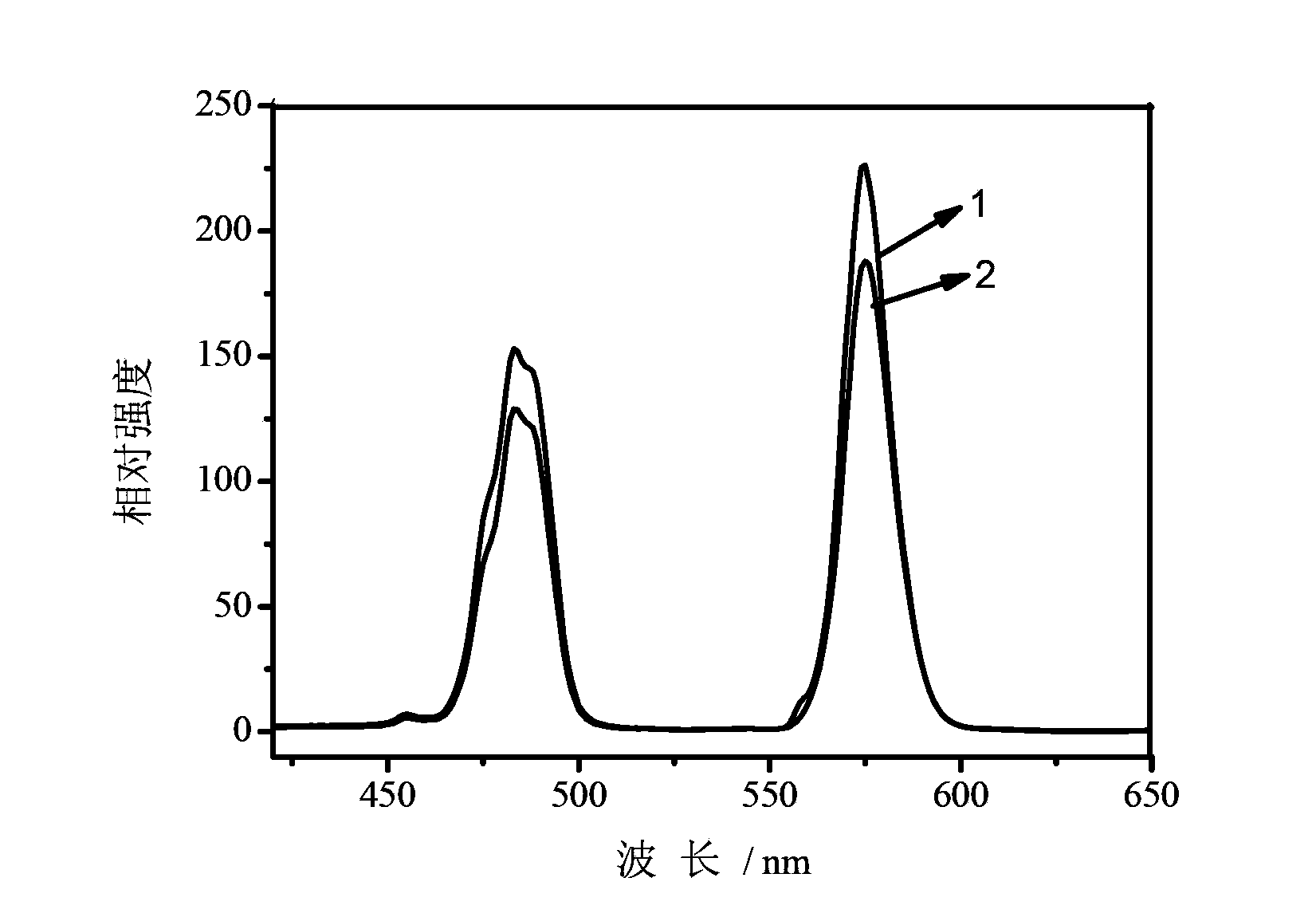

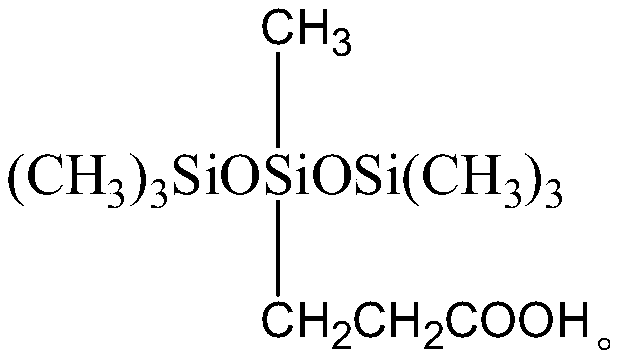

Rare earth complex coated with silicon dioxide and preparation method of rare earth complex

InactiveCN102153576AGood solvent resistanceCost-effectiveStampsGroup 3/13 element organic compoundsOrganic solventRare earth

The invention provides a rare earth complex coated with silicon dioxide and a preparation method of the rare earth complex, wherein the rare earth complex is a particle product formed by using the rare earth complex as a nuclear body and using the silicon dioxide generated after a silicon dioxide precursor is hydrolyzed as a surface coating object. A fluorescence test shows that the fluorescence intensity of the coated rare earth complex is obviously strengthened. Meanwhile, the obtained rare earth complex has the characteristic that the rare earth complex coated with the silicon dioxide is insoluble in an organic solvent. By adopting the method, the cost of rare earth can be reduced to the great extent.

Owner:FUYANG NORMAL UNIVERSITY

NdFeB (neodymium iron boron) magnetic material with ultrafine powder and preparation method thereof

InactiveCN103151132AInhibit growthGuaranteed uniformityInorganic material magnetismChemical reactionGrain boundary

The invention discloses a NdFeB (neodymium iron boron) magnetic material with ultrafine powder and a preparation method thereof. The ultrafine powder generated through air-current mill is added into normal magnetic powder which comprises certain amount of Pr-Nd-Dy, mixed rare earth (La-Ce), B, Al, Cu and the balance of Fe to prepare the NdFeB product. Proper addition can enrich rare earth phase; the product is prevented from being oxidized because of over low total amount of rear earth; a crystal boundary is strengthened, and the coercivity is improved; and NdFeB crystalline grains are prevented from being grown in a sintering process, the uniformity of the grains in the product is guaranteed, and the squareness of the product is improved. The granularity of the ultrafine powder is less than 2 mu m, the grains are large in specific surface area and few in defects, so that the surface activity is high, chemical reaction speed is high, the solubility is high, particularly the coercivity is very high, the sintering temperature of a magnetic body is reduced, and the coercivity is increased.

Owner:辽宁恒德磁业有限公司

Method for preparing sintered Nd-Fe-B permanent magnet material with intergranular Nd-rich phase replaced

ActiveCN103495733ALow costSave rare earth resourcesInorganic material magnetismRare-earth elementMicrometer

The invention belongs to the field of rare earth permanent magnetic materials, and particularly provides a sintered Nd-Fe-B permanent magnet material with an intergranular Nd-rich phase replaced and a preparation method thereof. The sintered Nd-Fe-B permanent magnet material with the intergranular Nd-rich phase replaced is characterized in that the intergranular Nd-rich phase in the sintered Nd-Fe-B material is replaced by a grain boundary phase not containing Nd, and the grain boundary phase has the following characteristics that no magnetism exists, the melting point is 500-900 DEG C so that liquid state sintering can be facilitated, the proportion is 2:14:1, and main phase wettability is good. The grain boundary phase can be made of Al-Cu (the Cu content range is 5-50at%) alloy. The preparation method includes the steps that Nd-Fe-B main alloy ingots with the closely even distribution proportion being 2:14:1 are crushed to be manufactured into powder particles of 3-5 micrometers, Al-Cu alloy powder with the volume fraction being smaller than 5% and the average particle size being smaller than 100nm is added and evenly mixed, and through magnetic field profiling, isostatic pressing and sintering densification, products are obtained after heat treatment ultimately. The sintered Nd-Fe-B permanent magnet material with the intergranular Nd-rich phase replaced and the preparation method thereof have the advantages that conventional metal Al and Cu are used for replacing the rare earth element Nd, the cost of raw materials can be greatly lowered, and rare earth resources are saved. The preparation method is simple to operate and suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

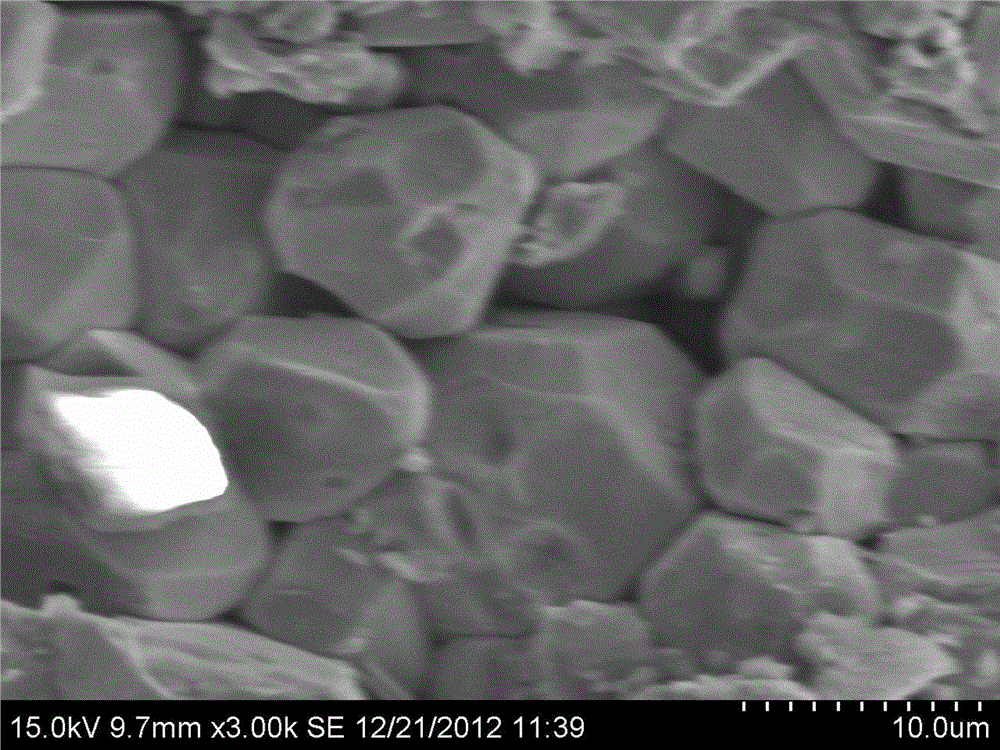

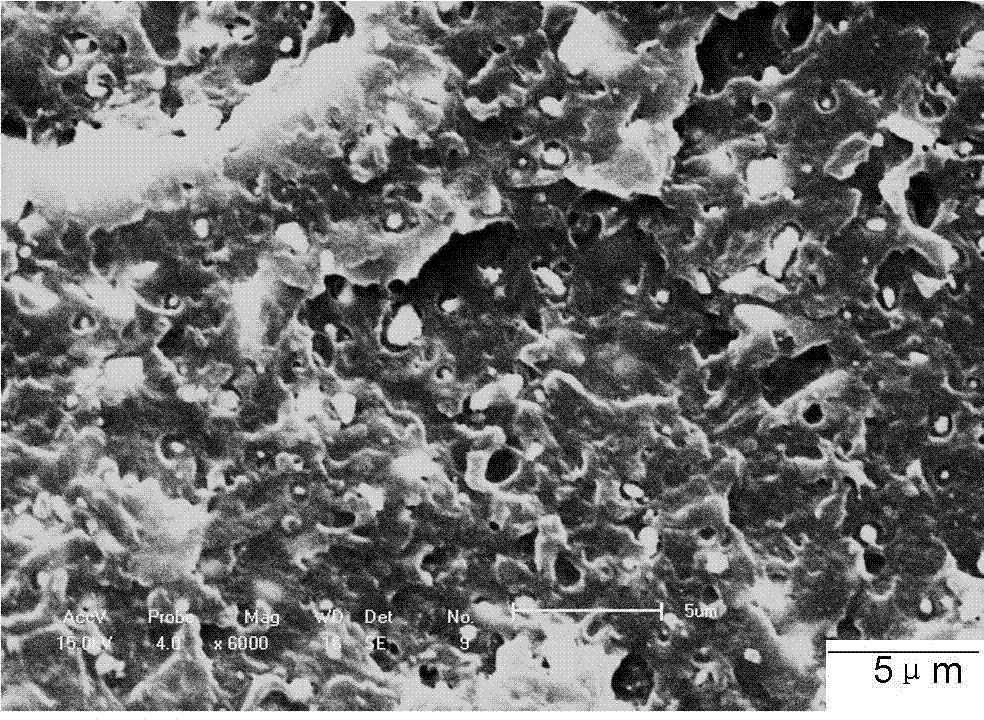

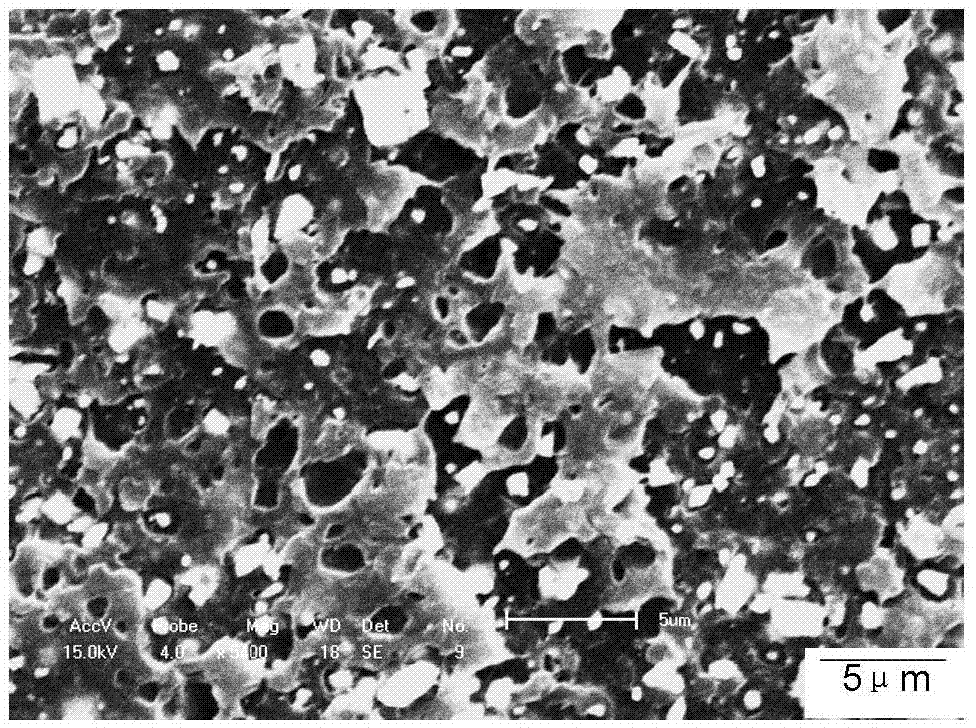

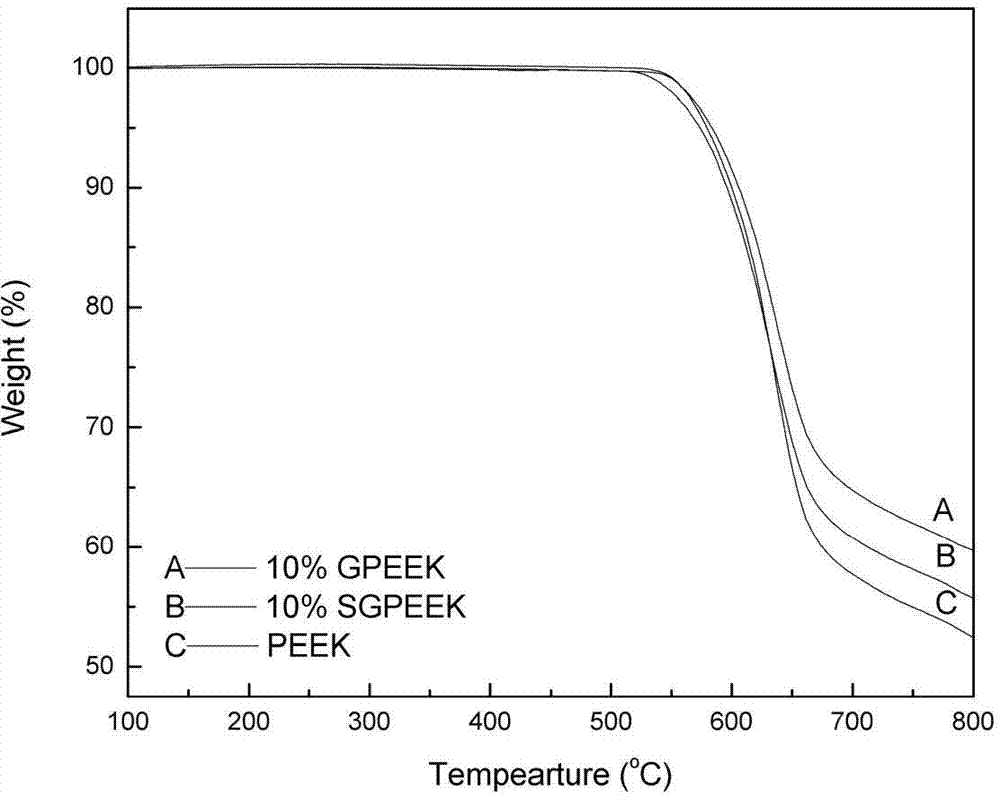

Polyether-ether-ketone composite material containing gadolinium oxide and preparation method of composite material

The invention relates to a polyether-ether-ketone composite material containing gadolinium oxide and a preparation method of the composite material, which belong to the technical field of special engineering plastics. The polyether-ether-ketone composite material comprises the following raw materials in parts by weight: 5-35 parts (X) of the gadolinium oxide, 0-0.08X of sulfonated polyether-ether-ketone and the balance of polyether-ether-ketone. The preparation method of the composite material comprises the following steps of: modified treatment of the gadolinium oxide and melt blending of the raw materials, wherein the modified gadolinium oxide and the polyether-ether-ketone are mixed together, and a double-screw extruding machine is used for carrying out the melting blending on the mixture to obtain the composite material. In order to improve interaction between two phases of the polyether-ether-ketone and the gadolinium oxide in the composite material, the sulfonated polyether-ether-ketone is firstly added into the gadolinium oxide to modify the gadolinium oxide, and then the melt blending is carried out on the mixture, so that the gadolinium oxide can be dispersed well in the polyether-ether-ketone matrix. The composite material has higher strength and modulus, excellent heat stability and a favorable X-ray shielding property.

Owner:JILIN UNIV

Method for preparing rare earth-iron-boron permanent magnet

ActiveCN103137314AAvoid lostReduce the ratioInductances/transformers/magnets manufactureMagnetic materialsRemanenceSmelting process

The invention discloses a method for preparing a rare earth-iron-boron permanent magnet. The method includes the steps of adding metal gallium (Ga) which is cooled to be in a lamellar shape in a coarse powder mixing stage in the hydrogen crushing process and after the hydrogen crushing of a cast piece, evenly mixing the metal Ga and the coase powder, and ensuring that the liquid phase Ga is evenly wrapped outside neodymium iron boron (NdFeB) powder on the condition that temperature of an airflow grinding chamber is higher than 30 DEG C. The method eliminates adverse effects on the magnetic performance of the magnet after the Ga enters NdFeB principal phase Nd2Fe14B, and avoids the loss due to the fact that the Ga is attached to a crucible in the smelting process. Therefore, compared with an NdFeB magnet which is prepared in the traditional process and has the same components with the rare earth-iron-boron permanent magnet, the rare earth-iron-boron permanent magnet is high in remanence Br, coercive force Hc and maximum magnetic energy product (BH) max. In addition, compared with an NdFeB magnet with high coercive force, the proportion of Ga which needs adding in the magnet prepared through the method is obviously decreased, and production and manufacture costs are reduced, and rare earth resources are saved.

Owner:ANHUI NINGCI ELECTRONICS TECH CO LTD

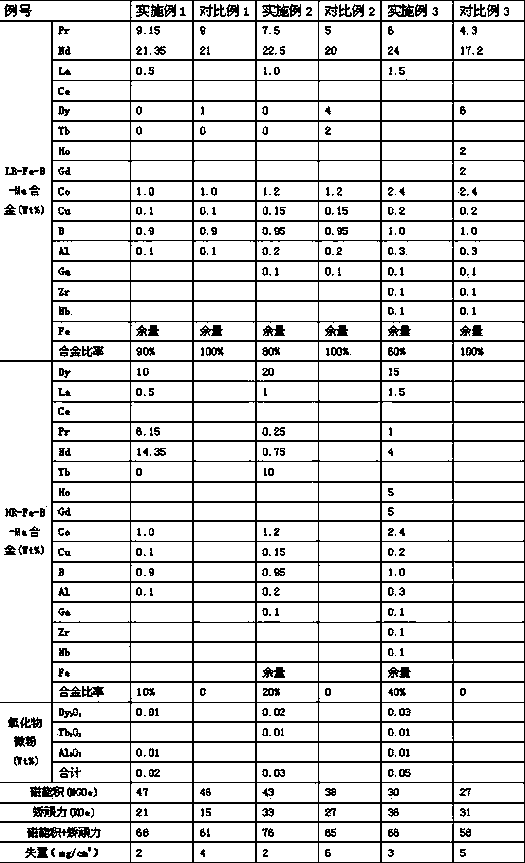

Manufacturing method for Ce-containing NdFeB rare earth permanent magnet

ActiveCN103996522AImprove antioxidant capacityReduce dosageInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHydrogen

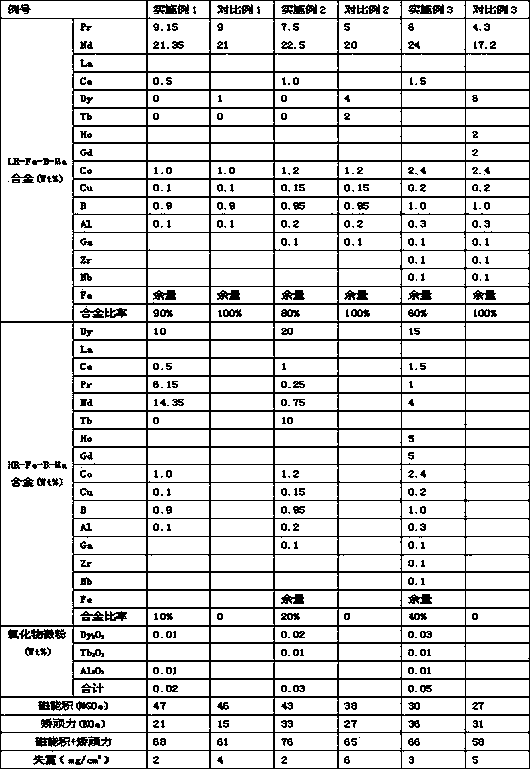

The invention discloses a manufacturing method for a Ce-containing NdFeB rare earth permanent magnet. The Ce-containing NdFeB rare earth permanent magnet is made of Ce-LR-Fe-B-Ma alloy, Ce-HR-Fe-B-Mb alloy and metal oxide micro-powder, wherein LR represents two or more rare-earth elements which do not contain Ce but contain Nd and Pr; HR represents one or more rare-earth elements which do not contain Ce but contain Dy or Tb; Ma represents one or more elements of Al, Co, Nb, Ga, Zr, and Cu; Mb represents one or more elements of Al, Co, Nb, Ga, Zr, Cu and Mo. The manufacturing method for the Ce-containing NdFeB rare earth permanent magnet comprises the following working procedures of smelting the Ce-LR-Fe-B-Ma alloy, smelting the Ce-HR-Fe-B-Mb alloy, performing hydrogen decrepitation on the alloy, performing surface adsorption on the metal oxide micro-powder and pulverization, performing magnetic field forming, performing sintering and performing aging. In this way, the NdFeB rare earth permanent magnet is manufactured.

Owner:SHENYANG GENERAL MAGNETIC

High-stability carbon nanometer fluorescence dye

InactiveCN103343005AChanging the luminescence spectrumExtended service lifeLuminescent compositionsFluorescent stainingCarbon nanodots

The invention provides a high-stability carbon nanometer fluorescence dye. The high-stability carbon nanometer fluorescence dye is coated on the surface of a conventional luminescent material, can be used for changing a luminescent spectrum and comprises a carbon nano-dot fluorescent material, a thinning agent, a binding agent and a fluorescent dyeing matter. The high-stability carbon nanometer fluorescence dye is characterized in that the carbon nano-dot fluorescent material is mixed with the thinning agent to form a fluorescent solution containing the carbon nano-dot fluorescent material; the fluorescent solution is uniformly mixed with the binding agent to form a fluorescent binding agent; and the fluorescent binding agent is combined with the fluorescent material. The high-stability carbon nanometer fluorescence dye provided by the invention has the characteristics of transparency, stability, no toxicity, environmental protection, low cost, simplicity in use and the like. The high-stability carbon nanometer fluorescence dye can be widely applied to the fields such as color long afterglow, light emitting display, light conversion agents, anti-fake fluorescent materials and various coatings.

Owner:SHANGHAI DONGZHOU IND

Nanometer red long-afterglow luminescent material and preparation method thereof

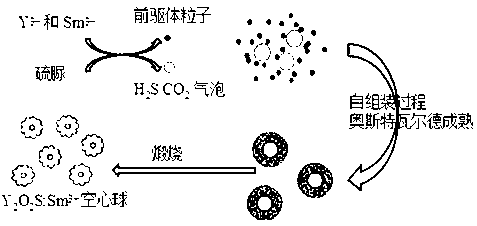

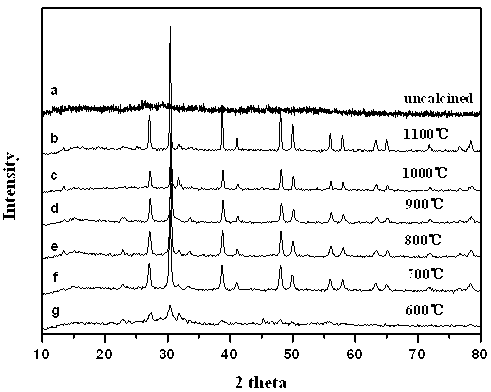

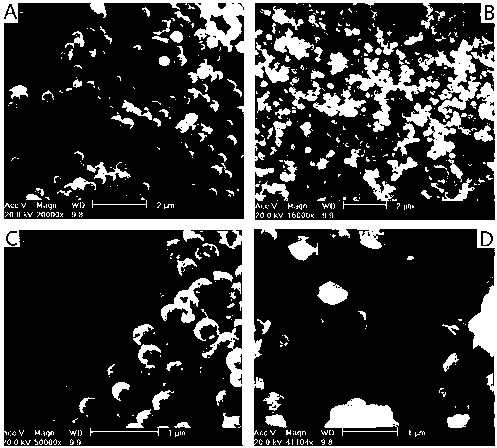

InactiveCN102827608ACalcination temperature is lowEnergy savingLuminescent compositionsActive agentAqueous solubility

The invention discloses a nanometer red long-afterglow luminescent material and a preparation method of the nanometer red long-afterglow luminescent material, belonging to the technical field of nanometer luminescent materials. The chemical formula of the material is Y202S: xSm<3+> and x=0.01-0.08; the preparation method comprises the following steps: weighing water soluble yttrium salt, water soluble samarium salt, thiocarbamide, a surfactant and ethylene glycol according to a molar ratio of 2:(0.03-0.08):(6-8):(0.05-0.1):(40-60); mixing the weighed materials for dissolution to obtain a solution; preserving the heat of the solution at a temperature from 100 DEG C to 200 DEG C in an enclosed state for 6-24 hours to obtain a brown product; cooling the brown product, filtering, washing and drying the cooled brown product to obtain a precursor; and annealing the precursor at a temperature from 600 DEG C to 1100 DEG C in a reducing atmosphere for 2-3 hours to obtain the needed product. The nanometer red long-afterglow luminescent material disclosed by the invention is good in dispersity, uniform in size and hollow in sphere structure and can be widely used for bioluminescent markers, drug release and transmission materials, light filling materials and the like.

Owner:SOUTH CHINA AGRI UNIV

Special nodulizer for low-temperature impact resistant and high-ductility nodular cast iron and method for preparing special nodulizer

The invention discloses a special nodulizer for low-temperature impact resistant and high-ductility nodular cast iron and a method for preparing the special nodulizer. Components of the special nodulizer include, in mass percent, 0.5-1.5% of RE, 4-7% of Mg, 42-49% of Si, 0.5-3% of Ca, less than or equal to 0.5% of Al, less than 0.4% of MgO and the balance Fe. The special nodulizer requires high purity, has the stable components, and is small in segregation, strict in granular control and reasonable in distribution. When in use, the special nodulizer has the advantages that nodularity is higher than 85% and recession resistance is high when Mg residues in castings are controlled within the low limit of 0.036-0.040%, Mg absorption rate is high, addition of the special nodulizer is decreased by 20-30% as compared with that of a general nodulizer, less slag is generated in nodulizing reaction, slag inclusion defects of the castings are obviously decreased, magnetic particle inspection passing rate is obviously increased, the number of graphite nodules ranges from 120 to 150, the tendency of shrinkage porosity of the castings is obviously decreased, and ultrasonic inspection passing rate is obviously increased. The content of rare earth in a traditional common nodulizer generally ranges from 2% to 6%, the content of rare earth in the special nodulizer ranges from 0.5% to 1.5%, and previous rare earth resources are saved.

Owner:JIANGSU YAFENG ALLOY MATERIAL

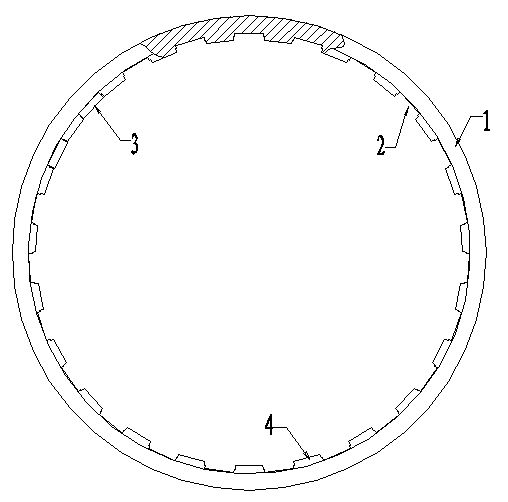

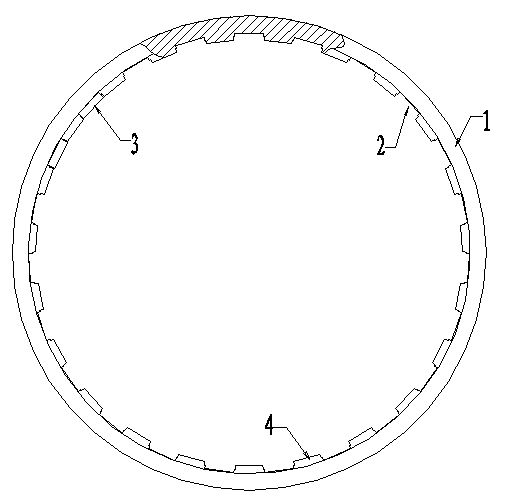

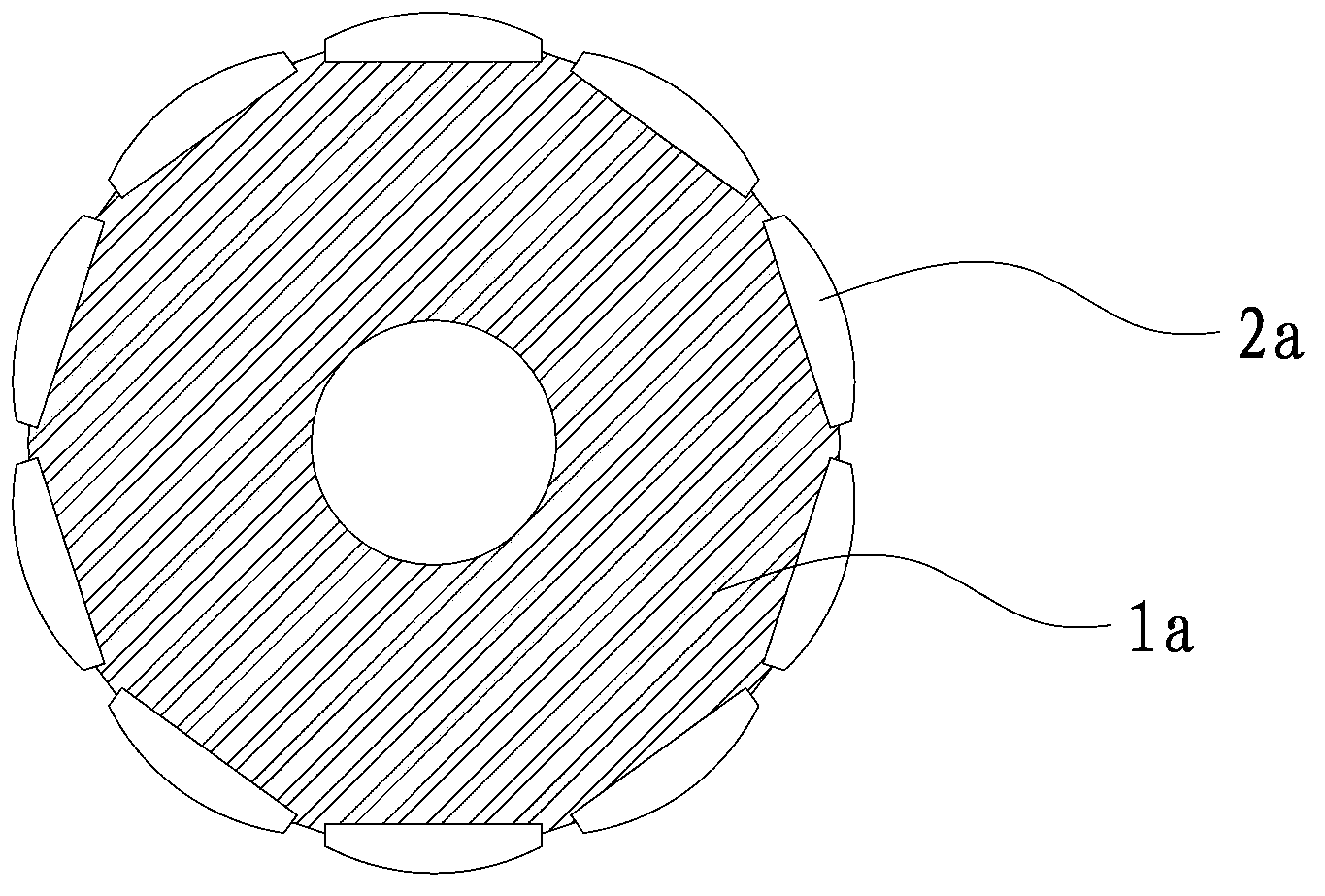

Electric vehicle motor

InactiveCN102158000AReduce dosageReduce manufacturing costMagnetic circuit rotating partsElectric machinesElectric machineElectrical polarity

The invention discloses an electric vehicle motor, which is used for solving the problem that the magnetic steel consumption in an existing electric vehicle motor is large and the manufacturing cost is high. The electric vehicle motor comprises a stator and an annular rotor, wherein the rotor is provided with a plurality of magnetic steels, and the stator is provided with wire windings. The electric vehicle motor is characterized in that the rotor is provided with an annularly fixed ring made from a permeability material; the inner circumference of the fixed ring is provided with a plurality of convex bodies and fixed grooves; the convex bodies and the fixed ring which are made from the same material are connected into a whole; the fixed grooves and the convex bodies are arranged at intervals; one magnetic steel is fixedly arranged inside each fixed groove; and the same-side ends of all the magnetic steels are same in polarity.

Owner:应光捷

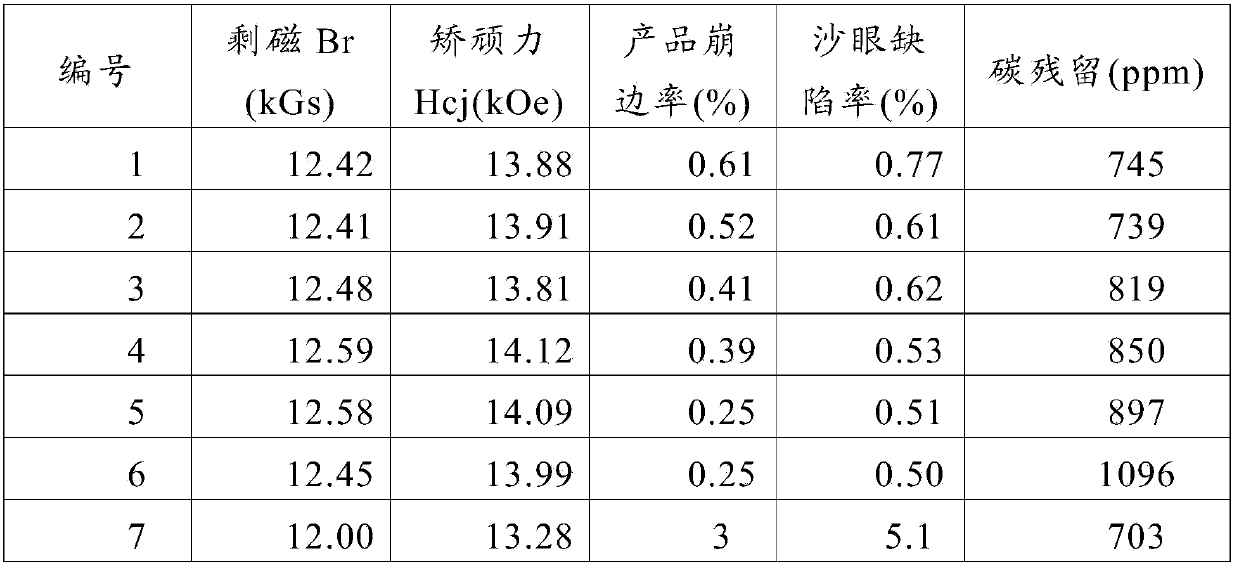

Method for manufacturing neodymium iron boron magnet

ActiveCN103996478AEfficient use ofNot prone to spontaneous combustionInorganic material magnetismInductances/transformers/magnets manufactureSpontaneous combustionPowder mixture

The invention provides an organic additive for neodymium iron boron magnet manufacturing. The additive is characterized by comprising, by mass percentage, 0.1-50% of ester matter, 0.1-25% of liquid paraffin, 0.05-10% of polybutylene, 0.01-5% of coupling agents and the balance varsol. The invention provides a method for manufacturing a neodymium iron boron magnet. The method includes the following steps that neodymium iron boron ultra-fine powder is mixed with the organic additive to obtain a neodymium iron boron ultra-fine powder mixture, and then the obtained neodymium iron boron ultra-fine powder mixture and neodymium iron boron powder are sintered to obtain the neodymium iron boron magnet. According to the method for manufacturing the neodymium iron boron magnet, the prepared organic additive and the neodymium iron boron ultra-fine powder are added into the sintering process of the magnet so that the ultra-fine powder can be effectively used; besides, the ultra-fine powder is not prone to spontaneous combustion and agglomeration in the production process, and safety hidden hazards are reduced, and production cost is lowered.

Owner:廊坊京磁精密材料有限公司

Method for recycling crystal glass rare earth polishing powder for ornaments

InactiveCN107099254AReduce generationSave rare earth resourcesPolishing compositions with abrasivesStrong acidsRare earth

The invention discloses a method for recycling crystal glass rare earth polishing powder for ornaments. The method comprises the following steps: roasting at high temperature, quenching, performing slurry mixing, performing separation, dissolving soluble substances with a strong acid mixture, coarsely sieving to remove impurities and large particles, performing fine grinding by a ball mill, drying, removing iron impurities by a magnetic separator, calcining, quenching, drying and grinding and sieving to prepare regenerated rare earth polishing powder. Compared with the prior art, the technical scheme of the invention can effectively change disposable rare earth polishing powder into recycling powder, saves precious rare earth resources and reduces generation of solid waste.

Owner:王丹

Method for manufacturing La-contained high-performance neodymium iron boron rare earth permanent magnet

ActiveCN103996523AImprove antioxidant capacityReduce dosageInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHydrogen

The invention discloses a method for manufacturing a La-contained high-performance neodymium iron boron rare earth permanent magnet. Raw materials are formed by La-LR-Fe-B-Ma alloy, La-HR-Fe-B-Mb alloy and metallic oxide micro powder, wherein the LR represents two or more rare earth elements which do not include La but include Nd and Pr, the HR represents one or more rare earth elements which do not include La but include Dy or Tb, the Ma represents one or more of Al, Co, Nb, Ga, Zr and Cu, and the Mb represents one or more of Al, Co, Nb, Ga, Zr, Cu and Mo. The manufacturing method includes the working procedures of La-LR-Fe-B-Ma alloy smelting, La-HR-Fe-B-Mb alloy smelting, alloy hydrogen decrepitation, metallic oxide micro powder surface adsorbing and making, magnetic field forming, sintering and aging, and the neodymium iron boron rare earth permanent magnet is manufactured.

Owner:SHENYANG GENERAL MAGNETIC

Metal particle-doped hollow structure orthophosphate luminescence material and preparation method thereof

InactiveCN103923658AImprove luminosityWavelength does not changeLuminescent compositionsMetal particleLength wave

The invention belongs to the field of luminescence materials, and discloses a metal particle-doped hollow structure orthophosphate luminescence material and a preparation method thereof, wherein the structure general formula of the luminescence material is Ba3-xGd(PO4)3:Dyx@My, M is doped metal nanoparticles and is at least one selected from Ag, Au, Pt, Pd and Cu, @ represents cladding, M is the inner core, and Ba3-xGd(PO4)3:Dyx is the outer shell. According to the metal particle-doped hollow structure orthophosphate luminescence material, the dispersed carbon spheres are adopted as the template, such that the obtained hollow structure having the spherical orthophosphate has the controlled morphology; and due to introduction of the M metal nanoparticles, the luminescence efficiency of the orthophosphate luminescence material can be substantially increased under the same excitation condition, and the wavelength of the emission light is not changed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for preparing high-coercivity, high-toughness and high-corrosion-resistance sintered Nd-Fe-B permanent magnet

ActiveCN103680919AImprove toughnessReduce dosageInorganic material magnetismInductances/transformers/magnets manufactureRare earthToughness

The invention belongs to the field of rare earth permanent magnetic materials, and particularly provides a method for preparing a high-coercivity, high-toughness and high-corrosion-resistance sintered Nd-Fe-B permanent magnet. The method is characterized in that pure Cu nanopowder is used for completely replacing a grain boundary Nd-rich phase to achieve isolation of a liquid phase and the magnet. The Cu nanopowder with the even grain size being 20-150nm is added in 3-5 microns of Nd-Fe-B base powder with the proportion being 2:14:1 to be evenly mixed, the adding proportion is 2-8% of the weight of the 2:14:1 Nd-Fe-B base powder, and orientation, briquetting and isostatic pressing are conducted on the mixture in a magnetic filed larger than 1.5T. The mixture is placed in a vacuum sintering furnace and is sintered for 2-5 hours at the temperature of 1000-1100 DEG C, at last, secondary heat treatment is conducted, namely heat treatment is conducted for 1-4 hours at the temperature of 600-800 DEG C (primary heat treatment temperature) and at the temperature of 300-500 DEG C (secondary heat treatment temperature) respectively, and Nd-Fe-B magnetic materials are obtained. The method has the advantages that the Cu nanopowder is used for completely replacing the grain boundary Nd-rich phase to achieve isolation of the liquid phase and the magnet, high coercivity, high toughness and high corrosion resistance can be achieved, the cost of raw materials can also be greatly lowered, and rare earth resources are saved. The method is simple in operation and facilitates industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Calcium stannate europium luminescence material having hollow structure, and preparation method thereof

InactiveCN103923649AReduce dosageShape is easy to controlLuminescent compositionsMaterials scienceEuropium luminescence

The invention belongs to the field of luminescence materials, and discloses a calcium stannate europium luminescence material having a hollow structure, and a preparation method thereof, wherein the structure general formula of the luminescence material is Ca2-xSnO4:Eux, and x is more than 0 and is less than or equal to 0.05. According to the calcium stannate europium luminescence material having the hollow structure, the dispersed carbon spheres are adopted as the template so as to obtain the hollow structure having the spherical calcium stannate europium, such that the morphology can be controlled, and the luminescence efficiency is enhanced.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

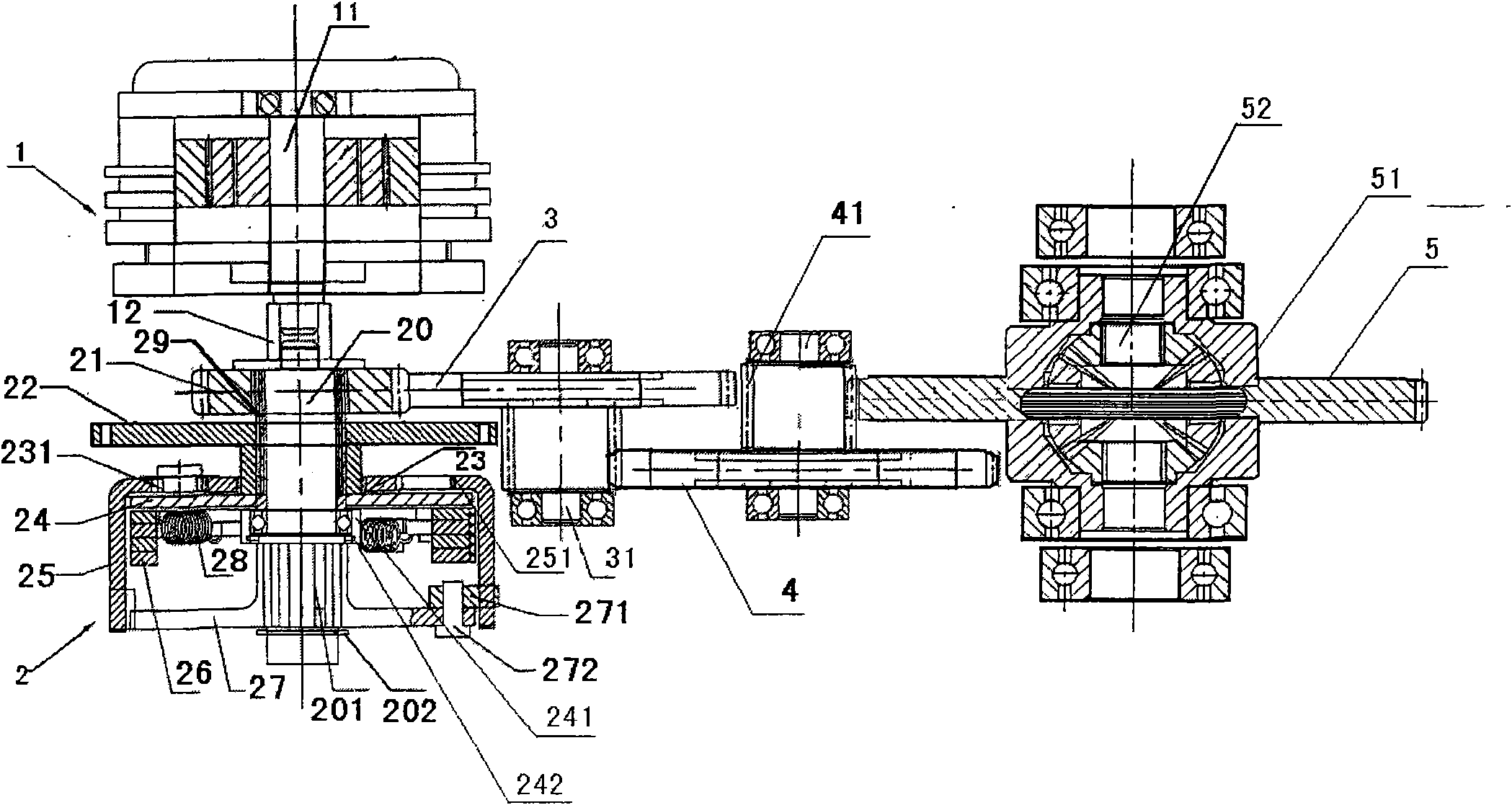

Auto-wave differential electrical motor transmission mechanism of electrombile

InactiveCN102848910ASimple structureReduce the amount of magnetic steelWheel based transmissionCycle actuatorsDrive wheelAutomatic transmission

The invention discloses an auto-wave differential electrical motor transmission mechanism of an electrombile. The mechanism comprises an electrical motor, an automatic speed changer, a gear reduction mechanism and a differential system and is characterized in that the automatic speed changer comprises a speed changer shaft, a main gear, a sun wheel fixing plate, a driving disk, a casing and a connecting plate, a motor shaft of the electrical motor drives a shaft of the speed changer, the connecting plate is installed at the other end of the speed changer, a fixing block on the connecting plate is connected the casing, a planetary gear is installed on the upper portion of the casing, the lower portion of the planetary gear is connected with the driving disk with a shoe fixedly, the shoe is connected with a pulling spring, the driving disk is sleeved outside the shaft of the speed changer through a driving disk spline, a sun wheel spline housing is matched with a spline of the sun wheel fixing plate, two sides of the sun wheel fixing plate is drilled and fixed on a body of the speed changer, the driving disk is connected with the driving gear through the driving disk spline, the driving gear drives a first carrier gear, a first carrier driven wheel drives a second carrier gear, a second carrier driven wheel drives the driven gear, the driven gear is connected with the differential system, and a spline housing of the differential system is connected with a rear axle shaft of the electrombile.

Owner:金碧波

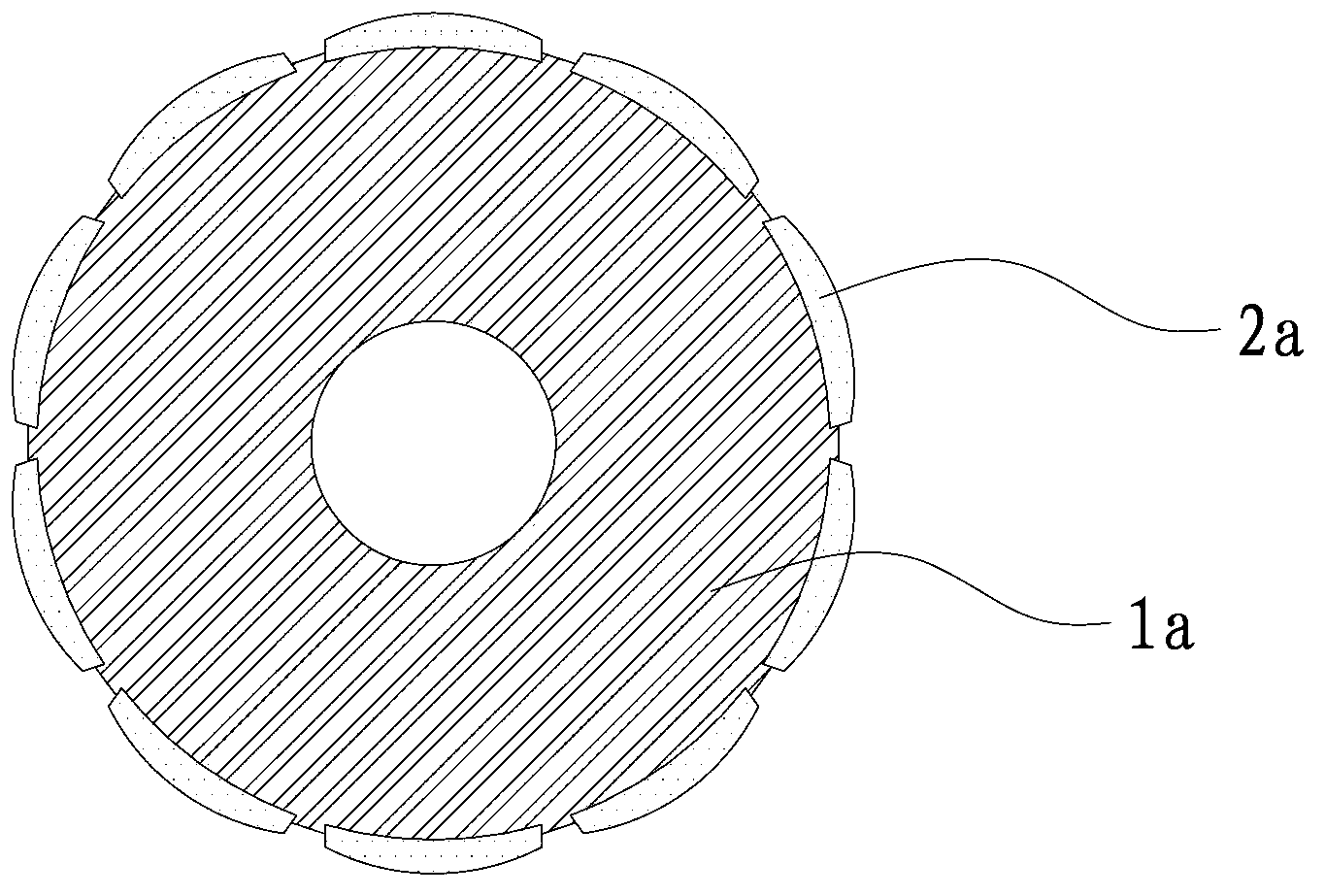

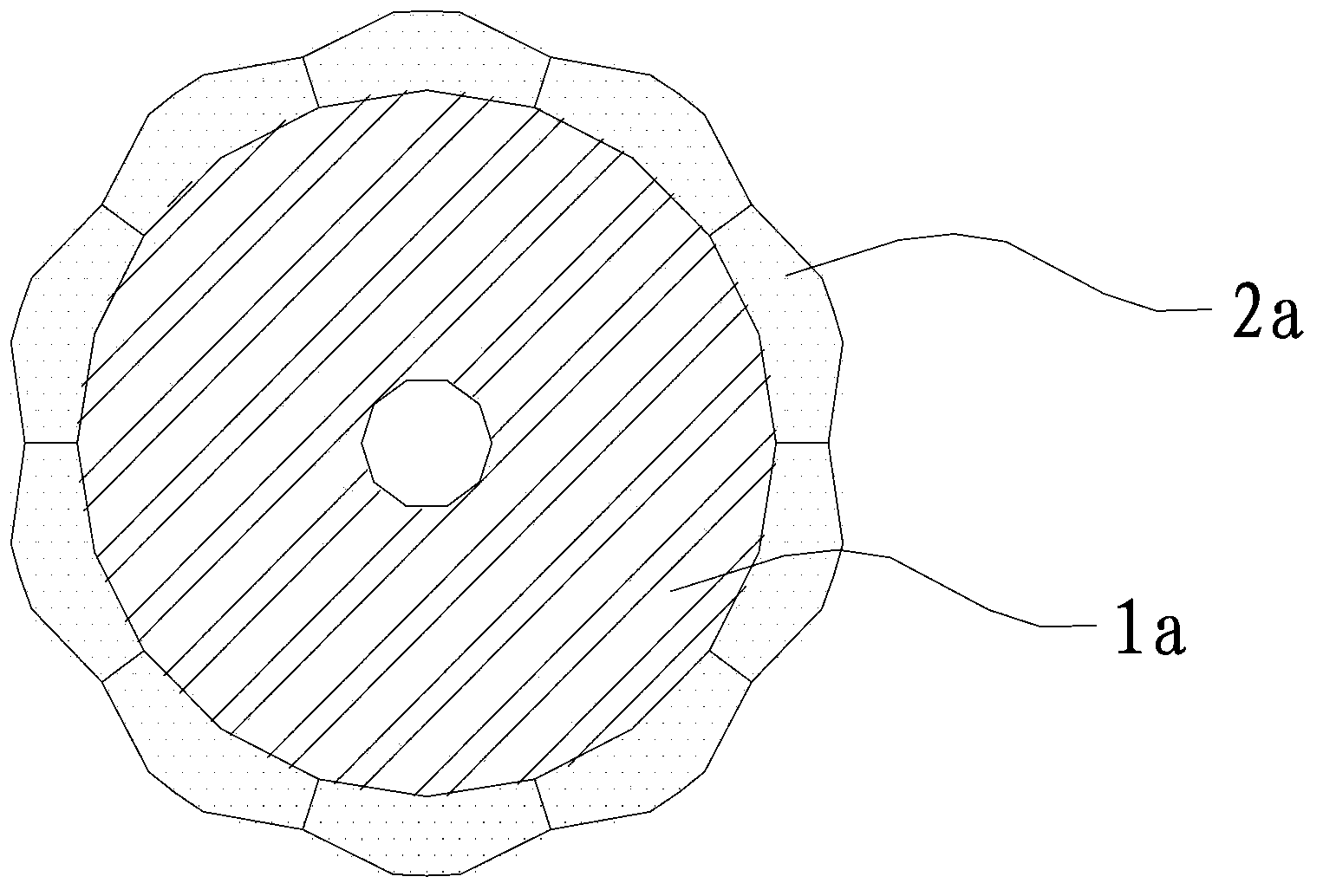

Motor and manufacturing method thereof

InactiveCN104113153AImprove resistance to demagnetizationImproving the anti-demagnetization ability of magnetic steelMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringHigh current

The invention is suitable for the technical field of motors, and discloses a motor and a manufacturing method thereof. The aforementioned motor comprises a rotor which comprises a rotor iron core and magnetic steel. There are multiple sets of magnetic steel arranged at the external side of the rotor iron core. The rotor iron core is provided with groove positions which are inwardly recessed from the external surface of the rotor iron core to a rotor. The groove positions are arranged between adjacent magnetic steel. The bottom part of the groove positions is closer to the center of the rotor in a way of being relative to the bottom surface of magnetic steel. The aforementioned manufacturing method comprises the following steps that a stator and the rotor iron core with the groove positions arranged at the external side surface are prepared; positioning strips are arranged in the groove positions; and magnetic steel is adhered at the external side of the rotor iron core, and the side surface of magnetic steel and the side surface of the positioning strips are enabled to be adhered. According to the motor and the manufacturing method thereof, the groove positions are arranged on the rotor iron core, and relatively high magnetic resistance is generated at the groove positions so that resistance to demagnetization of magnetic steel can be substantially enhanced when high current is inputted to the motor at high temperature. Besides, the motor is great in performance and long in the service life.

Owner:MIDEA WELLING MOTOR TECH SHANGHAI

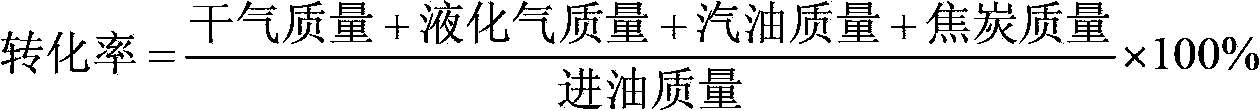

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657700AHigh thermal and hydrothermal stabilityImprove structural stabilityCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component comprises a rare-earth Y-type molecular sieve; and the rare-earth content in the Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, adhesive and clay, carrying out spray drying, washing and drying. Compared with the prior art, the rare-earth-containing Y-type molecular sieve has higher structural stability and activity stability; and the catalyst has higher thermal and hydrothermal stability, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal particle-doped hollow structure calcium titanate praseodymium luminescence material and preparation method thereof

InactiveCN103923651AImprove luminous efficiencyWavelength does not changeLuminescent compositionsPhysical chemistryMetal particle

The invention belongs to the field of luminescence materials, and discloses a metal particle-doped hollow structure calcium titanate praseodymium luminescence material and a preparation method thereof, wherein the structure general formula of the luminescence material is Ca1-xTi1-ySnyO3:Prx@Mz, M is doped metal nanoparticles and is at least one selected from Ag, Au, Pt, Pd and Cu, @ represents cladding, M is the inner core, and Ca1-xTi1-ySnyO3:Prx is the outer shell. According to the metal particle-doped hollow structure calcium titanate praseodymium luminescence material, the dispersed carbon spheres are adopted as the template, such that the obtained hollow structure having the spherical calcium titanate praseodymium has the controlled morphology; and due to introduction of the M metal nanoparticles, the luminescence efficiency of the calcium titanate praseodymium luminescence material can be substantially increased under the same excitation condition, and the wavelength of the emission light is not changed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Samarium-doped hollow-structure Sr2CeO4 luminescent material and preparation method thereof

InactiveCN104119900AReduce dosageShape is easy to controlLuminescent compositionsSamariumLuminescent material

The invention belongs to the field of luminescent materials, and discloses a samarium-doped hollow-structure Sr2CeO4 luminescent material and a preparation method thereof. The chemical general formula of the luminescent material is Sr2-xCeO4:Smx<3+>, wherein x is the molar number of Sm<3+> replacing Sr ion, and 0<x<=0.2. According to the provided samarium-doped hollow-structure Sr2CeO4 luminescent material, dispersed carbon small spheres C are taken as a template, and the obtained Sr2CeO4 luminescent material has a spherical hollow structure, and is controllable in morphology and improved in luminescent efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

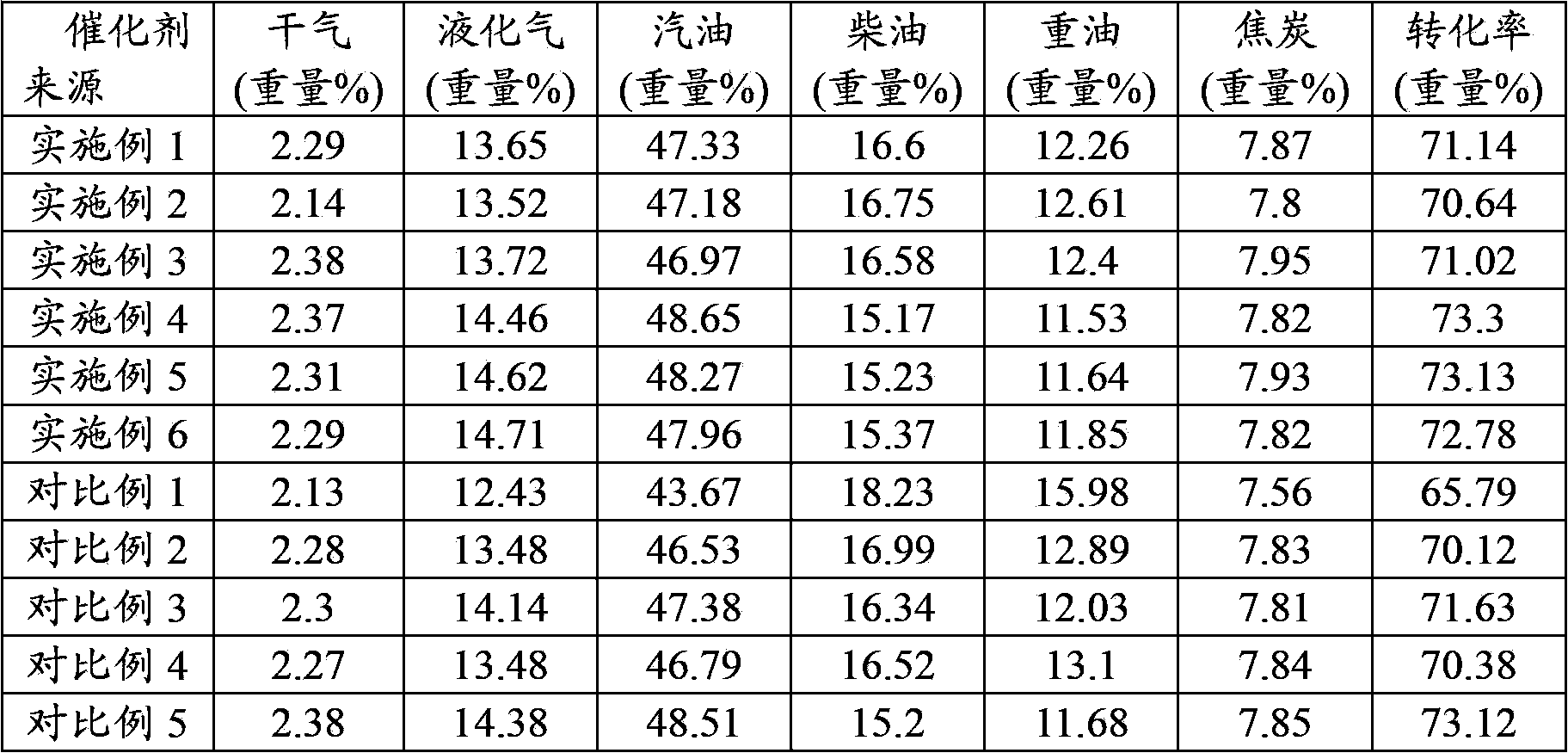

Rare-earth complex coated nanometer hollow SiO2, coated -earth complex and preparation method of coated -earth complex

InactiveCN109504366AReduce consumptionGood solvent resistanceMaterial nanotechnologyFluorescence/phosphorescenceBiocompatibility TestingRare earth

The invention discloses rare-earth complex coated nanometer hollow SiO2. The rare-earth complex coated nanometer hollow SiO2 takes nanometer hollow silicon dioxide as a core, and takes rare-earth complex as a shell to be coated on the surface of the hollow silicon dioxide in an electrostatic adsorption mode, so as to form a particulate material. The rare-earth complex coated nanometer hollow SiO2effectively solves the problems of stability and fluorescence intensity of the rare-earth complex, not only greatly improves the fluorescence intensity of the rare-earth complex of a core-shell structure, but also reduce the dosage of the rare-earth complex. The rare-earth complex coated nanometer hollow SiO2 uses the high biocompatibility of silicon dioxide, and can be applied to biological carriers and fluorescence probes.

Owner:QINGDAO UNIV

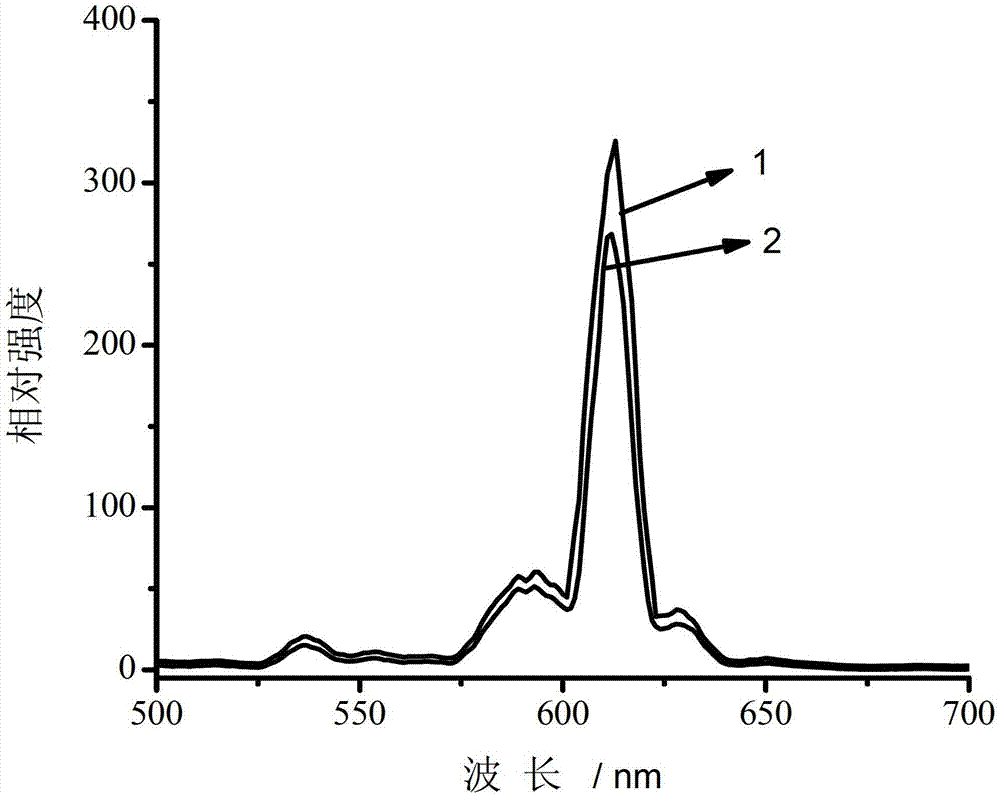

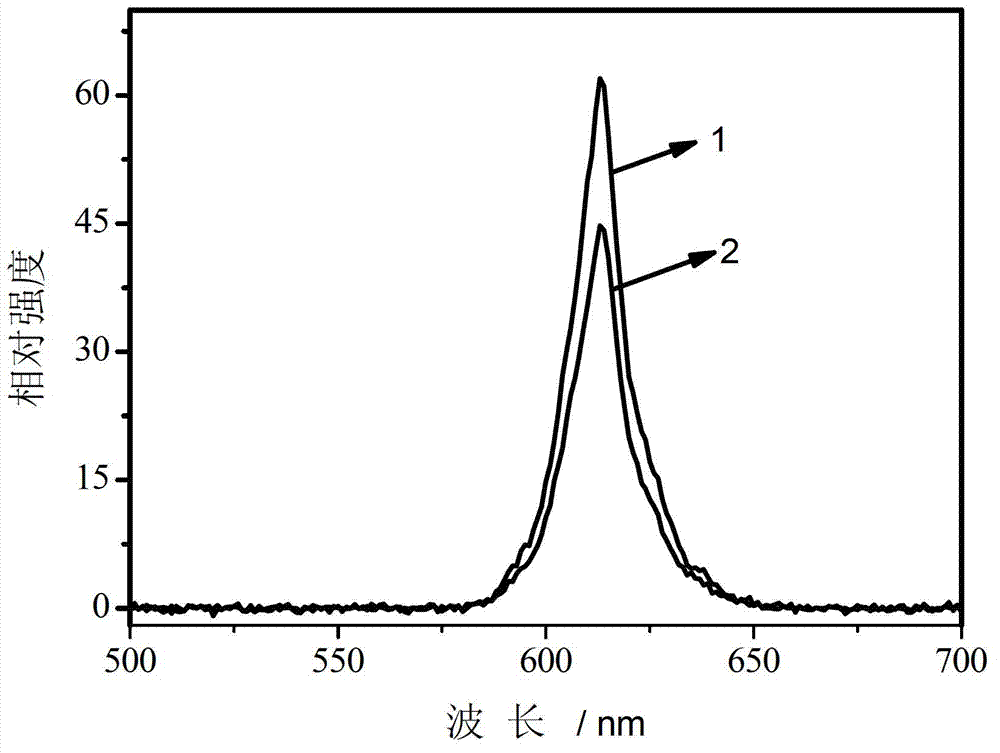

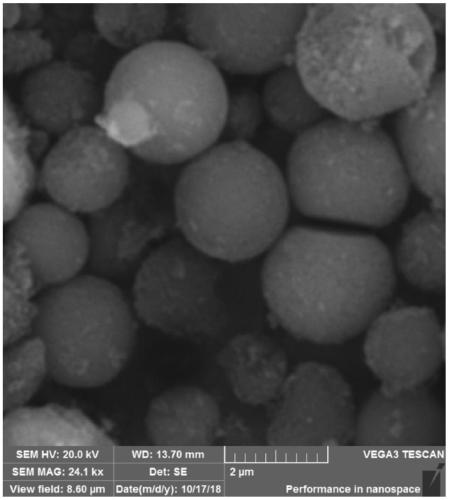

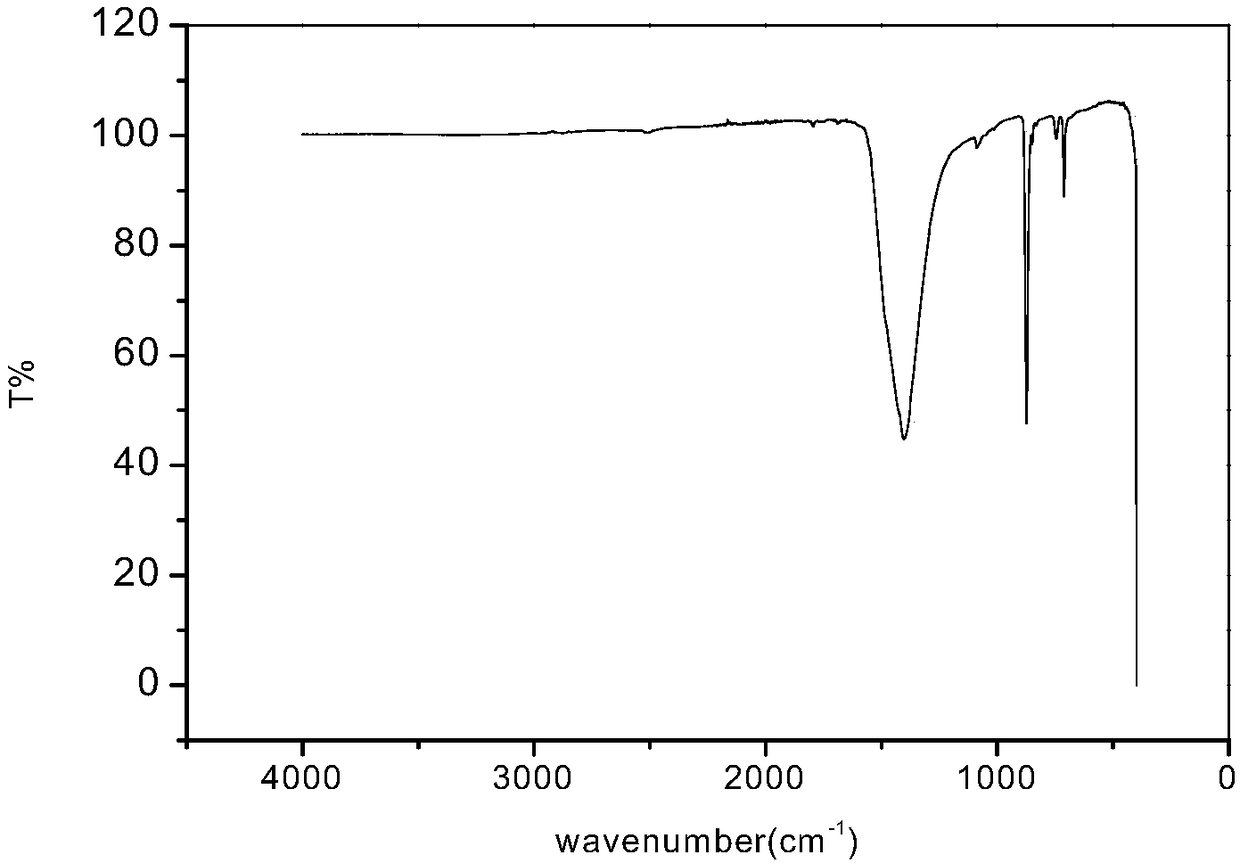

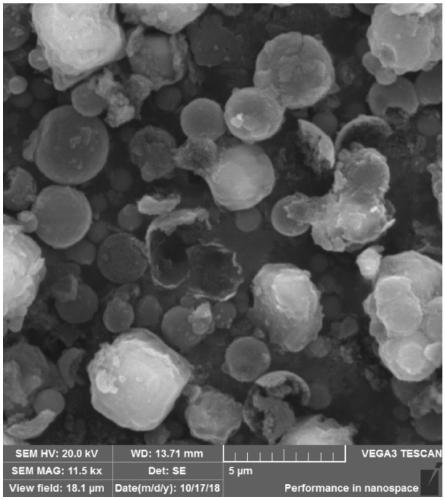

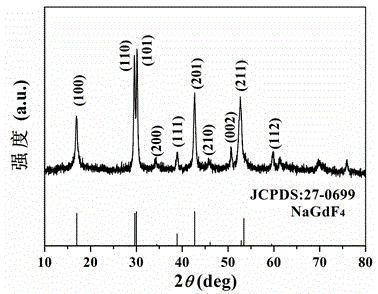

Preparation method of europium-doped sodium gadolinium fluoride red light-emitting porous nanocrystal material

ActiveCN104357056ASimple preparation processEase of industrial productionNanoopticsLuminescent compositionsOrganic solventActive agent

The invention discloses a preparation method of a europium-doped sodium gadolinium fluoride red light-emitting porous nanocrystal material, relating to a light-emitting nano material of which the nominal composition is NaGd[1-x]EuxF4 (x=0-10mol%). The red light-emitting porous nanocrystal material has the advantages of favorable dispersity, controllable crystal form structure and shape, high fluorescence intensity, low rare-earth consumption due to porous structure, energy saving and the like. The preparation technique is simple and does not need any surfactant; and the whole reaction is carried out in the water solution without using any organic solvent, so the method is economical and environment-friendly and is convenient for industrial production.

Owner:江苏晶曌半导体有限公司

Lanthanum calcium gallate luminescent material and preparation method thereof

ActiveCN103849402AImprove luminous efficiencyImprove luminosityLuminescent compositionsLanthanumLength wave

The invention belongs to the field of luminescent materials and discloses a lanthanum calcium gallate luminescent material and a preparation method thereof. The lanthanum calcium gallate luminescent material has a general molecular formula of CaLa1-xGa3O7: Dy<3+>@My; and in the general molecular formula, M represents at least one of Ag, Au, Pt, Pd and Cu nanoparticles, @ represents coating, the M metal nanoparticle is used as a core, CaLa1-xGa3O7: Dy<3+> is used as a shell, x is >0 and <=0.2, and y is > 0 and <= 1*10<-2>. Through use of the M metal nanoparticles, the luminescence efficiency of the lanthanum calcium gallate luminescent material is greatly improved under the same excitation condition and emitted light wavelength is not changed. The lanthanum calcium gallate luminescent material has good luminescence performances and color purity and brightness of the excited emitted light are high.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Preparation method of luminescent material based on rare earth phosphate

PendingCN111019641AImprove fluorescence performanceGood water solubility and biocompatibilityLuminescent compositionsBiological macromoleculeLanthanum nitrate

The invention discloses a preparation method of a luminescent material based on rare earth phosphate. A rare earth nitric acid compound is prepared from rare earth oxide; rare earth phosphate containing two rare earth elements is prepared by doping yttrium nitrate, lanthanum nitrate and gadolinium nitrate with terbium nitrate or europium nitrate; in the preparation process, nanometer silicon dioxide is used for coating rare earth phosphate, and due to the existence of a silicon dioxide shell layer, the ion fluorescence of rare earth is obviously enhanced; meanwhile, the nanometer silicon dioxide shell layer can protect inner-layer particles from being influenced by an external physical and chemical environment, and the fluorescence property of the rare earth luminescent material is enhanced; meanwhile, through rich Si-OH groups on the surface of the nanometer silicon dioxide, the rare earth phosphate can be combined with biomacromolecules and can be used for researching the applicationof the rare earth phosphate in the field of fluorescence labeling materials; and by using a modified organic silicon ligand, the nanometer silicon dioxide and the rare earth phosphate are combined more tightly, and a structure is more stable.

Owner:HEBEI NORTH UNIV

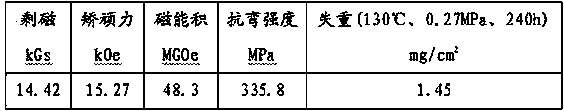

Preparation method of a high performance and low cost composite magnet

ActiveCN108242336BIncrease profitImprove diffusion efficiencyInductances/transformers/magnets manufactureRare-earth elementGrain boundary

The invention provides a preparation method of a high-performance and low-cost composite magnet, relating to the preparation techniques of permanent magnet materials. The preparation method comprisesthe steps of with superfine powder recycled during neodymium iron boron jet-milling pulverization as a rare earth diffusion source, mixing the superfine powder with reducing powder, coating the surface of an NdCeFeB magnet with two main phases of Nd2Fe14B and Ce2F214B with the mixture, putting the NdCeFeB magnet into a vacuum heat treatment furnace, and carrying out grain boundary diffusion to generate reduction reaction between the superfine powder and the reducing powder so as to separate out a rare earth element RE in the superfine powder through reduction, wherein the rare earth element REcontains one or more of Nd, Pr, Dy and Tb; and diffusing the rare earth element RE into the dual-main-phase NdCeFeB magnet so as to form hard magnetic layers on the surfaces of grain crystals, and reducing the magnetic coupling effect among grain crystals so as to increase the coercive force of the dual-main-phase magnet and obtain high-performance and low-cost composite magnet. The preparation method is simple in craft process, easy in operation and low in cost and applicable to large-scale batch production.

Owner:苏州心愿美电子商务有限公司

Low neodymium content magnetic particle and preparation process thereof

The invention relates to the field of magnetic material, in particular to a low neodymium content magnetic particle and a preparation process thereof. The raw materials of low neodymium content magnetic particle include, by weight percentage: 10% to 15% of neodymium, 70% to 80% of iron, 1% to 5% of aluminum, 1% to 5% of boron, and 3% to 10% of zirconium. The preparation process includes weighing the neodymium, iron, aluminum, boron and zirconium properly, arranging in a vacuum induction furnace, and smelting to obtain alloy ingots; crushing the alloy ingots into particles with the particle degree smaller than 10mm, arranging in a vacuum quenching furnace, cooling the liquid alloy in the speed of hundred thousand to million degree centigrade per second, and obtaining amorphous or microcrystalline thin strips with the thickness of 30 micrometers; pressing the amorphous or microcrystalline thin strips to obtain particles with the particle degree of 150 micrometers, performing crystallization treatment in a vacuum crystallization furnace at the temperature of 70 DEG C, crushing the magnetic powder into powder material with the mesh ranging from 100 to 200, and obtaining the low neodymium content magnetic particle after detection qualification.

Owner:MIANYANG XINYA TECH

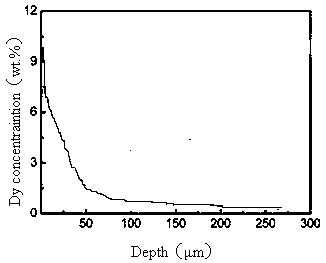

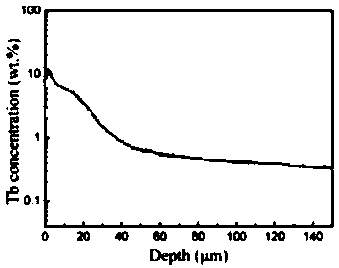

NdFeB sintered magnet with coating and preparation method thereof

ActiveCN108565088AEasy to operateImprove product qualityPermanent magnetsElectrophoretic coatingsMetallurgyRare earth

Disclosed is a NdFeB sintered magnet with coating. A dysprosium (Dy) or terbium(Tb)-containing transition layer is formed inside a magnet body ,which is in contact with a dysprosium fluoride or Terbium fluoride coating, of the NdFeB sintered magnet. A preparation method of the NdFeB sintered magnet with coating includes (1), taking NdFeB sintered magnet as a positive electrode, taking a steel plate as a negative electrode, preparing electrophoresis buffer by mixing DyF3 or TbF3 powder into an organic solvent, performing electrophoretic deposition, removing the magnet from the electrophoresis buffer until mass of the DyF3 or TbF3 coating is 1-2.5wt% of that the magnet, and then drying; (2), dispersing the dried magnet at the temperature of 700-950 DEG C, performing vacuum annealing, coolingto obtain the NdFeB sintered magnet with coating; the concentration of DyF3 or TbF3 powder of the electrophoresis buffer is 5-7g / L. According to the preparation method, operation is facilitated, requirements on processing conditions are low, quality of products is stable, and production cost is saved as usage of heavy rare earth DyF3 or TbF3 is saved.

Owner:严高林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com