Molybdenum-aluminum-silicon intermediate alloy and preparation method thereof

A master alloy, molybdenum-aluminum technology, applied in molybdenum-aluminum-silicon master alloy and its preparation, master alloy field, can solve problems such as composition segregation, achieve the effect of small composition segregation, good uniformity, and preventing composition segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. MoO with a purity of more than 99.9% 3 , Al with a purity of 99.7% or more and Si with a purity of 99.5% or more are dried, the drying temperature is 110° C., and the drying time is 6 hours.

[0024] 2. Then follow 100 copies of MoO 3 , 65 parts of Al, and 5 parts of Si were weighed for each raw material.

[0025] 3. Fully mix the weighed raw materials to obtain the mixed material.

[0026] 4. Put the mixed material in a furnace at normal temperature, and carry out alloy smelting by the aluminothermic smelting method outside the furnace to obtain a molybdenum-aluminum-silicon intermediate alloy.

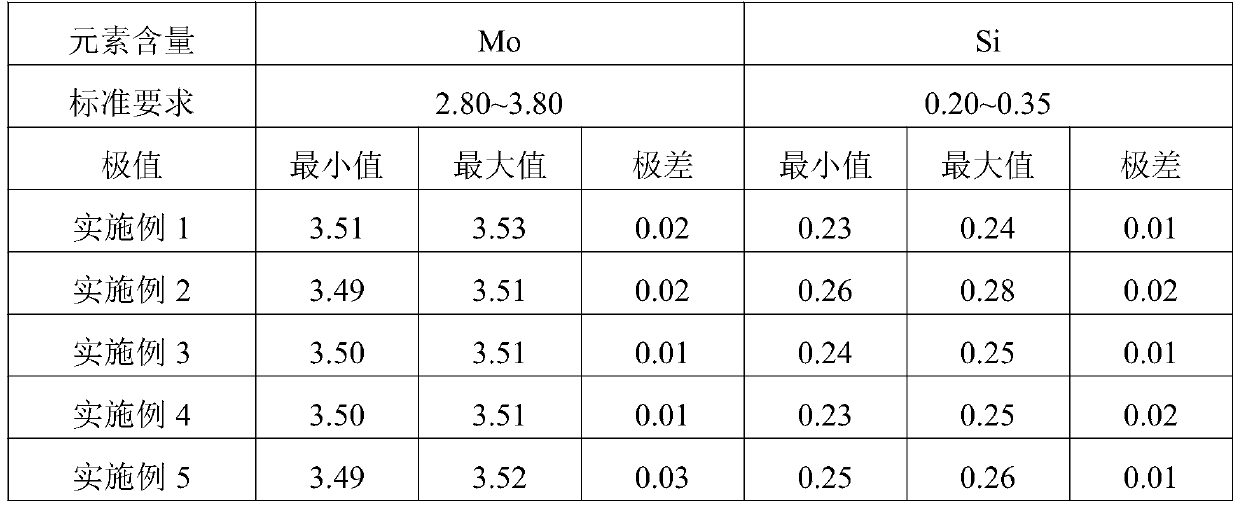

[0027] The chemical composition of the molybdenum-aluminum-silicon master alloy prepared in this example was analyzed, and the results are shown in Table 1. The molybdenum-aluminum-silicon master alloy prepared in this example was applied to the grade TC8 titanium alloy for Mo content and Si content analysis, and the results are shown in Table 2. The molybdenum-aluminum...

Embodiment 2

[0029] 1. MoO with a purity of more than 99.9% 3 , Al with a purity of 99.7% or more and Si with a purity of 99.5% or more are dried, the drying temperature is 130° C., and the drying time is 12 hours.

[0030] 2. Then follow 100 copies of MoO 3 , 72 parts of Al, and 9 parts of Si were weighed for each raw material.

[0031] 3. Fully mix the weighed raw materials to obtain the mixed material.

[0032] 4. Put the mixed material in a furnace at normal temperature, and carry out alloy smelting by the aluminothermic smelting method outside the furnace to obtain a molybdenum-aluminum-silicon intermediate alloy.

[0033] The chemical composition of the molybdenum-aluminum-silicon master alloy prepared in this example was analyzed, and the results are shown in Table 1. The molybdenum-aluminum-silicon master alloy prepared in this example was applied to the grade TC8 titanium alloy for Mo content and Si content analysis, and the results are shown in Table 2. The molybdenum-aluminu...

Embodiment 3

[0035] 1. MoO with a purity of more than 99.9% 3 , Al with a purity of 99.7% or more and Si with a purity of 99.5% or more are dried, the drying temperature is 120° C., and the drying time is 10 h.

[0036] 2. Then follow 100 copies of MoO 3 , 68 parts of Al, and 7 parts of Si were weighed for each raw material.

[0037] 3. Fully mix the weighed raw materials to obtain the mixed material.

[0038] 4. Put the mixed material in a furnace at normal temperature, and carry out alloy smelting by the aluminothermic smelting method outside the furnace to obtain a molybdenum-aluminum-silicon intermediate alloy.

[0039] The chemical composition of the molybdenum-aluminum-silicon master alloy prepared in this example was analyzed, and the results are shown in Table 1. The molybdenum-aluminum-silicon master alloy prepared in this example was applied to the grade TC8 titanium alloy for Mo content and Si content analysis, and the results are shown in Table 2. The molybdenum-aluminum-si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com