Tungsten-copper alloy and production method thereof

A technology of tungsten-copper alloy and tungsten powder, applied in the field of tungsten-copper alloy and its preparation, can solve problems such as uneven structure, and achieve the effects of good structure uniformity, improved dispersion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a kind of preparation method of tungsten copper alloy, comprises the following steps:

[0045] a. Plasma spheroidization treatment of tungsten powder

[0046] The induction plasma powder spheroidization device is used to conduct plasma spheroidization treatment on tungsten powder to obtain spheroidized tungsten powder;

[0047] b. Electroless copper plating with spheroidized tungsten powder

[0048] Mix the spheroidized tungsten powder obtained in step a with the plating solution, adjust the pH value to 11-14, heat the water bath to 40-75°C, stir the mixed solution, and perform electroless copper plating; the composition of the plating solution includes: copper sulfate , formaldehyde, potassium sodium tartrate, 2,2'-bipyridyl and methanol;

[0049] c. Compression molding

[0050] The spheroidized tungsten powder after copper plating in step b is pre-pressed in a mold, and after isostatic pressing and repressing treatment, a blank is obtained; ...

Embodiment 1

[0078] Embodiment 1 Adopt the method of the present invention to prepare the tungsten-copper alloy with uniform structure

[0079] A kind of tungsten-copper alloy, its composition is: tungsten 90wt%, copper 10wt%, preparation process is as follows:

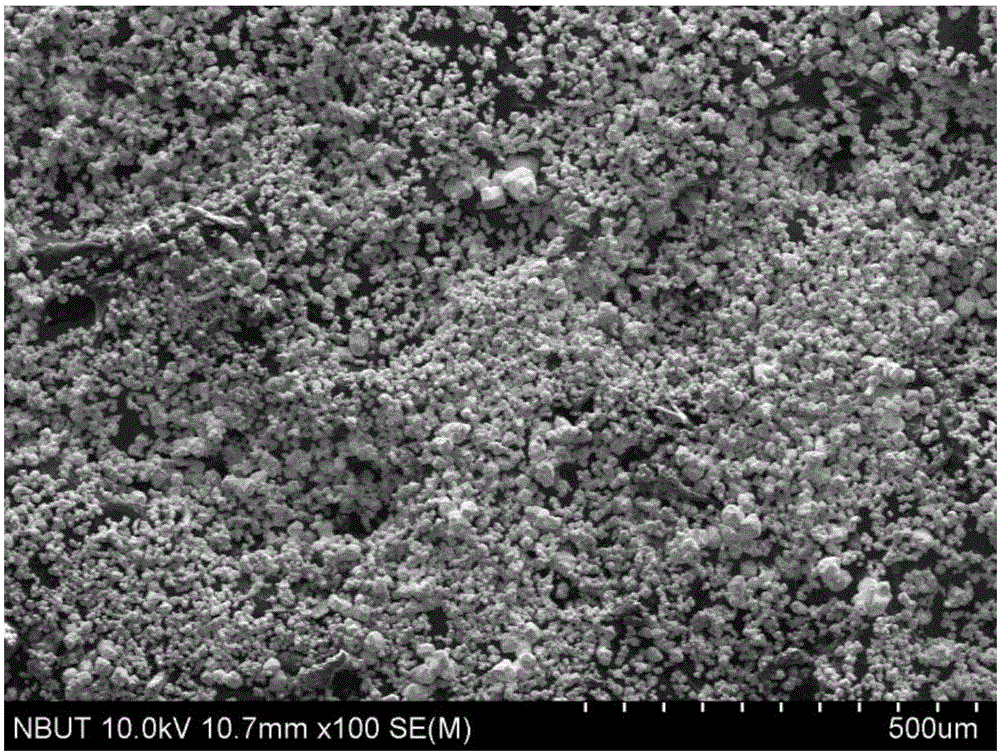

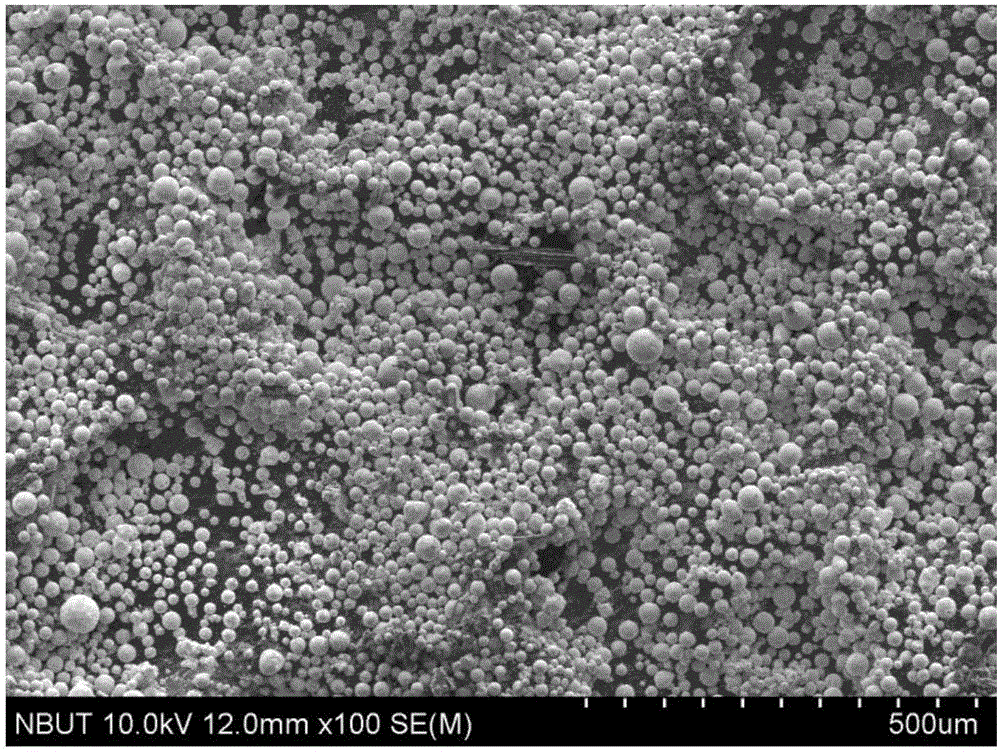

[0080] a. Plasma spheroidization treatment of tungsten powder

[0081] Take tungsten powder with a purity ≥ 99.95% and an average Fischer particle size of 8 microns, and use an induction plasma powder spheroidizer for spheroidization treatment;

[0082]

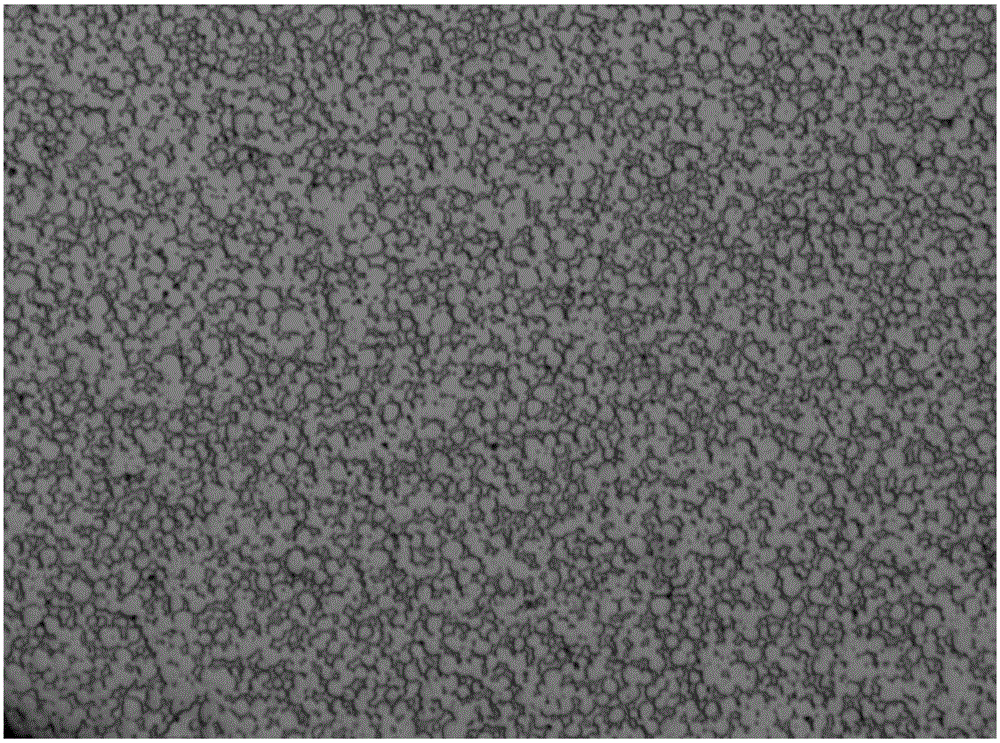

[0083] b. Electroless copper plating with ion spheroidized tungsten powder

[0084] The spherical tungsten powder obtained in step a is cleaned with acetone solution and ultrasonic waves, and the surface of the tungsten powder is roughened by dilute hydrofluoric acid aqueous solution, and the tungsten powder is sensitized and activated by colloidal palladium sensitization and activation solution;

[0085] The activated tungsten powder is mixed with the plating solution, heat...

Embodiment 2

[0095] Embodiment 2 Adopt the method of the present invention to prepare the tungsten-copper alloy with uniform structure

[0096] A tungsten-copper alloy, which is composed of: tungsten 70wt%, copper 30wt%, the preparation process is as follows:

[0097] a. Plasma spheroidization treatment of tungsten powder

[0098] Take tungsten powder with a purity ≥ 99.95% and an average Fischer particle size of 15 microns, and use an induction plasma powder spheroidizer for spheroidization treatment;

[0099]

[0100] b. Electroless copper plating with ion spheroidized tungsten powder

[0101] The spherical tungsten powder obtained in step a is cleaned with acetone solution and ultrasonic waves, and the surface of the tungsten powder is roughened by dilute hydrofluoric acid aqueous solution, and the tungsten powder is sensitized and activated by colloidal palladium sensitization and activation solution;

[0102] The activated tungsten powder is mixed with the plating solution, heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com