Patents

Literature

104results about How to "Avoid compositional segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

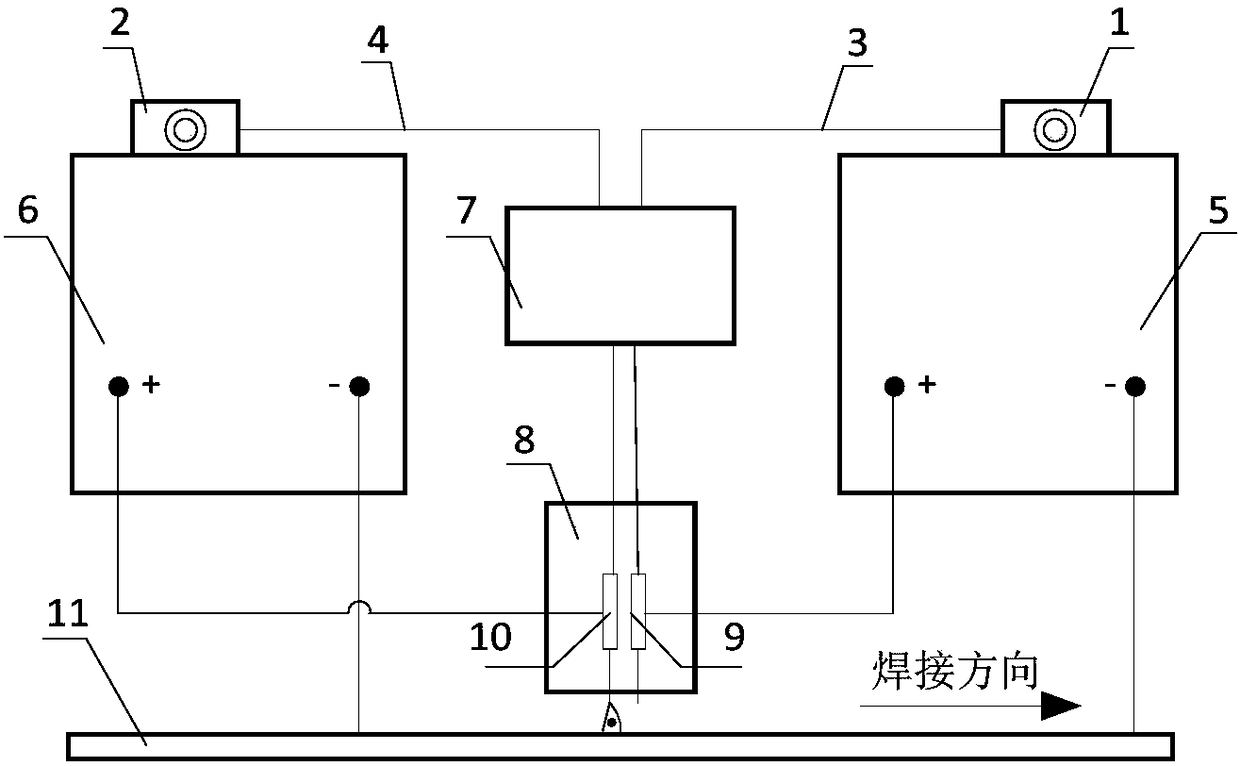

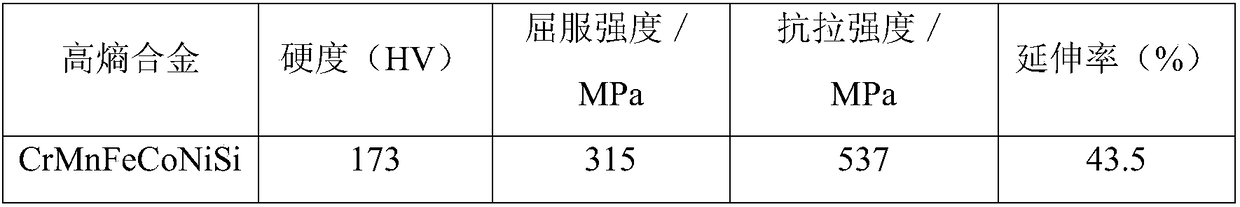

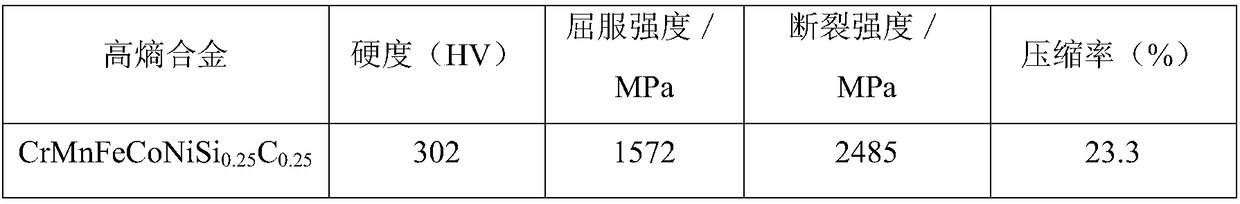

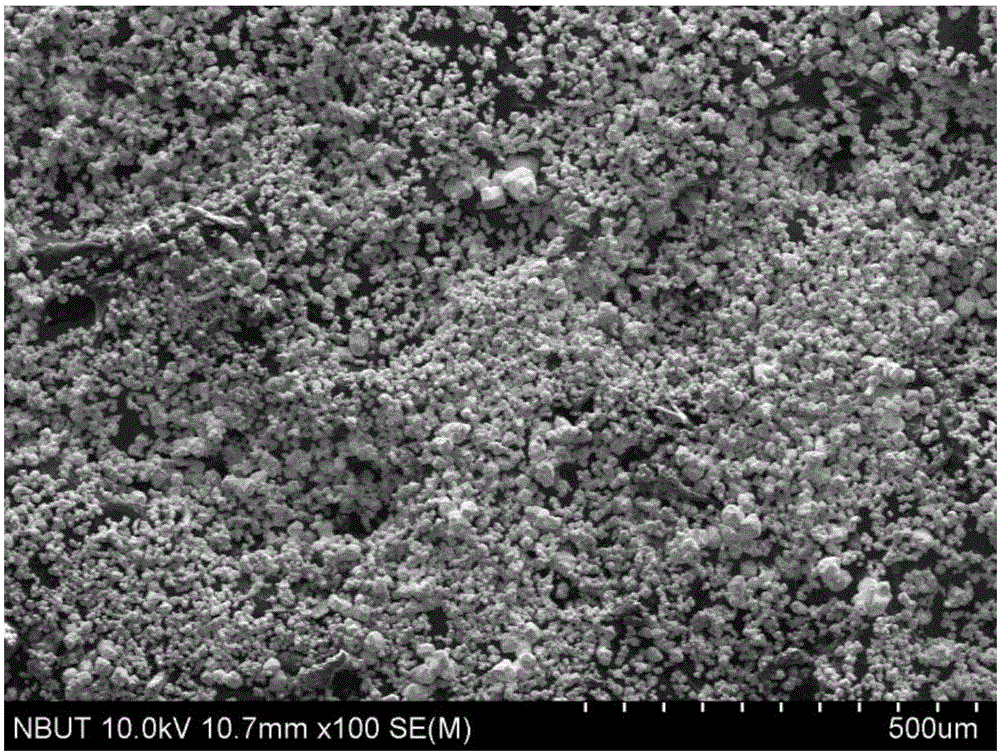

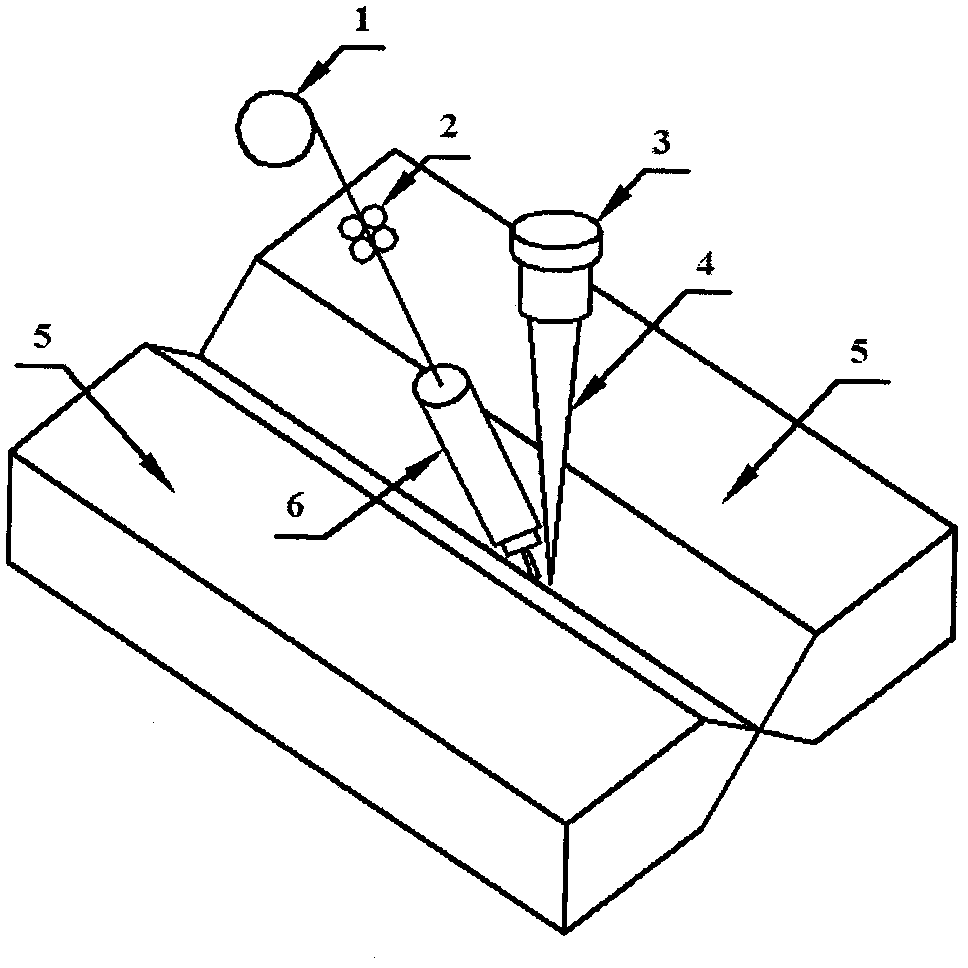

Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

ActiveCN108326427AEasy to adjust ingredientsEasy to adjust grain sizeAdditive manufacturing apparatusLaser beam welding apparatusManufacturing technologyHigh entropy alloys

The invention relates to the technical field of high-entropy alloys, and specifically discloses a double-arc fuse collaborative additive manufacturing method of a high-entropy alloy. The method is characterized in that raw materials are supplied based on a formula of the high-entropy alloy, wherein the raw materials include an alloy strip and flux core powder; the alloy strip and the flux core powder are prepared into a flux cored welding wire; and then a double-arc fuse collaborative additive manufacturing method is carried out to obtain a part or a blocky alloy as requirement. The method isstable in processes, high in cladding efficiency, high in preparation efficiency, wide in heat input adjusting range, low in cost, convenient to adjust the components of the alloy and the size of crystal grains; in addition, the method is applicable to manufacturing of massive high-entropy alloys as well as precise high-entropy alloy parts.

Owner:SHIJIAZHUANG TIEDAO UNIV

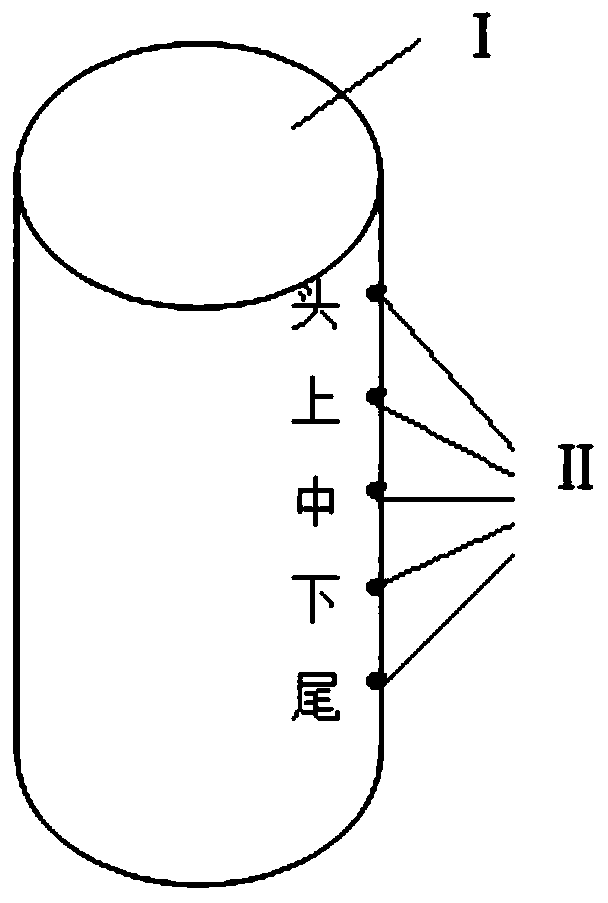

Process for producing large-size 7055 aluminum alloy round ingot

The invention discloses a process for producing a large-size 7055 aluminum alloy round ingot. The process comprises the following steps of firstly preparing the following raw materials in mass ratio: less than or equal to 0.10% of Si, less than or equal to 0.15% of Fe, 2.0-2.6%b of Cu, less than or equal to 0.05% of Mn, 1.8-2.3% of Mg, less than or equal to 0.04% of Cr, 7.6-8.4% of Zn, less than or equal to 0.06% of Ti, 0.08-0.25% of Zr and the balance of inevitable impurities and aluminum; smelting, refining, skimming slag, standing, carrying out heat preservation, carrying out online degassing and refining and casting by virtue of stepped casting process parameters, wherein the casting speed is 15-25mm / min and the water flow is 600-1300l / min. By the process for producing the large-size 7055 aluminum alloy round ingot, the casting composition segregation can be avoided and the generation of casting cracks can be solved, the finished product rate is high and the thickness of the coarse-grained layer is much lower than conventional levels.

Owner:CHINA ZHONGWANG

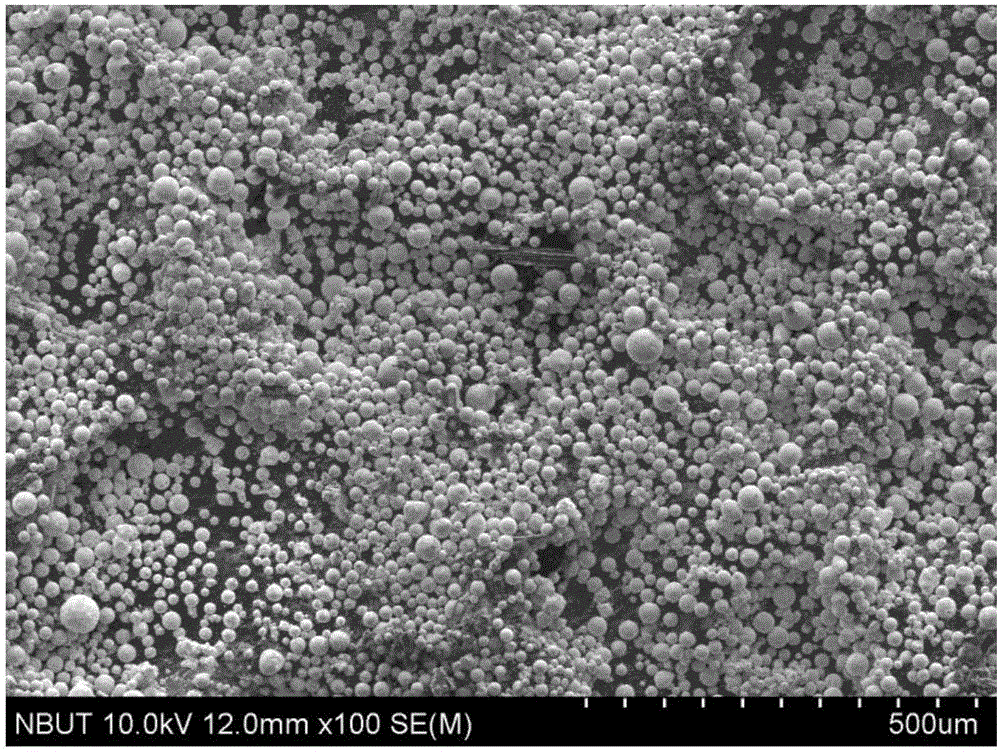

Tungsten-copper alloy and production method thereof

ActiveCN106435319AGood dispersionReduce clumpingTransportation and packagingMetal-working apparatusDispersityCompression molding

The invention belongs to the field of alloy material production, and particularly relates to tungsten-copper alloy and a production method thereof. The tungsten-copper alloy and the production method thereof aim to solve the problem that alloy structures are not uniform because of two-phase segregation of tungsten and copper in tungsten-copper alloy produced through existing methods. According to the production method, after tungsten powder undergoes plasma spheroidization, copper powder serves as an inducer for chemical copper plating, then compression molding, pre-sintering and tungsten-copper infiltration are carried out, and finally the tungsten-copper alloy with uniform structures can be obtained. According to the method, the shape of the tungsten powder is changed into a spherical shape from a polygonal shape, the dispersity is improved, and uniform distribution of the tungsten and the copper in the chemical copper plating process is guaranteed. According to the produced alloy material, two-phase composition segregation of the tungsten and the copper can be effectively prevented, the thermal conductivity, the electrical conductivity, the arc ablation resistance, the high temperature performance, the plasticity and the machinability of the alloy material are greatly improved, and the alloy material can be widely applied to heat sink materials, encapsulating materials and high explosive anti-tank cartridge liner materials.

Owner:四川恒珲新材料科技有限公司

Preparation method of iron, chromium and aluminum multielement electrothermal alloy with high resistance

The invention relates to a preparation method of an iron, chromium and aluminum multielement electrothermal alloy with high resistance and particularly relates to a preparation method of fusion and powder metallurgy combined for the iron, chromium and aluminum multielement electrothermal alloy with high resistance. The preparation method comprises the following steps: burdening; smelting; smashing; ball-milling; sintering by a discharge plasma; homogenizing annealing; isothermal forging; hot-rolling of a wire rod; stress relief annealing; and multi-pass drawing after rinsing and the like. The preparation method combining fusion and powder metallurgy can effectively avoid composition segregation in conventional smelting methods due to great difference on melting point, density and mass ratio of the components, so that the components are uniformly distributed. The microstructure of the alloy is effectively improved by combining subsequent processes such as homogenizing annealing, isothermal forging and wire rod hot-rolling, so that the toughness, the tensile strength and the inoxidizability of the alloy are improved.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

Method for manufacturing copper base alloy bearing bush wear-resisting layer

The invention discloses a method for manufacturing a copper base alloy bearing bush wear-resisting layer and relates to a bead weld method. The method for manufacturing the copper base alloy bearing bush wear-resisting layer aims at solving the problems that an existing bearing bush coating is low in combining strength, poor in coating performance and short in service life. The method includes the first step of polishing, the second step of cleaning, the third step of tin coating, the fourth step of bead weld of babbit metal on the surface of a bearing bush by a CMT welding machine and the fifth step of turning or scraping. The method is used for improving the combining strength of the wear-resisting coating and a copper base bearing bush base body, optimizing a coating organization, prolonging service life, improving the machining precision of the bearing bush and manufacturing the copper base alloy bearing bush wear-resisting layer.

Owner:严格集团股份有限公司

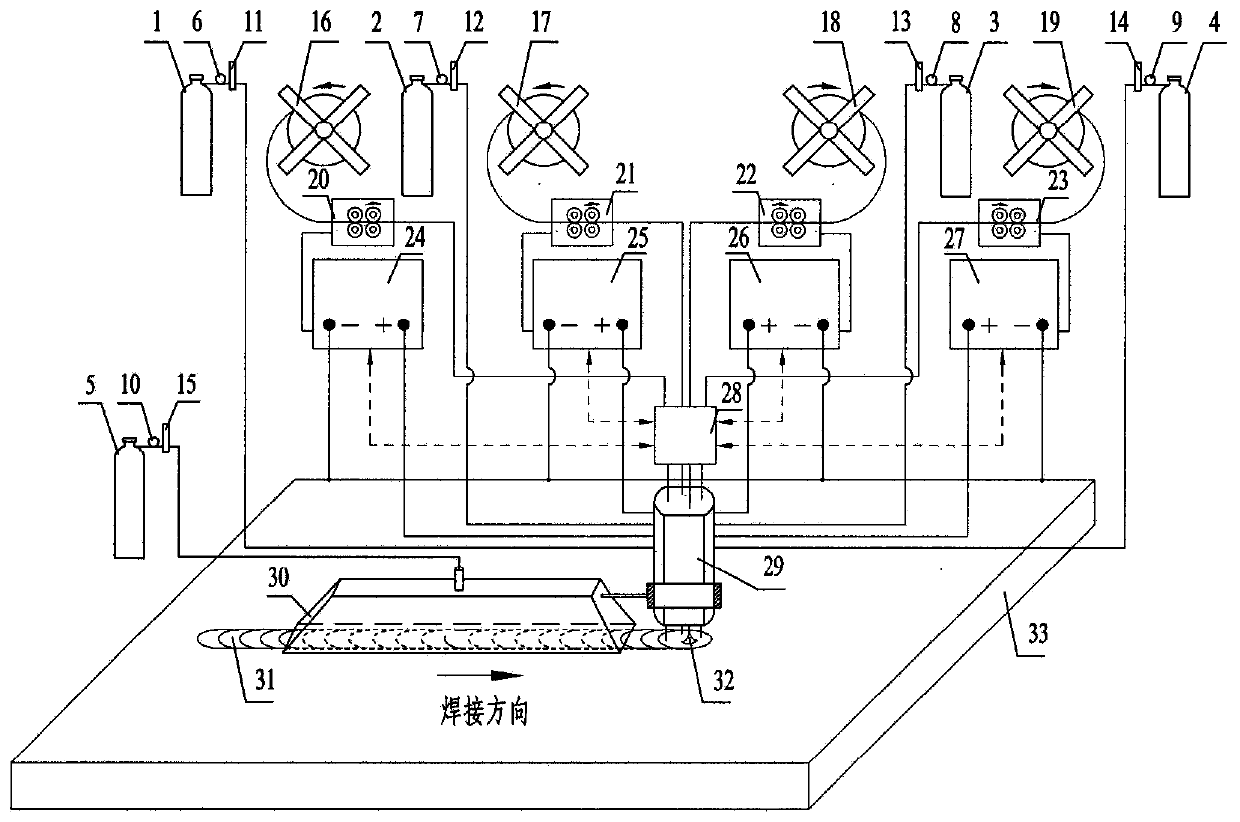

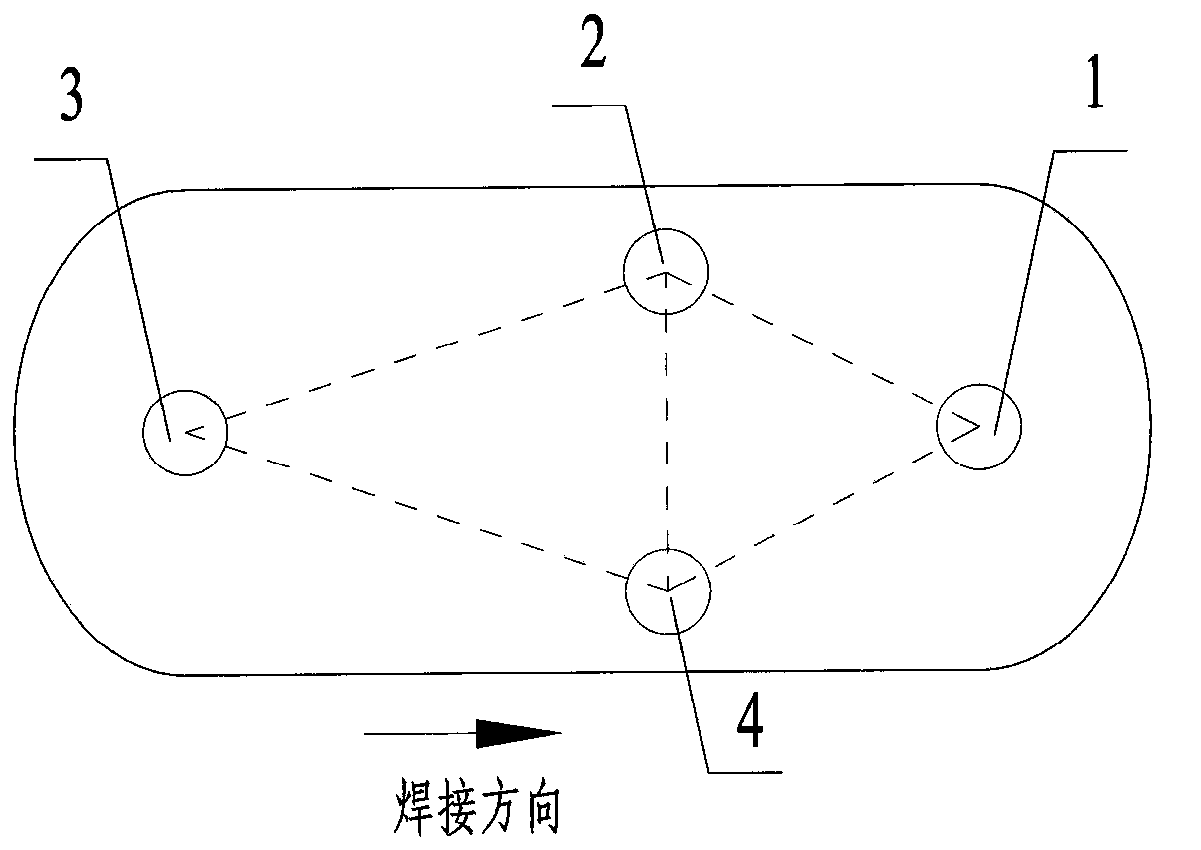

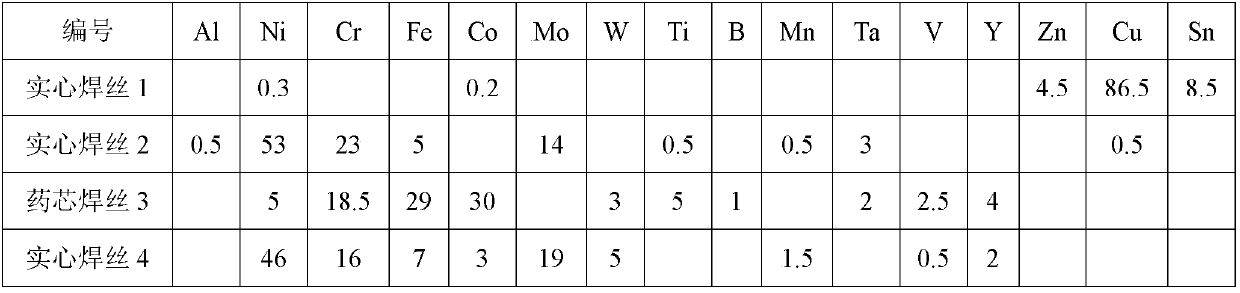

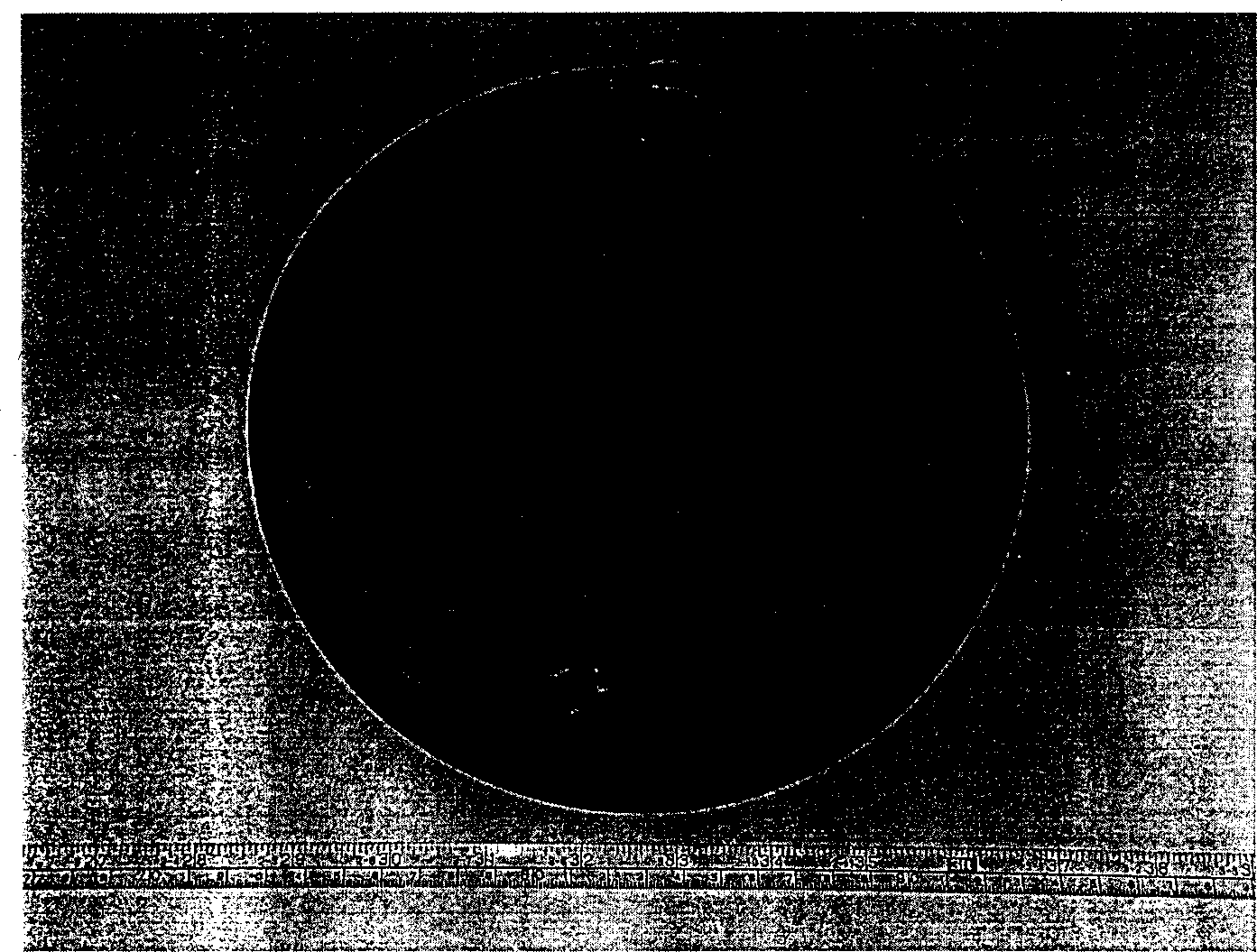

High-entropy alloy double technology preparation method

The invention relates to the technical field of high-entropy alloy, in particular to a high-entropy alloy double technology preparation method. The high-entropy alloy double technology preparation method comprises the steps that firstly, types of four welding wires and components, contents, existence forms and existence positions of welding wire elements are decomposed and designed according to the element components, contents and physico-chemical properties of high-entropy alloy needing to be prepared, and the welding wires are prepared; secondly, an integrated four-wire pulse gas shielded welding technology is adopted to cooperate with additional materials to manufacture the high-entropy alloy; and finally, a vacuum self-consumption remelting technology is adopted to refine the high-entropy alloy. According to the high-entropy alloy double technology preparation method provided by the invention, the technology is stable, the preparation efficiency is high, the cost is low, the heat input adjusting range is wide, the optional alloy element range is wide, the quantity of types of prepared high-entropy alloy is large, alloy component adjusting is convenient and accurately controllable, chemical components are uniform, the structure is compact and uniform, the degree of purity is high, and the inner quality is good.

Owner:SHIJIAZHUANG TIEDAO UNIV

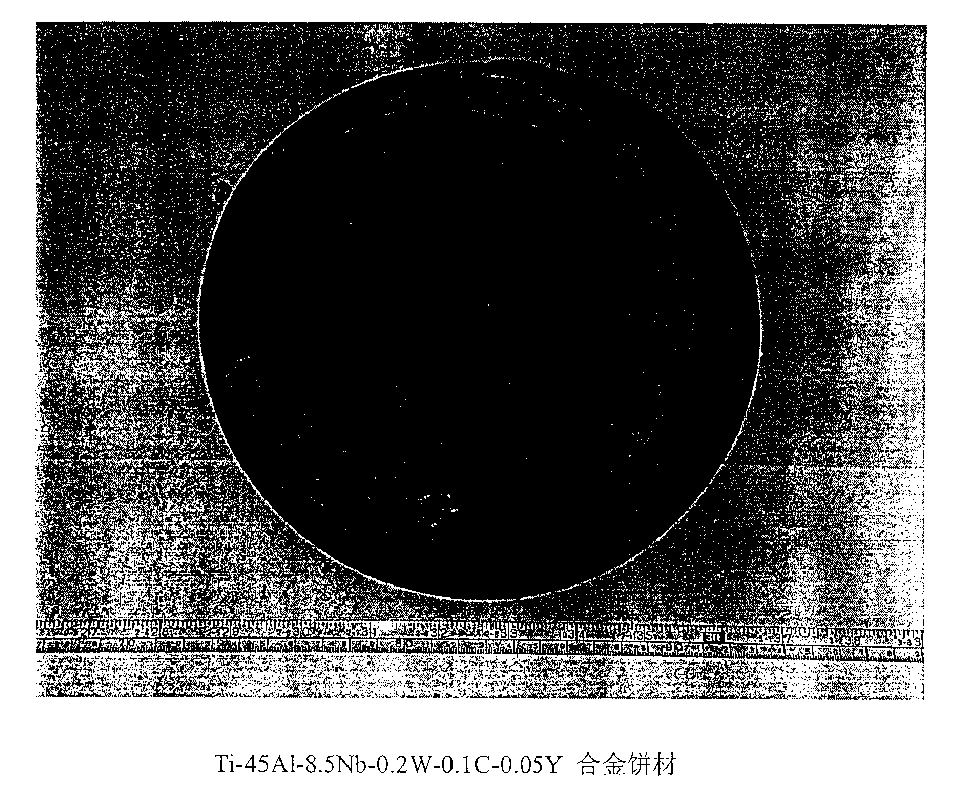

Process for preparing high niobium Ti Al alloy large size cake material

The preparation of large high-Nb TiAl alloy cake includes the technological process of smelting, soakage treatment, turning, canning, forging and slow cooling. The preparation process features the smelitng including the first self-consuming, the self-consuming kish and the second self0consuming steps; the soakage treatment at 1100-1300 deg.c for 24-48 hr; turning to eliminate surface scale; canning with stainless steel pipe, titanium pipe and stainless steel plate; forging in a 3000-5000 oil press at deformation temperature of 1200-1350 deg.c after heating at 1250-1300 deg.c for 40-60 min in the furnace and preheating for 6-10 hr to produce deformatino amount of 60-80 % at the rate of 0.001-0.1 / s; and tempering at low temperature. The present ivnention has the advantages of fine crystal grains and excellent comprehensive mechanical performance.

Owner:UNIV OF SCI & TECH BEIJING

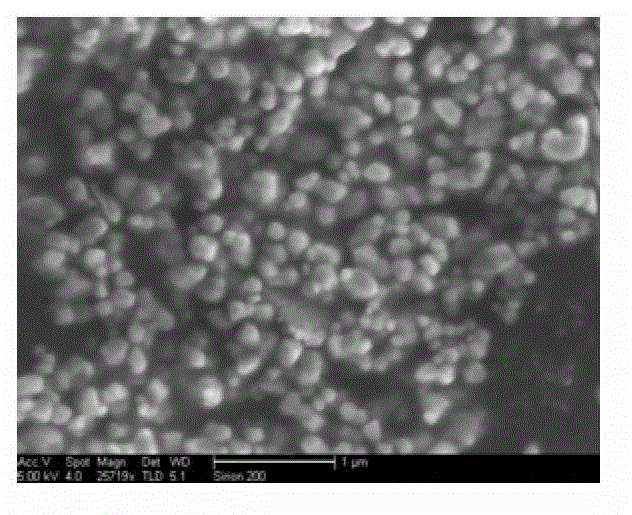

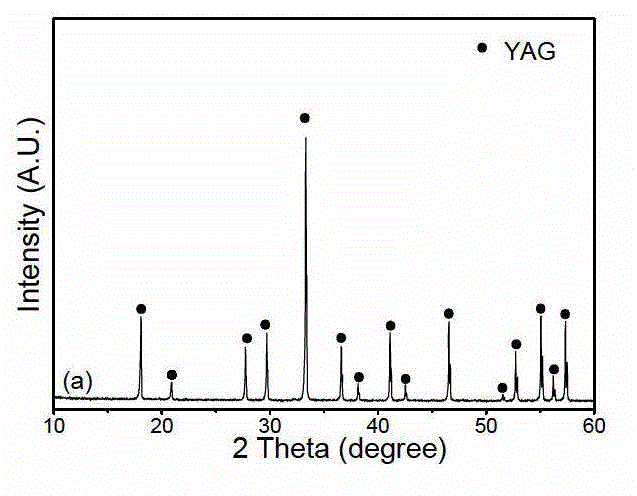

Method for preparing rare earth doping yttrium aluminum garnet crystalline ceramic through synthesis of rare earth doping Y2O3 nanometer powder

InactiveCN103058644ASolve the problem of impuritiesAvoid compositional segregationMetallurgyRare earth

The invention discloses a method for preparing rare earth doping yttrium aluminum garnet crystalline ceramic through synthesis of rare earth doping Y2O3 nanometer powder. Through a new preparation process, the method for preparing the rare earth doping yttrium aluminum garnet crystalline ceramic through the synthesis of the rare earth doping Y2O3 nanometer powder realizes the purposes of not only solving an impurity problem in a solid phase method, but also avoiding a component segregation problem in a liquid phase method, and optimizes the preparation process.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for preparing nickel-chromium multi-component high-resistance electrothermal alloy

ActiveCN103952594AImprove mechanical propertiesImprove high temperature oxidation resistancePowder metallurgyChromium

The invention relates to a method for preparing a nickel-chromium multi-component high-resistance electrothermal alloy and particularly relates to a method for preparing the nickel-chromium multi-component high-resistance electrothermal alloy by melting in combination with powder metallurgy. The preparation method comprises the following steps of proportioning raw materials, melting, crushing, ball-milling, carrying out spark plasma sintering, carrying out homogenizing annealing and isothermal forging, hot-rolling steel wire rods, carrying out stress relief annealing, rinsing and carrying out multi-pass drawing and the like. Due to the adoption of the preparation method combining melting and powder metallurgy, the composition segregation caused by the large difference in the melting point, density and mass ratio of each component in a conventional smelting method can be effectively avoided, uniform distribution of each component is achieved, the microstructures of the alloy are effectively improved in combination with subsequent homogenizing annealing, isothermal forging, hot rolling of steel wire rods and the like and the mechanical properties, application temperature and service life are improved.

Owner:YANCHENG XINYANG ELECTROTHERMAL MATERIAL CO LTD

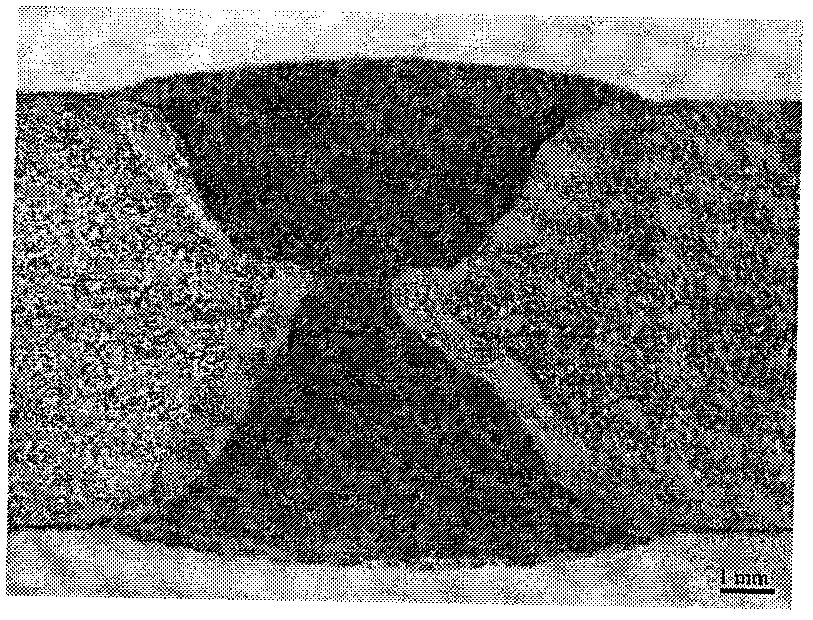

Laser auxiliary consumable electrode arc additive connecting method for high-temperature alloy

ActiveCN106862771AReduce adverse effectsReduce welding heat inputLaser beam welding apparatusHeat-affected zoneManufacturing technology

The invention discloses a laser auxiliary consumable electrode arc additive connecting method for a high-temperature alloy, and belongs to the technical field of welding. According to the method, the laser arc composite welding technology and the additive manufacturing technology are combined, through the coupling function of laser photoinduced plasmas and consumable electrode arcs, stable globular transfer under small current is achieved, layer-by-layer accumulation of micro weld passes is achieved through accurate control over the width and depth of each welding line, a welding connector is formed, the heat input of each welding line is smaller, the welding heat affected zone is narrower, the high-temperature staying time of a melting pool is short, and the solidification speed is increased; the obtained melting pool is narrowed and becomes shallow, chemical components and structures are more uniform, and air holes, cracks and other defects are easier to control; and grain is finer, welding stress and residual deformation are small, the comprehensive performance of a high-temperature alloy welding connector is obviously improved, the component service life is prolonged, and high cost performance is achieved.

Owner:济南英维新材料科技合伙企业(有限合伙)

Diamond grinding wheel for high-speed four-edge grinding and manufacturing method thereof

InactiveCN104440601AHigh hardnessHigh impact strengthAbrasion apparatusGrinding devicesBronzeMachine tool

The invention discloses a diamond grinding wheel for high-speed four-edge grinding and a manufacturing method of the diamond grinding wheel. The diamond grinding wheel comprises a base body and a work layer, and the work layer is composed of, by volume, 75 percent to 93 percent of bronze bond dedicated alloyed powder and seven percent to 25 percent of diamonds. Firstly, the diamonds are dumped into a grinding bowl, and liquid paraffin is added to be fully wetted with the diamonds. Then, the bronze bond dedicated alloyed powder is dumped for even mixing, and mixtures are obtained. The mixtures are dumped into an assembled mold, the mixtures are placed in a dual-body sintering furnace to be sintered after striking and prepressing, and mold unloading is carried out after sintering and cooling. An obtained semi-finished product is ground and finished, and the diamond grinding wheel for high-speed four-edge grinding is obtained. The diamond grinding wheel for high-speed four-edge grinding has the advantages of being stable in performance, sharp in grinding, high in efficiency, low in cost and the like, and the machining requirement that sheet glass machined by imported and domestic high-speed four-edge grinding machine tools is 30 m / min to the maximum degree can be fully met.

Owner:河南新源超硬材料有限公司

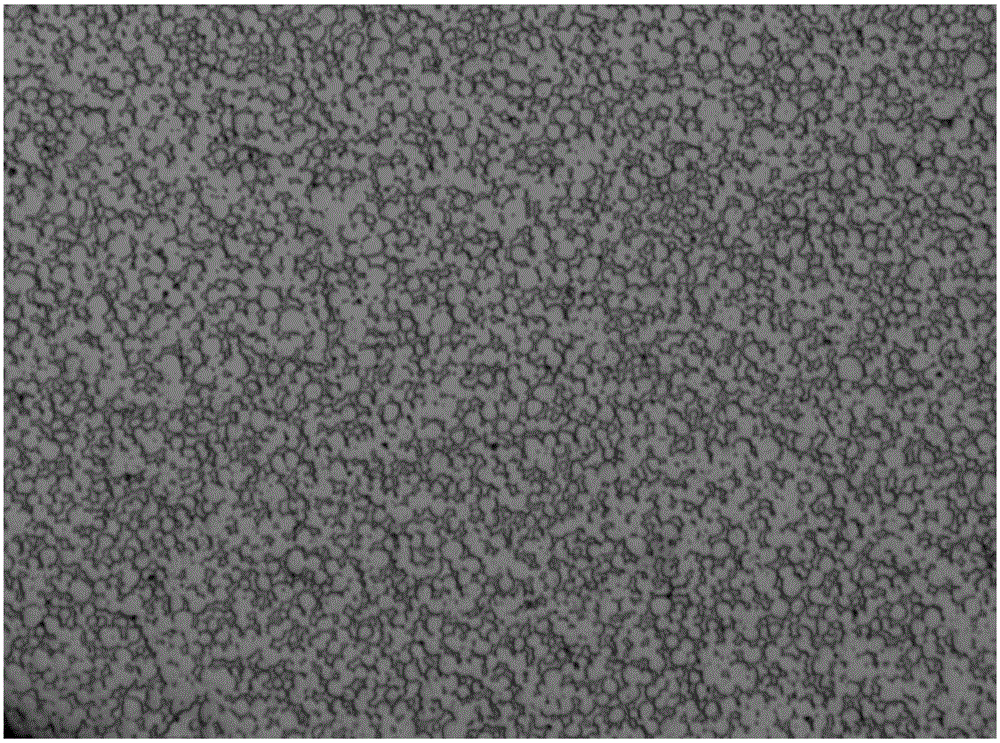

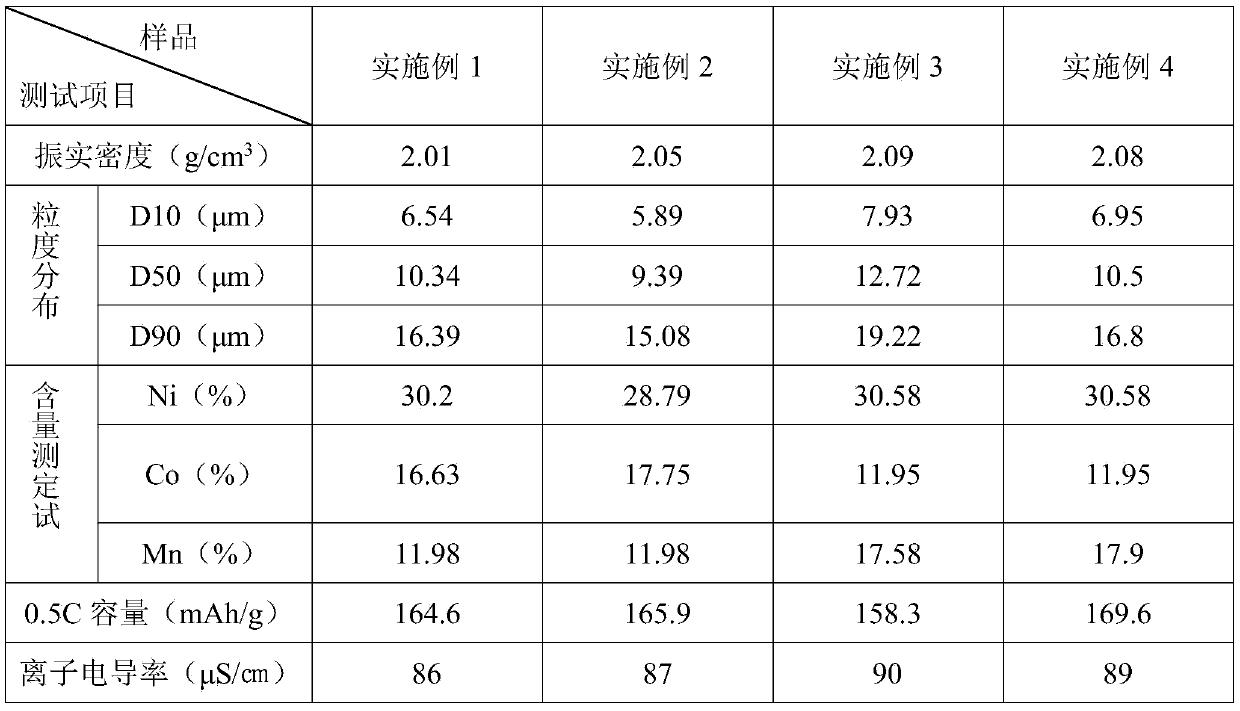

Preparation method of spherical lithium nickel cobalt manganese oxide precursor mixture

InactiveCN105375020APrevent oxidationAvoid compositional segregationCell electrodesSecondary cellsManganese oxideNanometre

The invention belongs to the technical field of lithium battery material and discloses a preparation method of a spherical lithium nickel cobalt manganese oxide precursor mixture. The preparation method comprises raw material pretreatment, wet synthesis, aging after reaction, and spray pyrolysis secondary granulation. The prepared product is the micron-scale secondary spherical lithium nickel cobalt manganese oxide precursor mixture comprising a plurality of nano spherical particles. The precursor mixture has the medium particle diameter of 9-13[mu]m, the iron conductivity of 20-100 [mu]S / cm and the tap density not less than 2.00g / cm<3>. The preparation method has the advantages of small investment, reliable technology, low running cost and the like and therefore has excellent economic benefit and market popularization value.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

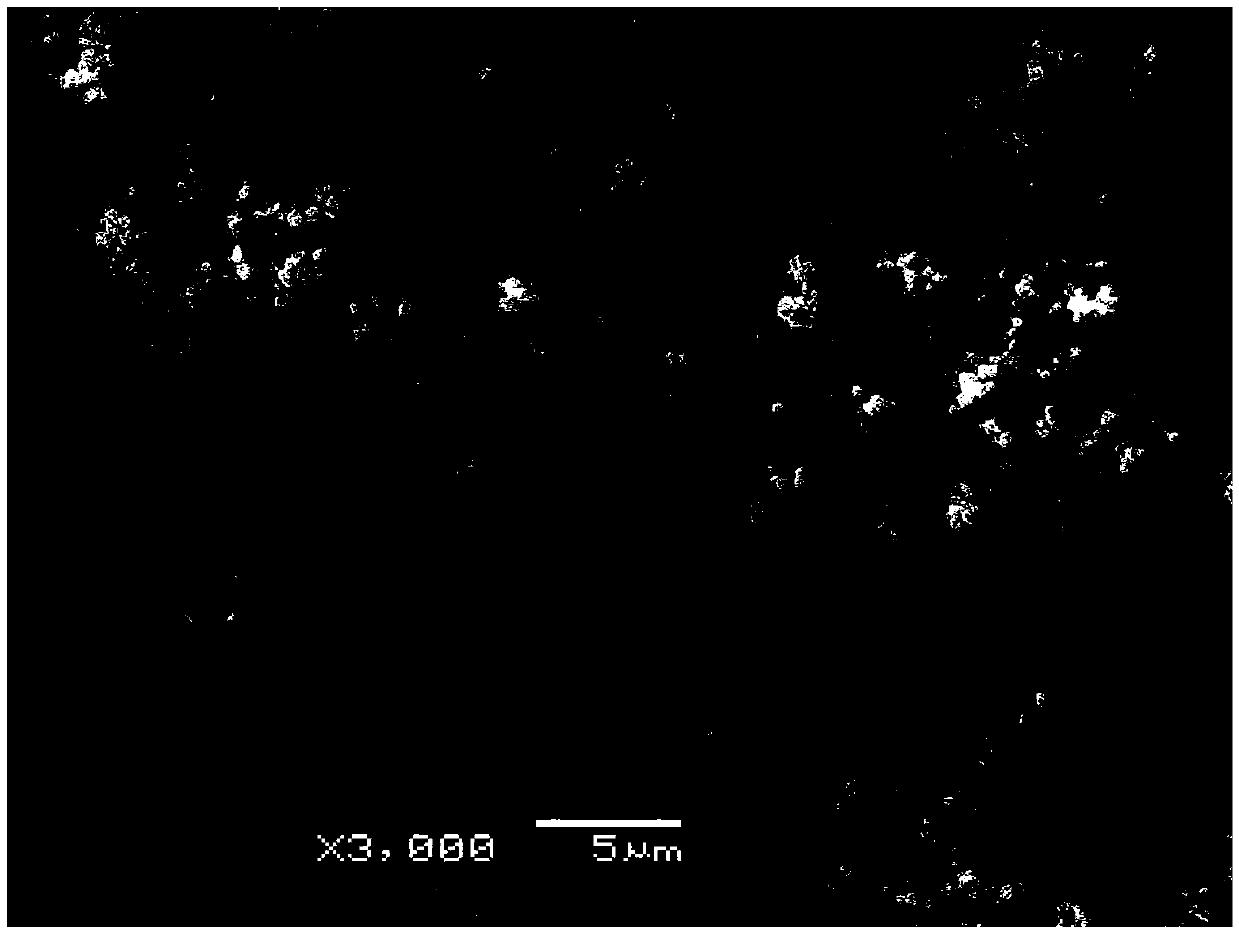

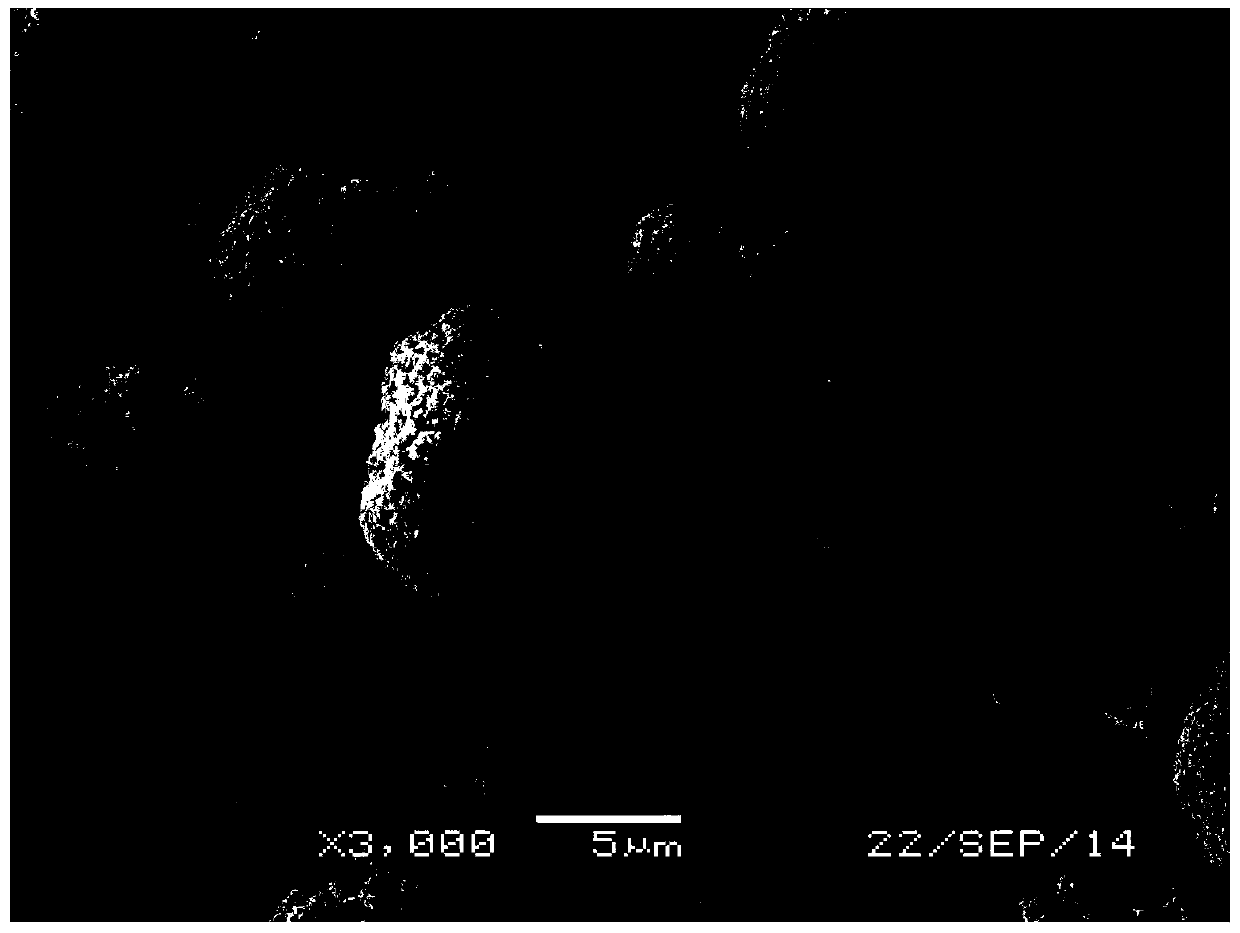

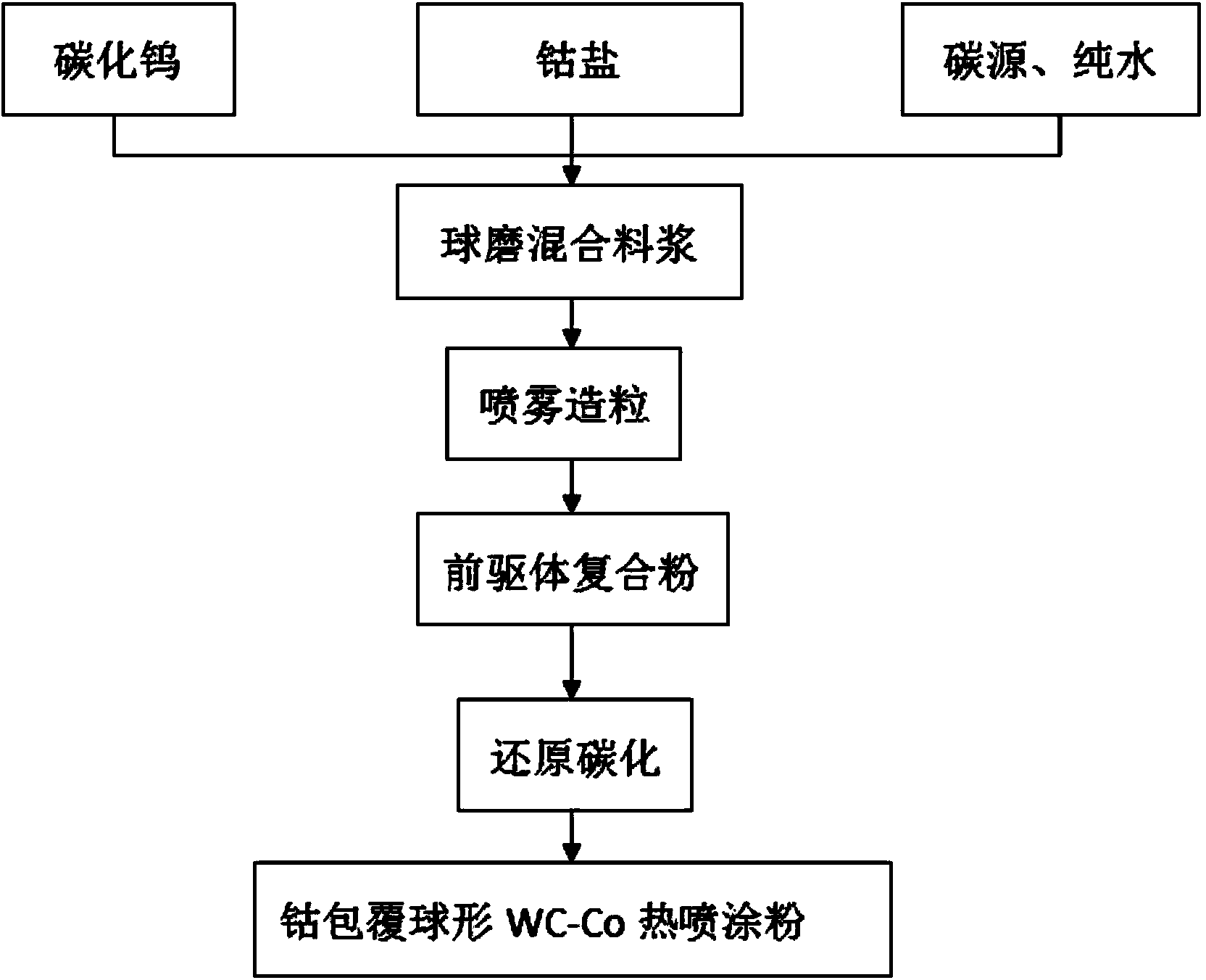

Method for preparing WC-Co powder used for thermal spraying

ActiveCN103920887AHigh free carbon contentAvoid compositional segregationMolten spray coatingSolubilityThermal spraying

The invention provides a method for preparing WC-Co powder used for thermal spraying. The method includes the following steps that tungsten carbide, water solubility cobalt salt, carbon sources and water are mixed to acquire mixed slurry; after ball-milling and even blending are conducted on the mixed slurry, spray granulation is conducted, and WC precursor powder coated by the cobalt salt is acquired; reduction and carbonization are conducted on the WC precursor powder coated by the cobalt salt, and the WC-Co powder is acquired. According to the method, the water solubility cobalt salt serves as the cobalt sources, the WC precursor powder coated by the cobalt salt is prepared by the adoption of the liquid phase method, so that the cobalt can evenly coat the surface of the WC in a solution molecular mode, reduction and carbonization are conducted on the WC precursor powder coated by the cobalt salt, and the WC-Co powder is acquired. The acquired WC-Co powder by the adoption of the method is even in granularity, controllable in ingredients, even in powder ingredients, free of W2C, eta-Co3W3C, eta-Co6W6C, metal tungsten and the like in the ingredients, the degree of sphericity is high, mobility is good, the decarburization phase and phase decomposition does not occur on the surface of the spraying matrix.

Owner:ADVANCED FOR MATERIALS & EQUIP

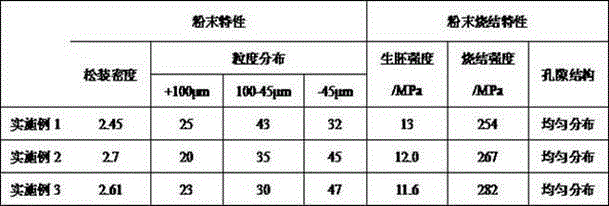

Iron-copper alloy powder and preparation method thereof

The invention discloses iron-copper alloy powder and a preparation method thereof. The iron-copper alloy powder is prepared from the following raw materials in percentage by mass: 10-30 percent of copper oxide powder and 70-90 percent of iron-copper pre-alloyed powder. The preparation method comprises the following steps: selecting the copper oxide powder prepared through roasting and crushing, uniformly mixing the copper oxide powder and the iron-copper pre-alloyed powder according to a ratio, carrying out active diffusion sintering on the mixture in a reducing atmosphere, crushing and sieving the mixture subjected to sintering, and finally preparing the iron-copper alloy powder. The iron-copper alloy powder is lower in apparent density and good in formability, has the apparent density being 2.5-3.0g / cm<3> and the green strength being 12-15MPa, makes up for the deficiencies in the prior art and broadens the application market.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

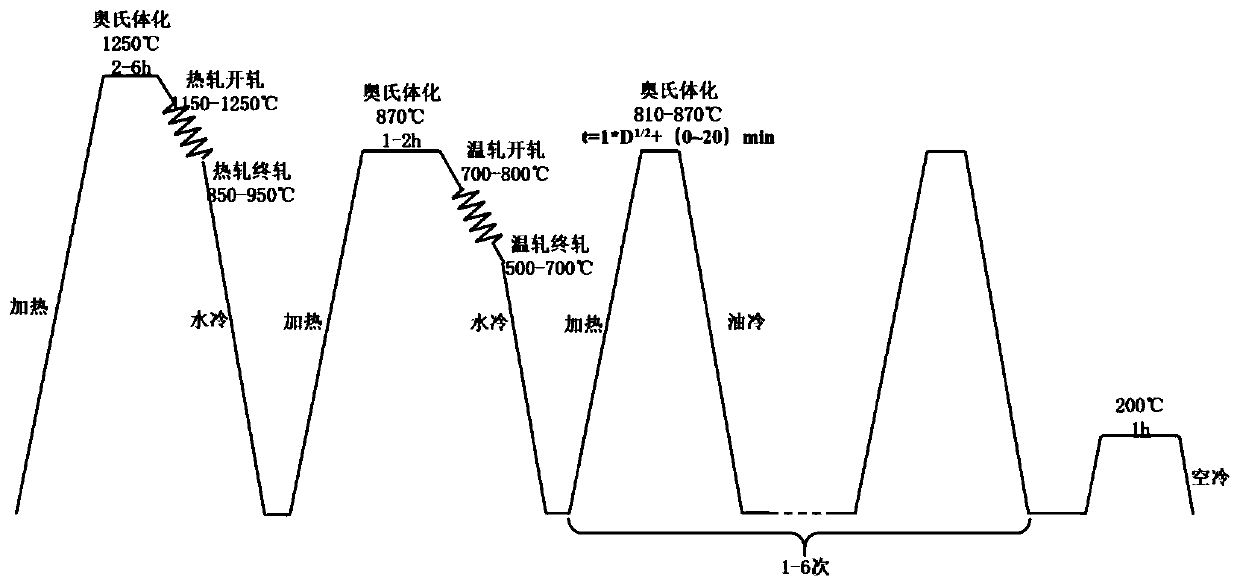

1960 MPa grade galvanized steel wire rope for ocean engineering, and production method of 1960 MPa grade galvanized steel wire rope

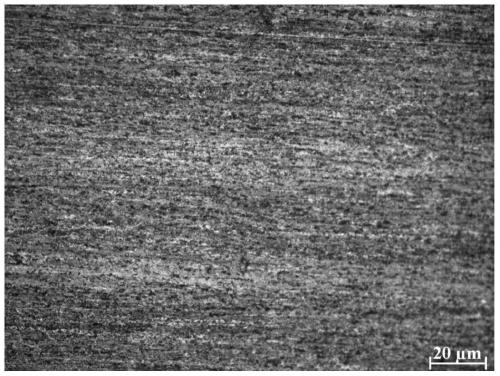

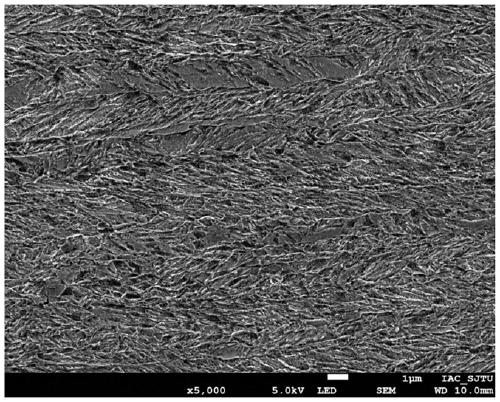

ActiveCN108486478AHigh tensile strengthEasy to refineHot-dipping/immersion processesMetallurgyMartensite

The invention provides a 1960 MPa grade galvanized steel wire rope for ocean engineering, and a production method of the 1960 MPa grade galvanized steel wire rope. The 1960 MPa grade galvanized steelwire rope for the ocean engineering comprises the following components of, 0.87-0.91% of C, 0.15-0.30% of Si, 0.65-0.85% of Mn, 0.15-0.25% of Cr, 0.020-0.060% of V, less than or equal to 0.015% of P,less than or equal to 0.010% of S, less than or equal to 0.05% of Ni, less than or equal to 0.10% of Cu, less than or equal to 0.010% of Alt, less than or equal to 1.0 PPm of H, and the balance Fe andunavoidable impurity elements. Compared with the prior art, refining and continuous casting technologies are optimized, so that composition segregation is avoided; with the adoption of an optimized rolling-control and cold-control rolling technology, network cementite and martensite are avoided, so that a metallographic structure with the sorbitizing rate of 90% or above can be obtained; and a galvanized steel wire made of a hot rolling wire fully meets the use requirement of the 1960 MPa grade galvanized steel wire rope for the ocean engineering.

Owner:MAANSHAN IRON & STEEL CO LTD

Superstrength high-toughness alloy steel and preparing method thereof

The invention discloses superstrength high-toughness alloy steel, and relates to the technical field of metal material and machining. The alloy steel comprises following components, by mass percent, 0.35 to 0.45% of C, 0.60 to 1.00% of Mn, 1.50 to 1.80% of Si, 0.60 to 1.00% of Cr, 1.60 to 2.00% of Ni, 0.30 to 0.50% of Mo, 0.025 to 0.045% of Nb, 0.05 to 0.10% of V, not larger than 0.010% of P, notlarger than 0.005% of S, 0.015 to 0.025% of La and the balance Fe and inevitable impurities. The weight percentage of (Cr+Ni) / Mo ranges from 6.0 to 8.0. The invention further discloses a preparing method of the superstrength high-toughness alloy steel. The production process is simple, the production equipment need is low, production efficiency is high, and industrial and production application isfacilitated.

Owner:SHANGHAI JIAO TONG UNIV

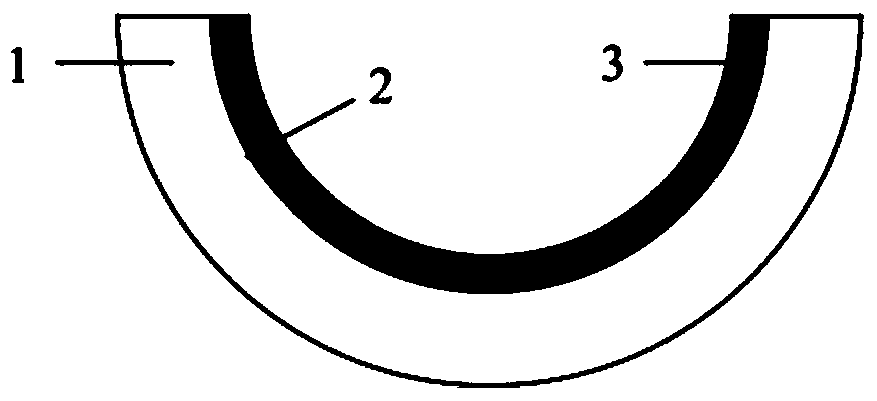

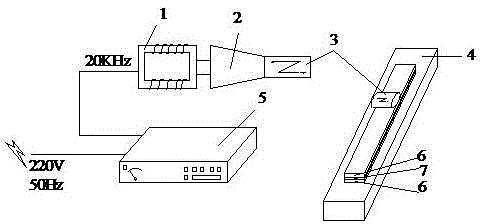

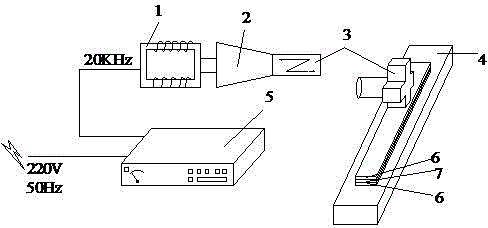

Ultrasonic welding preparation method of Ag-Cu-Ti layer-shaped composite solder

ActiveCN104588863AEasy to shapeEasy to useWelding/cutting media/materialsSoldering mediaMetallurgyMetal foil

Disclosed is an ultrasonic welding preparation method of an Ag-Cu-Ti layer-shaped composite solder. According to the method, solid-state forming characteristics of ultrasonic welding are utilized for the Ag-Cu-Ti layer-shaped composite solder for ceramic and ceramic brazing and for ceramic and metal brazing. The method comprises the steps that three layers of metal foil with the width of 30 mm are stacked for ultrasonic welding, the layer-shaped composite solder is prepared, the upper layer and the lower layer are Ag-Cu eutectic foil, the thickness of the eutectic foil ranges from 21 micrometers to 51 micrometers, and pure Ti foil is arranged on a middle layer; the thickness ratio of the metal foil on the upper layer to the metal foil on the middle layer to the metal foil on the lower layer is 1:0.02-0.50:1, the thickness ratio of the metal foil is adjusted, and therefore the content of active elements in the solder can be adjusted; the mass percent of the active element Ti ranges from 0.4 percent to 10 percent. The thickness of the composite solder ranges from 50 micrometers to 100 micrometers, and the molten temperature region ranges from 780 DEG C to 870 DEG C. The composite solder prepared through the method has the good wettability on the ceramic, and the soldering requirement of the ceramic / ceramic and ceramic / metal can be met.

Owner:NANCHANG UNIV

Method for producing premixed copper-tin 10 bronze

ActiveCN105382253AAvoid compositional segregationImprove toughnessTransportation and packagingMetal-working apparatusPrillMaterials science

The invention discloses a method for producing premixed copper-tin 10 bronze. The method comprises the steps that copper powder is subjected to water atomization by a conical spray tray and then is subjected to thermal treatment, the copper powder subjected to thermal treatment is crushed and subjected to oxidation resistance, and raw material copper powder is obtained through screening; the prepared copper powder and tin powder are evenly mixed according to the mass fraction; the powder is subjected to thermal treatment in a reducing atmosphere, and copper powder particles and tin powder particles are bonded with each other in a diffusion mode in the thermal treatment process; the thermal treatment powder is crushed, and powder is obtained through screening; a lubricating agent is added into the powder to be mixed evenly. According to mixed bronze powder produced by the method, the water atomization copper powder in irregular shapes is used and then is subjected to thermal treatment, so that the raw material copper powder has good toughness, and composition segregation of the bronze powder is avoided; in addition, the water atomization copper powder is likely to form communicated pores after being sintered, and the environment can not be polluted by the water atomization method for producing the bronze powder. The premixed bronze prepared by the method is free of composition segregation, stable in apparent density, good in forming property and high in sintered strength; well distributed pores are formed in a sintered mode.

Owner:湖南省天心博力科技有限公司

Preparation method for high-performance diamond sintered products

PendingCN110218924AHeating evenlyReduce consumptionTransportation and packagingMetal-working apparatusHardnessUltimate tensile strength

The invention belongs to the field of diamond product preparation, and relates to a preparation method for high-performance diamond sintered products. The preparation method comprises the following steps: (a) 70-90% of prealloy powder and 10-30% of diamond particles are taken according to the mass percentage for uniform mixing; and temporary bonding agents are fed for sealing placement by 12-24 h;(b) the mixtures prepared in the step (a) are molded through primary pressing by an oil press; (c) the products prepared in the step (b) are vacuumized, and are further pressed and dried by adoptinga cold isostatic press to prepare grinder blanks; and (d) the grinder blanks prepared in the step (c) are sintered by using a microwave sintering furnace or a discharge plasma sintering furnace to prepare metal bond diamond products. The method has the characteristics of high strength, high hardness, uniform components, low sintering temperature, energy conservation, simple operation and easy industrial production.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

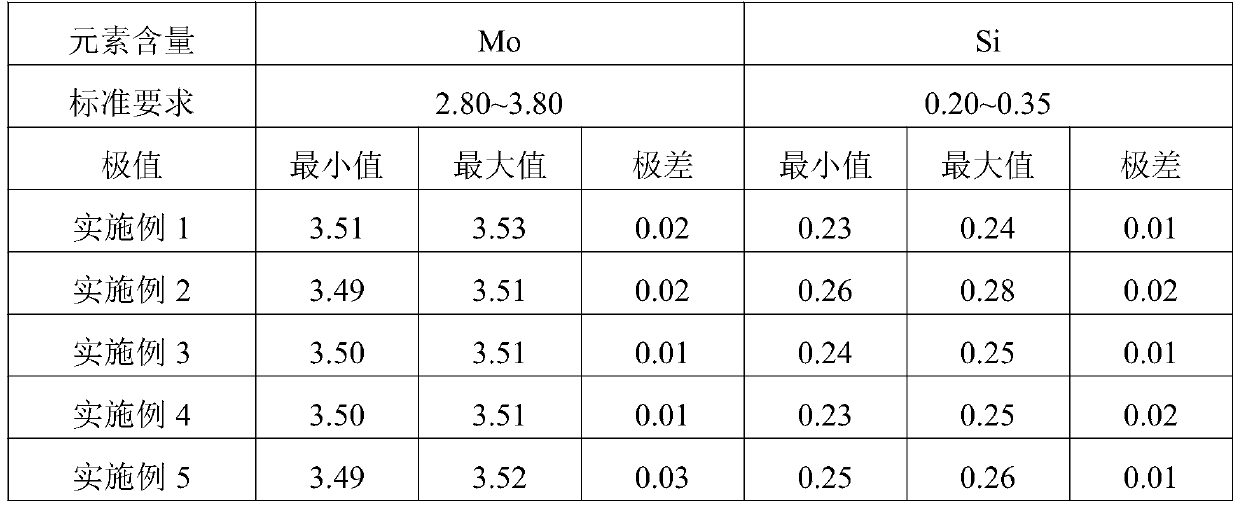

Molybdenum-aluminum-silicon intermediate alloy and preparation method thereof

InactiveCN109811225AReduce composition segregationLower melting point differenceHigh densityTitanium

The invention provides a molybdenum-aluminum-silicon intermediate alloy and a preparation method thereof. The molybdenum-aluminum-silicon intermediate alloy comprises the following components with contents in mass: 62wt%-68wt% of Mo, 4wt%-6wt% of Si and the balance Al. According to the molybdenum-aluminum-silicon intermediate alloy, through design for alloy components, the melting point and the density of the molybdenum-aluminum-silicon intermediate alloy are approximate to those of a matrix sponge titanium, low component segregation is achieved, and when the molybdenum-aluminum-silicon intermediate alloy is used for TC8 titanium alloy melting by replacing AlMo60 and metal Si, the melting point difference and the density difference between the molybdenum-aluminum-silicon intermediate alloyand the matrix sponge titanium can be reduced, so that the occurrence of component segregation due to high melting point difference and high density difference is effectively prevented. Experimentalresults indicate that the melting point of the molybdenum-aluminum-silicon intermediate alloy is 1565-1627 DEG C, the density is 4.88-5.33g / cm<3>, and low component segregation is achieved. The experimental results indicate that high uniformity of Si element and Mo element in a TC8 titanium alloy can be guaranteed by using the molybdenum-aluminum-silicon intermediate alloy for the TC8 titanium alloy. The preparation method is simple, easy to control, and applicable to large-scale industrial production.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

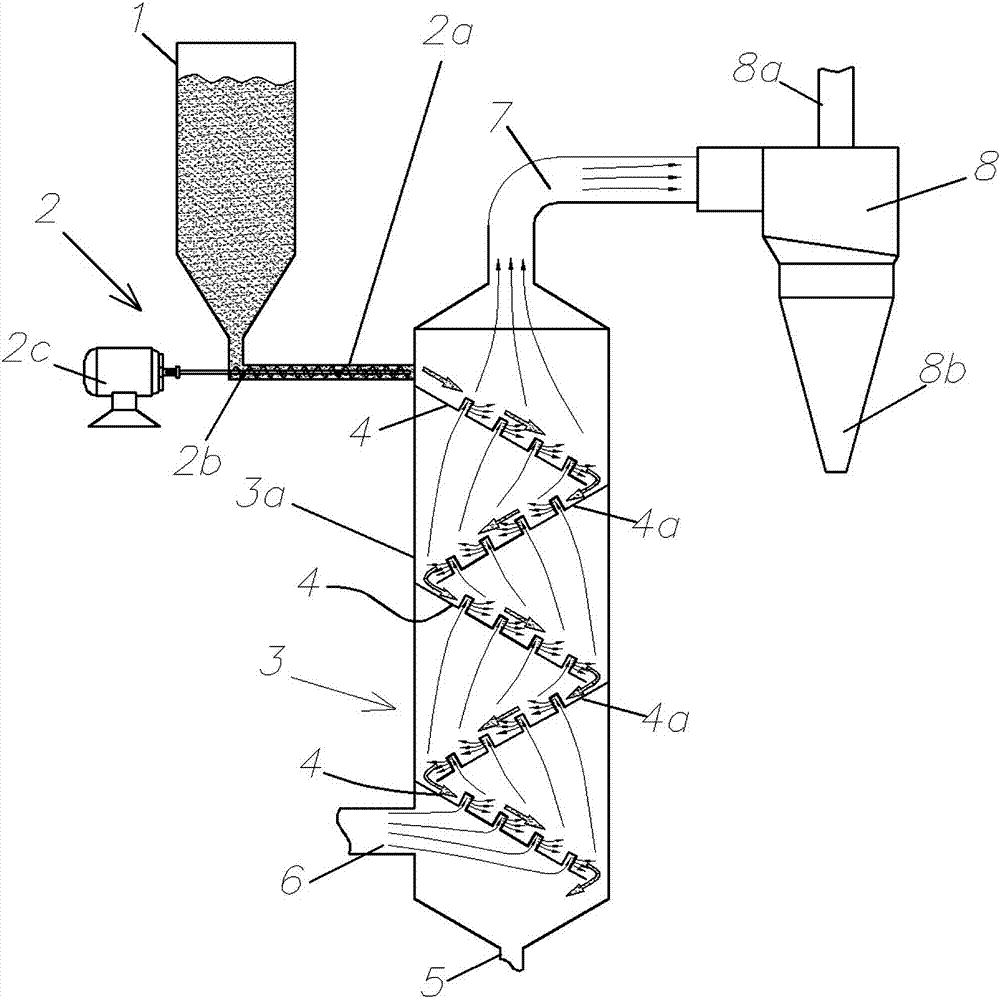

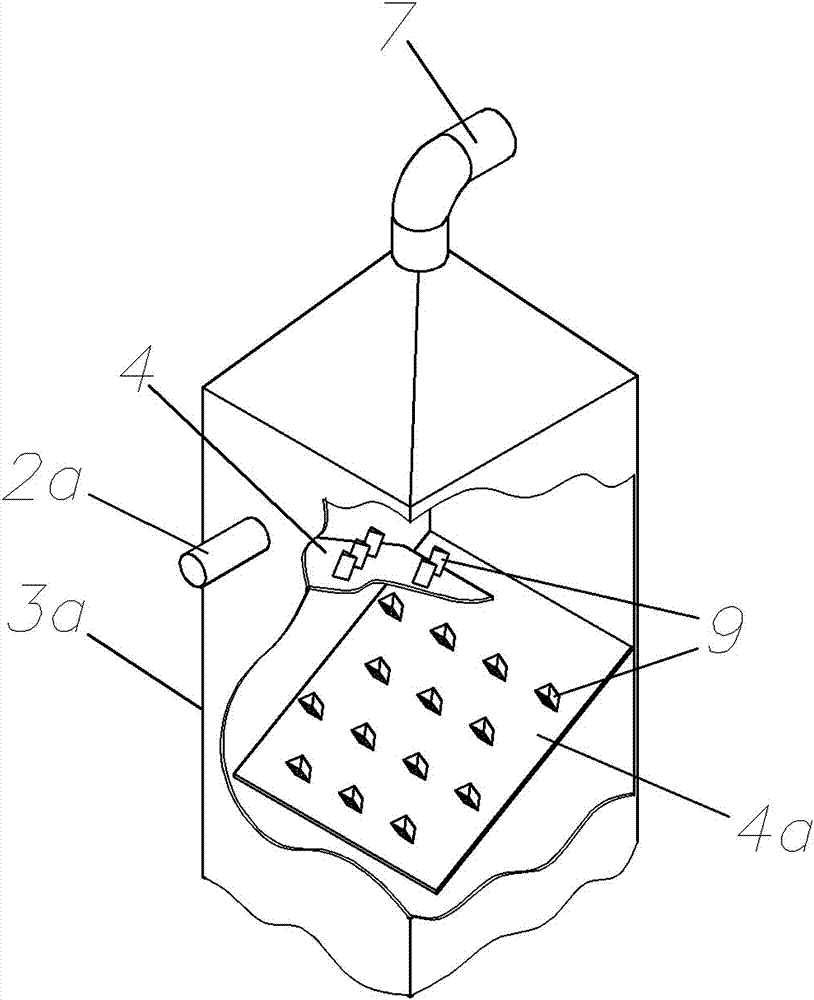

Baffling type glass batch mixture preheating device

PendingCN107879595AReduce energy consumptionImprove melting qualityCharging furnaceGlass productionFlue gasEnergy consumption

The invention provides a baffling type glass batch mixture preheating device. The baffling type glass batch mixture preheating device comprises a batch mixture bin (1). The baffling type glass batch mixture preheating device is characterized in that the batch mixture bin (1) is communicated with a preheater (3) through a feeding device (2), a group of first material-guiding heat-exchanging plates(4) and a group of second material-guiding heat-exchanging plates (4a) are arranged in a shell of the preheater (3), a discharging hole (5) is formed in the bottom of the preheater (3), a flue gas inlet (6) is formed in a shell above the discharging hole (5), and the top of the preheater is communicated with a dust collector (8) through a flue (7). The baffling type glass batch mixture preheatingdevice is simple in structure and convenient to use; and the kiln feeding temperature of the batch mixture is increased, the energy consumption of a kiln can be effectively reduced, the energy sourceis saved, and the glass fusion quality is improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

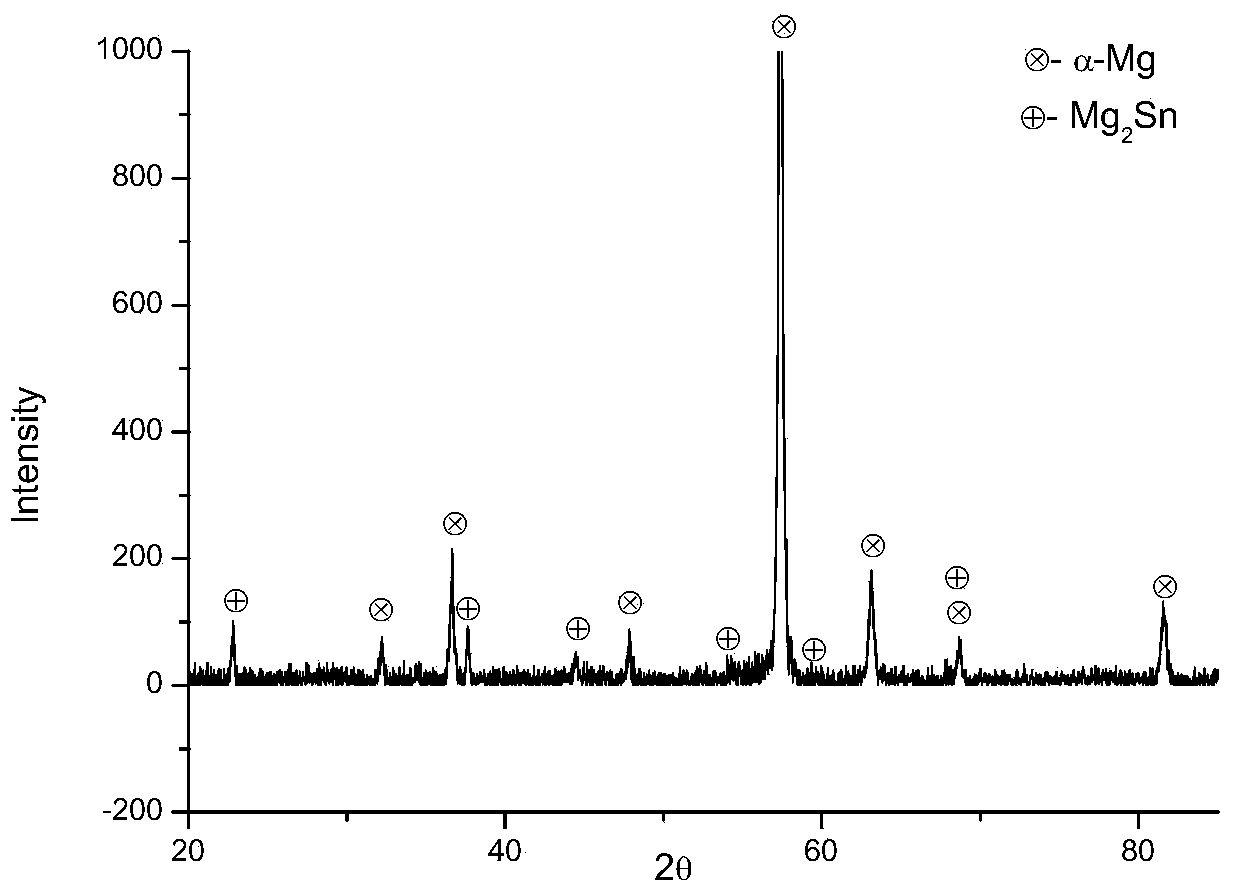

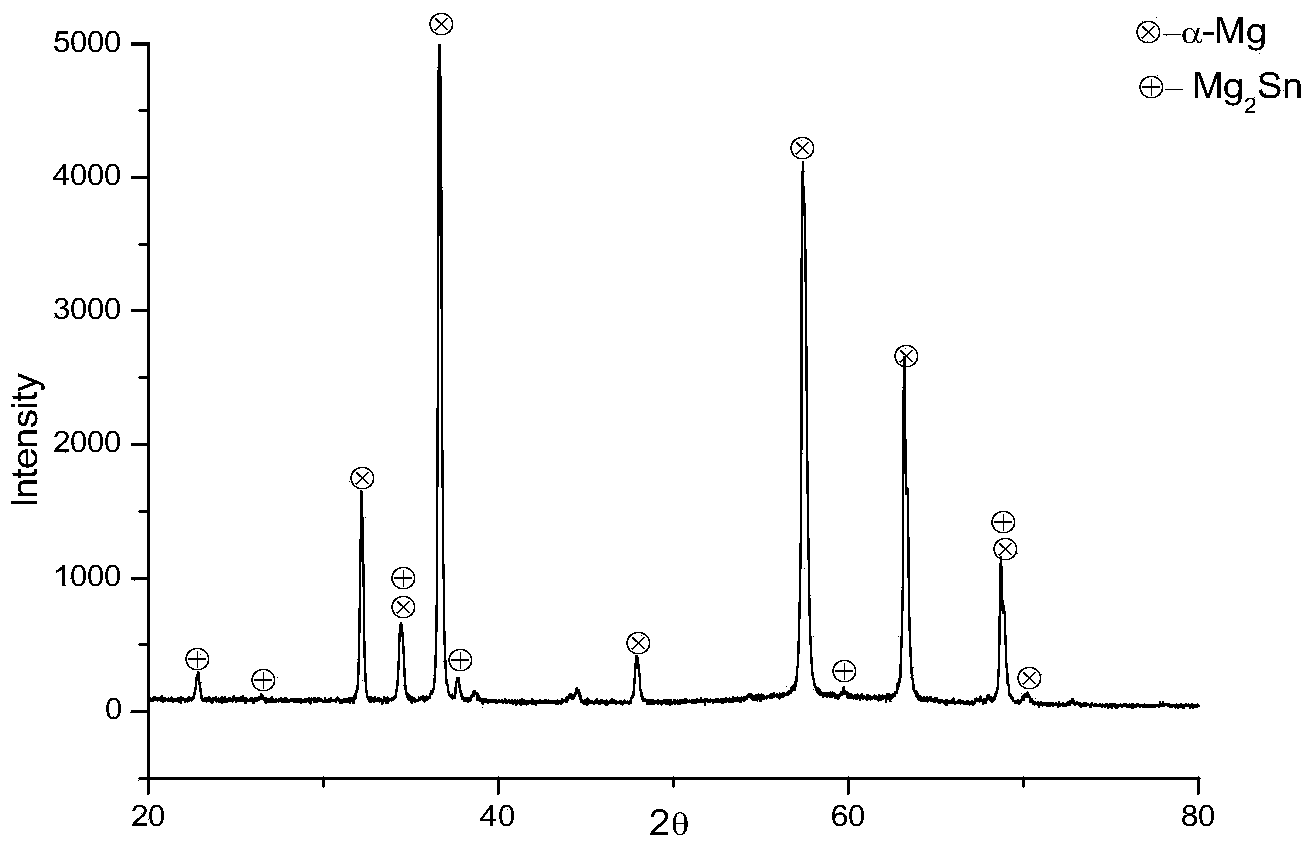

Magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded

The invention relates to a magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded. The wrought magnesium alloy comprises the following components in percentage by mass: 3-5% of Sn, 1% of Al, 0.5-2.0% of Zn, less than or equal to 0.10% of inevitable impurities and the balance of Mg. According to the alloy provided by the invention, the Mg-Sn magnesium alloy is subjected to modification treatment by adopting Zn and Al, so that the grains can be refined and the alloy tissue can be improved. Meanwhile, the tensile strength and the ductility of the alloy are improved to facilitate processing and moulding in the later period. The wrought magnesium alloy provided by the invention is simple in preparation method, relatively low in equipment cost and easy to implement.

Owner:CHONGQING UNIV

Chromium-zirconium-copper alloy and preparation method thereof

The invention provides a preparation method of a chromium-zirconium-copper alloy. The preparation method comprises the following steps copper foil is coated with chromium powder and then is placed inthe center area of the bottom of a crucible; a copper rod is placed in the high-temperature area of the middle of the crucible; a copper plate is arranged between the copper foil and the copper rod; copper particles are placed in the low-temperature area at the upper part of the crucible; copper smelting is carried out, and chromium smelting is carried out after copper substances in the crucible are completely molten; after all the chromium powder is molten, sponge zirconium coated with the copper foil and raw materials of trace elements are added into the crucible for smelting, so that an alloy liquid is obtained; and the alloy liquid is casted to obtain the chromium-zirconium-copper alloy. The invention further provides a chromium-zirconium-copper alloy prepared by the method.

Owner:XIAN XD ELECTRIC RES INST CO LTD +1

Method for combining different types of aluminum materials and combined part of different types of aluminum materials

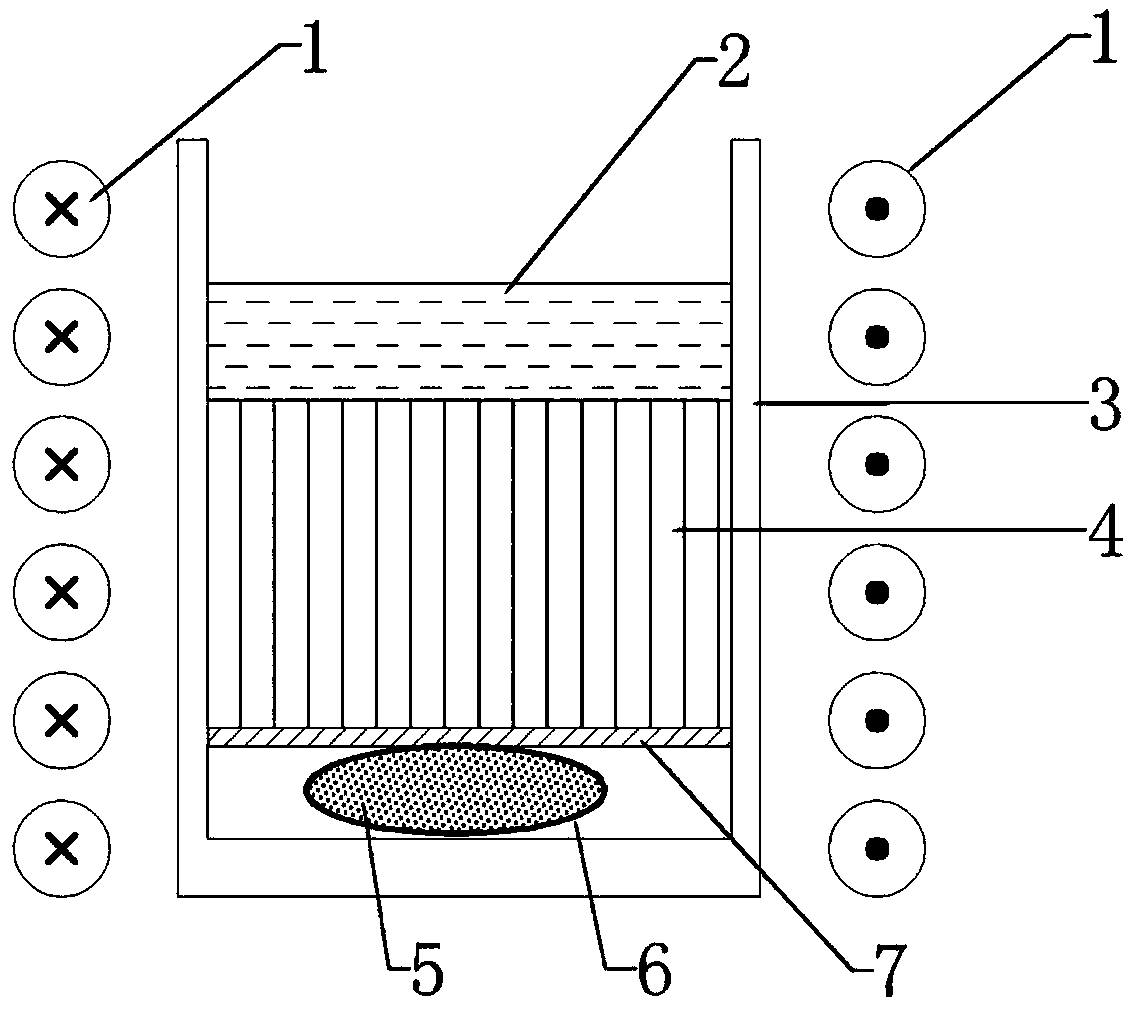

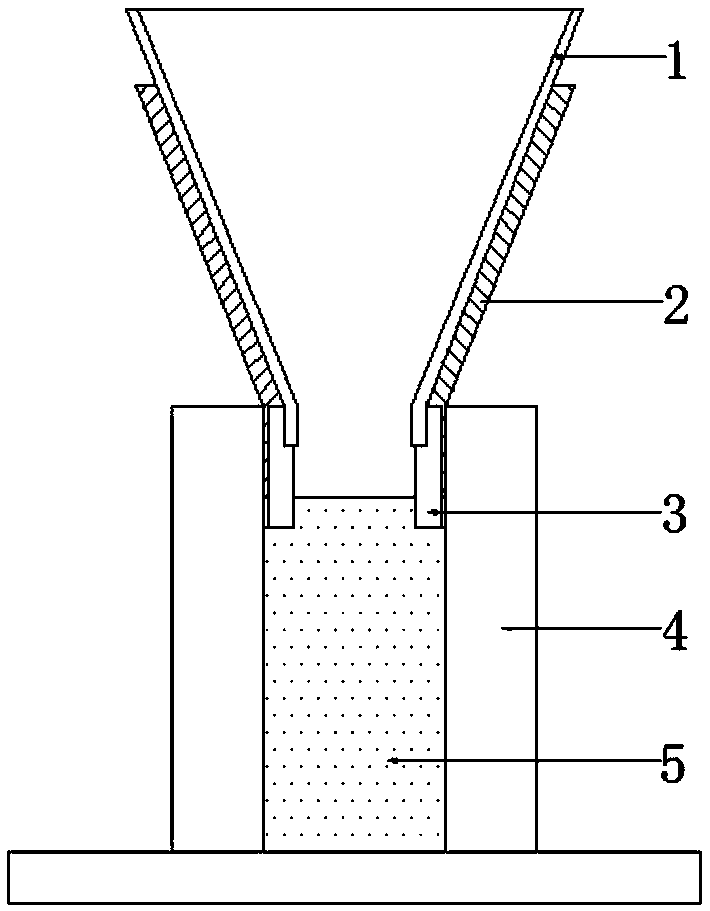

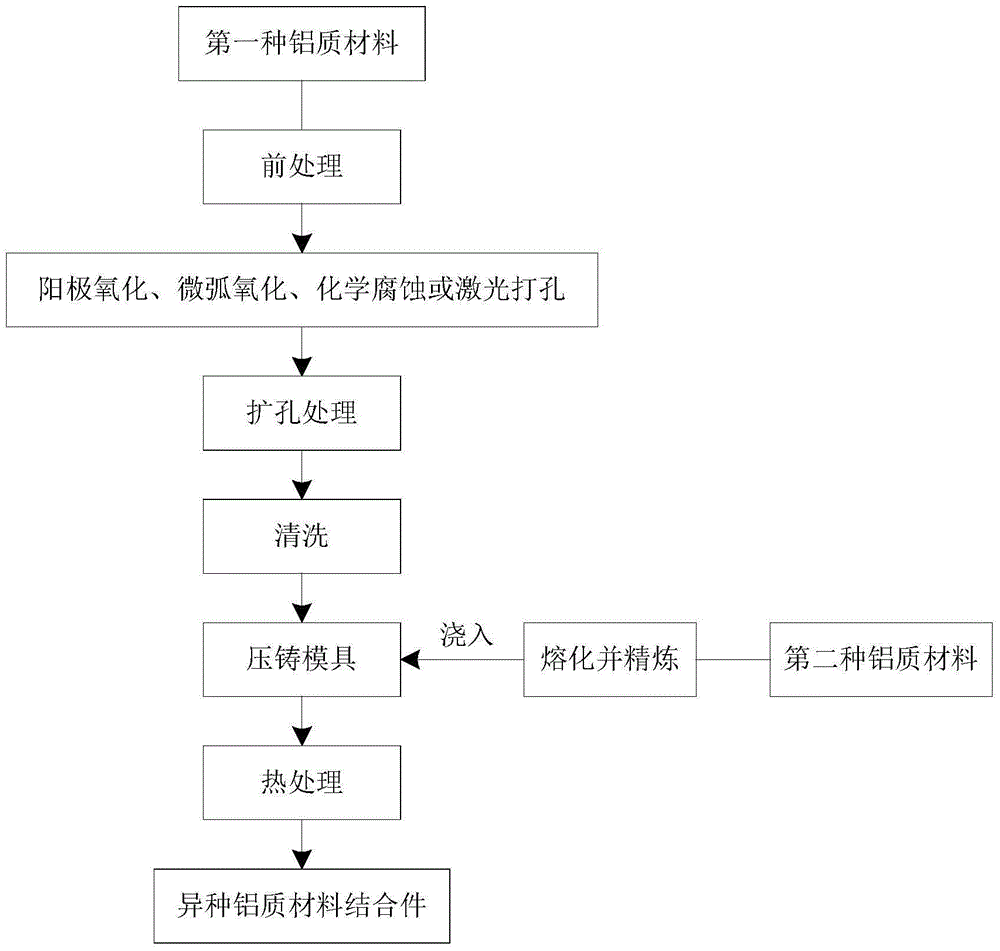

The invention discloses a method for combining different types of aluminum materials and a combined part of the different types of aluminum materials. The method includes the following steps: S1, carrying out anodic oxidation, micro-arc oxidation, chemical corrosion or laser drilling on a first type of aluminum material subjected to pretreatment, so as to form a mipor oxide film layer on the surface of the first type of aluminum material; S2, carrying out chambering treatment on the first type of aluminum material; S3, placing the first type of aluminum material in a die-casting mold; S4, smelting a second type of aluminum material; S5, pouring the second type of aluminum material into the die-casting mold for die-cast formation, so as to form the combined part of the two types of aluminum materials. The combined part of different types of aluminum materials, provided by the invention, is formed through combining the first type of aluminum material and the second type of aluminum material through the combining method. The method for combining different types of aluminum materials and the combined part of the different types of aluminum materials, provided by the invention, are stable in combination, high in strength, low in cost and wide in adaptability.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

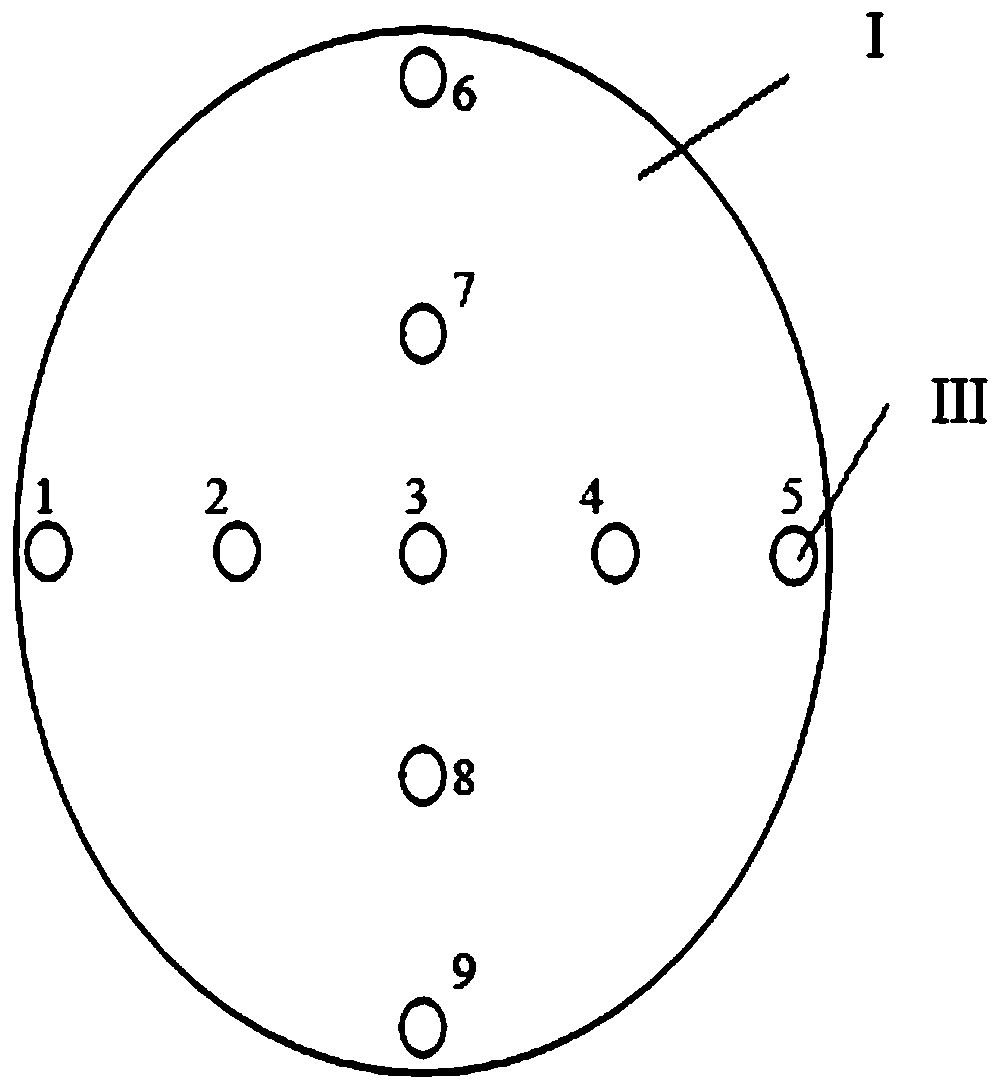

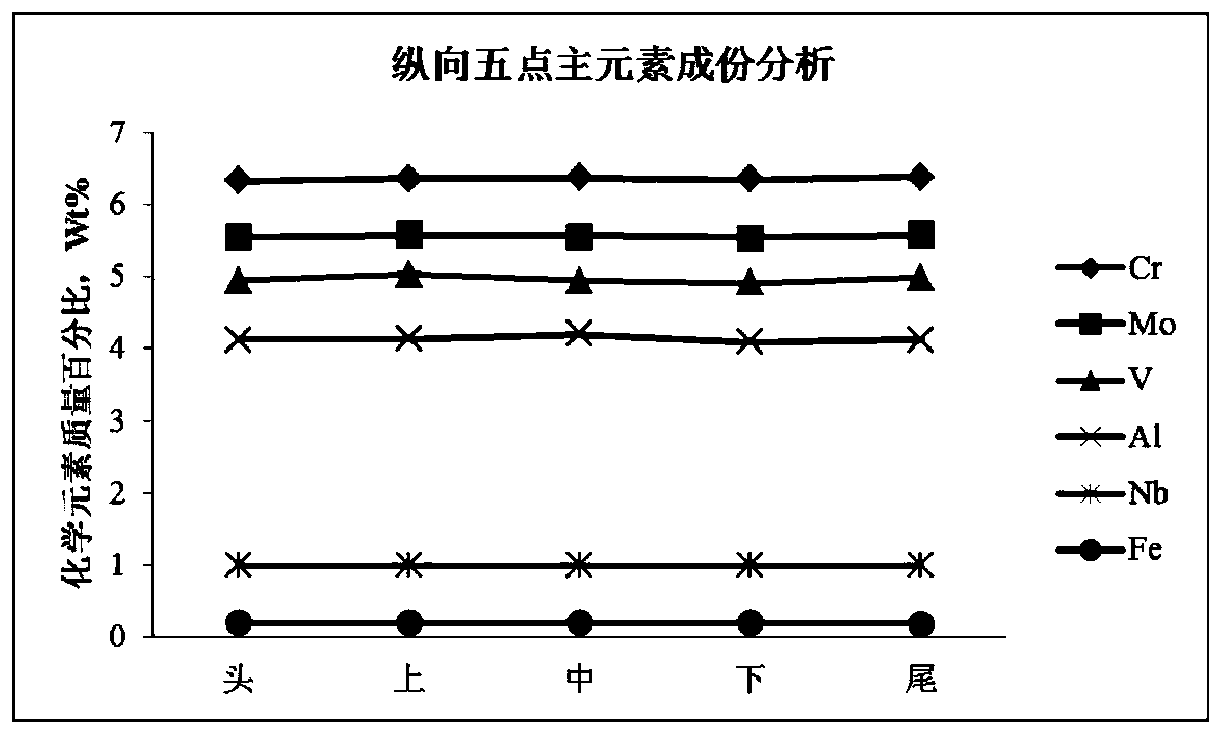

WSTi1400 ultrahigh-strength titanium alloy and preparing method thereof

InactiveCN110724852AReduce risk of segregationIncrease the level of toughness and plasticityIngot castingSmelting process

The invention belongs to the technical field of titanium alloy processing, and particularly relates to WSTi1400 ultrahigh-strength titanium alloy. The WSTi1400 ultrahigh-strength titanium alloy is prepared from, by weight percentage, 5.0-9.0% of Cr, 4.0-8.0% of Mo, 3.0-7.0% of V, 2.0-6.0% of Al, 0.0-4.0% of Nb, 0-2.00% of Fe, 0-0.30% of O and the balance Ti and inevitable impurities. The inventionfurther discloses a preparing method of the titanium alloy. The components of the titanium alloy prepared by means of the method are high in transverse and longitudinal homogeneity, breakthrough is made in the industrial tonnage large-specification ingot casting chemical component homogeneity control technology, burning loss of the aluminum element in the smelting process is reduced, metallurgical defects caused when high-melting-point molybdenum, vanadium and niobium elements form infusible blocks are overcome, and a titanium alloy rod which has the strength larger than 1,400 Mpa and the breaking tenacity larger than 55 MPa.m <0.5> is obtained.

Owner:西部超导材料科技股份有限公司

Iron-base powder metallurgy material for high pressure valve and preparation method thereof

InactiveCN104550934AIncreases wettability and adhesionAvoid compositional segregationPowder metallurgyCorrosion

The invention relates to an iron-base powder metallurgy material for a high pressure valve. The iron-base powder metallurgy material is made of the following raw materials in parts by weight: 4 to 5 parts of nano carbonyl iron powder, 1.0 to 1.3 parts of fatty acid diamide, 10 to 20 parts of Co, 4 to 5 parts of Ni, 2 to 3 parts of Sn, 1 to 1.5 parts of Nb2O5, 2 to 3 parts of Bi2o3, 8 to 12 parts of WC, 5 to 7 parts of Al2O3, 4 to 6 parts of TaC, 3 to 4 parts of LaB, 0.5 to 0.6 part of silane coupling agent kh-550, appropriate amount of 1% sodium carbonate solution, appropriate amount of water, 4 to 4.5 parts of sodium hypophosphite, 0.4 to 0.6 part of polyethylene glycol, 50 to 55 parts of 2Mol / L copper sulfate solution, 2 to 3 parts of wetting additive and 56 to 59 parts of iron powder. The iron-base powder metallurgy material is suitable for producing a valve with nominal pressure being less than or equal to 32MPa; by adding WC, Al2O3, TaC and LaB, the heat resistance and corrosion resistance of the valve can be improved, and mediums such as water, steam, hydrogen, ammonium, nitrogen, petroleum and the like at the temperature of -30 to 425 DEG C can be conveyed.

Owner:TONGLING JINGWEI FLUID SCI & TECH

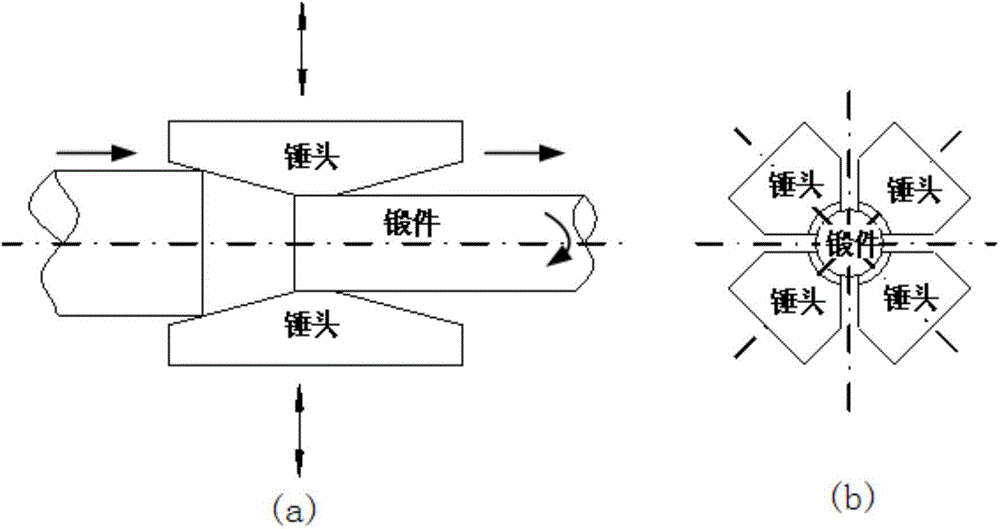

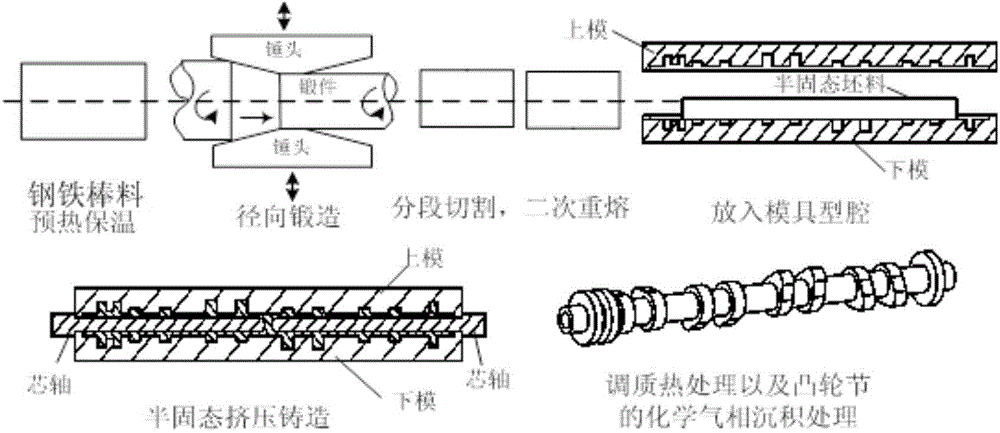

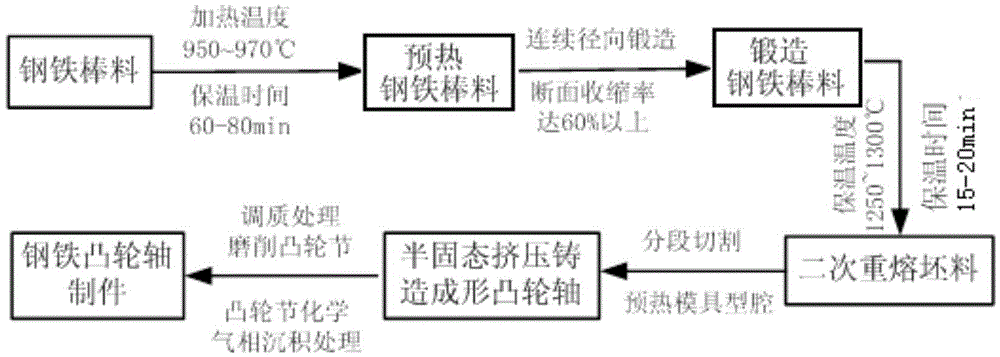

Process for manufacturing semi-solid steel cam shaft through radial forging strain induction method

InactiveCN104550838AUniform compositionFew ingredientsMetal-working apparatusTissue defectSemi solid

The invention discloses a process for manufacturing a semi-solid steel cam shaft through a radial forging strain induction method. The process comprises the following steps: preheating a steel bar material and preserving heat; radially forging the steel bar material; re-melting a radially-forged blank; performing extrusion casting on the steel cam shaft; performing subsequent treatment on the steel cam shaft. By adopting the process, steel semi-solid blanks which are uniform and free from micro-defects can be manufactured in batches, and the steel cam shaft which has less micro tissue defects, high mechanical performance and high wear resistance can be formed. The process flow is simple, and operation is easy.

Owner:XI AN JIAOTONG UNIV

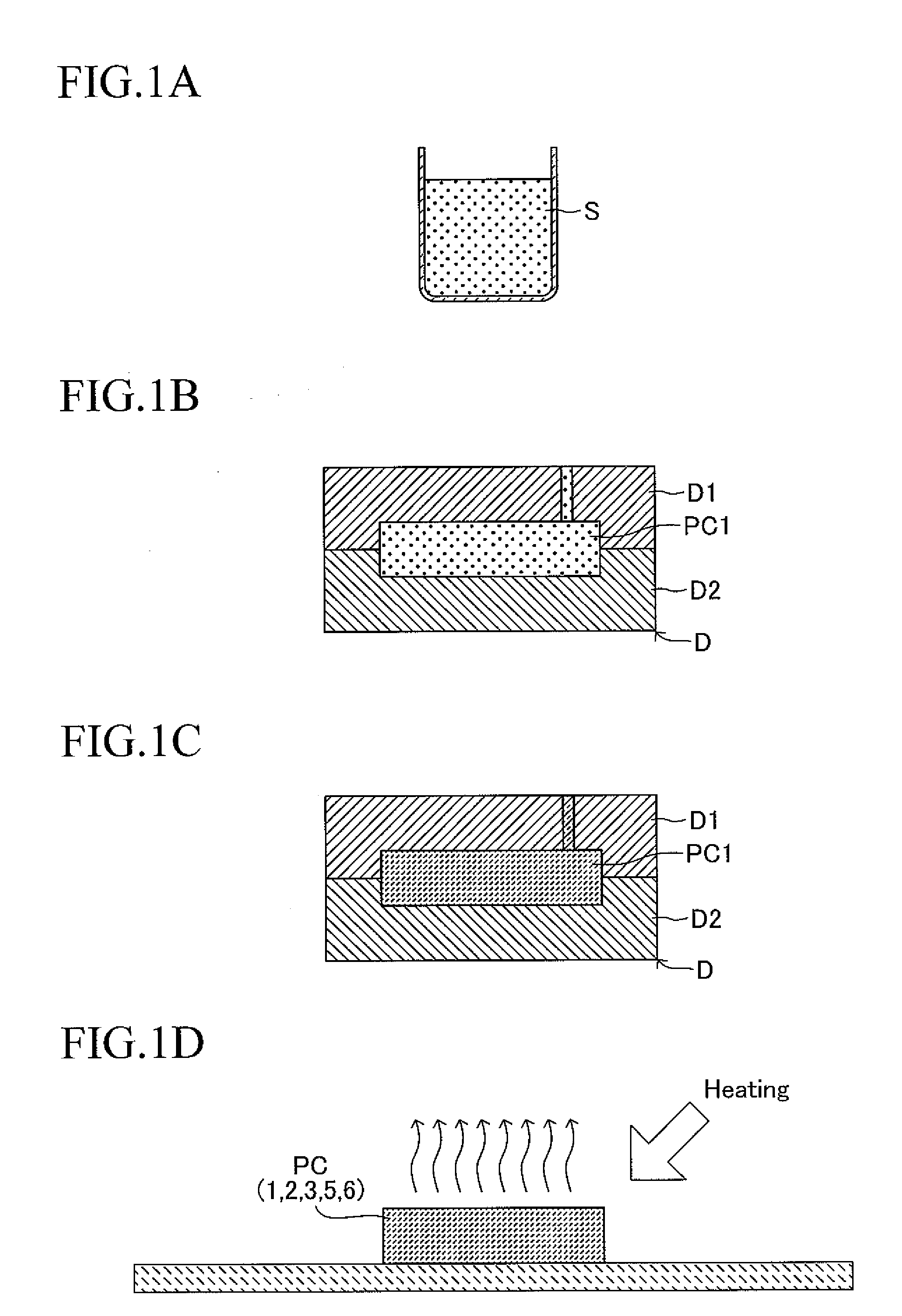

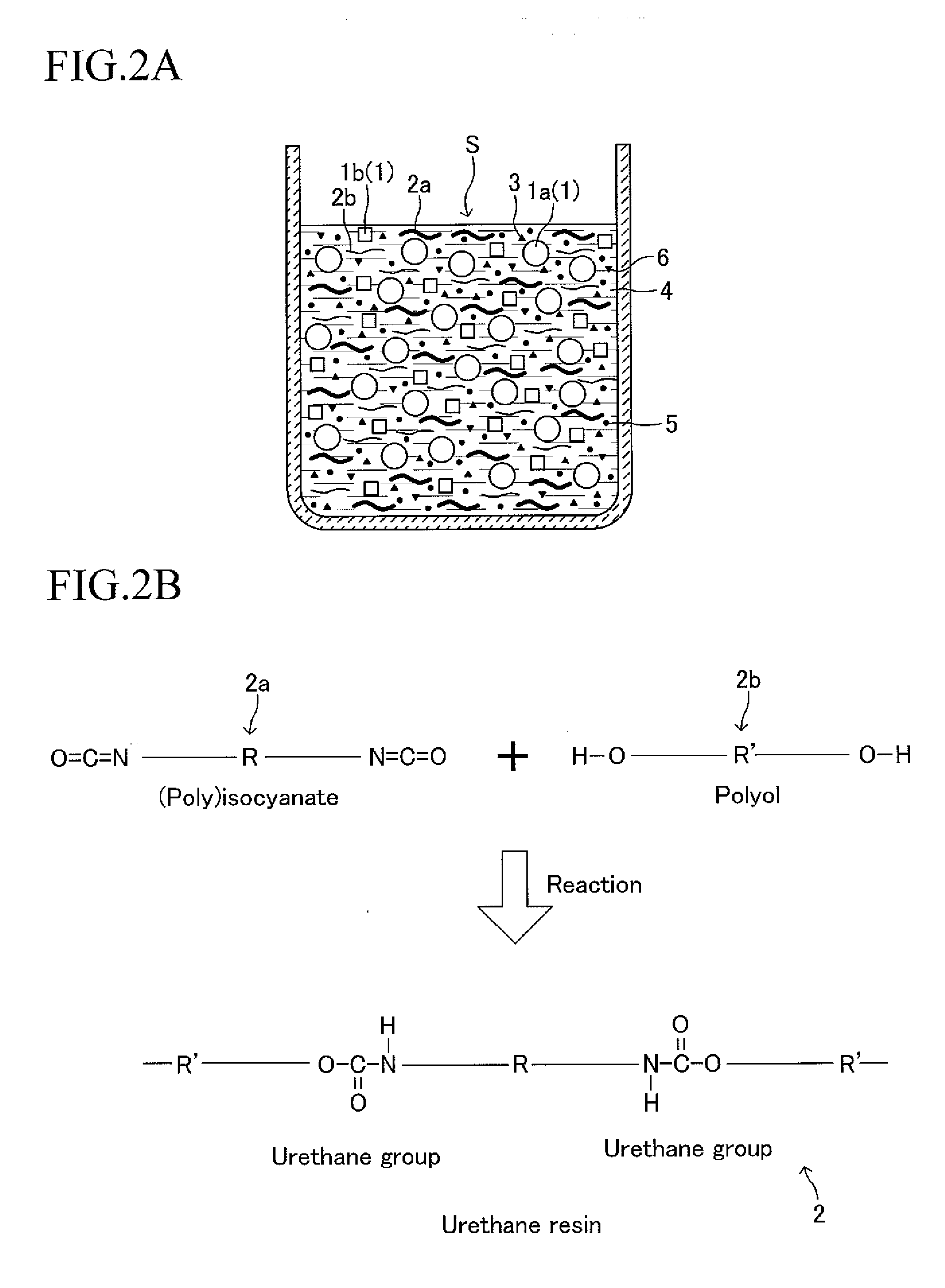

Method for producing powder molded product and powder molded product

InactiveUS20120214942A1Improve featuresHigh viscosityCeramic shaping apparatusNon-woven fabricsChemical reactionEvaporation

A powder molded product produced through molding of a slurry containing a powdery molding raw material, a dispersion medium for dispersing the molding raw material, a dispersant for uniformly dispersing the molding raw material in the dispersion medium, a binder precursor for producing an organic binder through a chemical reaction, a reaction promoter for promoting the chemical reaction, and a pseudo-plasticity-imparting agent for imparting pseudo-plasticity to the slurry. The method for producing a powder molded product of the present invention includes a slurry preparation step; a molding step of molding the prepared slurry into a primary molded product having a specific shape; and a drying-solidification step of solidifying the slurry by promoting the aforementioned chemical reaction in the primary molded product, and removing, through evaporation, the dispersion medium from the primary molded product.

Owner:NGK INSULATORS LTD

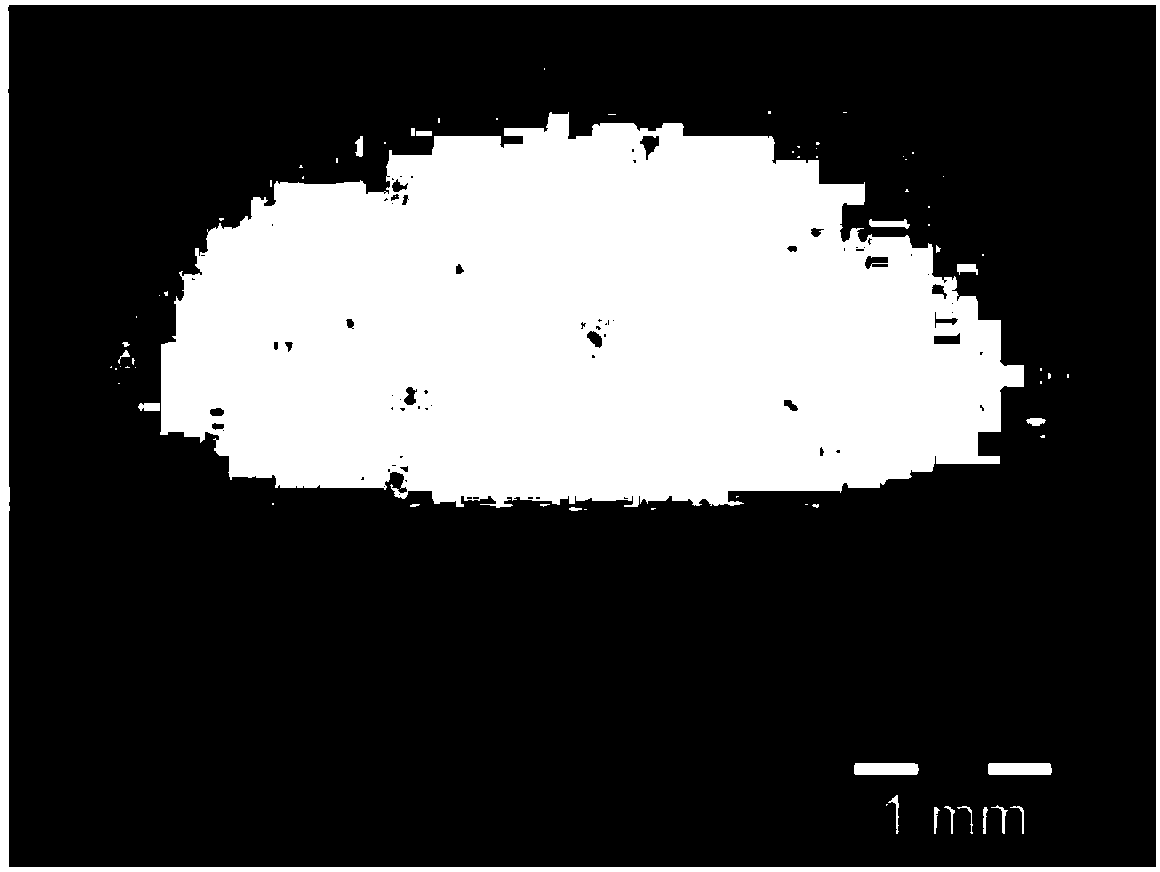

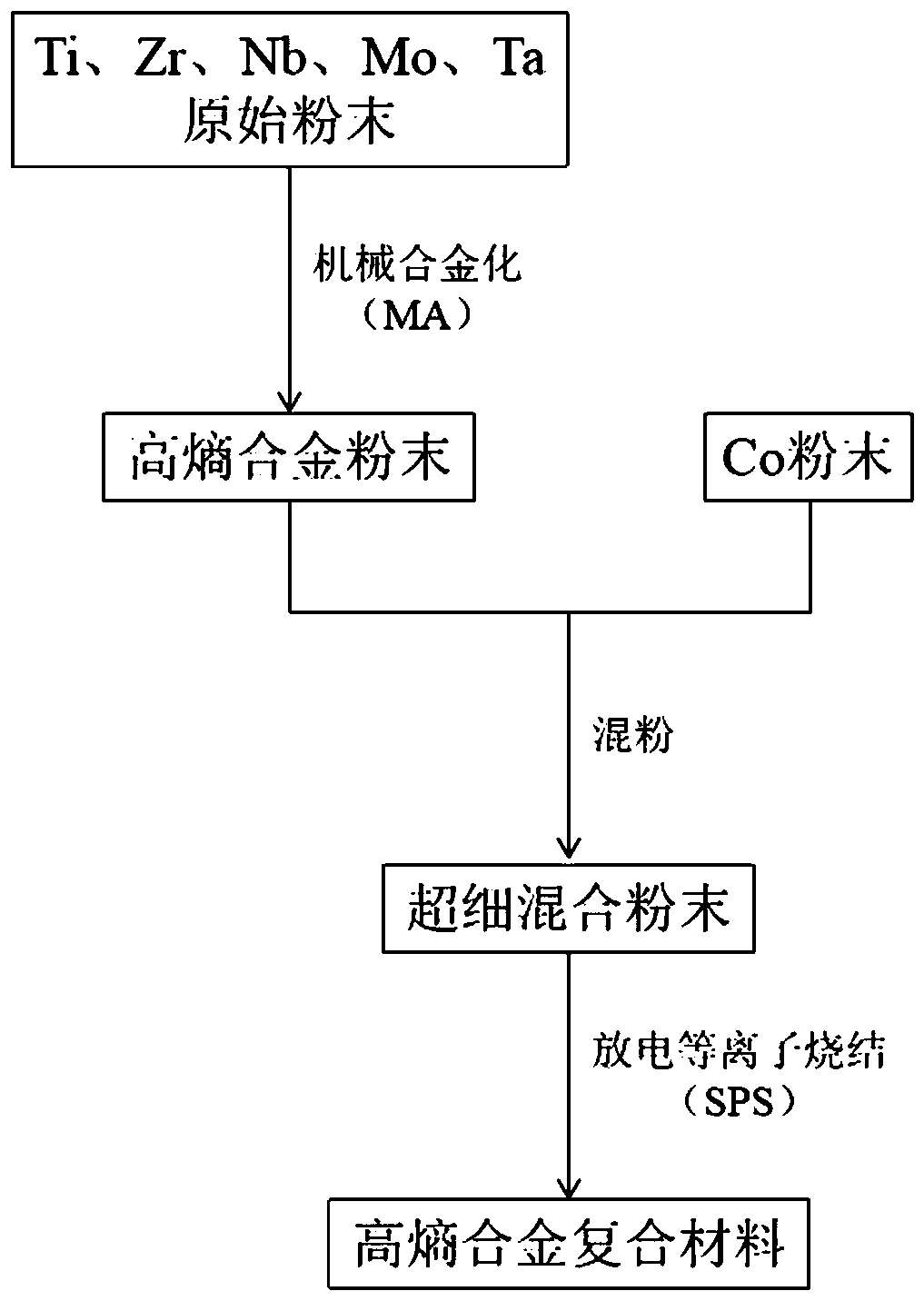

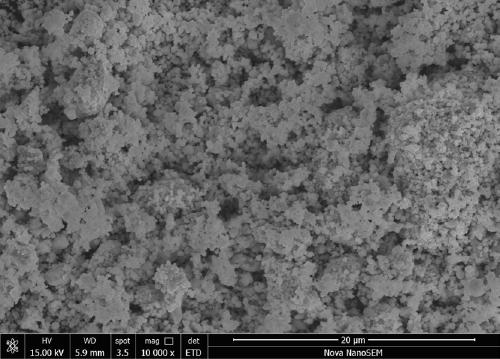

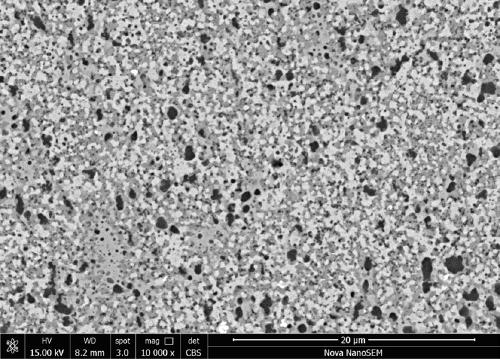

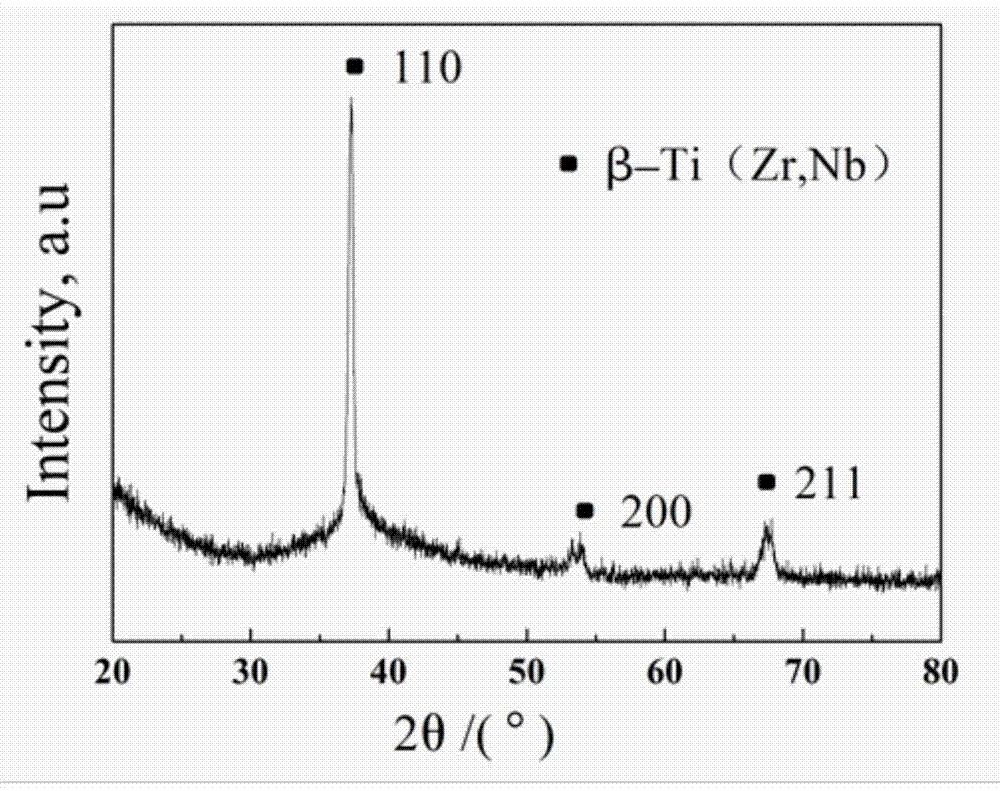

Co-bonded TiZrNbMoTa refractory high-entropy alloy and preparation method thereof

ActiveCN111118379AAvoid compositional segregationFine grainIncreasing energy efficiencyHigh entropy alloysMaterials science

The invention discloses a TiZrNbMoTa refractory high-entropy alloy with Co as a binder and a preparation method thereof, and belongs to the technical field of alloy materials. The preparation method comprises the following steps that high-melting-point metal elements Ti, Zr, Nb, Mo and Ta are adopted as raw materials, and high-entropy alloy powder is prepared through mechanical alloying; and the high-entropy alloy powder and Co powder are evenly mixed and then subjected to spark plasma sintering, and block alloy materials are obtained. The Co-bonded TiZrNbMoTa refractory high-entropy alloy hasthe advantages that the grain size is small, the compactness is high, meanwhile, the components of the alloy are evenly distributed, the performance is good, and therefore the Co-bonded TiZrNbMoTa refractory high-entropy alloy has good application prospects.

Owner:FUJIAN UNIV OF TECH

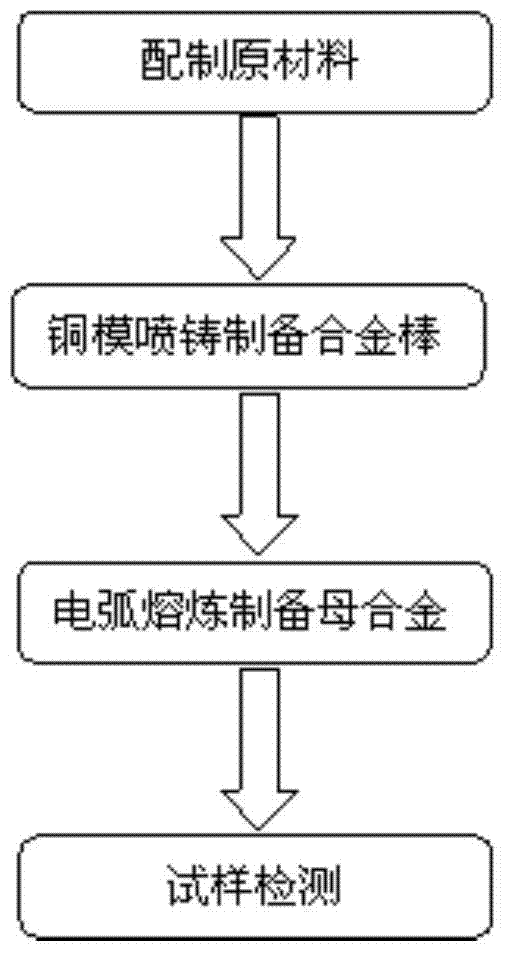

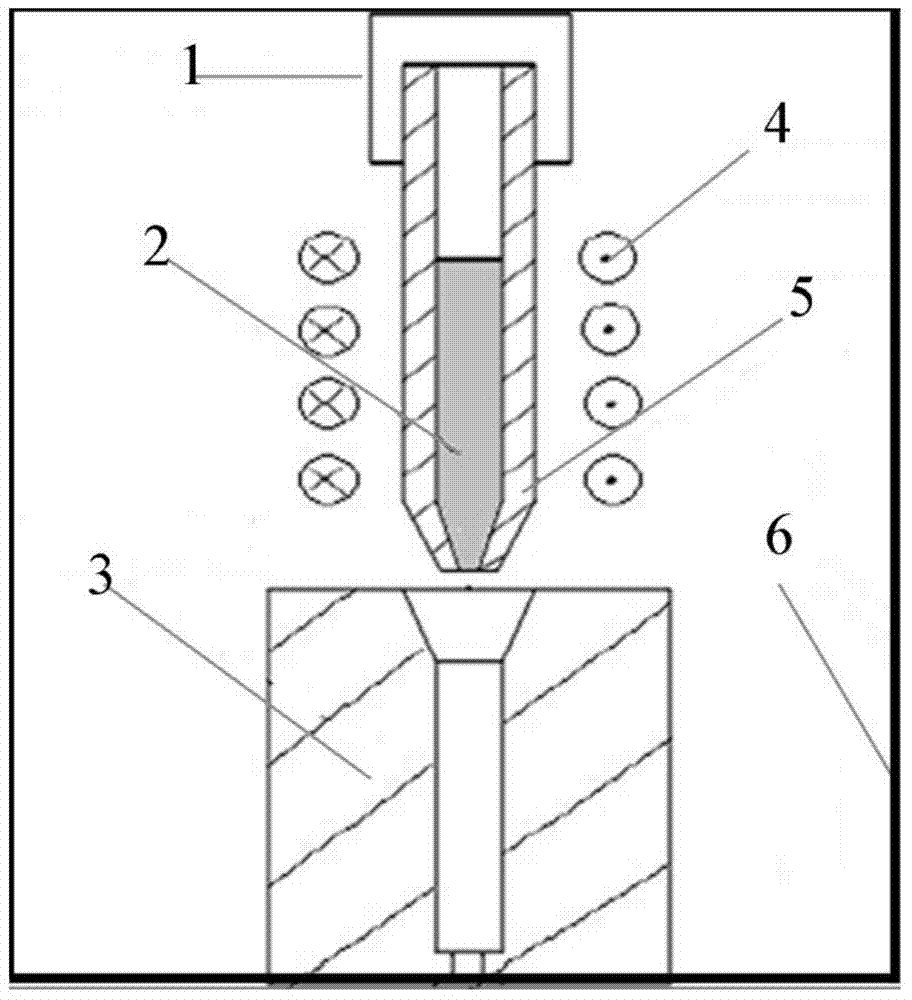

Endogenous-phase titanium-based amorphous composite material with improved strength and plasticity and preparation method thereof

The invention relates to the field of the amorphous composite materials and provides an endogenous-phase titanium-based amorphous composite material with improved strength and plasticity and a preparation method thereof. The composite material is composed of the following elements in atomic proportions: Ti44.55Zr21.78Nb9.9Cu7.92Be14.85Ag1 (at%). The preparation method comprises the steps of preparing raw materials, preparing a master alloy ingot, and preparing the endogenous-phase titanium-based amorphous composite material by use of a spray-casting method based on a copper mold, and specifically comprises the following steps: 1) grinding one end of a quartz tube into a round hole of the appropriate size, cutting the prepared master alloy ingot into cubes and putting the cubes into the quartz tube; 2) fixing the quartz tube into an induction coil in a cavity; 3) vacuumizing the cavity and filling the cavity with a protective inert gas; and 4) melting the alloy cubes in the quartz tube by use of the induction coil and spraying the melt into the copper mold to obtain the endogenous-phase titanium-based amorphous composite material. The preparation method is simple, convenient to operate, and capable of obtaining the large-size bulk titanium-based amorphous composite material, and thus has an excellent application value.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com