Endogenous-phase titanium-based amorphous composite material with improved strength and plasticity and preparation method thereof

A technology for improving the strength of amorphous composite materials, applied in the field of endogenous phase titanium-based amorphous composite materials, can solve the problems of material softening, no obvious plastic deformation, softening shear plane fracture, etc., and achieve large amorphous formation ability, Excellent mechanical properties, the effect of avoiding component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The atomic ratio composition described in this example is: Ti: 44.55%; Zr: 21.78%; Nb: 9.9%; Cu: 7.92%; Be: 14.85%; Ag: 1% endogenous phase titanium-based amorphous composite material .

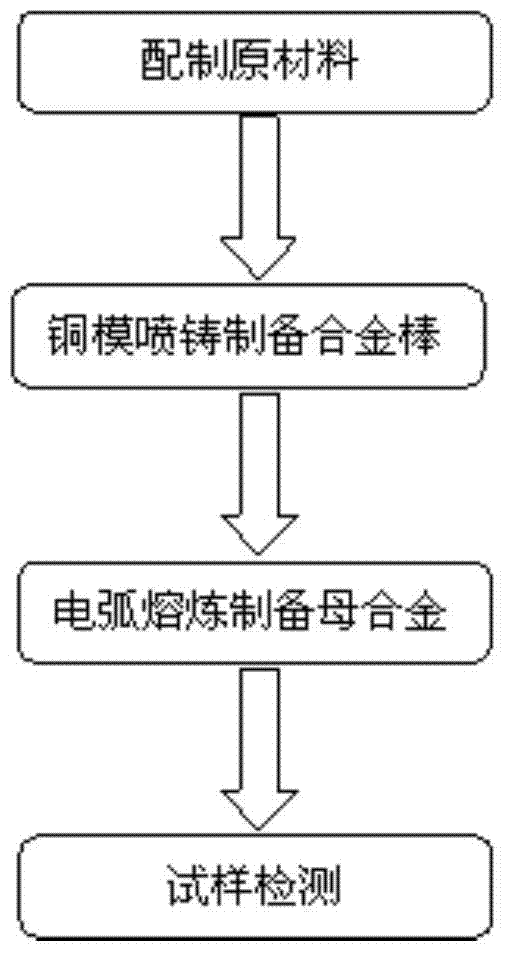

[0046] The preparation process of an endogenous phase titanium-based amorphous composite material with improved strength and plasticity according to the present invention is as follows:

[0047] The first step, the preparation of raw materials:

[0048] The prepared raw materials were ultrasonically cleaned in acetone and alcohol for about 20 minutes respectively to ensure that the raw materials were clean and free of impurities.

[0049] The second step is to prepare the master alloy ingot:

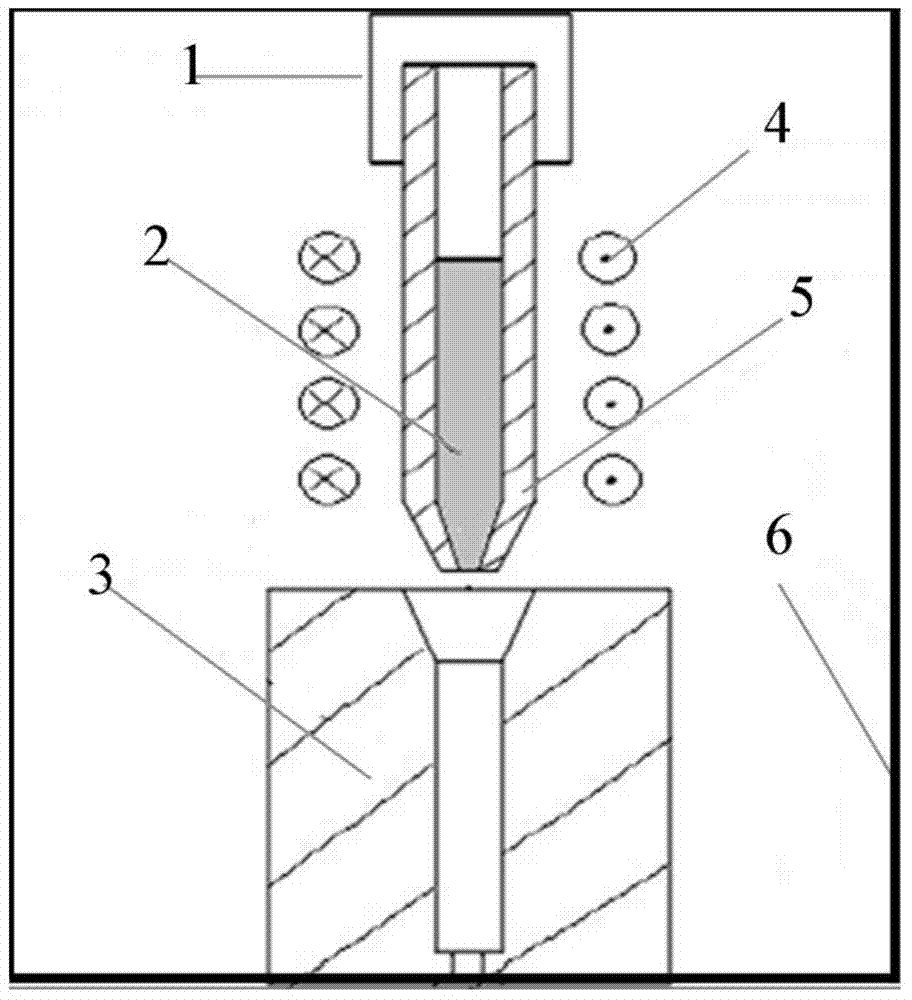

[0050] Place the prepared raw materials in a water-cooled copper crucible and vacuumize to 2.5×10 -3 Pa filled with 0.03-0.05Mpa inert protective gas argon, first smelt the titanium block in the crucible to absorb oxygen; when smelting, use a small current to melt the unfused block slowly, and...

Embodiment 2

[0057] The atomic ratio composition described in this embodiment is: Ti: 45%; Zr: 22%; Nb: 10%; Cu: 8%; Be: 15% endogenous titanium-based amorphous composite material.

[0058] The preparation process of the endogenous titanium-based amorphous composite material with improved strength and plasticity described in the present invention is the same as that described in Example 1.

[0059] Cut the obtained endogenous phase Ti-based amorphous composite alloy rod into Cylindrical samples were subjected to X-ray diffraction, metallographic observation and quasi-static compression tests.

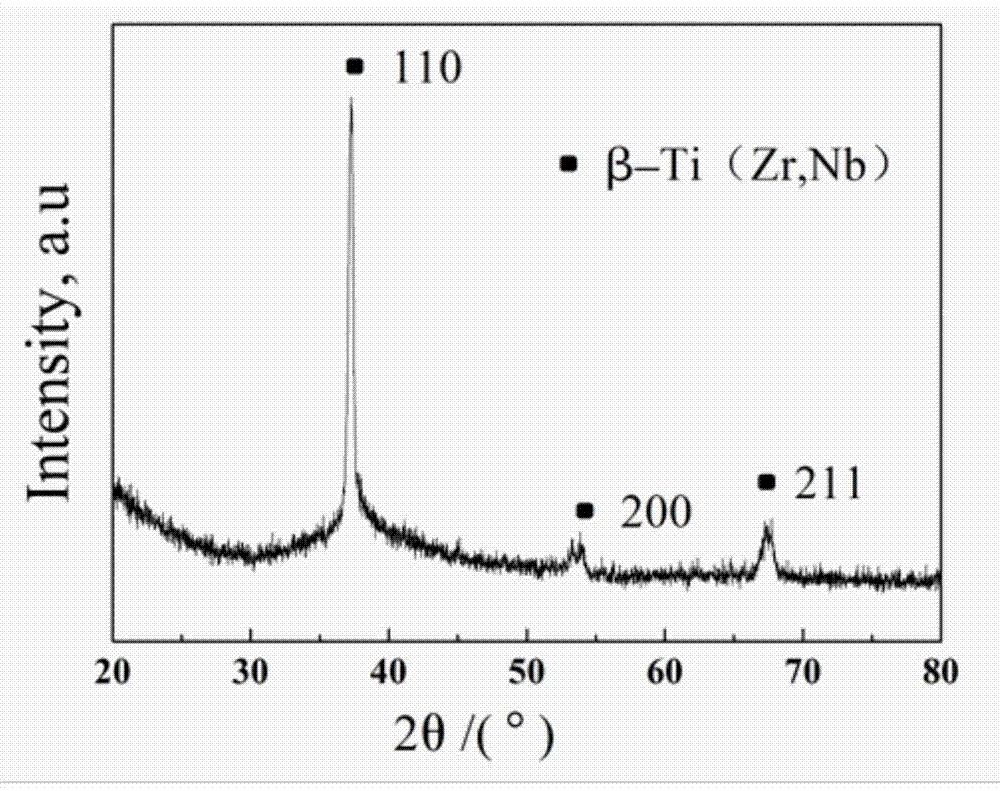

[0060] The experimental results are: Figure 6 As shown, in addition to the diffuse amorphous diffraction peaks at 30-50° in the XRD pattern, there are relatively sharp diffraction peaks corresponding to the β-Ti(Zr, Nb) crystal state with a body-centered cubic structure; Figure 7 It is the metallographic structure of the endogenous phase titanium-based amorphous composite material with the atom...

Embodiment 3

[0062] The atomic ratio composition described in this implementation example is: Ti: 43.65%; Zr: 21.34%; Nb: 9.7%; Cu: 7.76%; Be: 14.55%; Ag: 3% endogenous titanium-based amorphous composite material .

[0063] The preparation process of the endogenous titanium-based amorphous composite material with improved strength and plasticity described in the present invention is the same as that described in Example 1.

[0064] The experimental results are: Figure 9 As shown, in addition to the diffuse amorphous diffraction peaks at 30-50° in the XRD pattern, there are relatively sharp diffraction peaks corresponding to the β-Ti(Zr, Nb) crystal state with a body-centered cubic structure; Figure 10 It is the metallographic structure of the endogenous phase titanium-based amorphous composite material of the atomic ratio described in Example 3: the β-Ti (Zr, Nb) crystal phase is evenly distributed on the light-colored amorphous substrate, and is analyzed by image analysis software The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com