Colored toner prepared through in-situ miniemulsion polymerization and electrostatic agglomeration and preparation method thereof

An in-situ mini-emulsion and electrostatic coagulation technology, applied in electrographics, instruments, developers, etc., can solve the problems of easy leakage and weak bonding, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

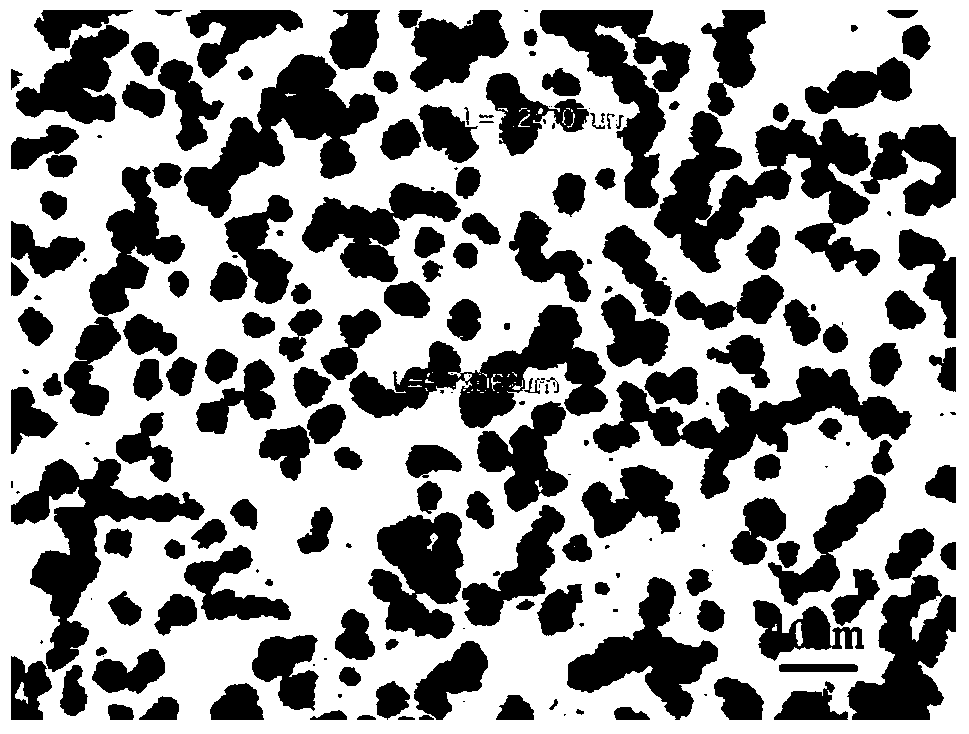

Image

Examples

Embodiment 1

[0047] 70 parts of styrene, 30 parts of butyl acrylate, 7 parts of absolute ethanol, 5 parts of paraffin, yellow pigment PY 17 4 parts, 0.3 parts of charge regulator, 1000 parts of deionized water, and weigh two parts of the above components;

[0048] And 1.5 parts of potassium persulfate, 0.5 parts of azobisisobutylammonium hydrochloride, 1 part of anionic emulsifier SDS, 5 parts of nonionic emulsifier TX-1000, cetyltrimethylammonium bromide CTAB 10 parts, hydrophobic nano-SiO 2 2 parts, 50 parts of 4% silicone defoamer XP-130A solution;

[0049] Dissolve the charge regulator in absolute ethanol, disperse the yellow PY17 pigment in the mixed monomer of styrene and butyl acrylate under ultrasonic, add the ethanol solution of the charge regulator into the mixed monomer under ultrasonic, and continue the ultrasonic dispersion for 10 minutes, Obtain uniformly mixed material A;

[0050] Put the mixture A in a water bath at 65°C, add the paraffin to the mixture A, wait until the...

Embodiment example 2

[0058] 80 parts of styrene, 20 parts of butyl acrylate, 3 parts of absolute ethanol, 15 parts of paraffin, 36 parts of blue pigment PB15, 0.1 part of charge regulator, 800 parts of deionized water, weigh two parts of the above components;

[0059] And 2.5 parts of potassium persulfate, 1.5 parts of azobisisobutyl rice hydrochloride, 2 parts of anionic emulsifier SDS, 6 parts of nonionic emulsifier TX-100, 7 parts of cationic emulsifier DTAB, hydrophobic nano-SiO 2 5 parts, 80 parts of 4% silicone defoamer XP-130A;

[0060] Dissolve the charge regulator in absolute ethanol, disperse the blue PB15:3 pigment in the mixed monomer of styrene and butyl acrylate under ultrasonic, add the ethanol solution of the charge regulator into the mixed monomer under ultrasonic, and continue the ultrasonic dispersion 15min, the material A that mixes homogeneously is obtained;

[0061] Put the mixture A in a water bath at 65°C, add the paraffin to the mixture A, wait until the paraffin is compl...

Embodiment 3

[0068] 75 parts of styrene, 25 parts of butyl acrylate, 10 parts of absolute ethanol, 10 parts of paraffin, red pigment PR 122 8 parts, 0.5 parts of charge regulator, 1200 parts of deionized water, and weigh two parts of the above components;

[0069] 1 part of ammonium persulfate, 1 part of azobisisobutyl rice hydrochloride, 2 parts of anionic emulsifier SDS, 8 parts of nonionic emulsifier, 5 parts of cationic emulsifier DTAB, hydrophobic nano-SiO 2 3 parts, 100 parts of 4% silicone defoamer XP-130A solution;

[0070] Dissolve the charge regulator in absolute ethanol, disperse the red PR122 pigment in the mixed monomer of styrene and butyl acrylate under ultrasonic, add the ethanol solution of the charge regulator into the mixed monomer under ultrasonic, continue ultrasonic dispersion for 20min, and prepare Obtain mixed material A;

[0071] Put the mixture A in a water bath at 65°C, add the paraffin to the mixture A, wait until the paraffin is completely melted, stir to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com