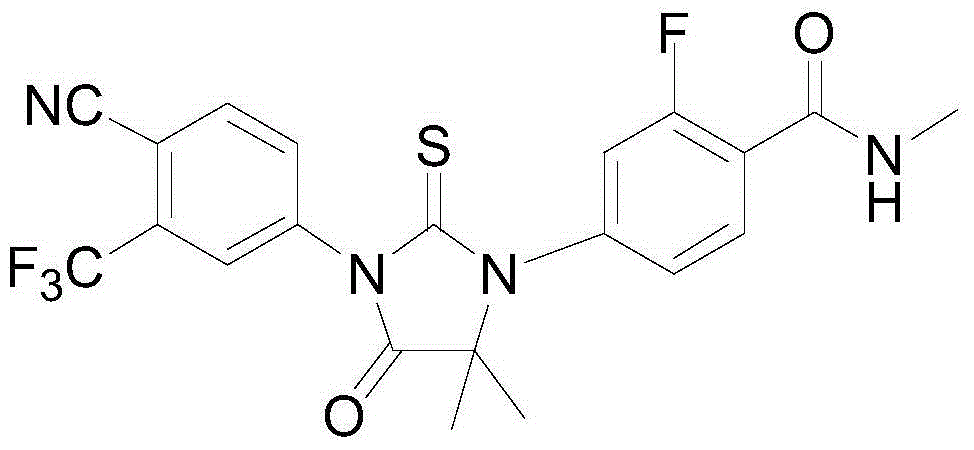

Purification method of enzalutamide

A technology of enzalutamide and refining methods, applied in the direction of organic chemistry, can solve the problems of material precipitation and agglomeration, and can not be produced on a large scale, and achieve the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 1000ml reaction flask, add 500ml of absolute ethanol, stir 50g of 95% crude enzalutamide, add 2.5g of activated carbon after stirring for 10 minutes, heat to reflux for 10 minutes, filter while hot, collect the filtrate, and set aside.

[0025] Add the above-mentioned 500ml enzalutamide filtrate into a 1500ml reaction flask, cool to 10°C, add 100ml cyclohexane dropwise for about 15 minutes while stirring, at a stirring speed of 50 rpm, continue stirring for 20 minutes, white crystals gradually precipitate out, After filtering and washing with cyclohexane, 37.2 g of refined enzalutamide was obtained. The product was analyzed by HPLC, the content was 99.5%, and the yield was 77.9%.

Embodiment 2

[0027] In a 1000ml reaction flask, add 600ml of isopropanol, add 50g of 95% enzalutamide crude product under stirring, add 5g of activated carbon after stirring for 10 minutes, heat to reflux for 15 minutes, filter while hot, collect the filtrate, and set aside.

[0028] Add the above-mentioned 600ml enzalutamide filtrate into a 1500ml reaction bottle, cool to 20°C, add 200ml of n-hexane dropwise for about 15 minutes while stirring, at a stirring speed of 200 rpm, continue stirring for 30 minutes, white crystals gradually precipitate, After filtering and washing with n-hexane, 35.8 g of refined enzalutamide was obtained. The product was analyzed by HPLC, the content was 99.6%, and the yield was 75.1%.

Embodiment 3

[0030] In a 1000ml reaction flask, add 500ml of n-butanol, add 50g of 95% enzalutamide crude product under stirring, add 4g of activated carbon after stirring for 10 minutes, heat to reflux for 20 minutes, filter while hot, collect the filtrate, and set aside.

[0031] Add the above-mentioned 500ml enzalutamide filtrate into a 1500ml reaction bottle, cool to 20°C, add 500ml of n-heptane dropwise for about 30 minutes while stirring at a stirring speed of 150 rpm, and continue stirring for 30 minutes, white crystals gradually precipitate out. After filtering and washing with n-heptane, 36.0 g of refined enzalutamide was obtained. The product was analyzed by HPLC, the content was 99.5%, and the yield was 75.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com