Circuit board double-roller ink coating machine and working method thereof

A circuit board and coating machine technology, applied in the coating field, can solve the problems of low degree of automation, time-consuming and laborious, and high labor cost, and achieve the effect of reducing the time for changing the machine, avoiding foreign objects on the board surface, and compact equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

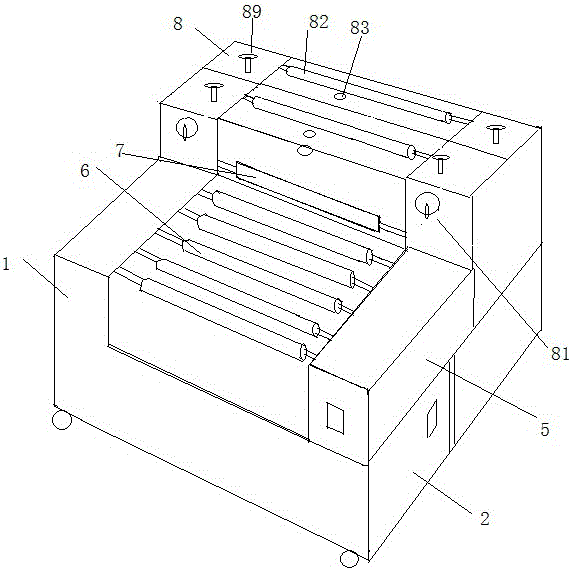

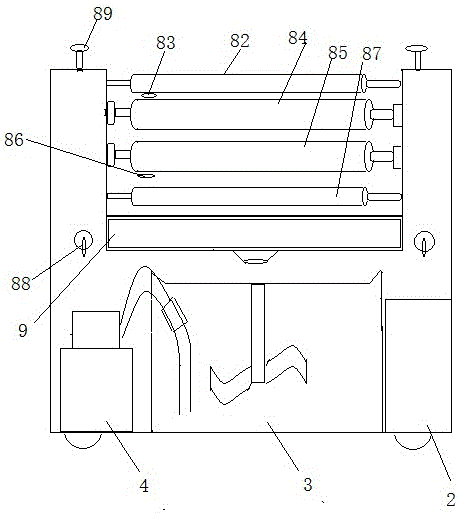

[0018] Such as Figure 1-2 A circuit board double-wheel ink coating machine shown includes a body 1, an electric control box 2, an ink stirring device 3, and a pneumatic diaphragm pump 4 are arranged at the bottom of the body 1, and the electric control box 2 is arranged on the body 3 On the right side, the ink stirring device 3 is set in the middle of the body 1, and the pneumatic diaphragm pump 4 is set on the left side of the body 1;

[0019] The top of the body 1 is provided with a control panel 5, a silica gel transmission roller 6, an automatic dust-sticking roller and a paper roll device 7, a coating mechanism 8, and an ink tray 9. The control panel 5 includes a coating governor, a power button, Manual key, counter, coating key, ink pumping key, and stirring key; the coating mechanism 8 is two and arranged side by side at the discharge end of the silica gel transmission roller 5, and the automatic dust-sticking roller and paper rolling device 6 are arranged on the At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com