Patents

Literature

67results about How to "Solve the problem of impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

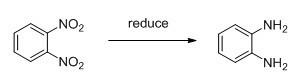

Method for preparing o-phenylenediamine by catalytic hydrogenation of o-nitrophenylamine

InactiveCN102633653ASolve the problem of impuritiesReduce the presence of impuritiesOrganic compound preparationAmino compound preparationPtru catalystHydrogen pressure

The invention discloses a method for preparing o-phenylenediamine by catalytic hydrogenation of o-nitrophenylamine. The method is characterized in that: in the hydrogenation reaction of o-nitrophenylamine, alcohol is used as a solvent, nickel is used as a catalyst, reduction reaction is performed for 2 to 10 hours under the hydrogen pressure of 1.0 to 6 MPa at the temperature of between 40 and 80 DEG C, and the reaction product is rectified to form the while o-phenylenediamine. The method has the advantages that the alcohol is used as the solvent in the catalytic hydrogenation for producing o-phenylenediamine, the alcohol can be reclaimed and directly used for next reaction, and the waste residue produced by distillation can be used as an organic fuel, so that the problem that a large amount of waste water containing organic substances is produced in reduction of iron powder or sodium sulfide in the conventional process is solved; and thick acid and thick alkali used in the conventional process are avoided in the hydrogenation process, so that corrosion of equipment is greatly reduced, pollution is reduced, and almost zero pollution is realized. In addition, compared with the conventional iron powder or sodium sulfide reduction, the catalytic hydrogenation process has the advantages of low pollution, high yield, high quality, short production period and low energy consumption.

Owner:JIANGSU KANGHENG CHEM

Ferrite ductile iron used at low temperature and manufacturing method thereof

ActiveCN102634723AEasy to controlSolve the problem of impuritiesProcess efficiency improvementChemical compositionFerrosilicon

The invention discloses chemical compositions of ferrite ductile iron used at low temperature and a manufacturing method of the ferrite ductile iron, determines the range of the chemical compositions of the ferrite ductile iron used at low temperature being minus 40 DEG C and provides a quality standard for the production of qualified and stable ductile iron workpieces. The manufacturing method comprises the steps of adopting pure iron, a carburant and silicon iron as raw materials, synthesizing and melting the raw materials in an electric furnace, conducting spheroidization on the raw materials by utilizing a low-rare-earth spheroidizing agent, and producing the ferrite ductile iron by adopting a combined inoculation method. According to the method, the purity of molten iron is improved stably, and the difficulties of high phosphorus, sulphur, titanium, other imputies and interference elements contents in the molten iron, large fluctuation and instability are solved. According to the method, a novel technical scheme is provided for the production of ferrite ductile iron workpiece which contains small, circular and smooth ductile iron and does not contain cementite and iron phosphide eutectic basically, the ferrite ductile iron can meet the demands of high-performance ferrite ductile iron workpiece in electrical industry, high-speed rail industry and the like, the dependence on imported products can be broken; and the running safety of nuclear power and the high-speed rail can be improved substantially.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

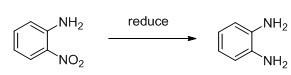

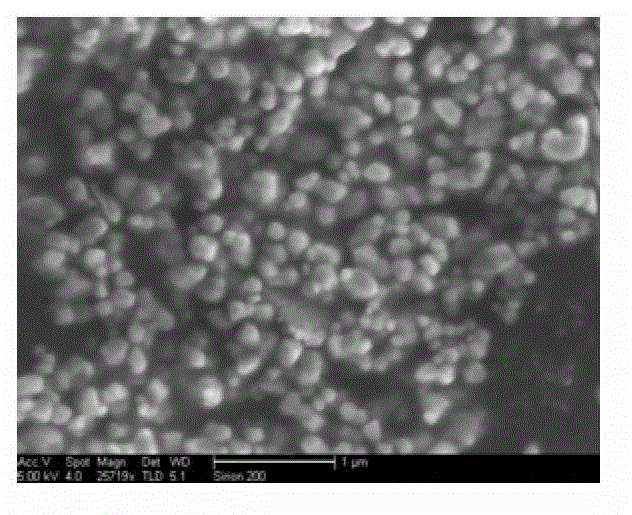

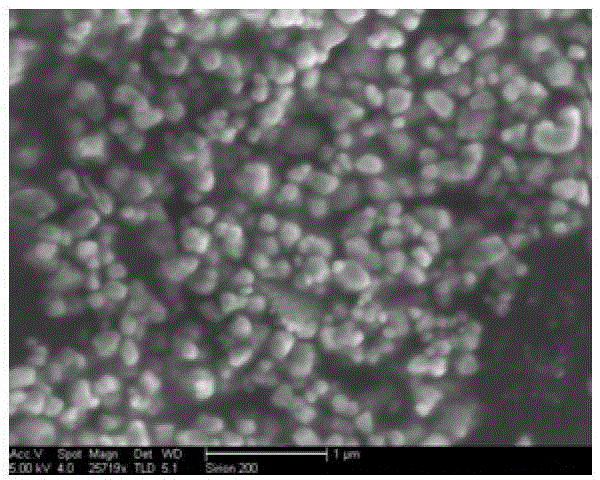

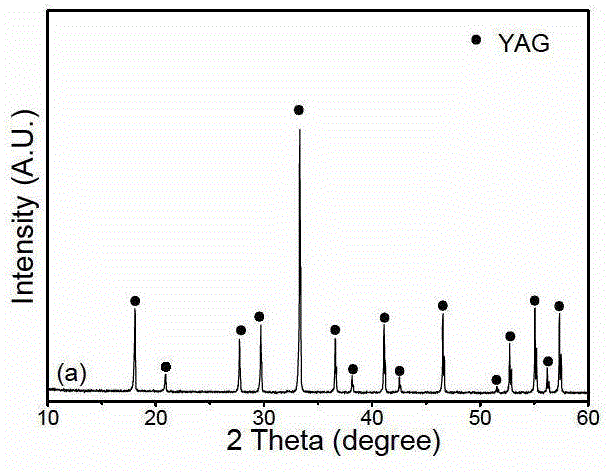

Method for preparing rare earth doping yttrium aluminum garnet crystalline ceramic through synthesis of rare earth doping Y2O3 nanometer powder

InactiveCN103058644ASolve the problem of impuritiesAvoid compositional segregationMetallurgyRare earth

The invention discloses a method for preparing rare earth doping yttrium aluminum garnet crystalline ceramic through synthesis of rare earth doping Y2O3 nanometer powder. Through a new preparation process, the method for preparing the rare earth doping yttrium aluminum garnet crystalline ceramic through the synthesis of the rare earth doping Y2O3 nanometer powder realizes the purposes of not only solving an impurity problem in a solid phase method, but also avoiding a component segregation problem in a liquid phase method, and optimizes the preparation process.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

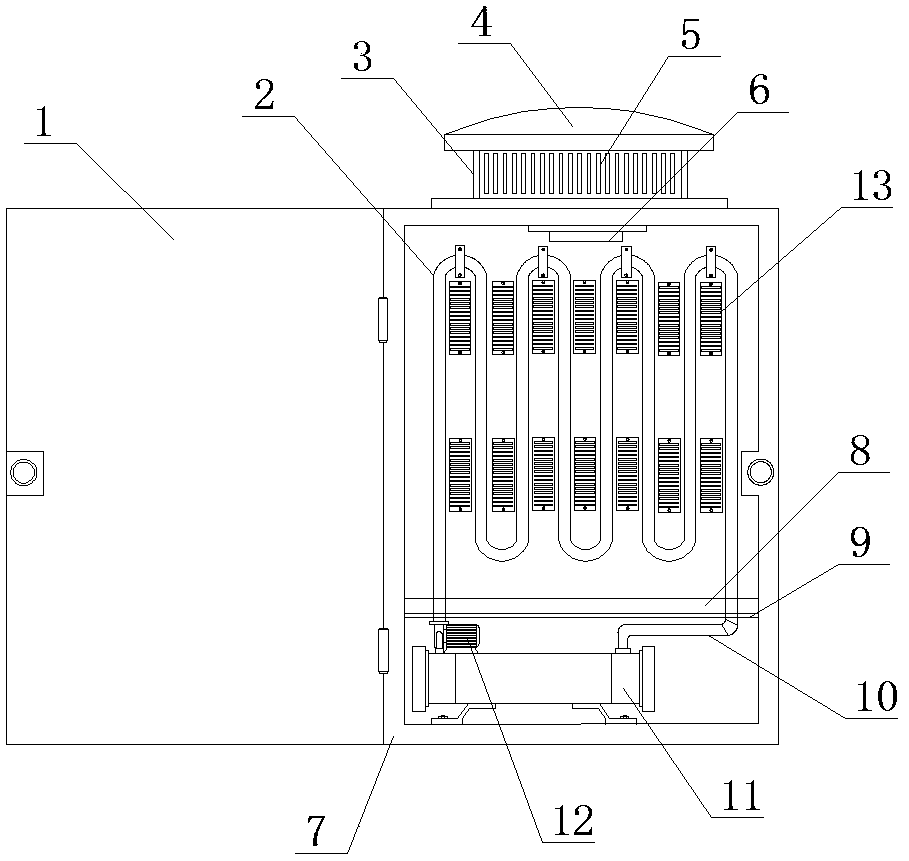

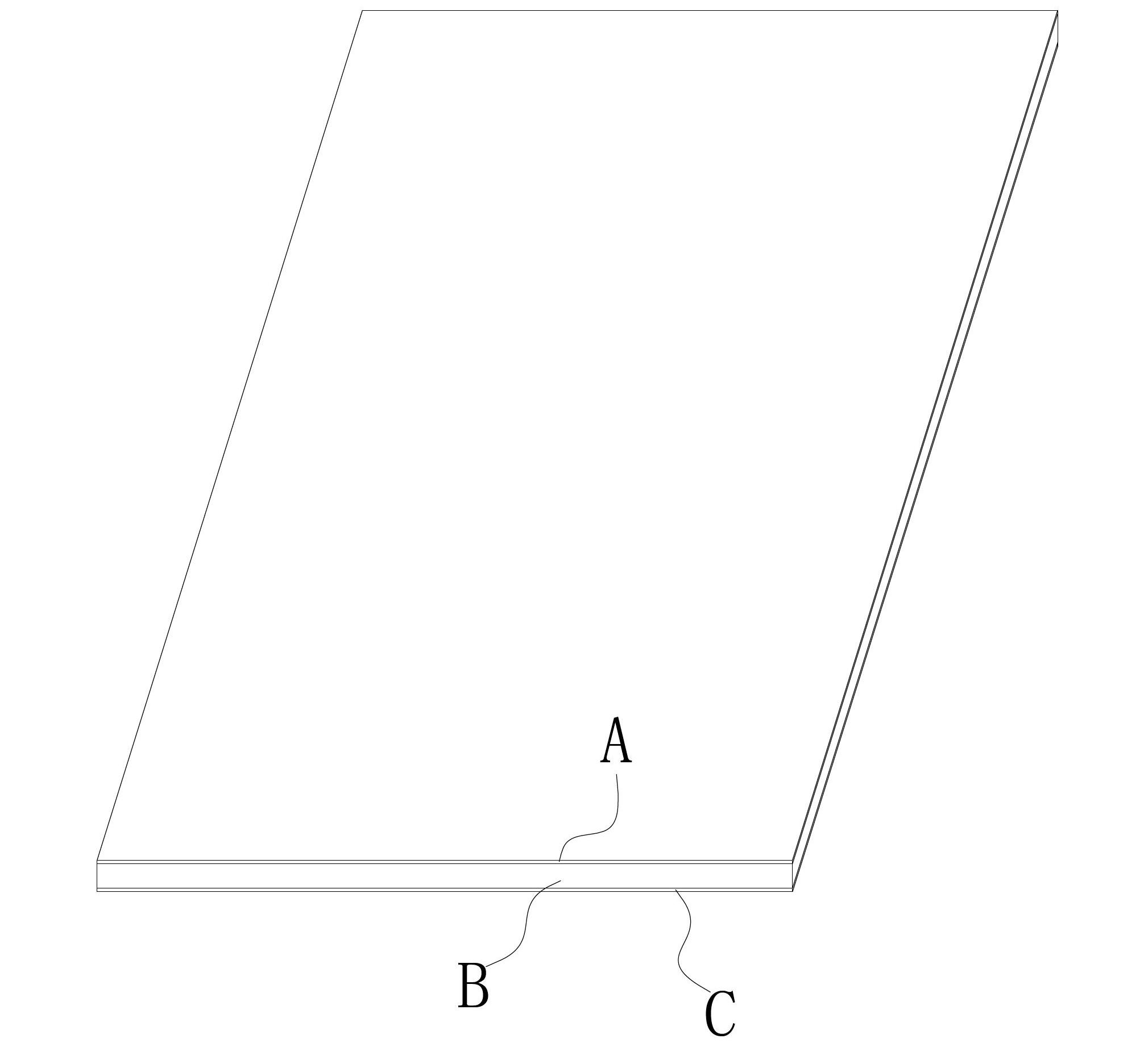

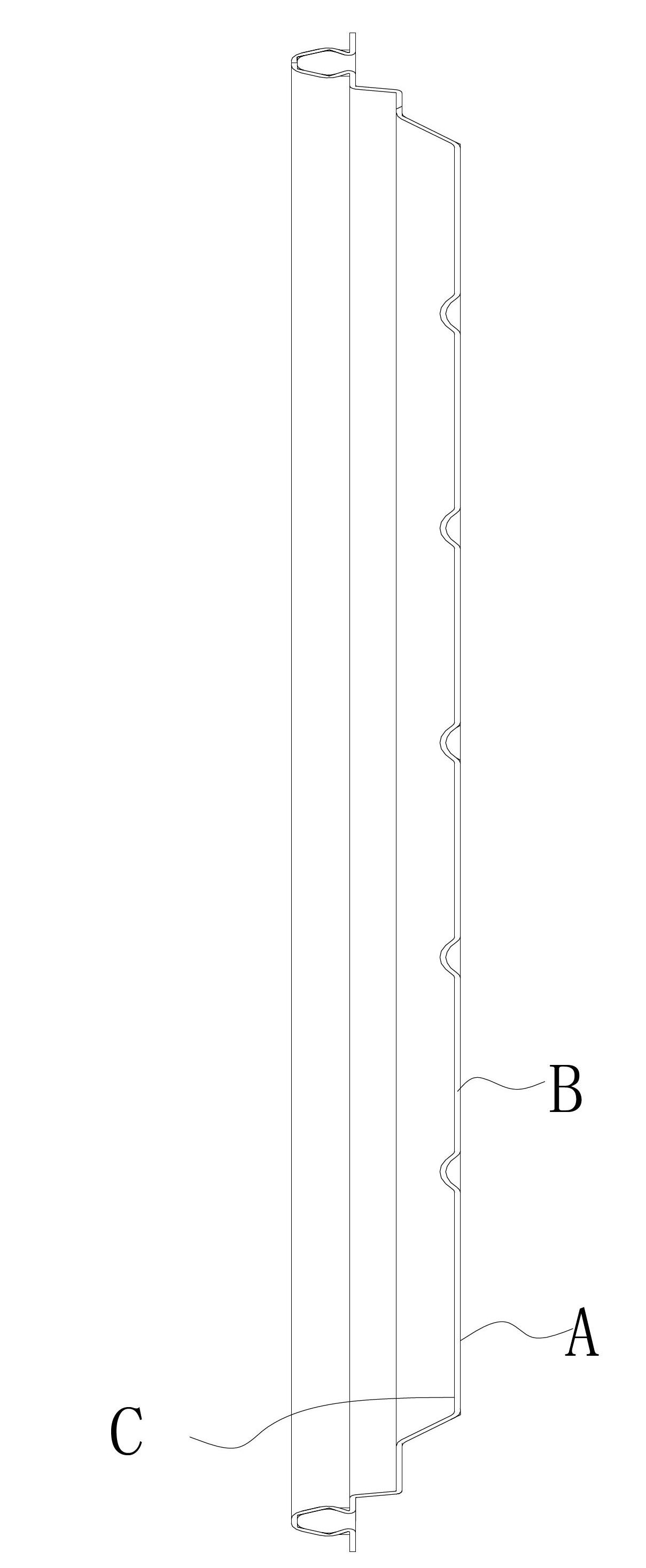

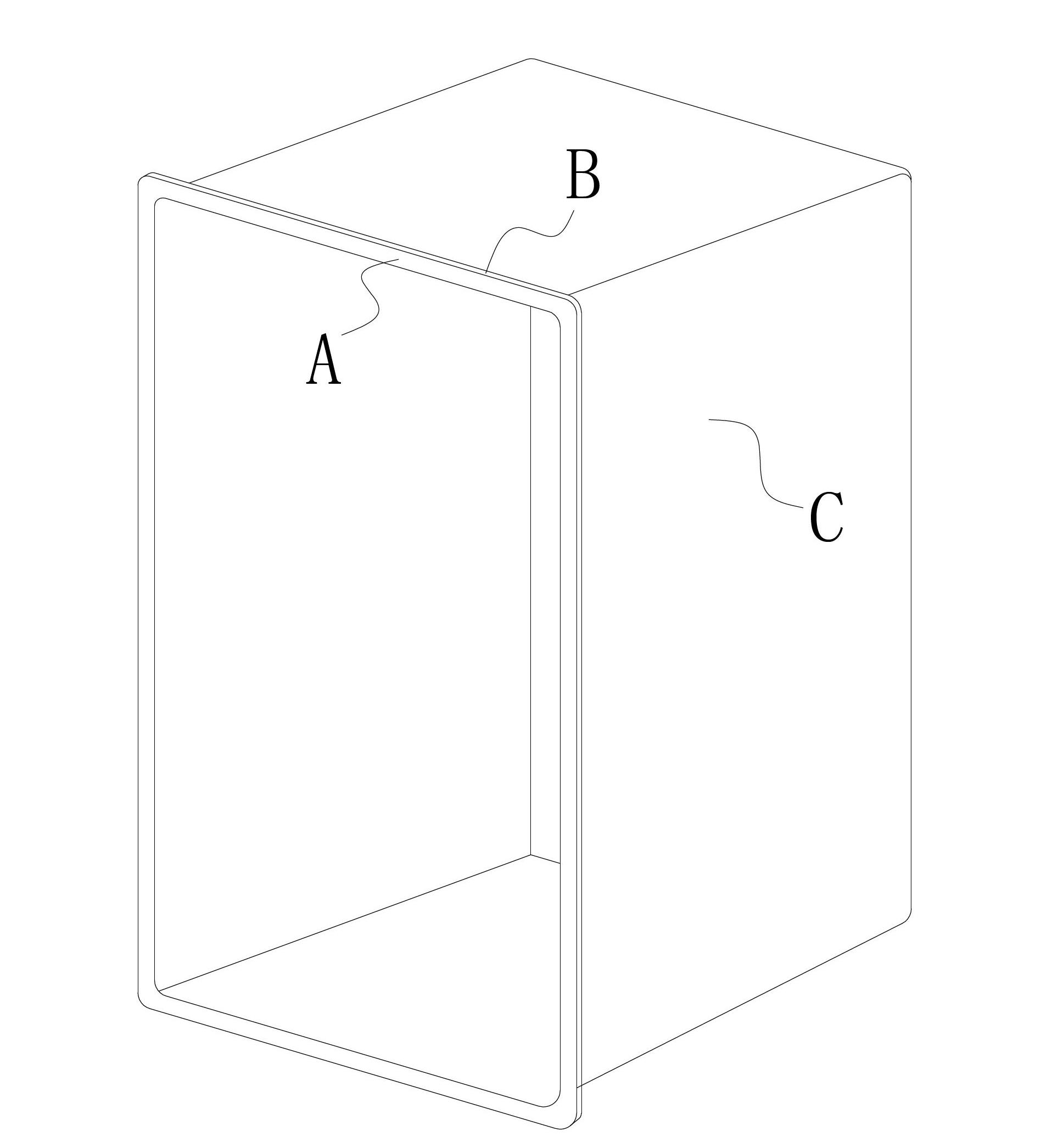

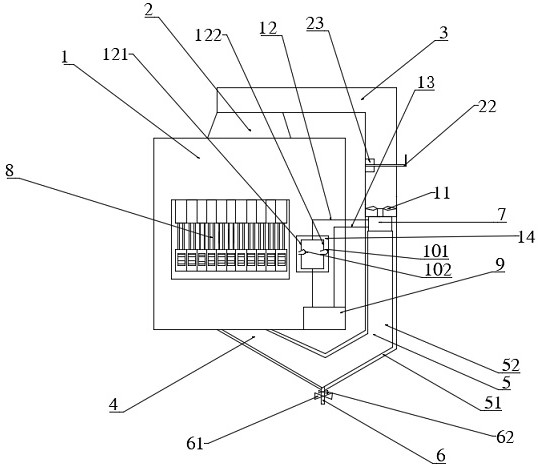

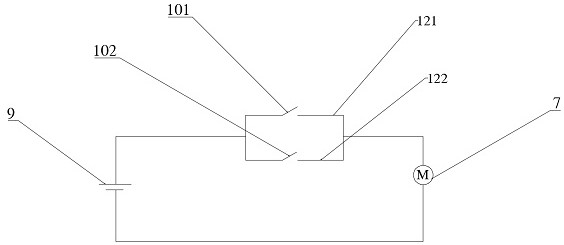

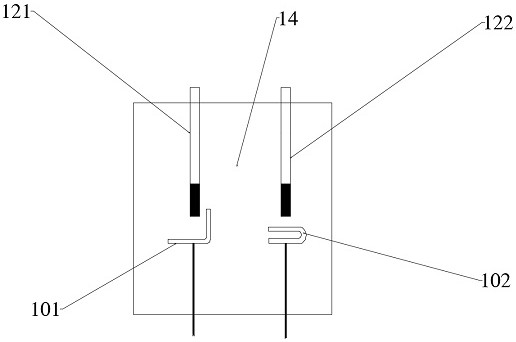

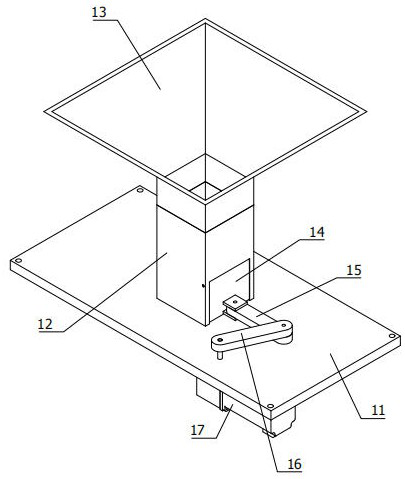

Low-voltage electrical appliance cabinet having circular heat-dissipation function

InactiveCN107645890AAvoid introducingImprove cooling efficiencyCooling/ventilation/heating modificationsLow voltageCirculator pump

The invention discloses a low-voltage electrical appliance cabinet having a circular heat-dissipation function. The low-voltage electrical appliance cabinet comprises an electrical appliance cabinet body, wherein the electrical appliance cabinet body is hinged with a cabinet door by means of hinges, a substrate is horizontally arranged inside the electrical appliance cabinet body, the bottom partinside the electrical appliance cabinet body is provided with a water cooler by means of screws, a circulation pump is arranged on the top part of the water cooler, a cooling pipe is arranged on the circulation pump, the cooling pipe extends upwards after passing through the substrate, the cooling pipe is fixed on the inner wall of the electrical appliance cabinet body by means of hoop members, and the water cooler is fixed connected with the cooling pipe by means of a return pipe. According to the low-voltage electrical appliance cabinet, a radiating plate absorbs heat rapidly, the high-temperature heat of the radiating plate is taken away by using circulating cold water when the cooling pipe flows through the radiating plate, the absorption efficiency is high, the temperature reducing speed is fast, the internal heat of the electrical appliance cabinet is released to the outside by means of a draught fan, the problem of introduction of impurities in the air is solved since the air flows outwards, a flow guiding top is of an arch-shaped structure, the flow guiding effect is good, and backward flow of rainwater is prevented.

Owner:江阴多高自动化科技有限公司

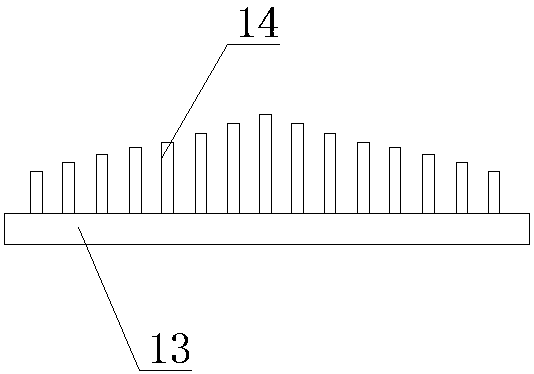

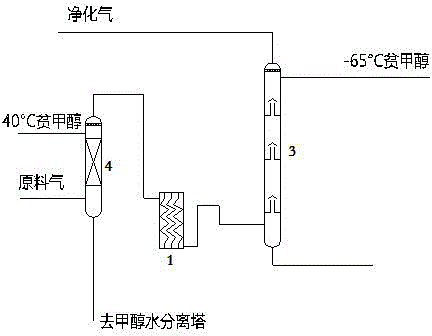

Method for removing acid gas by adopting methanol as absorbent

InactiveCN104436998ASolve the impuritiesSolve the shortcomings of waterDispersed particle separationGas coolerPre washing

The present invention belongs to the field of gas processing, and provides a method for removing acid gas by adopting methanol as an absorbent. According to the present invention, the method is mainly characterized in that a pre-washing tower is designed in front of an absorption tower, and pre-washing is performed on raw material gas with a barren solution obtained from the original low temperature methanol washing device and with a temperature of about 30-40 DEG C, such that the raw material gas is dewatered and completely dried, and ammonia naphthalene, benzene and other components carried in the raw material gas are removed; the liquid on the bottom portion of the pre-washing tower enters a methanol water separation tower; and the gas on the top of the pre-washing tower enters a process gas cooler and then enters the absorption tower. With the method of the present invention, the problem of the impurity and the moisture carried by carried raw material gas before entering the absorption tower is solved, wherein the raw material gas is pre-washed, such that the raw material gas is dewatered and dried, and the impurity such as ammonia, naphthalene, benzene and the like are removed so as to make the subsequent treatment system stable.

Owner:CHINA PETROLEUM & CHEM CORP +1

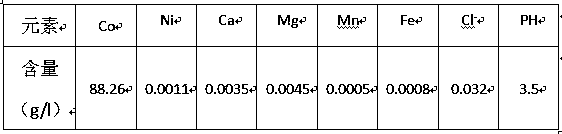

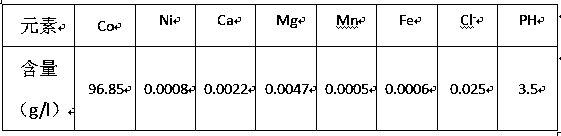

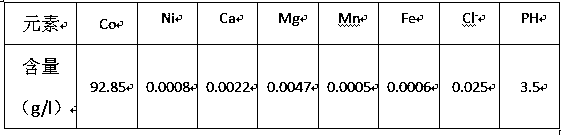

Extraction washing method for low-chlorine-ion high-purity cobaltous sulfate

ActiveCN109609758AHigh product puritySolve the problem of impuritiesProcess efficiency improvementIonCounter current

The invention discloses an extraction washing method for low-chlorine-ion high-purity cobaltous sulfate. The extraction washing method comprises the following steps that firstly, cobalt containing rawmaterials are subjected to leaching and P204 extraction and impurity removal through a conventional method, raffinate is obtained, an organic extraction agent and sulfonated kerosene are mixed, and counter-current extraction is conducted through an extraction box; secondly, a loaded organic phase enters an extraction washing section for counter-current washing, hydrochloric acid is used for washing a small number of nickel, magnesium and calcium impurities in the organic phase, and the obtained washed loaded organic phase is subjected to washing and chlorine ion removal; and thirdly, second-section washing is conducted, the washed loaded organic phase in the second step enters second-section washing and is subjected to counter-current chlorine ion washing, sulfuric acid is added for washing, the PH value is controlled, and the obtained washed loaded organic phase is subjected to reverse extraction through sulfuric acid. The problem that cobaltous sulfate products are high in impurityor chlorine ion content is solved, the purity of the cobaltous sulfate products is improved, the quality of raw materials of the battery positive electrode material precursor is guaranteed, the two-section washing manner is adopted, the chlorine ion washing effect is achieved, magnesium calcium sulfate sediments cannot be formed, so that extraction tank blockage is avoided

Owner:江苏雄风科技有限公司

Inner container of refrigeration equipment and preparation method thereof

InactiveCN102661646AHigh strengthAvoid crackingDomestic cooling apparatusLighting and heating apparatusFoaming agentSurface layer

The invention discloses an inner container of refrigeration equipment and a preparation method thereof. The inner container of the refrigeration equipment is formed by an HIPS (high impact polystyrene) three-layer composite board, the HIPS three-layer composite board comprises a surface layer, a basic layer and a bottom layer, wherein the surface layer is composed of a surface layer HIPS, and the surface layer HIPS is selected from one or more types of natural color HIPS, tinction HIPS and modification extrusion grade HIPS; and the basic layer comprises the natural color extrusion grade HIPS and a feeding material, and the bottom layer is composed of a resistance foaming agent erosion HIPS. According to the inner container of the refrigeration equipment provided by the embodiment of the invention, the HIPS three-layer composite board is adopted to shape, and the surface layer, the basic layer and the bottom layer of the HIPS three-layer composite board are all made of HIPS materials; the different HIPS materials after screening have good consistency, and can be mutually mixed; and the appearance and processing behaviour of the board can not be obviously influenced, the intensity of the board is improved, and the cracking risk is reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

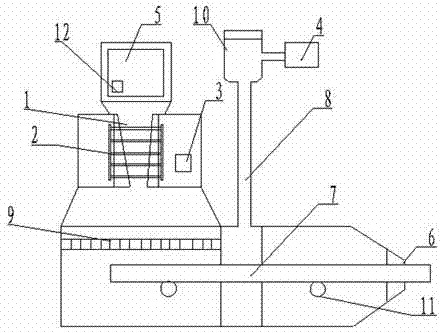

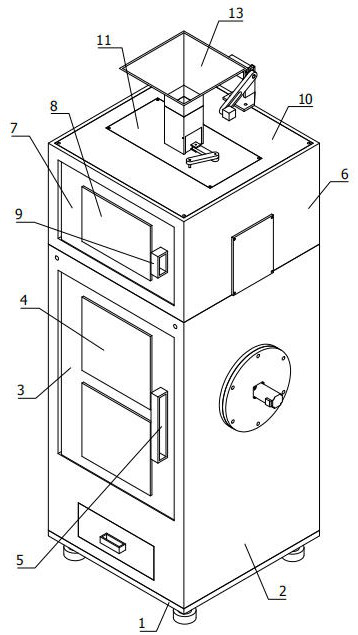

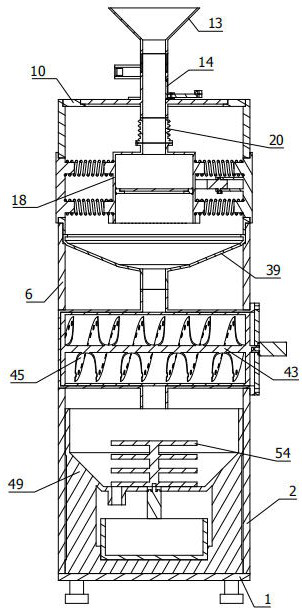

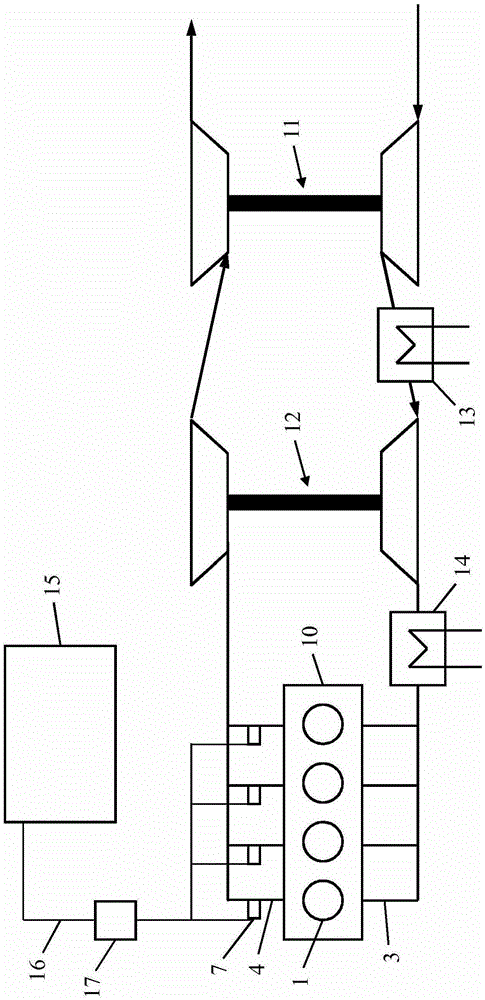

Grain-drying dust collector

InactiveCN104738158ADry in timePrevent spoilageSeed preservation by dryingCleaning using gasesAgricultural engineeringEngineering

The invention discloses a grain-drying dust collector. The grain-drying dust collector comprises a grain inlet, a drying part, a dust collection part, a transmission part and a grain outlet, wherein the grain inlet is connected with a drying channel, the barrel body at the periphery of the drying channel is made of an iron sheet material, the drying channel is connected with a drying machine by a hot air pipe, and the drying channel, the hot air pipe and the drying machine form the drying part of the grain-drying dust collector. The grain-drying dust collector is high in drying speed, only requires ten more seconds generally, has the characteristic of instantaneously drying, and can effectively solve the problems that grain products are moist and contain impurities.

Owner:CHANGSHU GUANGHUI MECHANICAL EQUIP CO LTD

Colored toner prepared through in-situ miniemulsion polymerization and electrostatic agglomeration and preparation method thereof

InactiveCN104252106ASolve the leakSolve the problem of impuritiesDevelopersLatex particleReaction temperature

The invention discloses colored toner prepared through in-situ miniemulsion polymerization and electrostatic agglomeration and a preparation method thereof. The preparation method comprises the following steps: selecting a surfactant and an initiator with different charges, through the in-situ miniemulsion polymerization, preparing two composite colored latex particles having the particle size of 50-160 nanometers and opposite surface charges and comprising resin-coated pigment, wax and a charge regulator; mixing the two colored latexes with the opposite surface charges according to a certain ratio, wherein the latex particles flocculate due to the opposite charges, and finally obtaining composite colored toner particles with the particle size of 5-10 microns by changing the reaction temperature, the stirring speed, the stirring time and the like. According to the preparation method, by polymerizing the resin-coated pigment, the wax and other functional components, the problems of leakage and non-uniform distribution of the wax and the pigment and the like are solved; through agglomeration of the two colored latexes with the opposite surface charges, the impurity problem caused by addition of a flocculant during ordinary emulsion agglomeration is solved; the prepared composite colored toner particles have the advantages of uniform component distribution, controllable particle size, relatively good shape, few impurities and the like.

Owner:NANJING UNIV OF SCI & TECH

Solar panel preparing method

ActiveCN102315309AImpurities are simpleSolve the problem of impuritiesFinal product manufacturePhotovoltaic energy generationOptoelectronicsSolar battery

The invention provides a solar panel preparing method, which comprises the steps of: a, preparing a-Si:H film on the surface of a silicon chip after texturing; b, treating the silicon chip containing the a-Si:H film on the surface obtained in the step a at 800 to 900 DEG C for 60 to 120 min; and c, carrying out corrosion treatment on the surface of the silicon chip treated through high temperature. The solar panel preparing method has the advantages that a layer of a-Si:H film is deposited on the back surface of the silicon chip after the texturing, the problems of many impurities and micro defects in the silicon chip can be perfectly solved, the electrochemical performance such as the service life, the photoelectric conversion efficiency and the like of solar panels is improved, in addition, good back side and body passivation effects can be realized, the current and voltage (I-V) character of solar batteries is improved, and simultaneously, the process is simple and is easy to implement.

Owner:BYD CO LTD

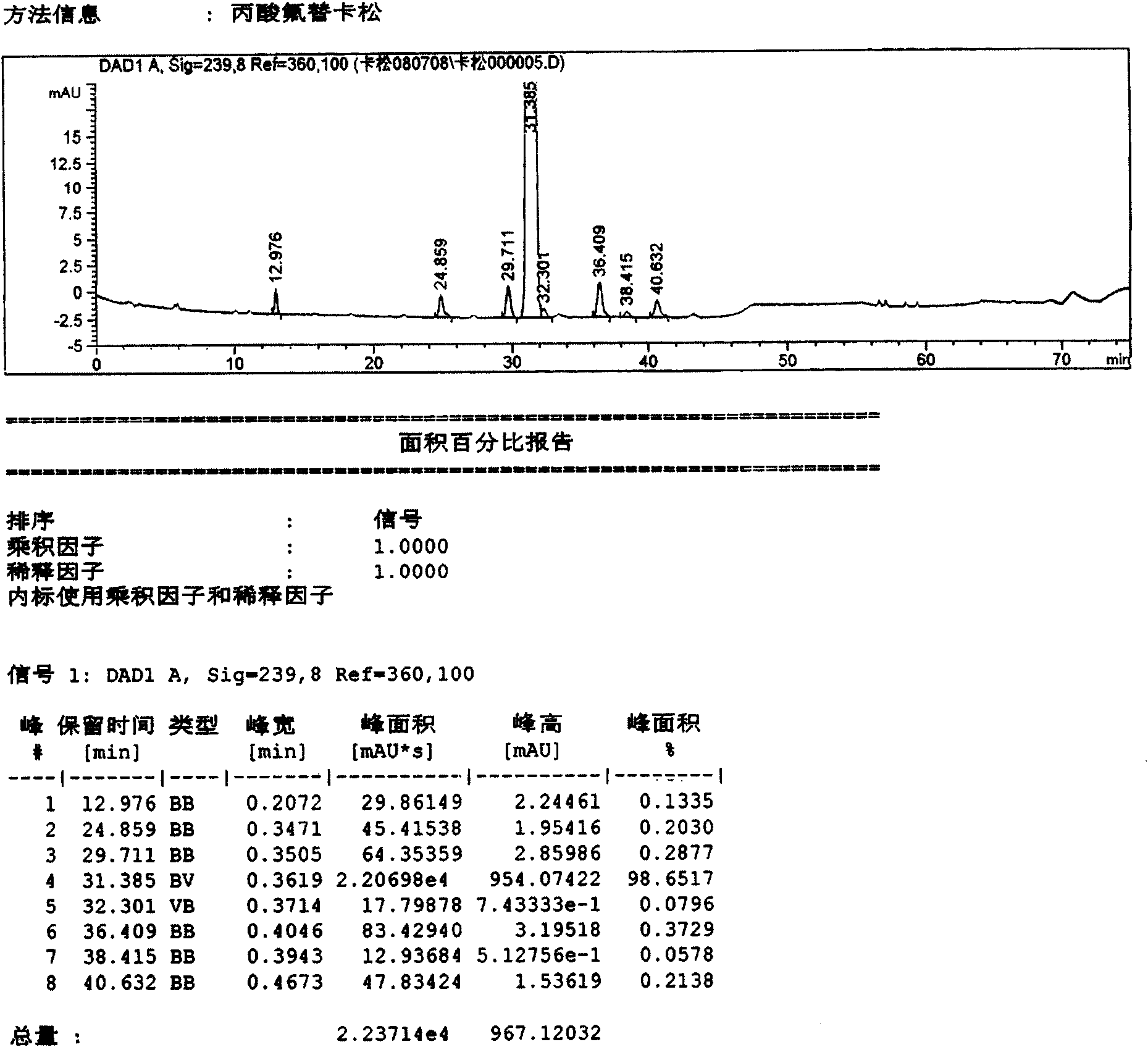

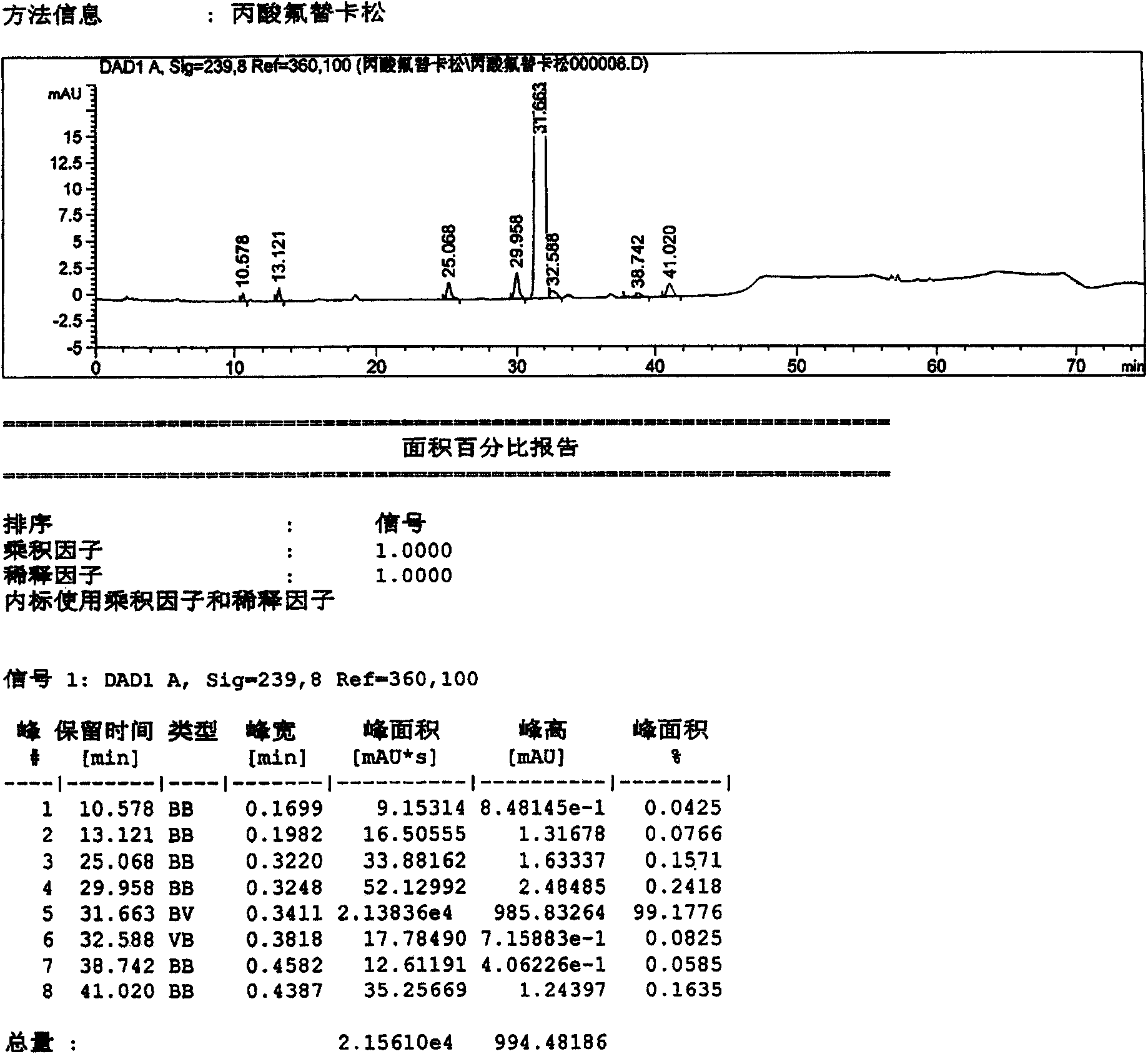

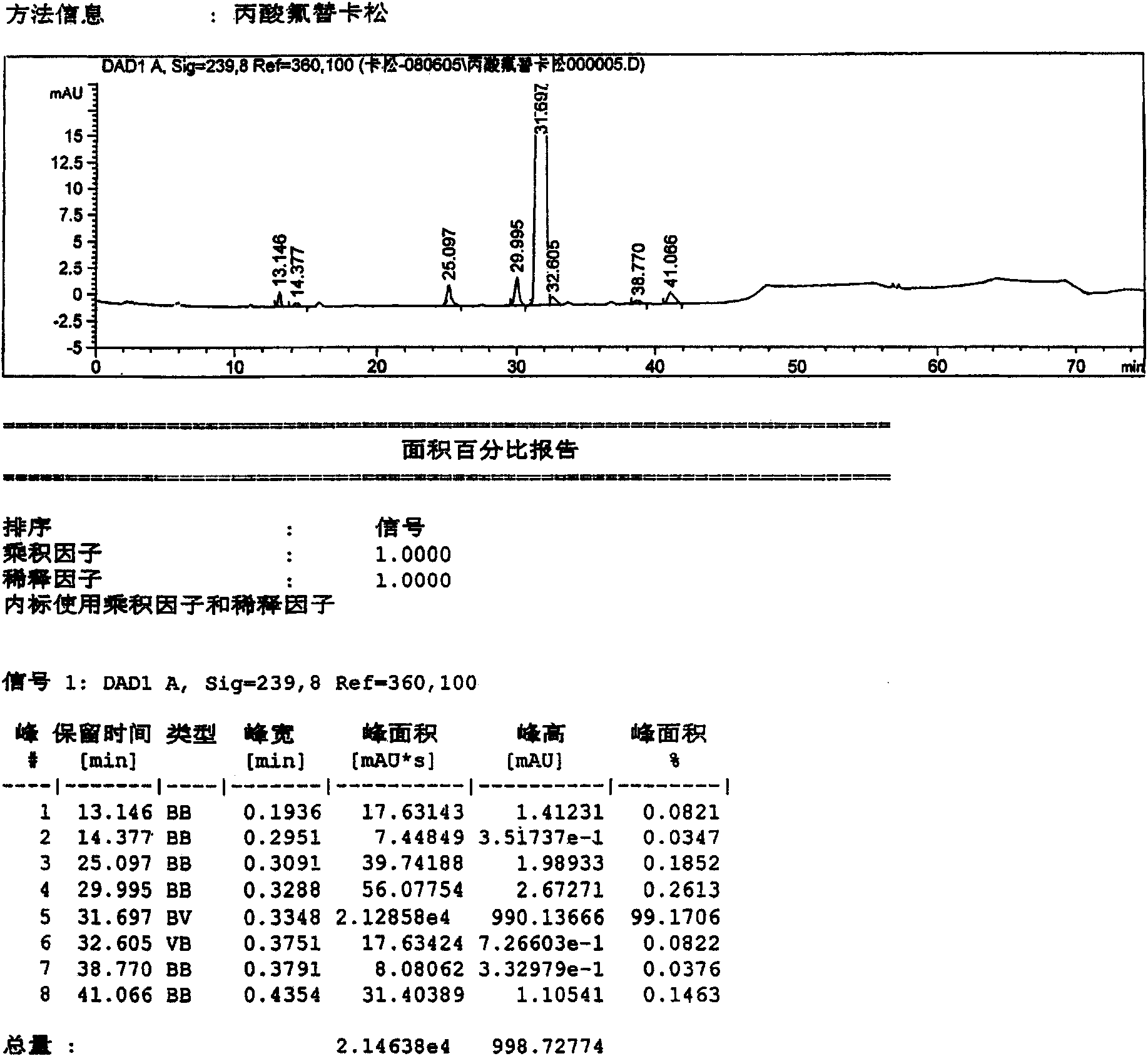

Method for recrystallizing and refining fluticasone propionate

ActiveCN101659688ASolve the problem of impuritiesSolve the impurity problemSteroidsRespiratory disorderFluticasone propionateOrganic solvent

The invention provides a method for recrystallizing fluticasone propionate. The method is characterized in that the fluticasone propionate is recrystallized in one or more solvents of alkylene oxide organic solvents and amide organic solvents to solve the impurity problem of the fluticasone propionate, so that related substances of the fluticasone propionate completely accord with the requirementof European Pharmacopoeia 2008 Edition EP6, namely total related substances are 1.2 percent maximally, impurities D and G are 0.3 percent maximally, impurities A, B, C, E, F, H and I are 0.2 percent maximally, and other unknown impurities are 0.1 percent maximally.

Owner:TIANJIN JINYAO GRP

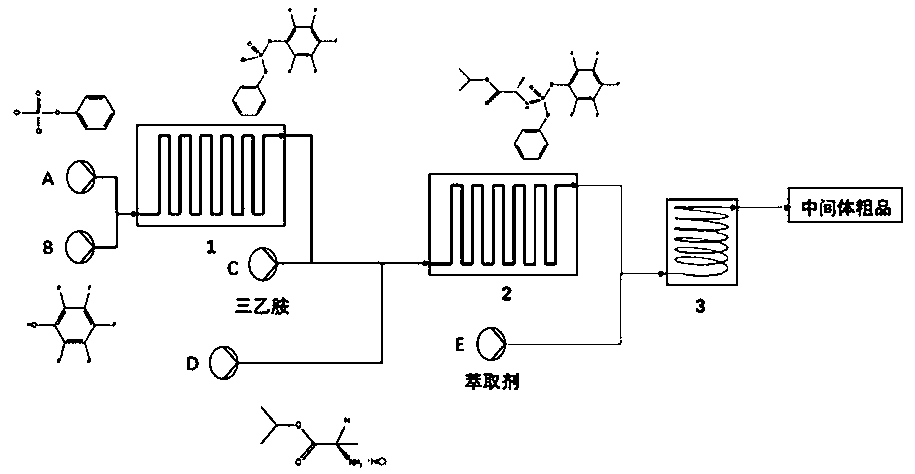

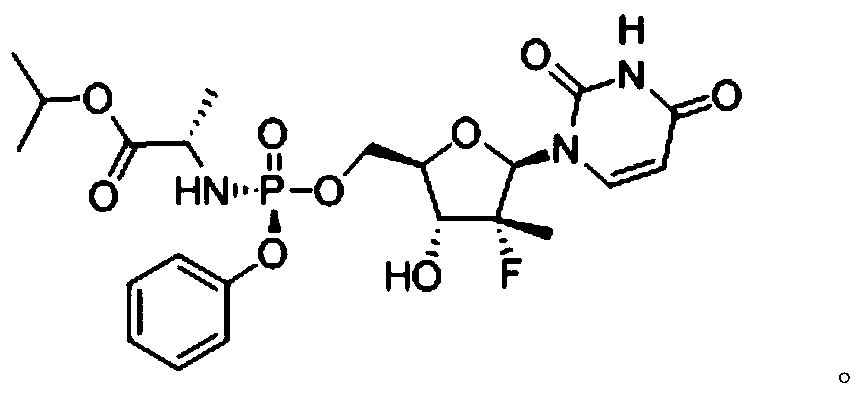

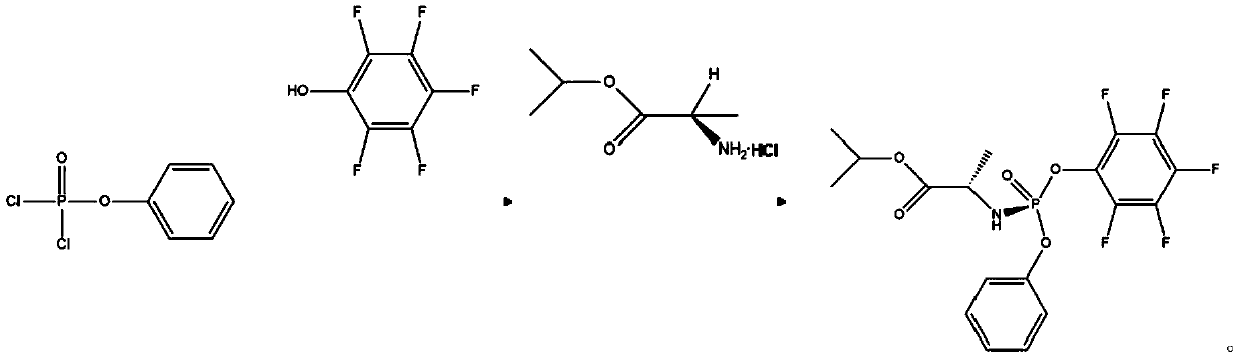

Method for preparing sofosbuvir intermediate by using microfluid reaction device

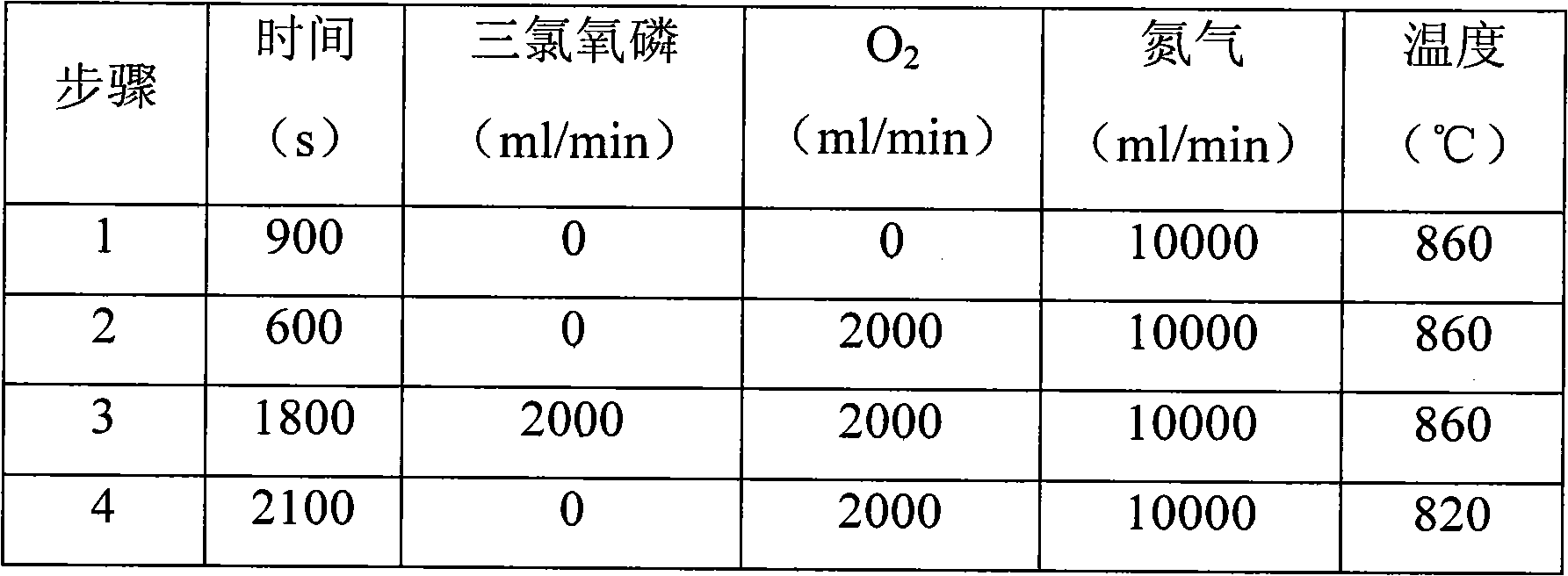

ActiveCN110964057ALarge specific surface areaIncrease contact areaGroup 5/15 element organic compoundsPhosphoric acidReactive separation

The invention discloses a method for preparing a sofosbuvir intermediate by using a microfluid reaction device. The method comprises the following steps: pumping phenyl dichlorophosphate and pentafluorophenol into a first micro-channel reactor, carrying out a first-step acylation reaction, pumping the product obtained in the first step and L-alanine isopropyl hydrochloride into a second micro-channel reactor, carrying out a second-step substitution reaction to prepare a racemic sofosbuvir intermediate mixture, enabling the product to directly enter a micro-flow extraction device, and finally re-crystallizing to obtain a single-configuration target compound. Compared with the method in the prior art, the method disclosed by the invention has the advantages that the integration of efficientreaction and separation can be realized, the operation is simple, the problems caused by intermittent operation of extraction after product collecting are avoided, the reaction steps are few, the yield of the final product is high, the energy consumption is low, and the continuous large-scale production operation can be realized.

Owner:SOUTHEAST UNIV

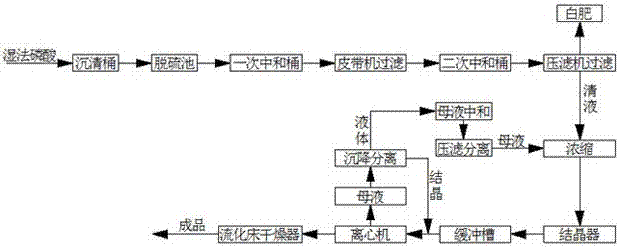

Method and device for producing monoammonium phosphate by wet-method phosphoric acid based on multiple neutralizations

The invention discloses a method and a device for producing monoammonium phosphate by wet-method phosphoric acid based on multiple neutralizations. The method of a process comprises the following steps of preparing the phosphoric acid through a wet method; pretreating the wet-method phosphoric acid; primarily neutralizing; primarily filtering through a belt conveyor; secondarily neutralizing; secondarily filtering through a press filter; regulating an index; concentrating and crystallizing; separating and oven-drying. The method has the following beneficial effects that the press filter is replaced by adopting the belt conveyor in a filtration procedure; on the basis of the same production capacity, the labor can be decreased by 90 percent; the labor intensity of a worker is greatly reduced; after the belt conveyor is adopted, the labor intensity is only 10 percent of original one. According to the process, a secondary neutralization method and the mother solution circular treatment are adopted to carry out deep impurity removal; the problem of impurity in the wet-method phosphoric acid can be quite well solved; the production requirement of industrial-grade monoammonium phosphate can be met; the production is run continuously and stably. Therefore, the effects of decreasing production cost and promoting the market competitiveness of a product are achieved.

Owner:四川省高宇化工有限公司

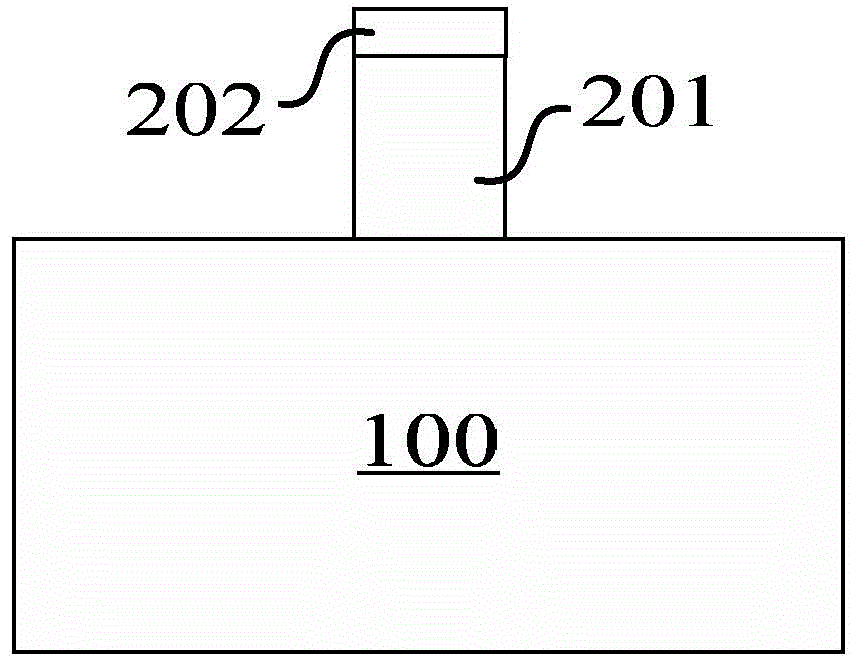

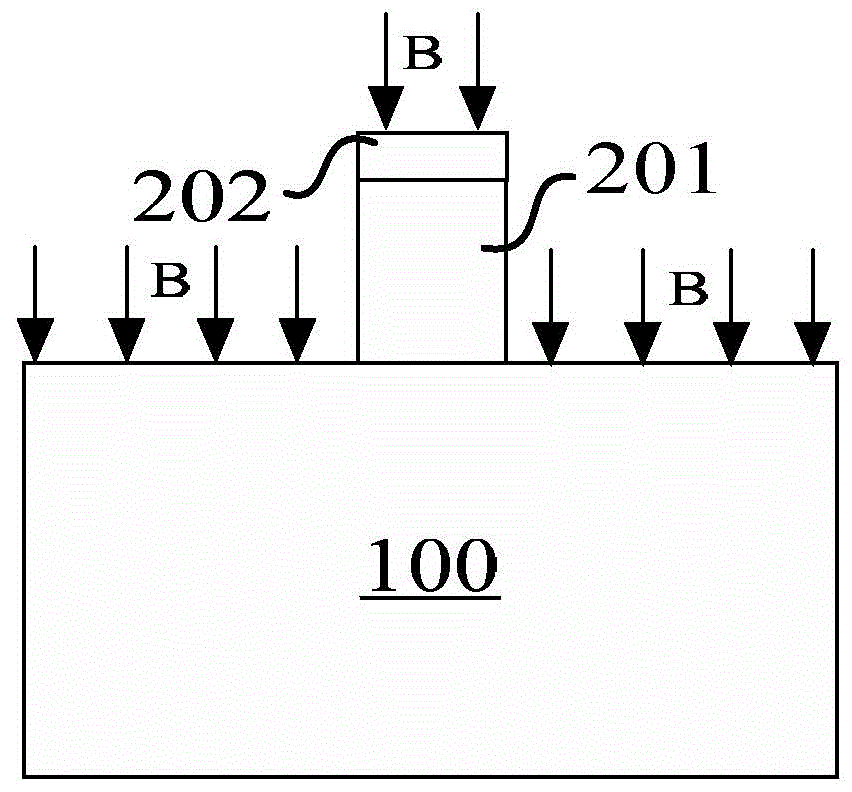

FINFET manufacturing method

InactiveCN105097528AAddress impurities and damageImprove device performanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMask layer

A FINFET manufacturing method, comprising: a. providing a semiconductor substrate, and forming a first fin on the substrate; b. covering the first fin with a mask layer; c. forming a punch-through barrier layer in the semiconductor substrate; d. etching the punch-through barrier layer and a part of the semiconductor substrate in sequence by taking the first fin and the mask layer as masks, expanding the first fin into a second fin, and removing the masks; and e. forming a trench isolation structure on the semiconductor substrate, forming a source-drain region on the second fin, and forming a gate laminate and an interlayer dielectric layer on the semiconductor substrate and the second fin. A punch-through barrier layer is formed by means of lateral scattering, and at the same time, an isolation layer is formed after the punch-through barrier layer is formed using a substrate material as a carrier of scattering impurities, thereby effectively solving the problems of impurities and damage introduced during lateral scattering, and greatly improving the performance of a device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

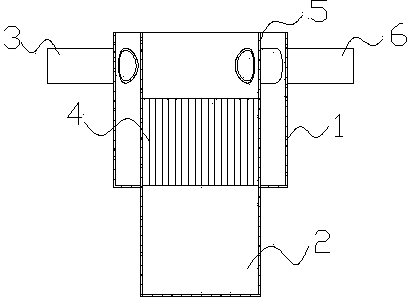

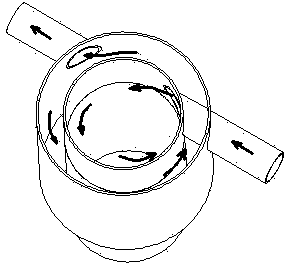

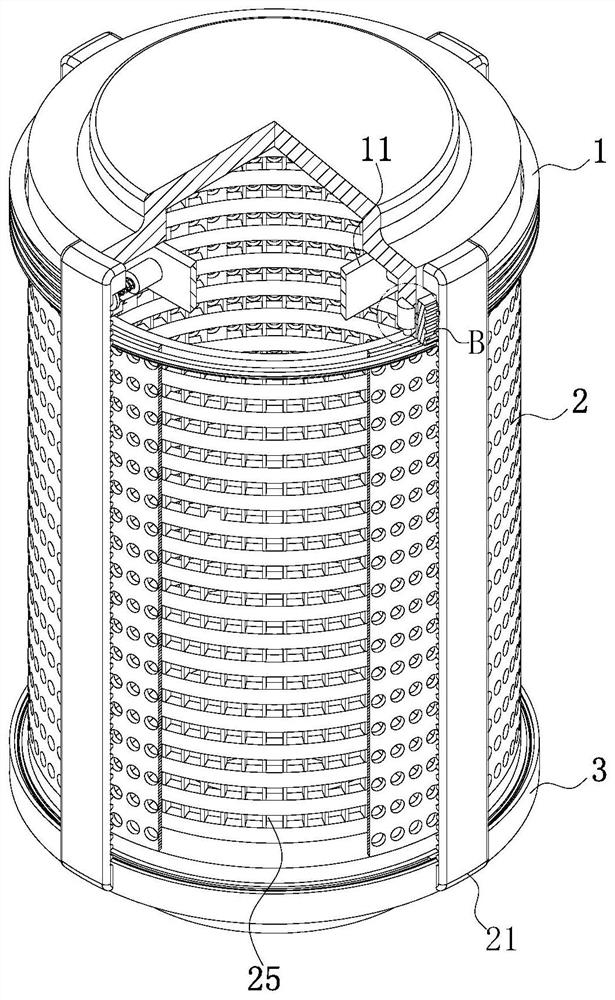

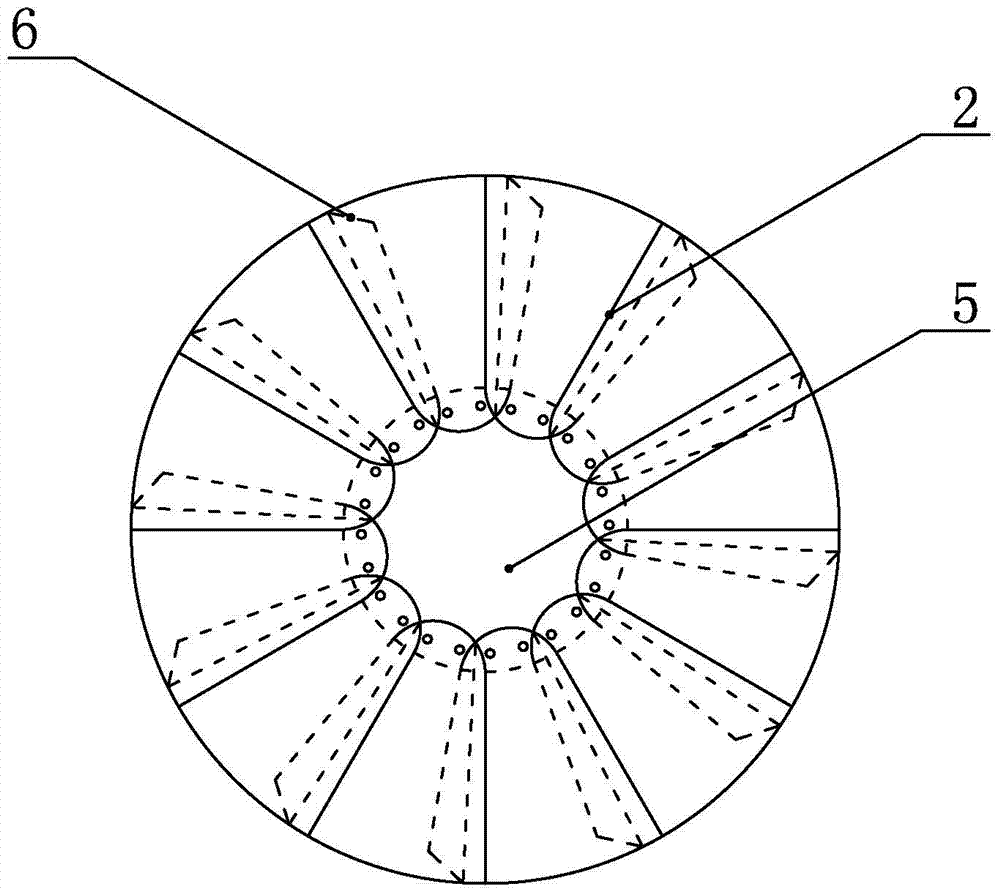

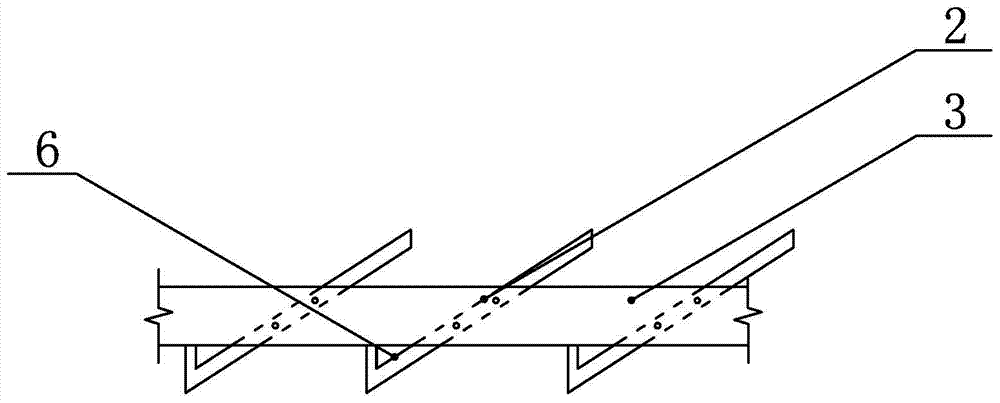

Tube well separator for rainwater tube well

InactiveCN104005469ASolve the problem of impuritiesGuaranteed uptimeFatty/oily/floating substances removal devicesSewerage structuresGratingSuspended matter

The invention discloses a tube well separator for a rainwater tube well. The tube well separator is characterized by comprising an outer-layer well chamber (1) and an inner-layer well chamber (2), wherein the outer-layer well chamber is provided with a water outlet tube (3); the inner-layer well chamber is provided with a cylindrical flexible grating (4) and a circular separation weir (5); the circular separation weir is provided with a water inlet tube (6); the inner-layer well chamber is capable of continuously separating suspended matters and floating matters in water by virtue of a rotational-flow action. The tube well separator disclosed by the invention has the advantages of being stable in running, energy-saving and environment-friendly, low in cost, and the like.

Owner:HEFEI YUE LAKE ENVIRONMENTAL PROTECTION EQUIPCO

N-type MWT solar cell and preparation method thereof

InactiveCN105957916AImprove photoelectric conversion efficiencyEliminates laser ablation processFinal product manufacturePhotovoltaic energy generationCost ControlsImpurity

The invention discloses an N-type MWT solar cell and a preparation method thereof, and relates to the technical field of solar cells. The N-type MWT solar cell comprises an N-type silicon substrate, wherein the N-type silicon substrate is provided with through holes; a P-type emitter junction region is arranged on the front surface of the N-type silicon substrate; metal contact electrodes are guided to the back surface of the N-type silicon substrate through the through holes; a non-back field N-type silicon substrate region is arranged on the periphery of each through hole on the back surface of the N-type silicon substrate; the surface of a phosphorus back field and the surfaces of the non-back field N-type silicon substrate regions are basically on the same plane; an antireflection film layer is arranged on the front surface of the N-type silicon substrate, the surfaces of the non-back field N-type silicon substrate regions, the surface of the phosphorus back field and the inner walls of the through holes; and the ends, on the back surface of the N-type silicon substrate, of the metal contact electrodes and the surface of the antireflection film layer are in contact. By the preparation method of the solar cell, damages and impurities due to the fact that the MWT solar cell is prepared by a laser ablation process are omitted; the photoelectric conversion efficiency of the solar cell is improved; the preparation technology of the method is simple; and cost control is facilitated.

Owner:YINGLI ENERGY CHINA

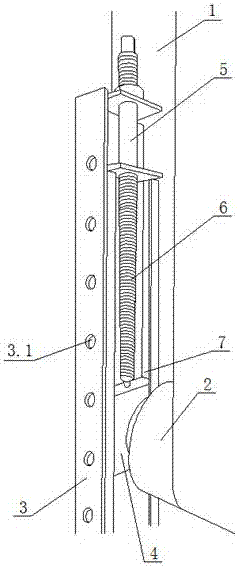

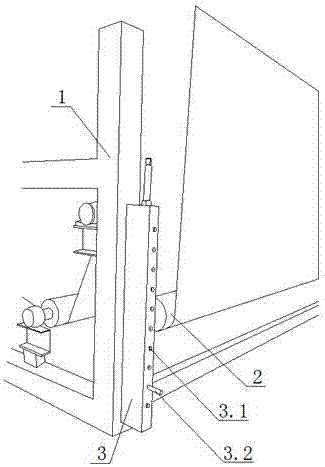

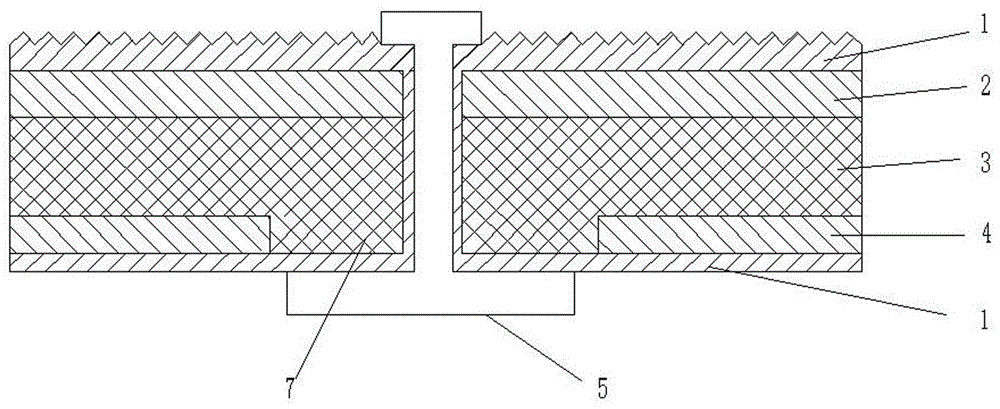

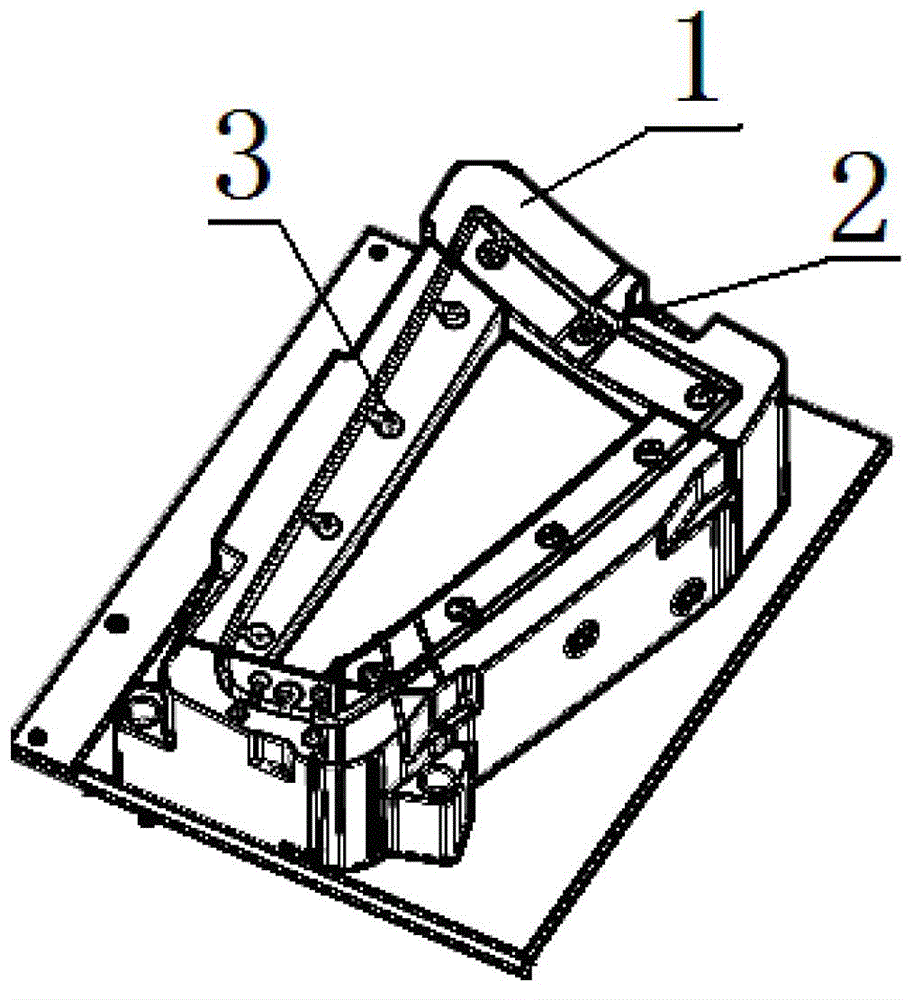

Infrared preheating friction welding process and welding tool thereof

InactiveCN104028887ARaise base temperatureImprove connection strengthNon-electric welding apparatusFriction weldingMolten state

The invention relates to the welding technology, particularly to an infrared preheating friction welding process. The infrared preheating friction welding process comprises the steps of, firstly, obtaining at least two workpieces to be welded; secondly heating the welding position, namely, the contact end surface of at least one workpiece to be welded through a heating plate serving as a heating source; thirdly, welding the two workpieces to be welded through a friction welding process. An infrared preheating friction welding tool comprises a frame which is provided with a friction welding device, and the heating plate which is used for heating the contact end surfaces of the workpieces to be welded, wherein the heating plate is provided with heating wires according to the contour of the contact end surfaces of the workpieces to be welded and is movably connected with the frame. The heating wires can heat the workpieces to be welded, so that heat generated by the heating wires can be organically combined with heat generated due to friction, and the contact end surfaces of the workpieces to be welded rapidly reach or approach a molten state, and further the problems existing in a welding mode which only relies on the heat generated due to friction, including impurities, cool slag, flashes, low welding speed and poor forming effects, can be solved.

Owner:SHANGHAI JIUQIAN IND

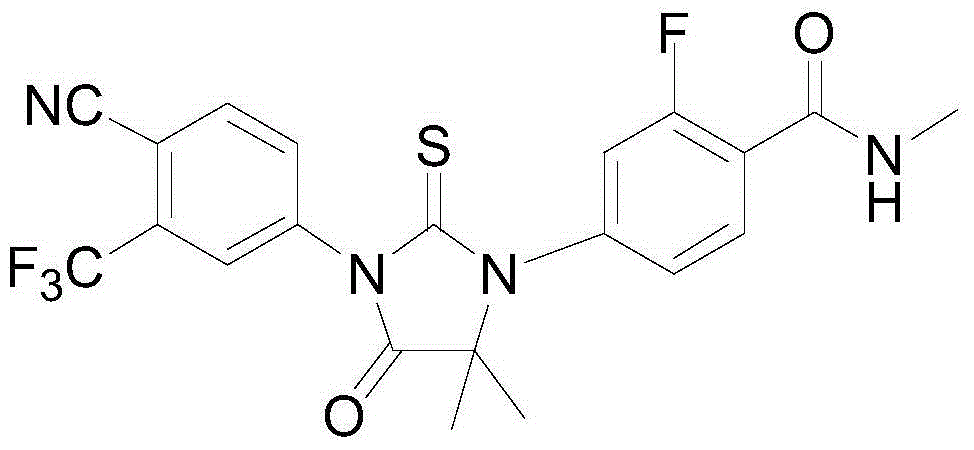

Purification method of enzalutamide

InactiveCN104610158ASolve instant agglomerationSolve the problem of impuritiesOrganic chemistryHydrocarbon solventsOrganic solvent

The invention discloses a purification method of enzalutamide. According to the method, a coarse enzalutamide product is added to a recrystallization vessel and dissolved through an alcohol or amide organic solvent; a hydrocarbon solvent is dropwise added while agitating, wherein the dropwise adding speed is controlled and a crystal precipitate of materials in the system can be gradually separated out, and after the dropwise adding is done, the solid can be separated out; the solid can be filtered to obtain the fine enzalutamide product. By virtue of the method, the problems such as instantaneous caking and impurities occurring in recrystallization of enzalutamide can be solved; the method is suitable for industrial production; the enzalutamide product obtained by recrystallization has the purity more than 99.5%, and the recrystallization yield is more than 75%; an enzalutamide preparation is processed according to the requirements of standard on raw medicines in Chinese Pharmacopoeia, so that a patient can use safely.

Owner:JIANGSU HUIBO BIOTECH

Distribution box convenient for heat dissipation and moisture prevention

PendingCN112909784ASolve the problem of retained waterSolve the dampBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationThermodynamicsElectric machine

The invention discloses a moisture-proof power distribution box convenient for heat dissipation, the power distribution box comprises a semi-closed box body made of metal, the semi-closed box body is used for supporting a circuit, a condensing device driven by a motor is arranged on the edge of the box body, the moisture-proof and heat-dissipation effects are achieved, the condensing device is connected with the side edge of the box body through an air inlet and an air outlet, the motor drives a propeller to rotate, gas in the box body is pumped out of the box body from the air outlet, the gas is brought to a condensation pipe through an air outlet pipe, the condensation pipe cools the air, water vapor in the air is liquefied and left in the condensation pipe, and then the water vapor is discharged through a water outlet, a storage battery for supplying power to the motor is installed in the box body, and a strain gauge 1 and a strain gauge 2 are further installed in the box body to change the temperature and the humidity in the box body respectively, so that a circuit is switched on, and the motor is started. The power distribution box has moisture-proof and heat-dissipation effects.

Owner:上海怀淳自动化工程有限公司

Novel rubber compound processing technology

ActiveCN105437402ASolve the six major defectsQuality does not drop but risesRubber materialMachine control

Disclosed is a novel rubber compound processing technology. After an upper associated machine controls an internal mixer to mix rubber materials, carbon black and compounding ingredients, unloading is carried out, and rubber materials are unloaded to a cooling open mixing machine through a buffer hopper. After being subjected to rubber overturning cooling through the clamping function of a rubber overturning belt of the open mixing machine, the rubber materials are discharged and distributed to a mixing open mixing machine through a conveying belt conveyer to be subjected to rubber overturning and pouring. After supplementary mixing, the rubber materials are discharged. An automatic rubber sheet bundling device is installed at the back of an outlet rubber belt conveyer of the mixing open mixing machine, and rubber sheets are automatically bundled, then are conveyed to a belt type rubber bundle weighing device through a belt conveyer, then are conveyed to a tablet compressing machine to be subjected to tablet compressing, enter a low-temperature rubber filter to be subjected to rubber filtering and purification, and enter a rubber cooling device in a tablet form to be subjected to cooling and rubber collection. If the rubber sheets are not filtered, the rubber sheets can directly enter the rubber cooling device by selectively omitting the rubber filter, and the rubber cooling process is started. The novel rubber compound processing technology has the advantages of being efficient, saving energy, achieving automation of a single thread, and improving the performance and yield of the rubber materials and rubber components in the later procedures.

Owner:SHANDONG FENGYUAN TIRE MFG

Method for purifying AgCd alloy from AgCd waste and recycling AgCd alloy

ActiveCN111020192AEfficient separationSolve the problem of impuritiesProcess efficiency improvementManufactured materialWaste material

The invention discloses a method for purifying an AgCd alloy from AgCd waste and recycling the AgCd alloy. The method comprises the steps that equal-area foam ceramic sheets are placed at the bottom of a smelting furnace, then the AgCd waste is placed, and high-temperature smelting treatment is conducted; after refining is completed, the foam ceramic sheets floating on the surface of a melt are taken out, and the high-purity AgCd alloy is obtained; and the AgCd alloy serves as a raw material to prepare an AgCdO material. An electric contact material fed by adopting the high-purity AgCd alloy is high in raw material purity and low in impurity, and thus has good physical and chemical property and excellent machining property. By adopting the method, AgCd leftover materials generated in the production process of the AgCd electric contact material are recovered and reutilized, AgCd alloy elements in the waste are effectively recovered, material transferring is quick, and economic benefitsare remarkable.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

A method for preparing rare earth-doped yttrium aluminum garnet transparent ceramics by synthesizing rare earth-doped Y2O3 nanopowder

InactiveCN103058644BSolve the problem of impuritiesAvoid compositional segregationMetallurgyRare earth

The invention discloses a method for preparing rare earth doping yttrium aluminum garnet crystalline ceramic through synthesis of rare earth doping Y2O3 nanometer powder. Through a new preparation process, the method for preparing the rare earth doping yttrium aluminum garnet crystalline ceramic through the synthesis of the rare earth doping Y2O3 nanometer powder realizes the purposes of not only solving an impurity problem in a solid phase method, but also avoiding a component segregation problem in a liquid phase method, and optimizes the preparation process.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

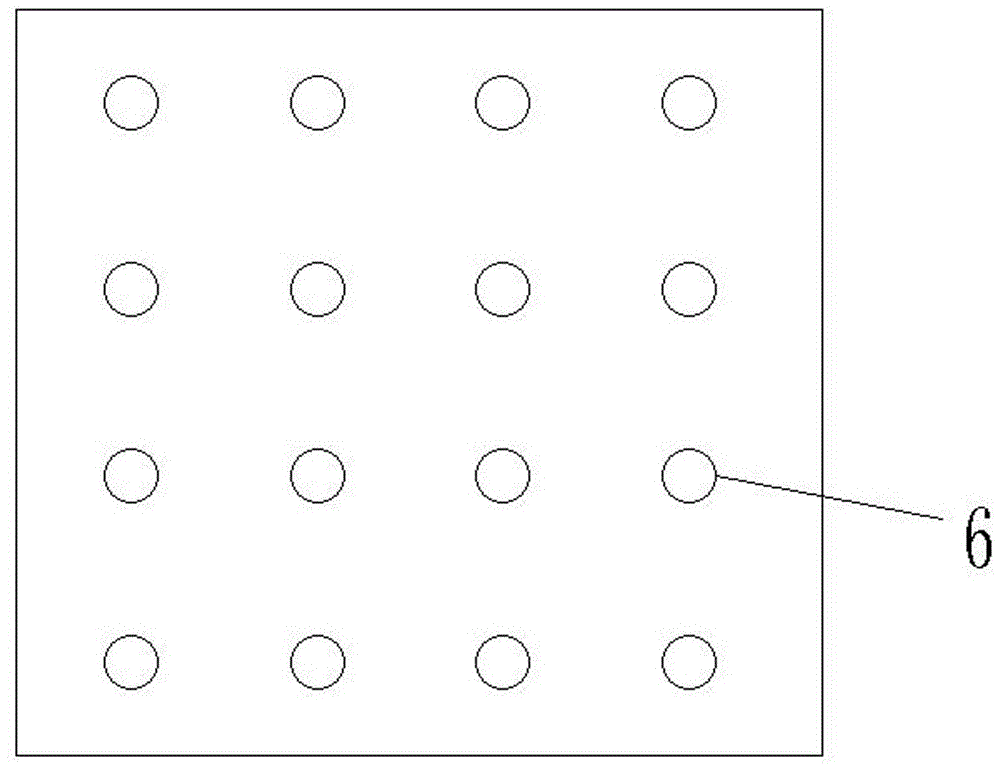

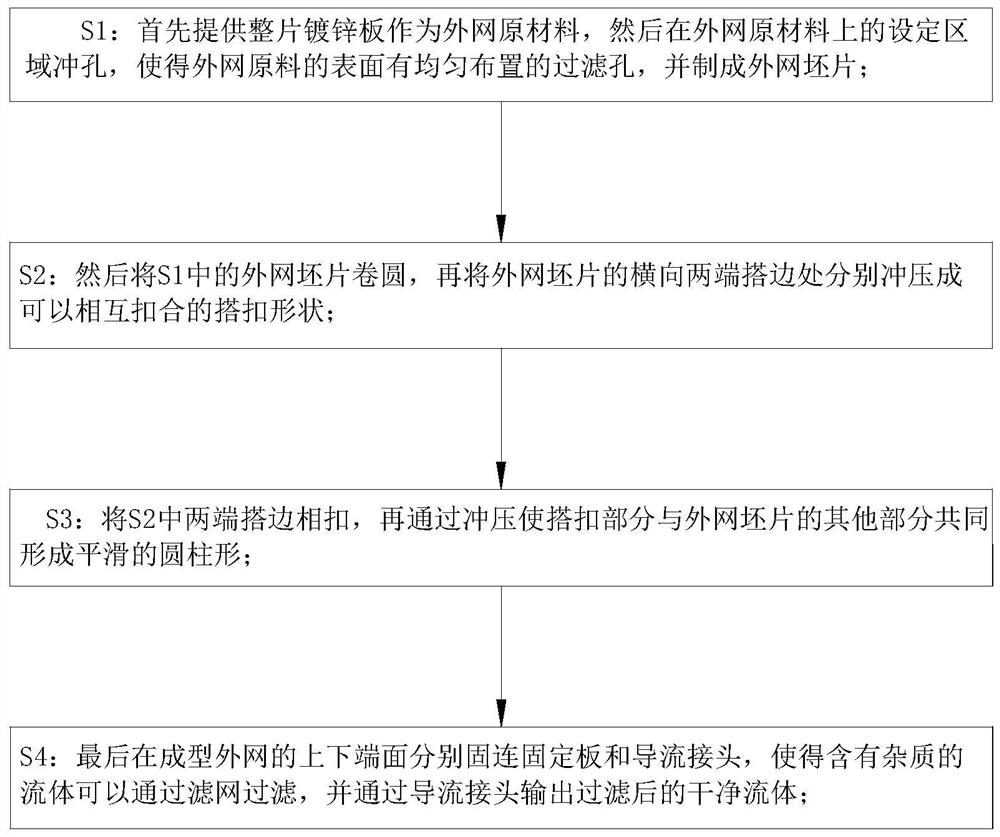

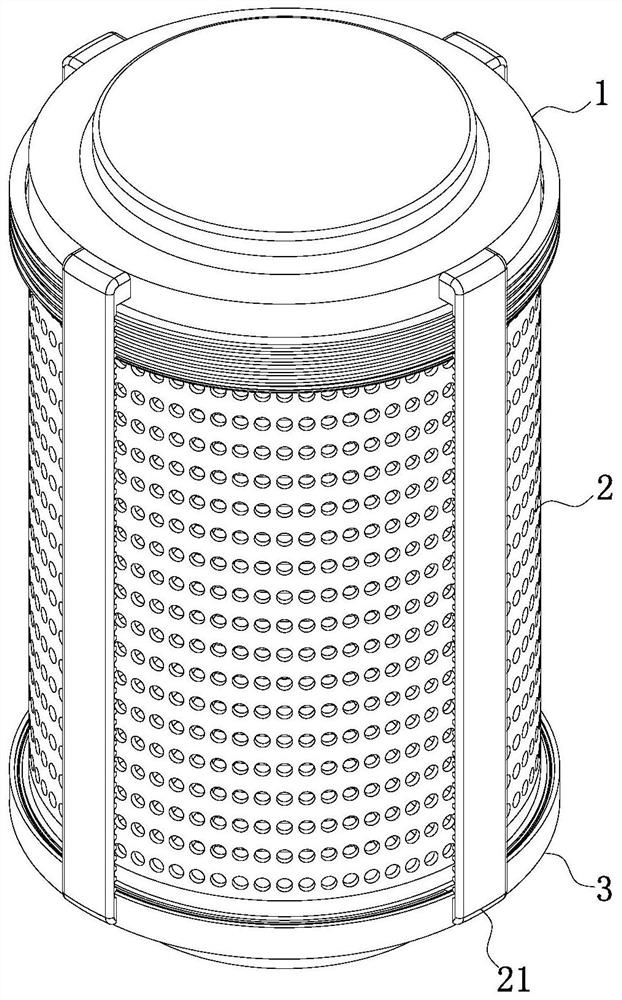

Filter outer net and preparation method thereof

InactiveCN111790204ARealize automatic adjustmentAvoid deficienciesGear lubrication/coolingLubrication elementsEngineeringFiltration technique

The invention belongs to the technical field of filter filtration, and particularly relates to a filter outer net and a preparation method thereof. The filter outer net comprises a fixed plate, a filter ring and a diversion joint; the filter ring is arranged between the fixed plate and the diversion joint; the inner arc surface of the filter ring is connected with an adjusting ring in a vertical sliding manner; filtering holes, which are uniformly distributed, are formed in the surface of the filter ring; adjusting holes, which are uniformly distributed, are formed in the surface of the adjusting ring, and the adjusting holes are matched with the filtering holes. The automatic adjustment of the filter value of the filter is effectively realized, the requirements of different fluids and different fluid states on various filter values can be met, and when the filter is used for a long time and the filter holes are blocked, the sizes of the filter holes can be automatically adjusted according to the pressure difference change, so that the problem of insufficient downstream fluids is solved.

Owner:李斌

Method for smelting and preparing vanadium iron alloy by taking Panxi vanadium as raw material

The invention relates to a method for smelting and preparing vanadium iron alloy by taking Panxi vanadium as a raw material, belonging to metallurgy field. The method comprises the following steps of: weighting various material and auxiliary materials according to a formulation, putting the weighted raw materials and the auxiliary materials into a material mixing device so as to be fully stirred till being uniformly stirred, putting the uniform mixed material into a reaction unit which is preheated to a temperature of 200 to 300 DEG C, carrying out fire beginning reaction, adding 30 to 50kg of retarder after reaction is over, cooling for 48 to 72 h, and finally separating slag and alloy; and putting inspected, finishing, and packaged vanadium iron alloy products in storages. Compared with the prior art, the steps of the process are simplified, thereby both increasing safety and reducing production cost; the high vanadium iron alloy product has high grade vanadium, low sulphur and phosphorous level, low aluminium and silicon content, effectively reduces the damage of possible drag-in impurities to types of steels and has positive promotion significance for deoxygenation alloying in the steel production.

Owner:攀枝花市银江金勇工贸有限责任公司

Refinement technique of fluorometholone

The invention relates to the field of refinement methods of compounds, and particularly relates to a refinement technique of fluorometholone. The refinement method is characterized by comprising the following particular technical steps of (1), dissolving 100g of fluorometholone crude product in 400mL to 500mL of one or several of amide organic solvents, agitating and heating an obtained first mixture to 80 to 90 DEG C, and maintaining the temperature for 0.5h; (2), slowly adding 1L to 2L of alcohol solvent, maintaining a temperature in an interval of 60 to 75 DEG C in an entire addition process, after the addition is completed, maintaining temperature for 0.5h, then decreasing the temperature to 0 to 5 DEG C, maintaining the second mixture at 0 to 5 DEG C to crystallize the second mixture for 12h; (3), filtering and drying an obtained third mixture to obtain 25g to 33g of similarly white crystal fluorometholone refined product. The mass concentration of the fluorometholone crude product in the step (1) is 97 to 98 percent. By using the refinement method, the impurity problem in the refinement of the fluorometholone is solved; not only is a related substance of the fluorometholone enabled to completely meet requirements in the British Pharmacopoeia BP2008 and the United States Pharmacopoeia USP36, that is, the purity is more than 99 percent, and a single impurity is less than 0.5 percent, but also a known single impurity can be guaranteed to be less than 0.15 percent, the total impurity can be guaranteed to be less than 0.1 percent; the great improvement is achieved compared with the requirements in the Pharmacopoeias.

Owner:TIANJIN PHARMACN MEDICAL TECH

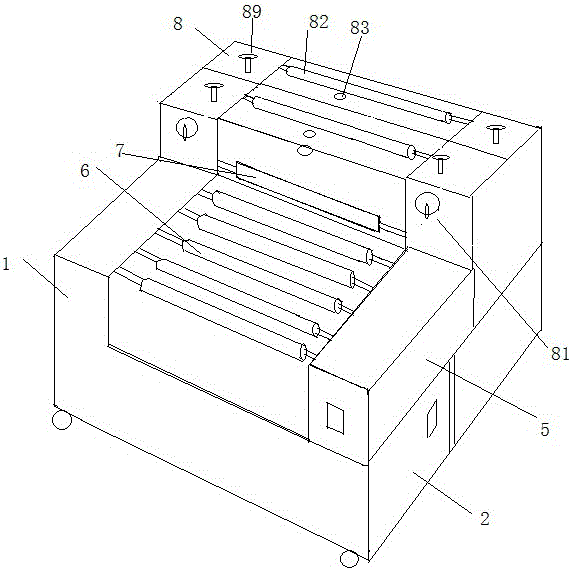

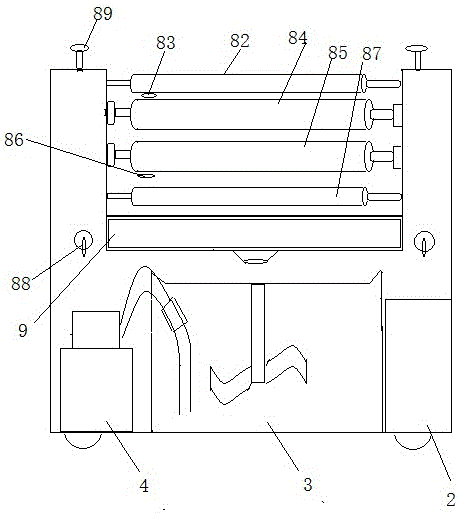

Circuit board double-roller ink coating machine and working method thereof

ActiveCN106493036ACompact structureImprove performanceLiquid surface applicatorsCoatingsDiaphragm pumpRolling paper

The invention discloses a circuit board double-roller ink coating machine. The circuit board double-roller ink coating machine comprises a machine body, the bottom of the machine body is provided with an electric cabinet, an ink stirring device and a pneumatic diaphragm pump, the electric cabinet is arranged on the right side of the machine body, the ink stirring device is arranged on the left side of the machine body, the pneumatic diaphragm pump is arranged in the middle of the machine body, two coating mechanisms are arranged side by side at a discharge end of a silica gel delivery roller, an automatic dust adhesion roller and a paper rolling device are arranged on the joint of the silica gel delivery roller and coating mechanisms, an ink receiving tray is arranged below the coating mechanisms and is located above the ink stirring device, and a circulating ink outlet pipe is arranged in the middle of the ink receiving tray. The coating machine adopts simultaneous rolling of the double coating rollers to coat the surface of a base plate with a layer of photosensitive ink so that the level of the product is improved and can use two different inks at the same time so that the replacement time is reduced.

Owner:TAICANG HE S CIRCUIT BOARD CO LTD

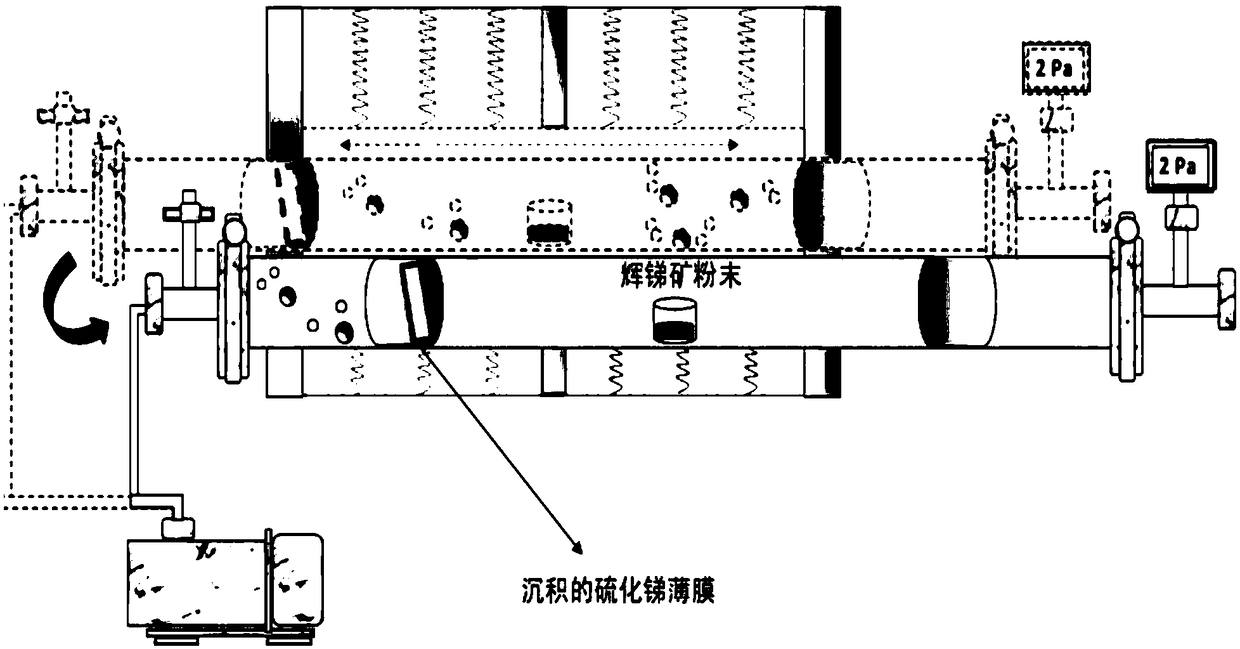

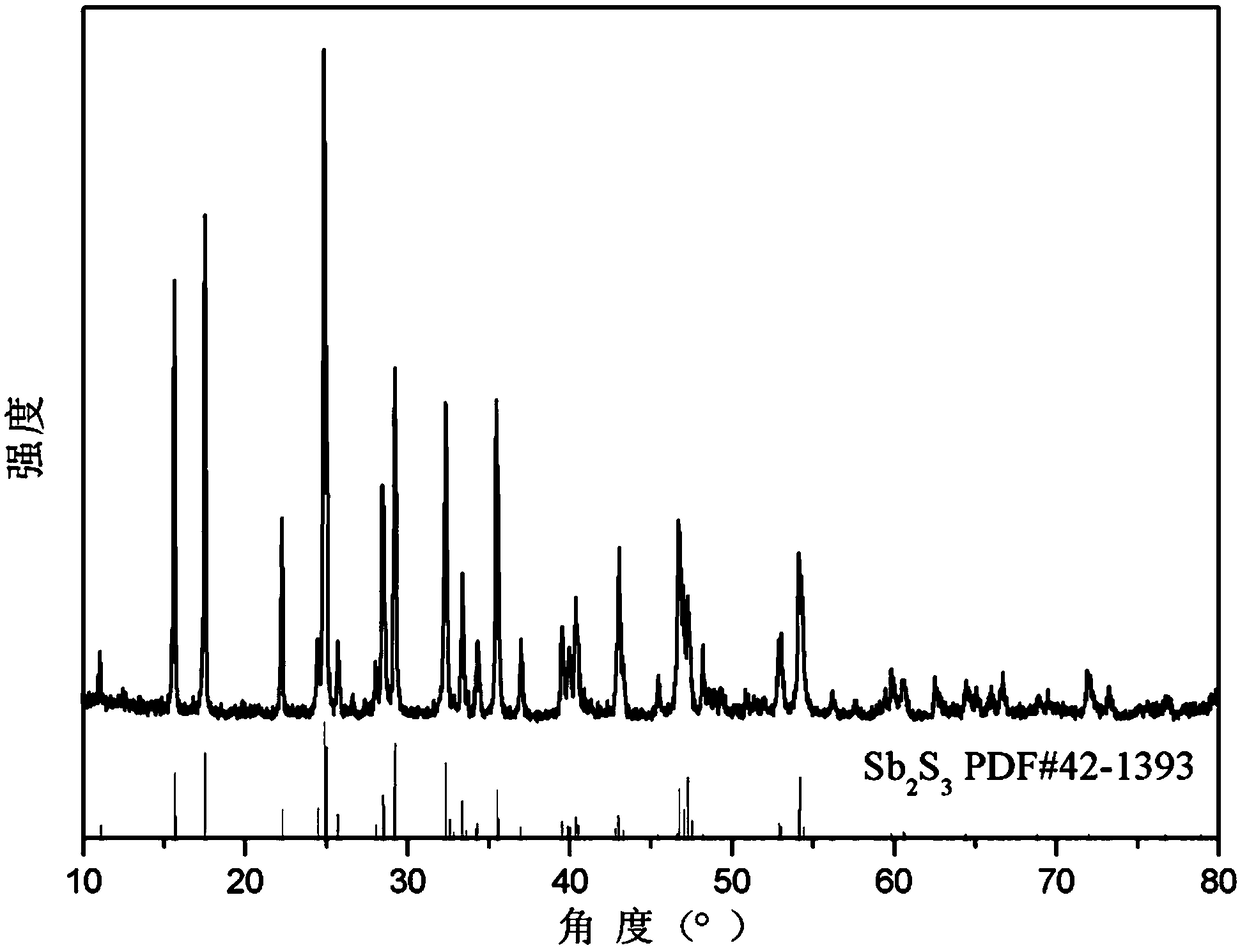

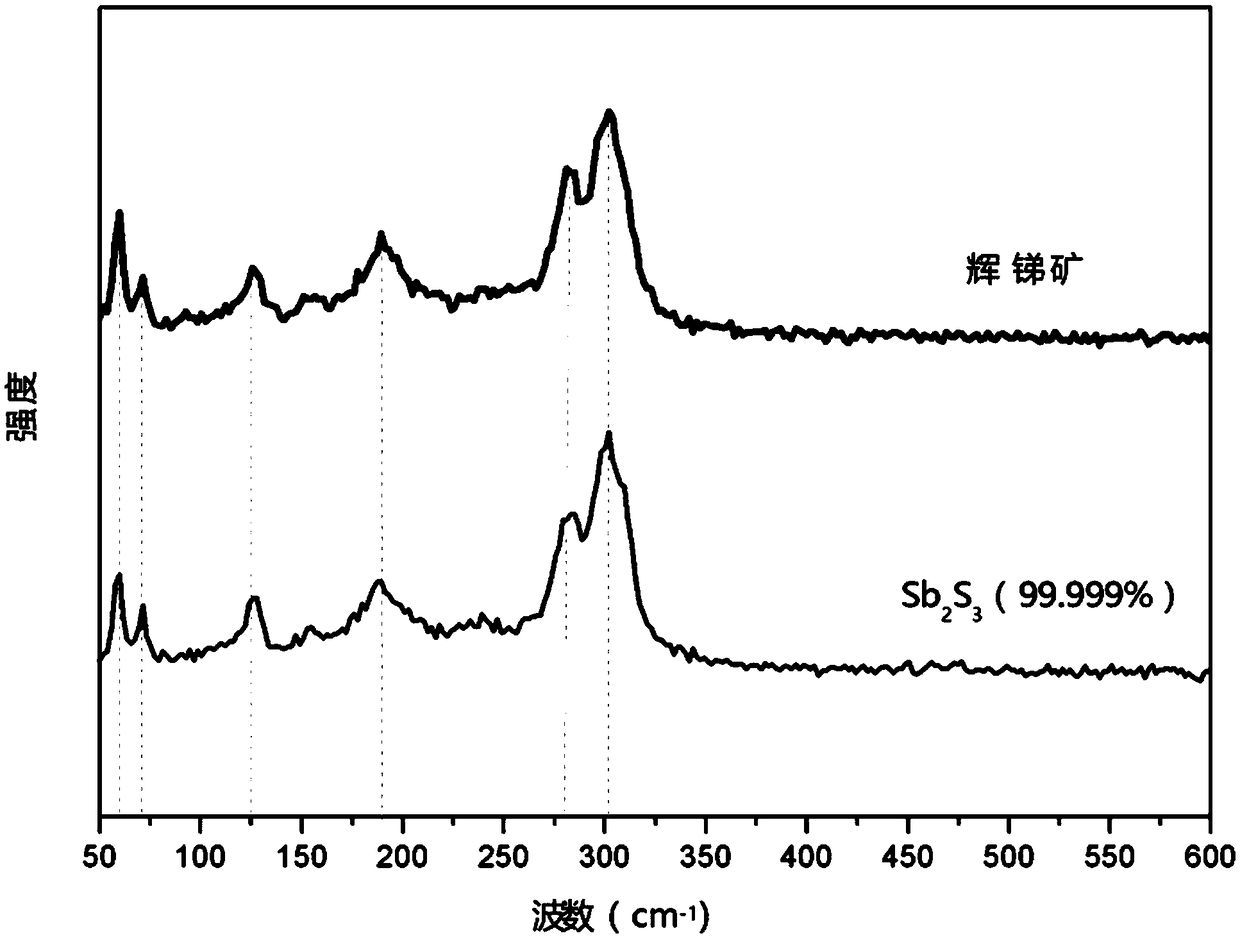

Preparation method for antimony sulfide film

ActiveCN109504939ASolve the problem of impuritiesSolve the problem of low sulfurVacuum evaporation coatingSputtering coatingStibniteImpurity

The invention discloses a preparation method for an antimony sulfide film. Raw materials for preparing the antimony sulfide film are stibnite which is simply screened. According to the preparation method, melting point differences of antimony sulfide in the stibnite from other impurities are used, tubular annealing furnace coating and annealing one-step treatment is used in cooperation, and the film which can be on a par with a film made of a raw material being high-purity antimony sulfide (with the purity higher than or equal to 99.999%) is prepared. In the process of preparing the antimony sulfide film, the preparation method can avoid the environmental pollution problem generated in the process of preparing the high-purity antimony sulfide raw material, can solve the problems of impurities and insufficient sulfur in the process of preparing the antimony sulfide film through the stibnite, is simple and efficient in technological process, greatly reduces the preparation cost, is stable, reliable, wide in application range and suitable for most substrates requiring coating with antimony sulfide, and is an energy-saving, high-efficiency, green and environment-friendly method.

Owner:CENT SOUTH UNIV

Multi-stage mixing and filtering impurity removal equipment for structural adhesive for building processing

InactiveCN112892368AImprove qualityHigh strengthTransportation and packagingMixer accessoriesAdhesiveClassical mechanics

The invention relates to the field of building processing, and in particular, relates to multi-stage mixing and filtering impurity removal equipment for a structural adhesive for building processing, wherein the equipment comprises a box body, a material control mechanism used for controlling the feeding amount, a filtering mechanism used for filtering impurities in the structural adhesive, a vibration mechanism used for driving the filtering mechanism to vibrate to enable the structural adhesive subjected to impurity removal to fall off, a heat conduction assembly used for heating and softening the structural adhesive in the filtering mechanism, a first-stage mixing mechanism used for preliminarily mixing and stirring the structural adhesive, a second-stage mixing mechanism used for further mixing and stirring the structural adhesive, and a storage mechanism used for storing the processed structural adhesive; and the storage mechanism is arranged at the bottom end of the inner side of the box body, and the storage mechanism is also located below the secondary mixing mechanism. According to the multi-stage mixing and filtering impurity removal equipment, the problems that impurities exist in traditional building structural adhesives and the quality is unqualified due to incomplete mixing of the traditional building structural adhesives are solved, the quality of the building structural adhesives is improved, and the strength of the building structural adhesives is enhanced.

Owner:李涛

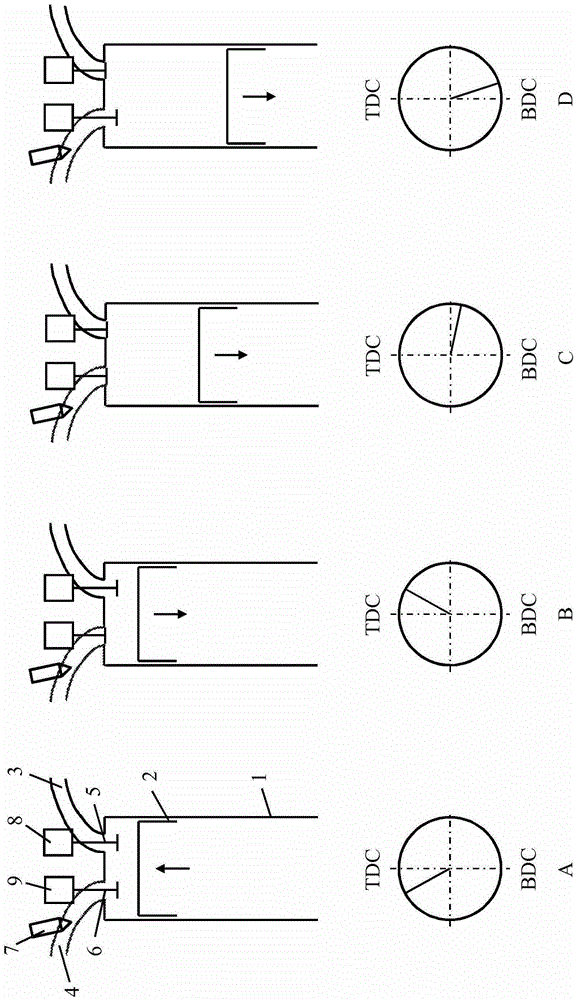

Method for reducing emissions of an internal combustion engine and internal combustion engine

ActiveCN103080507BEmission reductionReduce the temperatureElectrical controlNon-fuel substance addition to fuelExhaust valveInlet valve

A method for reducing emissions of an internal combustion engine(10), which engine (10) comprises at least one cylinder (1), a reciprocating piston (2) arranged inside the cylinder (1), an intake channel(3), an exhaust channel (4), at least one intake valve (5) and at least one exhaust valve (6). The intake valve (5) is closed during the intake stroke before the piston (2) reaches bottom dead center. After closing the intake valve (5), the exhaust valve (6) is reopened for letting exhaust gas flow into the cylinder (1). Before closing the exhaust valve (6), water is injected into the exhaust channel (4).The invention also concerns an internal combustion engine(10).

Owner:WARTSILA FINLAND OY

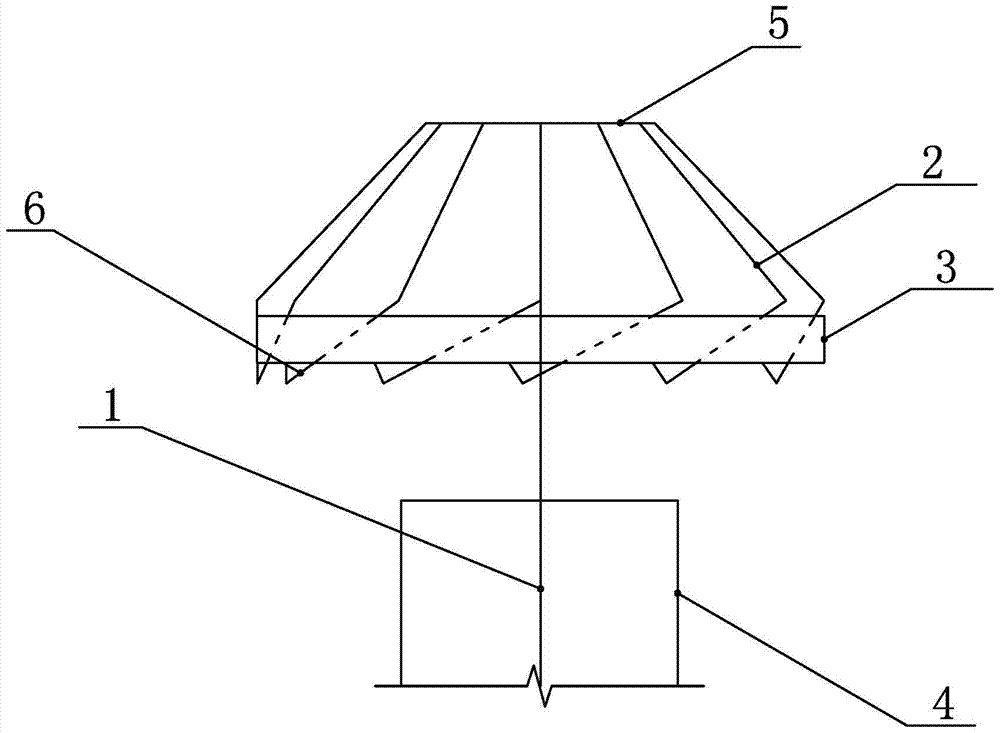

A fixed blade type low wind resistance windpipe rain cover

ActiveCN104180501BIncrease the air outlet areaImprove stabilityHeating and ventilation casings/coversForeign matterAxis of symmetry

The invention relates to a fixed blade type low wind resistance windpipe rain cover, which relates to a rainproof device for shielding rain, snow and other foreign objects for an exhaust pipe or an air inlet. The purpose of the utility model is to provide a fixed-blade low-wind-resistance windpipe rain cover with simple structure, low wind resistance, high ventilation efficiency and good rain-shielding effect. A fixed-blade type low-drag air duct rain cover of the present invention includes a bracket, the bracket is installed in the middle of the inside of the air duct, and a top cover is installed above the bracket, and several identical blades are evenly installed on the top cover. The blades are inclined downward from the root to the outer edge, and the blades are rotated and inclined at a certain angle along their symmetry axis, and the edge of the blade on the lower side is folded upwards to form a drainage groove. The projection of adjacent blades in the vertical direction has A part overlaps, and the ring-shaped rain shield is arranged on the outside of the blades, and is respectively connected with the outer edge of each blade.

Owner:BEIJING QIJIAYIJU TECHNOLOLGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com