Ultrasonic welding preparation method of Ag-Cu-Ti layer-shaped composite solder

An ag-cu-ti, layered composite technology, applied in welding equipment, welding equipment, non-electric welding equipment and other directions, can solve problems such as protection against unfavorable Ti activity, poor alloy smelting processability, difficult metal synchronous deformation, etc., to avoid Composition segregation, good weldability, easy size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

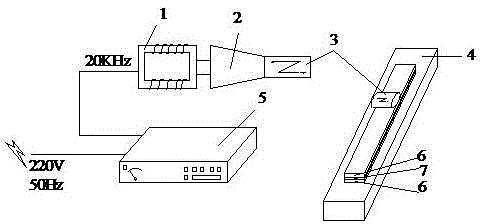

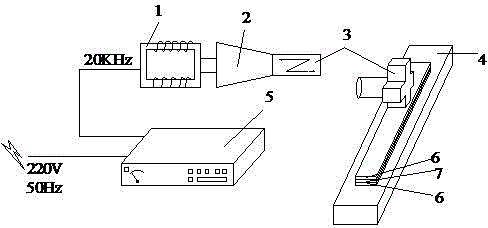

Image

Examples

Embodiment 1

[0013] The upper and lower layers are 21μm Ag-Cu eutectic foil, and the middle layer metal is 10.4μm pure Ti foil. Under the conditions of ultrasonic welding parameters such as welding pressure F: 120N, welding time t: 30ms, vibration frequency ?: 20kHz, amplitude A: 14μm, and welding speed 1m / min, the metal strips with a width of 30mm are superimposed and ultrasonic roll welding is performed. A layered composite solder with a thickness of 50 μm is prepared, the mass percentage of the active element Ti is 10.0%, the melting temperature range is 780 ° C ~ 870 ° C, it has good wettability to ceramics, and there is a higher joint after brazing strength.

Embodiment 2

[0015] The upper and lower layers are 51 μm Ag-Cu eutectic foil, and the middle layer metal is 1 μm pure Ti foil. Under the conditions of ultrasonic welding parameters such as welding pressure F: 150N, welding time t: 50ms, vibration frequency ?: 20kHz, amplitude A: 15μm, and welding speed 1.5m / min, the metal strips with a width of 30mm are stacked and ultrasonic seam welding is performed. , a layered composite solder with a thickness of 100 μm was prepared, the mass percentage of the active element Ti was 0.4%, and the melting temperature range was 780 ° C ~ 830 ° C. It has good wettability to ceramics and has a higher joint strength.

example 3

[0017] The upper and lower layers are 38μm Ag-Cu eutectic foil, and the middle layer metal is 7μm pure Ti foil. Under the conditions of ultrasonic welding parameters: welding pressure F: 140N, welding time t: 40ms, vibration frequency ?: 20kHz, amplitude A: 15μm, and welding speed 1.2m / min, the metal strips with a width of 30mm are superimposed and ultrasonic roll welding is performed. , a layered composite solder with a thickness of 100 μm was prepared, the mass percentage of the active element Ti was 4.1%, and the melting temperature range was 780 ° C ~ 850 ° C. It has good wettability to ceramics and has a higher joint strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com