Method and device for producing monoammonium phosphate by wet-method phosphoric acid based on multiple neutralizations

A wet-process phosphoric acid, monoammonium phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of large consumption of production auxiliary materials, high labor intensity of workers, large number of filter presses, etc., to improve the output rate , mobile intuitive, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

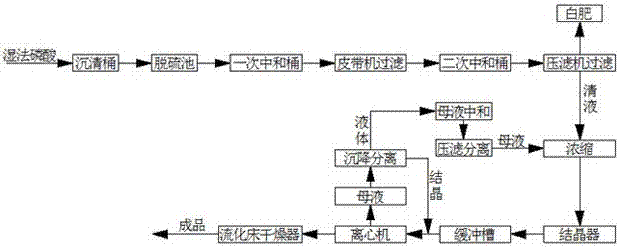

[0043] Such as figure 1 Shown, the method for producing monoammonium phosphate based on the wet-process phosphoric acid of repeated neutralization may further comprise the steps:

[0044] S1: wet-process phosphoric acid: use sulfuric acid to decompose phosphate rock to produce wet-process phosphoric acid;

[0045] S2: Pretreatment of wet-process phosphoric acid: desulfate and defluorinate wet-process phosphoric acid, and then add complexing agent to treat cationic impurities in wet-process phosphoric acid;

[0046] In the wet-process phosphoric acid pretreatment step, a sedimentation and purification step is also included before the desulfurization and defluorination treatment, and the soluble impurities in the wet-process phosphoric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com