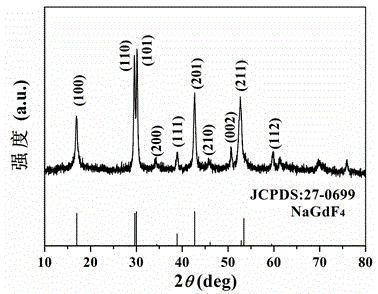

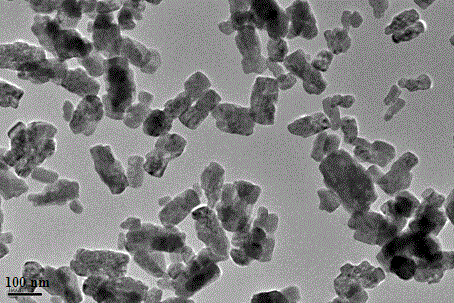

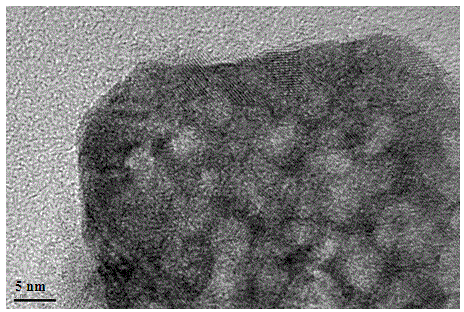

Preparation method of europium-doped sodium gadolinium fluoride red light-emitting porous nanocrystal material

A technology of europium gadolinium fluoride sodium and nanocrystalline materials, which is applied in the field of rare earth europium ion-doped gadolinium sodium fluoride red light-emitting porous nanocrystalline materials and the preparation field, achieving the effect of simple preparation process and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The red light-emitting porous nanocrystalline material of europium-doped gadolinium fluoride sodium of the present invention comprises: NaGd 1-x Eu x f 4 ,in x = 5 mol %. Its concrete preparation steps are as follows:

[0037] 1) Measure 9.5 ml of Gd(NO 3 ) 3 solution (0.4 mol / L) and 1 ml of Eu(NO 3 ) 3Solution (0.2 mol / L concentration) was dissolved in 150 ml distilled water to obtain [Gd(NO 3 ) 3 +Eu(NO 3 ) 3 ] Mix the solution, take out 25 ml and keep it for later use. Add 3 g of urea to the mixed solution, heat at 90 °C for 2 h, and slowly form a white precipitate. The resulting white precipitate was centrifuged and washed once with distilled water, then transferred to a beaker, added 40 ml of distilled water, ultrasonically dispersed for 15 min, and then magnetically stirred for 0.5 h to obtain a white suspension A;

[0038] 2) Add 14 ml of NaF aqueous solution to the suspension A with a concentration of 2 mol / L, stir magnetically to fully mix the rea...

Embodiment 2

[0042] The red light-emitting porous nanocrystalline material of europium-doped gadolinium fluoride sodium of the present invention comprises: NaGd 1-x Eu x f 4 ,in x = 2 mol %. Its concrete preparation steps are as follows:

[0043] 1) Measure 9.8 ml of Gd(NO 3 ) 3 solution (0.4 mol / L) and 0.8 ml of Eu(NO 3 ) 3 Solution (0.1 mol / L concentration) was dissolved in 180 ml distilled water to obtain [Gd(NO 3 ) 3 +Eu(NO 3 ) 3 ] Mix the solution, take out 30 ml and keep it for later use. Add 3.5 g of urea to the mixed solution, heat at 90°C for 2.5 h, and slowly form a white precipitate. The resulting white precipitate was centrifuged and washed twice with distilled water, then transferred to a beaker, added 30 ml of distilled water, ultrasonically dispersed for 18 min, and then magnetically stirred for 0.5 h to obtain a white suspension A;

[0044] 2) Add 8 ml of NaF aqueous solution to the suspension A with a concentration of 4 mol / L, stir magnetically to fully mix t...

Embodiment 3

[0049] The red light-emitting porous nanocrystalline material of europium-doped gadolinium fluoride sodium of the present invention comprises: NaGd 1-x Eu x f 4 ,in x = 8 mol%. Its concrete preparation steps are as follows:

[0050] 1) Measure 9.2 ml of Gd(NO 3 ) 3 solution (0.4 mol / L) and 1.6 ml of Eu(NO 3 ) 3 Solution (0.2 mol / L concentration) was dissolved in 200 ml distilled water to obtain [Gd(NO 3 ) 3 +Eu(NO 3 ) 3 ] Mix the solution, take out 35 ml and keep it for later use. Add 4 g of urea to the mixed solution, heat at 90 °C for 3 h, and slowly form a white precipitate. The resulting white precipitate was centrifuged and washed once with distilled water, then transferred to a beaker, added 30 ml of distilled water, ultrasonically dispersed for 20 min, and then magnetically stirred for 0.5 h to obtain a white suspension A;

[0051] 2) Add 15 ml of NaF aqueous solution to suspension A with a concentration of 2 mol / L to fully mix the reactants to obtain whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com