Preparation method for antimony sulfide film

An antimony sulfide and thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of waste of raw materials, long and complicated preparation process, high cost, etc., and avoid environmental pollution problems and processes. The process is simple and efficient, and the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Cut the copper foil used in batteries such as sodium-ion batteries, lithium-ion batteries, and solid-state thin-film batteries into a rectangular substrate of 10mm*20mm. At the same time, pre-cut a piece of white glass into a rectangle of 10mm*20mm (for detection). The rectangular white glass slices were ultrasonically cleaned with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dried with an air compressor.

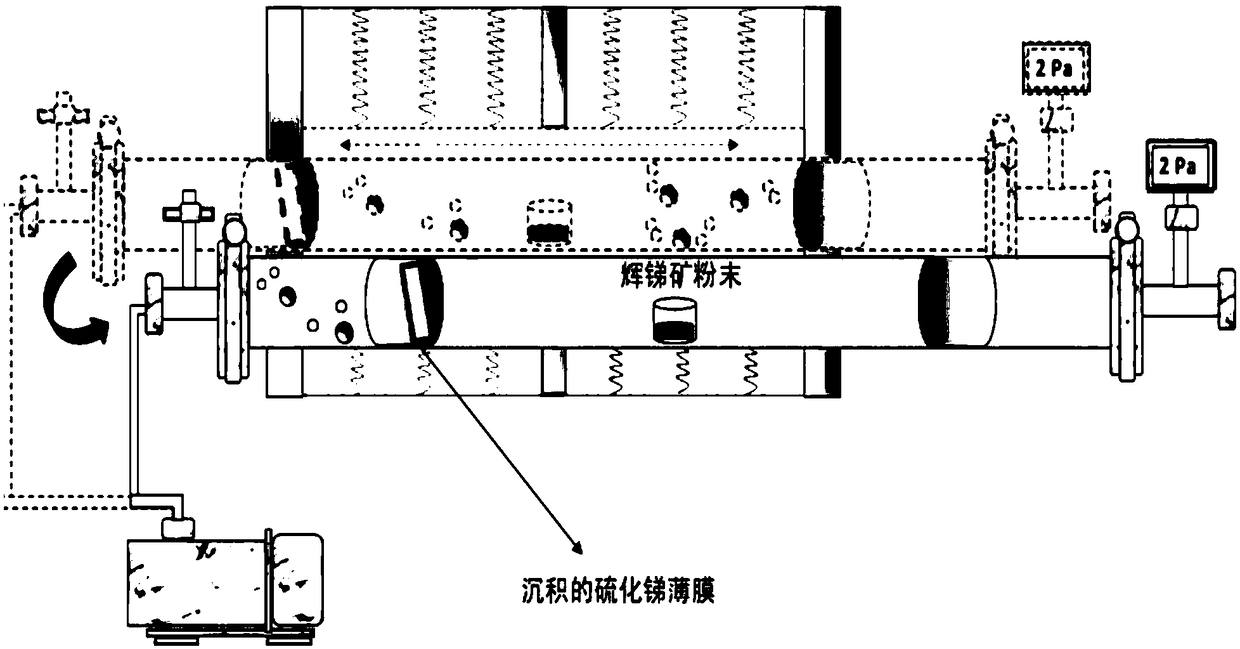

[0035] (2) Weigh 0.40 g of stibnite powder into a porcelain boat, and then put the porcelain boat and the stibnite powder into the middle of the temperature zone of the tubular annealing furnace.

[0036] (3) Put the required deposition film copper foil substrate and white glass into the suction end of the glass tube in the dual temperature zone tube furnace, and place it at the furnace mouth of the dual temperature zone tube furnace. Connect the glass tube and the mechanical pump with a flange, and turn on the m...

Embodiment 2

[0045] (1) The thickness is 1.1mm, resistance ≤ 14Ω / m 2 1. ITO conductive glass with a light transmittance ≥ 90% (Wuhan Jingge Solar Technology Co., Ltd.), pre-cut into 2 pieces of square substrate sheets of 50mm*50mm. The square slices were ultrasonically cleaned with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dried with an air compressor for use.

[0046] (2) A 50nm CdS electron transport layer was deposited on the ITO conductive glass sheet to be used by a chemical water bath method.

[0047] Specifically, 160 milliliters of deionized water was added to a 250 milliliter beaker, and then 0.03 mol / liter of cadmium sulfide solution, 1.5 mol / liter of thiourea and 14.5 milliliters of 25% ammonia were added to the beaker, Then put the beaker with the ITO conductive glass sheet into a heat-collecting constant temperature heating magnetic stirrer and conduct a water bath at 80°C. After 3-6 minutes, the solution turns orange, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com