Method for producing premixed copper-tin 10 bronze

A production method and pre-mixing technology, applied in the field of powder metallurgy, can solve problems such as high energy consumption, unfavorable sintering of electrolytic copper powder, high pollution, etc., and achieve good pore distribution, avoid component segregation, and high sintering strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

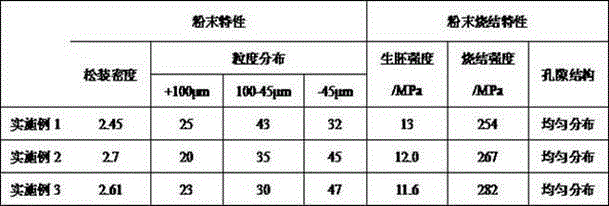

Embodiment 1

[0023] (1) Preparation of raw copper powder: Copper powder is atomized by water with a conical spray plate, with 30 spray holes, the diameter of the spray hole is 1.0mm, the water pressure of the spray plate is 15MPa, the particle size of the copper powder is less than 100μm, and the shape of the copper powder is Irregular in appearance, bulk density is 2.0~2.6g / cm 3 ;The atomized copper powder is heat treated in a heat treatment furnace, the heat treatment temperature is 500°C, the heat treatment atmosphere is reducing atmosphere, and the heat treatment time is 30 minutes; then the powder is crushed and oxidized and sieved, and the antioxidant is selected to passivate the copper powder with a volatilization temperature above 300°C agent, sieve to get raw copper powder less than 150um;

[0024] (2) Mix the raw materials copper powder and tin powder according to the ratio of 9:1, and mix them evenly in the batch machine, and the bulk density of the tin powder is less than 3.5g / ...

Embodiment 2

[0030] (1) Preparation of raw copper powder: Copper powder is atomized by water with a conical spray plate, with 30 spray holes, the diameter of the spray hole is 1.0mm, the water pressure of the spray plate is 15MPa, the particle size of the copper powder is less than 100μm, and the shape of the copper powder is Irregular in appearance, bulk density is 2.0~2.6g / cm 3 ;The atomized copper powder is heat treated in a heat treatment furnace, the heat treatment temperature is 500°C, the heat treatment atmosphere is reducing atmosphere, and the heat treatment time is 30 minutes; then the powder is crushed and oxidized and sieved, and the antioxidant is selected to passivate the copper powder with a volatilization temperature above 300°C agent, and sieve to obtain raw copper powder less than 150 μm;

[0031] (2) Mix raw copper powder and tin powder according to the ratio of 9:1, and mix them evenly in the batch machine. Among them, the bulk density of tin powder is less than 3.5g / c...

Embodiment 3

[0037] (1) Preparation of raw copper powder: Copper powder is atomized by water with a conical spray plate, with 30 spray holes, the diameter of the spray hole is 1.0mm, the water pressure of the spray plate is 15MPa, the particle size of the copper powder is less than 100μm, and the shape of the copper powder is Irregular in appearance, bulk density is 2.0~2.6g / cm 3 ;The atomized copper powder is heat treated in a heat treatment furnace, the heat treatment temperature is 500°C, the heat treatment atmosphere is reducing atmosphere, and the heat treatment time is 30 minutes; then the powder is crushed and oxidized and sieved, and the antioxidant is selected to passivate the copper powder with a volatilization temperature above 300°C agent, and sieve to obtain raw copper powder less than 150 μm;

[0038] (2) Mix raw copper powder and tin powder according to the ratio of 9:1, and mix them evenly in the batch machine. Among them, the bulk density of tin powder is less than 3.5g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com