Baffling type glass batch mixture preheating device

A technology of glass batch material and preheating device, which is applied in the direction of glass production, glass manufacturing equipment, and feeding of melting furnaces, etc. It can solve the problems of large heat consumption, reduce the flow rate of flue gas, reduce the loss of components, and reduce the furnace The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

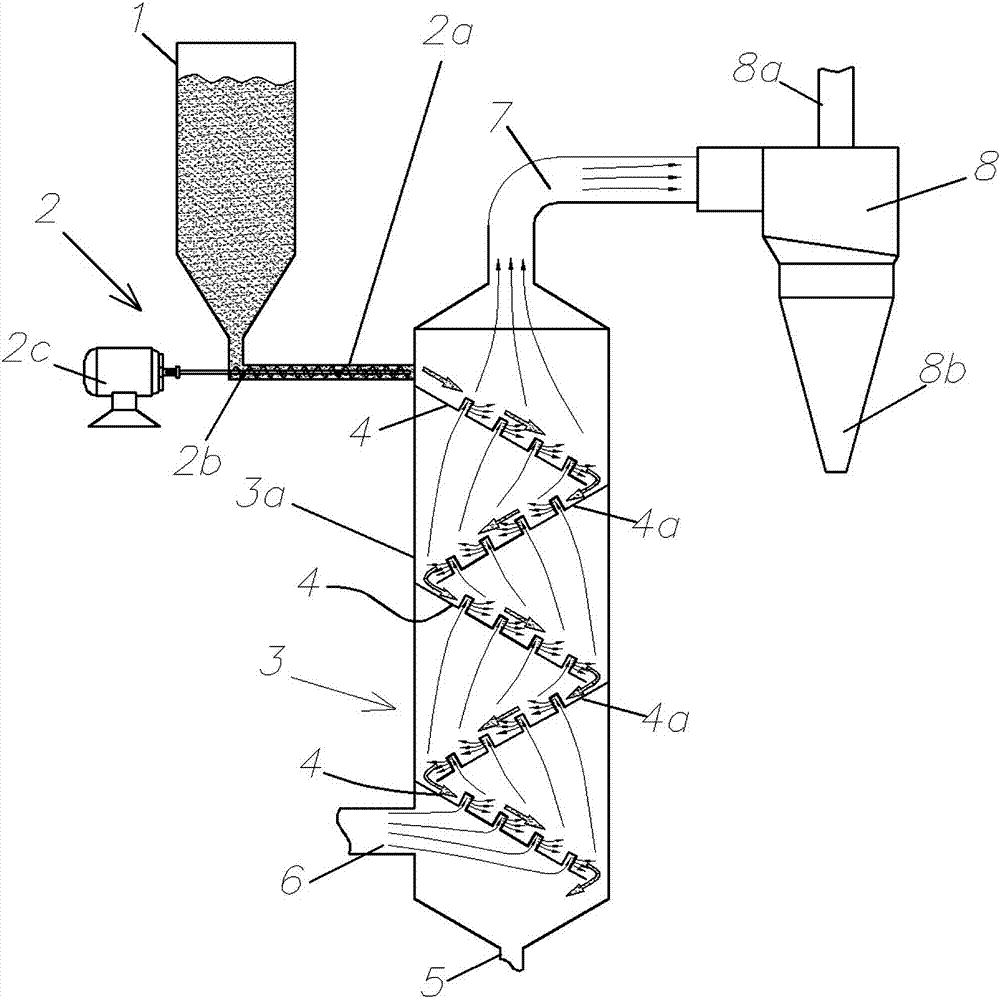

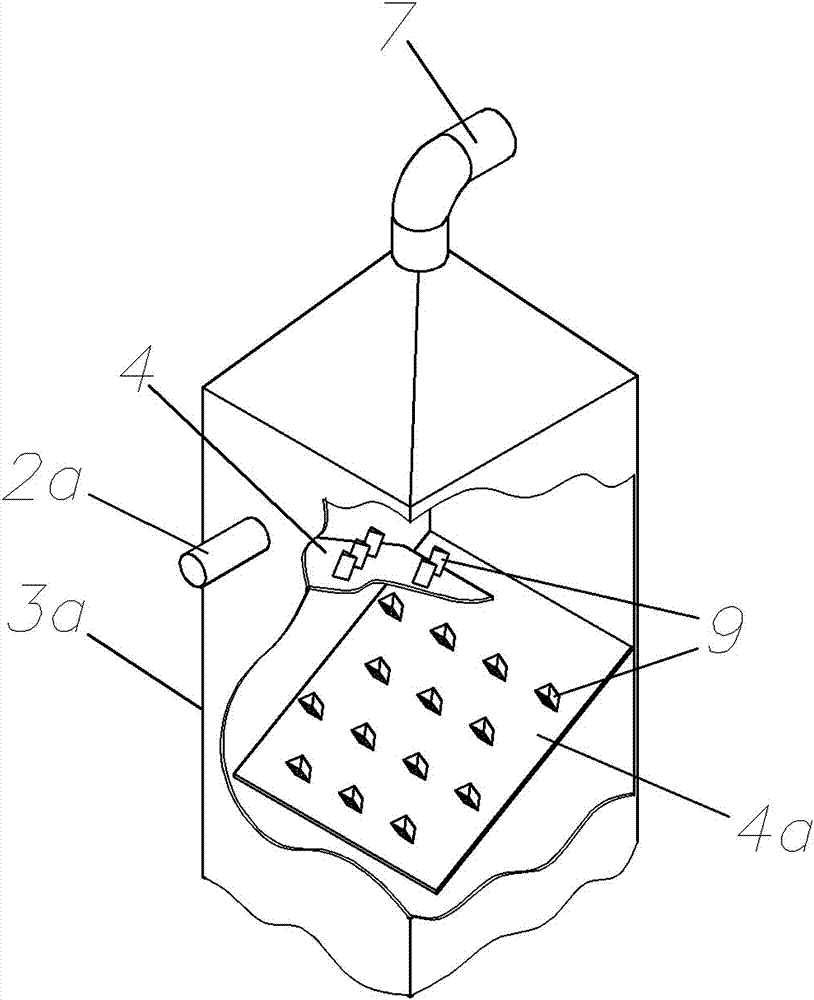

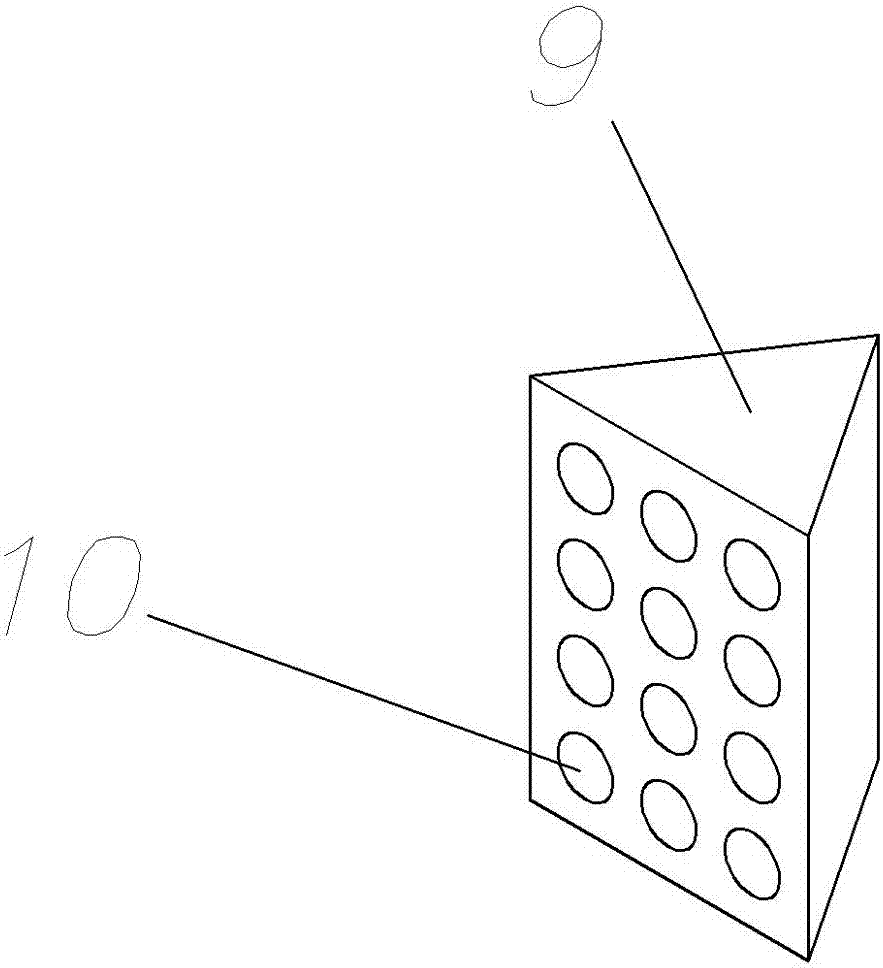

[0015] Such as Figure 1-3 As shown, a baffle type glass batch material preheating device, which includes a batch bin 1, a preheater 3 is arranged on one side of the batch bin 1, and the batch bin 1 is preheated by a feeding device 2 Device 3 is connected. The feeding device 2 is a screw feeding device, which includes a feeding channel 2a, the outlet at one end of the feeding channel 2a communicates with the upper left side of the preheater 3, and the position near the other end is connected to the side of the batching silo 1. The discharge port is connected, and a coaxial screw feeder 2b is worn in the feeding channel 2a, and one end of the rotating shaft of the screw feeder 2b forms a corresponding fit with the output shaft of the motor 2c provided outside the feeding channel 2a. In actual production, the outlet of the batching bin 1 can be connected with several horizontally arranged screw feeding devices to transport the batching materials to the preheater, so as to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com