Method for combining different types of aluminum materials and combined part of different types of aluminum materials

A technology for bonding parts and aluminum-based composite materials, which is applied to the bonding method of dissimilar aluminum materials and the field of bonding parts of dissimilar aluminum materials, can solve the problems of complex groove processing, accelerated corrosion, stress cracking, etc., so as to avoid component segregation, Combination method is simple, the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

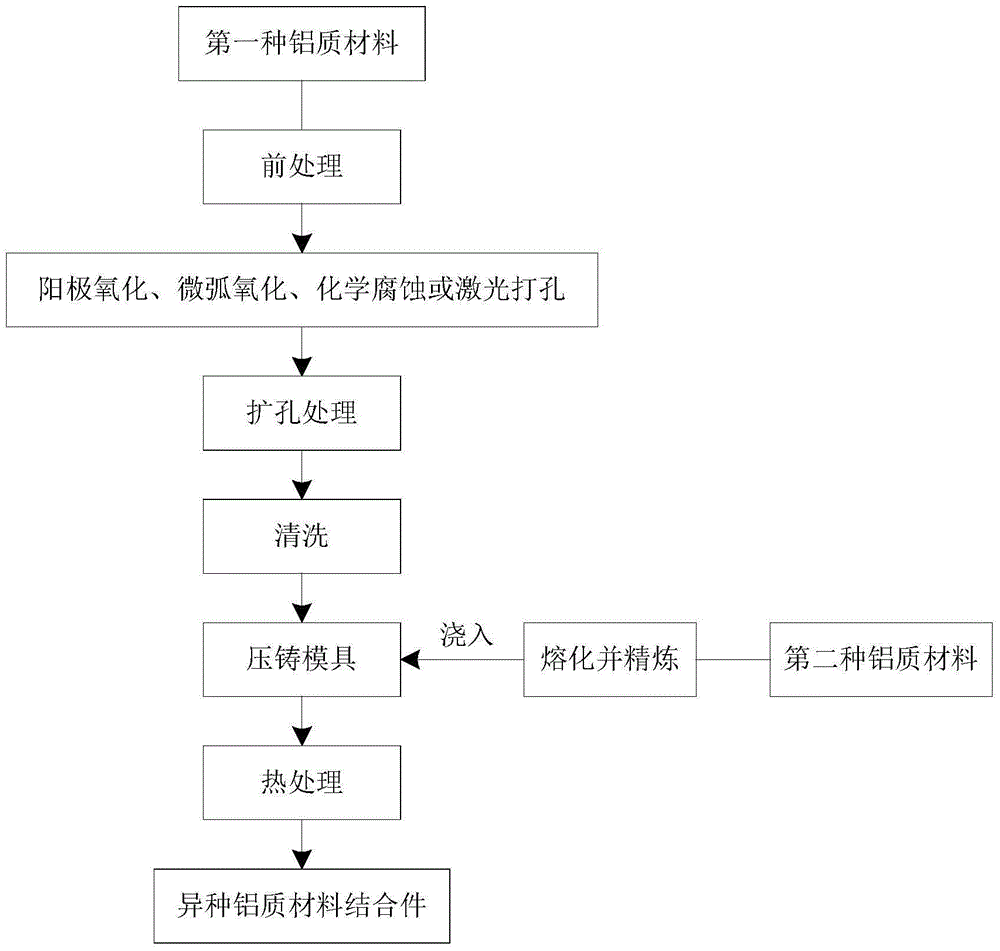

Method used

Image

Examples

example 1

[0026] Example 1 (combination of 6063 aluminum alloy and ADC12 aluminum alloy):

[0027] This example can be applied to the middle frame of the mobile phone. The 6063 aluminum alloy used in the middle frame of the mobile phone is an anodic material, which can provide a variety of colors of metal texture appearance, but its die-casting performance is poor. At present, the process is carried out after die-casting. CNC finishing has a large amount of processing and high cost; while the ADC12 aluminum alloy with good die-casting performance cannot be anodized due to silicon content. This example uses 6063 aluminum alloy as the outer frame. After treatment, it is directly die-casted to form the inner frame of ADC12 aluminum alloy, which greatly reduces the amount of processing and can be anodized for appearance. It is expected to be popular in the industry.

[0028] The combination method of the heterogeneous aluminum material of the present example comprises the following steps: ...

example 2

[0037] Example 2 (combination of 7475 aluminum alloy and ADC12 aluminum alloy):

[0038] This example can be applied to complex structures that require high surface mechanical properties. 7475 aluminum alloy has good mechanical properties (strength, hardness), corrosion resistance, and is easy to process, but its die-casting performance is poor, so it is used as a surface structure; ADC12 aluminum alloy is used for internal , which can meet the requirements of the die-casting process, connected by the method of the invention, and can be applied to structural parts with higher requirements on mechanical properties.

[0039] The combination method of the heterogeneous aluminum material of the present example comprises the following steps:

[0040] (1) The 7475 aluminum alloy components are pretreated, and the steps of grinding, degreasing, water washing, alkali washing, water washing, neutralization, and water washing are sequentially carried out according to the general process...

example 3

[0048] Example three (combination of 7075 aluminum alloy and ADC6 aluminum alloy):

[0049] In this example, 7075 aluminum alloy has high strength, is easy to process, and is widely used in the aviation industry. At the same time, it can be anodized, but it cannot be welded, and its corrosion resistance is poor; ADC6 aluminum alloy has good corrosion resistance and can protect 7075 aluminum alloy Free from corrosion and connected by the method of the invention, it can be applied to aircraft structural parts that require high mechanical properties and corrosion resistance of aluminum alloys.

[0050] The combination method of the heterogeneous aluminum material of the present example comprises the following steps:

[0051] (1) The 7075 aluminum alloy components are pretreated, and the steps of grinding, degreasing, water washing, alkali washing, water washing, neutralization, and water washing are sequentially carried out according to the general process of anodic oxidation pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com