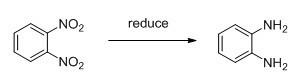

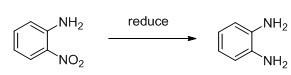

Method for preparing o-phenylenediamine by catalytic hydrogenation of o-nitrophenylamine

A technology of o-nitroaniline and o-phenylenediamine, which is applied in the field of preparing o-phenylenediamine by catalytic hydrogenation of o-nitroaniline, can solve the problems of many amine impurities and difficulties, and achieve short production cycle, low pollution, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] 150g of o-nitroaniline and 300g of methanol were added to the autoclave, and 7.5g of self-made 200 mesh Ni catalyst was added at the same time, the autoclave was closed, the hydrogen valve was opened, hydrogen gas was introduced into the autoclave, and the pressure of the autoclave was adjusted for 3 times. 2.0 MPa, stir and heat up to 60-70°C to react, so that the pressure does not change (about 2-3h), take a sample, and the result of gas chromatography analysis shows that the content of o-phenylenediamine is 98.50%.

example 2

[0028] Add 500 g of o-nitroaniline and 1000 g of methanol into the autoclave, and at the same time add 25 g of self-made Ni catalyst, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, ventilate 3 times, and adjust the pressure of the autoclave to 2.0 MPa , stir and heat up to 60-70°C to react, so that the pressure does not change (about 2-3h), take a sample, and the gas chromatography analysis results show that the content of o-phenylenediamine is 98.78%. After the reaction solution is filtered, the solvent is recovered, and then rectified to obtain a white o-phenylenediamine 360g of phenylenediamine, GC detection 99.9%, yield 92.0%.

example 3

[0030] Add 2000 g of o-nitroaniline and 4000 g of methanol into the autoclave, and at the same time add 25 g of self-made Ni catalyst, close the autoclave, open the hydrogen valve, feed hydrogen into the autoclave, ventilate 3 times, and adjust the pressure of the autoclave to 2.0 MPa , stir and heat up to 60-70°C for reaction, so that the pressure does not change (about 2-3h), sampling, and the result of gas chromatography analysis shows that the content of o-phenylenediamine is 99.00%. After the reaction solution is filtered, the solvent is recovered, and then rectified to obtain a white o-phenylenediamine 1455g of phenylenediamine, GC detection 99.9%, yield 92.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com