Coating spraying and 3D printing cermet material based on TiCN-MxC-Co and preparation method of coating spraying and 3D printing cermet material based on TiCN-MxC-Co

A cermet, 3D printing technology, applied in the direction of metal processing equipment, coating, metal material coating technology, etc., can solve the difficult to meet the requirements of raw materials for 3D printing technology, it is difficult to achieve high density and high mechanical properties, very difficult Difficult to prepare and mold in one piece, etc., to achieve the effect of uniform microstructure, reduced preparation cost, and high product performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] ①The ingredients are mixed and dried

[0035] Weigh 4kg Co powder and 6kg Ti(C 0.7 ,N 0.3 ) powder, add Polyethylene Glycol 500g, each raw material is mixed uniformly by ball-milling mixing method, ball-milling agent alcohol, and then vacuum-dry to obtain compound;

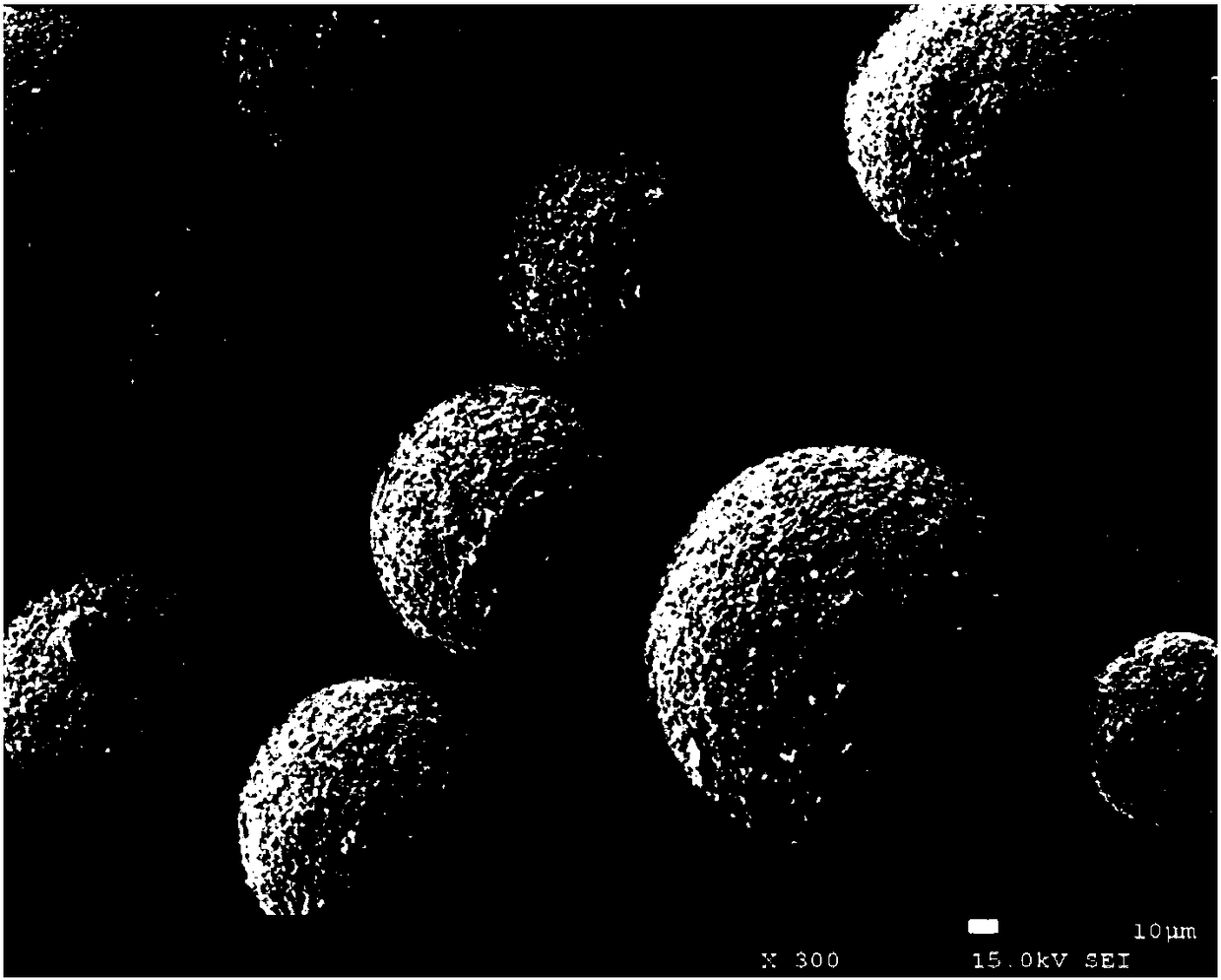

[0036] ②Spherification

[0037] The mixture prepared in step ① is crushed and sieved into powder, and the mesh size of the sieve is 300 mesh; then the powder is spheroidized by the method of roller spherification, and sieved with a 30-mesh sieve, and taken through the sieve Net powder; then sieve with a 50-mesh sieve, and take the powder that has not passed through the sieve to obtain a spherical powder with uniform particle size distribution;

[0038] ③ Remove molding agent and heat treatment

[0039] Put the spherical powder prepared in step ② into a vacuum sintering furnace, evacuate to below 1×10-1Pa, raise the temperature to 600°C and keep it for 2 hours to remove the added molding agent; then redu...

Embodiment 2

[0042] ①The ingredients are mixed and dried

[0043]Weigh TiC0.5N0.5 powder: 9.5kg; Co powder: 0.4kg; Fe powder: 0.1kg, add polyethylene glycol 50g, mix each raw material evenly by ball milling method, the ball milling agent is alcohol, and then vacuum dry dry mix;

[0044] ②Forming

[0045] Sieve and granulate with a 30-mesh sieve, and then compact the granulated pellets;

[0046] ③Pre-firing and crushing

[0047] Put the compact prepared in step ② into a vacuum sintering furnace, evacuate to below 1×10-1Pa, raise the temperature to 350°C and keep it for 8 hours to remove the added molding agent; then reduce the air pressure to below 1×10-1Pa , and then raised the temperature to 800 for firing for 4 hours; then cooled with the furnace, and the sintered compact was broken into particles of 30 microns.

[0048] ④ Discharge plasma spheroidization

[0049] The composite cermet particles prepared in step ③ are spheroidized in a stably operating radio frequency plasma spheroid...

Embodiment 3

[0052] ①The ingredients are mixed and dried

[0053] Weigh (Ti, 20W, 15Mo, 5Ta) C0.7N0.3 powder: 6kg; Co powder: 2.5kg; Ni powder: 1kg; Mo powder

[0054] 0.5kg, 200g of paraffin, each raw material is mixed uniformly by the ball mill mixing method, the ball milling agent is acetone, and then vacuum-dried to obtain the mixture;

[0055] ②Forming

[0056] Sieve and granulate with an 80-mesh sieve, and then compact the granulated pellets;

[0057] ③Pre-firing and crushing

[0058] Put the green compact prepared in step ② into a vacuum sintering furnace, then continuously feed and maintain the flowing Ar gas with a pressure of 500Pa in the vacuum furnace, raise the temperature to 600°C and keep it for 2 hours to remove the added molding agent; Lower the temperature below 1×10-1Pa, then raise the temperature to 1350°C for sintering for 0.5 hours; then cool with the furnace, and break the sintered compact into 100 micron particles.

[0059] ④ Discharge plasma spheroidization

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com