Process for preparing high niobium Ti Al alloy large size cake material

A large-size, alloy technology, which is applied in the field of high-niobium TiAl alloy large-size cake preparation, can solve the problems of no research reports, etc., and achieve the effects of avoiding composition segregation, small grain size, and excellent comprehensive mechanical properties

Inactive Publication Date: 2002-06-05

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is no research report on the preparation of large-sized high-niobium TiAl alloy cakes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] homogenization annealing

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

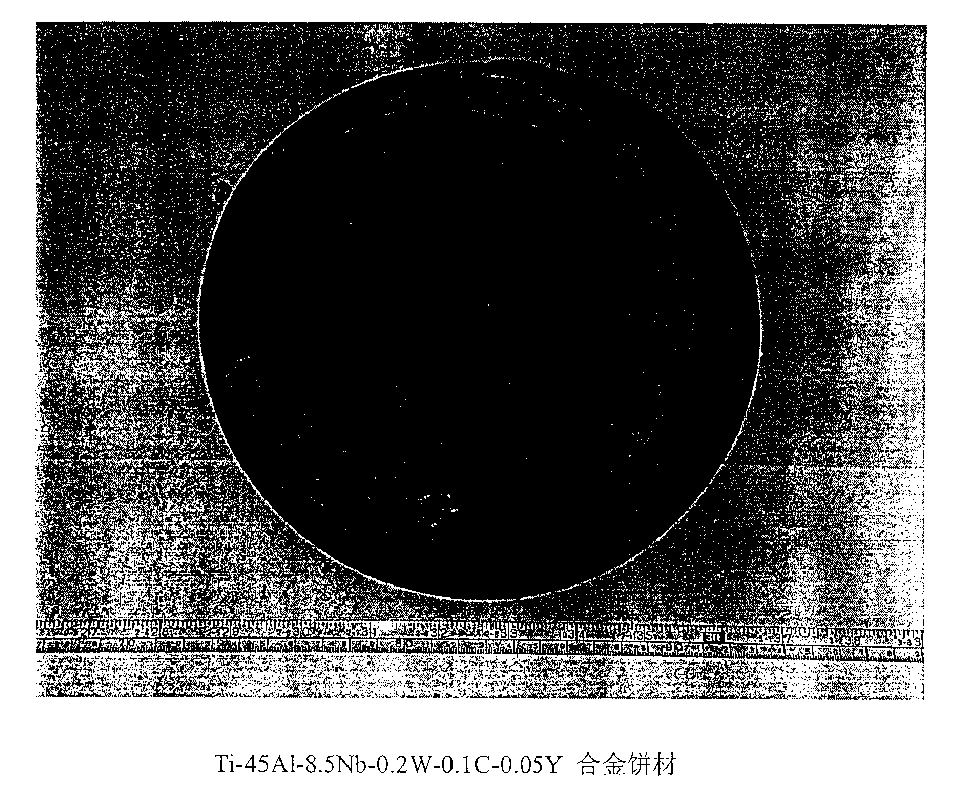

The preparation of large high-Nb TiAl alloy cake includes the technological process of smelting, soakage treatment, turning, canning, forging and slow cooling. The preparation process features the smelitng including the first self-consuming, the self-consuming kish and the second self0consuming steps; the soakage treatment at 1100-1300 deg.c for 24-48 hr; turning to eliminate surface scale; canning with stainless steel pipe, titanium pipe and stainless steel plate; forging in a 3000-5000 oil press at deformation temperature of 1200-1350 deg.c after heating at 1250-1300 deg.c for 40-60 min in the furnace and preheating for 6-10 hr to produce deformatino amount of 60-80 % at the rate of 0.001-0.1 / s; and tempering at low temperature. The present ivnention has the advantages of fine crystal grains and excellent comprehensive mechanical performance.

Description

Technical field: [0001] The invention provides a method for preparing a high-niobium TiAl alloy large-size cake material. Background technique: [0002] After recent years of research on high-niobium TiAl intermetallic compounds, a series of important progress has been made in the phase diagram, oxidation resistance, structure and performance. Its excellent high temperature performance, oxidation resistance and creep resistance are outstanding. It has received widespread attention. The addition of high-content refractory metal niobium increases the melting point of the alloy by about 90--100°C compared with ordinary titanium-aluminum alloys. The solid solution strengthening of niobium elements makes its 900°C yield strength higher than ordinary titanium-aluminum alloys. High 150---200MPa, the addition of niobium with high melting point reduces the diffusion coefficient and improves the oxidation resistance. It is a new generation of high-temperature structural materials with...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C1/00C22C14/00C22F1/18

Inventor 林均品王艳丽陈国良宋西平惠希东林志刘志成

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com