Electric vehicle motor

A technology for electric vehicles and stators, which is applied to electric vehicles, motors, vehicle parts, etc., can solve the problem of not showing the effect of saving the amount of magnetic steel, and achieve the effect of saving the amount of consumption, small impact, and saving rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

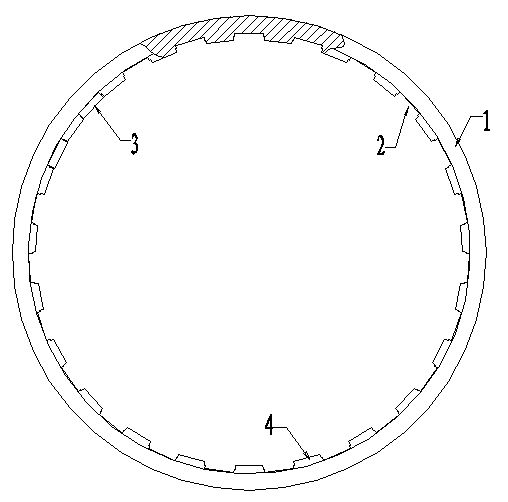

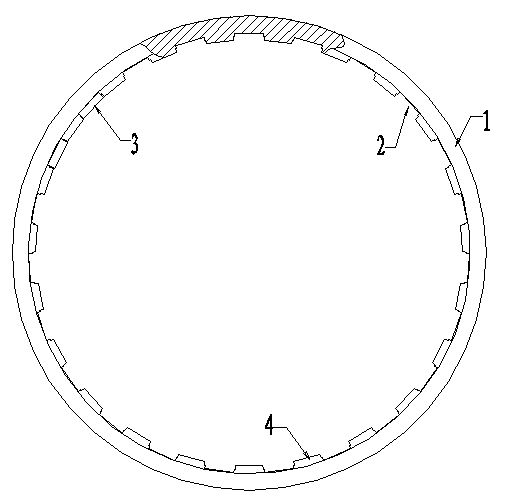

[0019] The structure of the electric vehicle motor of the present invention includes a stator and a rotor. The stator is provided with a wire winding, and the lead wire of the wire winding passes through the axle; the rotor is provided with magnetic steel 3 uniformly distributed along its circumference. The polarities of all the ends of the magnetic steels 3 facing the stator are the same, that is, they are all S poles or N poles.

[0020] An annular fixed ring 1 is arranged on the rotor, and the fixed ring 1 is made of iron. The fixed ring 1 and the rotor are connected as a whole with homogeneous materials, and they are actually constituted as a single piece.

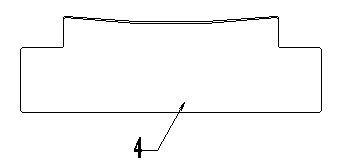

[0021] Several protrusions 4 and fixing grooves 2 are arranged on the inner peripheral surface of the fixing ring 1, and the protrusions 4 and the fixing ring 1 are connected as a whole by homogeneous materials. The convex body 4 protrudes inward along the radial direction of the fixed ring 1 , and the fixed groove 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com