Preparation method of spherical lithium nickel cobalt manganese oxide precursor mixture

A technology of nickel cobalt lithium manganate and mixture, applied in the field of battery materials, can solve the problems of poor rate performance and cycle performance, difficult to control composition and morphology, low tap density, etc., achieve good economic benefits and improve the quality of electrode sheets , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

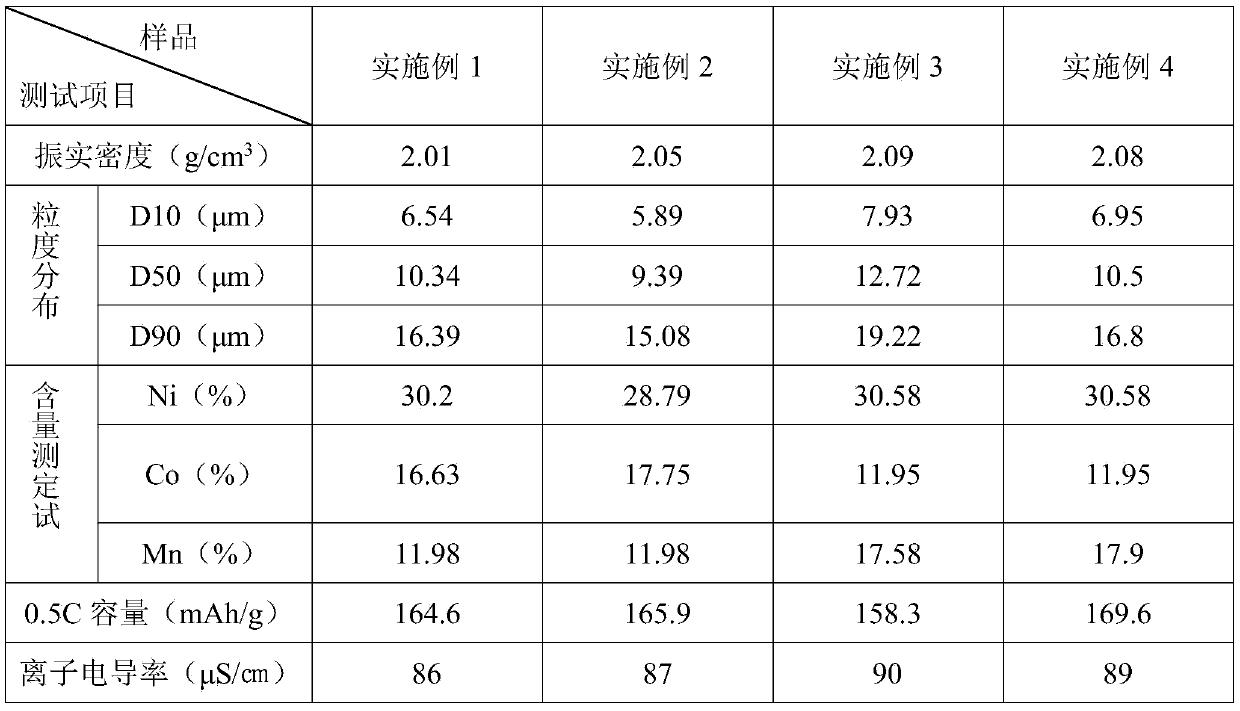

Embodiment 1

[0030] A preparation method of secondary spherical nickel cobalt lithium manganate precursor mixture, comprising the following steps:

[0031] (1) Raw material pretreatment: Weigh NiSO according to the molar ratio of nickel, cobalt and manganese elements of 5:2:3 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 0, then add ascorbic acid, its addition is 0.05% of the total mass of nickel salt, cobalt salt and manganese salt, at normal temperature, add deionized water and mix to obtain mixed solution 3L, wherein the solid content of the slurry is 60%;

[0032] (2) Wet synthesis: add the nickel salt, cobalt salt and manganese salt pretreated in step (1) into the reactor, and add an appropriate amount of 0.5mol / L ammonia and 1mol / LNaOH solution to carry out wet synthesis to obtain For the initial slurry, the reaction temperature in the reactor is 50°C, the pH of the solution is 11, and the stirring speed is 700rpm;

[0033] (3) Post-reaction aging: keep stirring for 5 hours, stop s...

Embodiment 2

[0036] (1) Raw material pretreatment: Weigh NiSO according to the molar ratio of nickel, cobalt and manganese elements of 5:2:3 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 0, then add ascorbic acid, its addition is 0.03% of the total mass of nickel salt, manganese salt and cobalt salt, at normal temperature, add deionized water and mix to obtain mixed solution 3L, wherein the solid content of the slurry is 50%;

[0037] (2) Wet synthesis: add the nickel salt, cobalt salt and manganese salt pretreated in step (1) into the reactor, and add an appropriate amount of 1.0mol / L ammonia water and 2mol / L NaOH solution to carry out wet synthesis The initial slurry was obtained. At this time, the reaction temperature in the reactor was 60° C., the pH of the solution was 11.5, and the stirring speed was 800 rpm;

[0038](3) Aging after the reaction: keep stirring for 6 hours, stop stirring, ventilate, stand and age for 18 hours, and then filter and wash to obtain the nano-spherical nic...

Embodiment 3

[0041] (1) Raw material pretreatment: Weigh NiSO according to the molar ratio of nickel, cobalt and manganese elements of 5:2:3 4 ·6H 2 O. CoSO 4 ·7H 2 O and MnSO 4 ·H 2 0, then add glucose, its addition is 0.04% of the total mass of nickel salt, manganese salt and cobalt salt, add deionized water at room temperature and mix uniformly to obtain 3L of mixed solution, wherein the solid content of the slurry is 40%;

[0042] (2) Wet synthesis: add the nickel salt, cobalt salt and manganese salt pretreated in step (1) into the reactor, and add an appropriate amount of 1.5mol / L ammonia water and 3mol / LNaOH solution to carry out wet synthesis to obtain For the initial slurry, the reaction temperature in the reactor is 70°C, the pH of the solution is 12, and the stirring speed is 900rpm;

[0043] (3) Aging after reaction: keep stirring for 7 hours, stop stirring, ventilate, stand and age for 17 hours, and then filter and wash to obtain the nano-spherical nickel-cobalt-manganese ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com