Magnesium-stannum-zinc-aluminum wrought magnesium alloy suitable for being extruded

A technology for deforming magnesium alloys, which is applied in the field of metal materials, can solve the problems of inability to effectively hinder dislocation slippage, long time to reach the aging peak, and limited increase in strength, so as to improve the age hardening reaction, shorten the time consumption, and The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

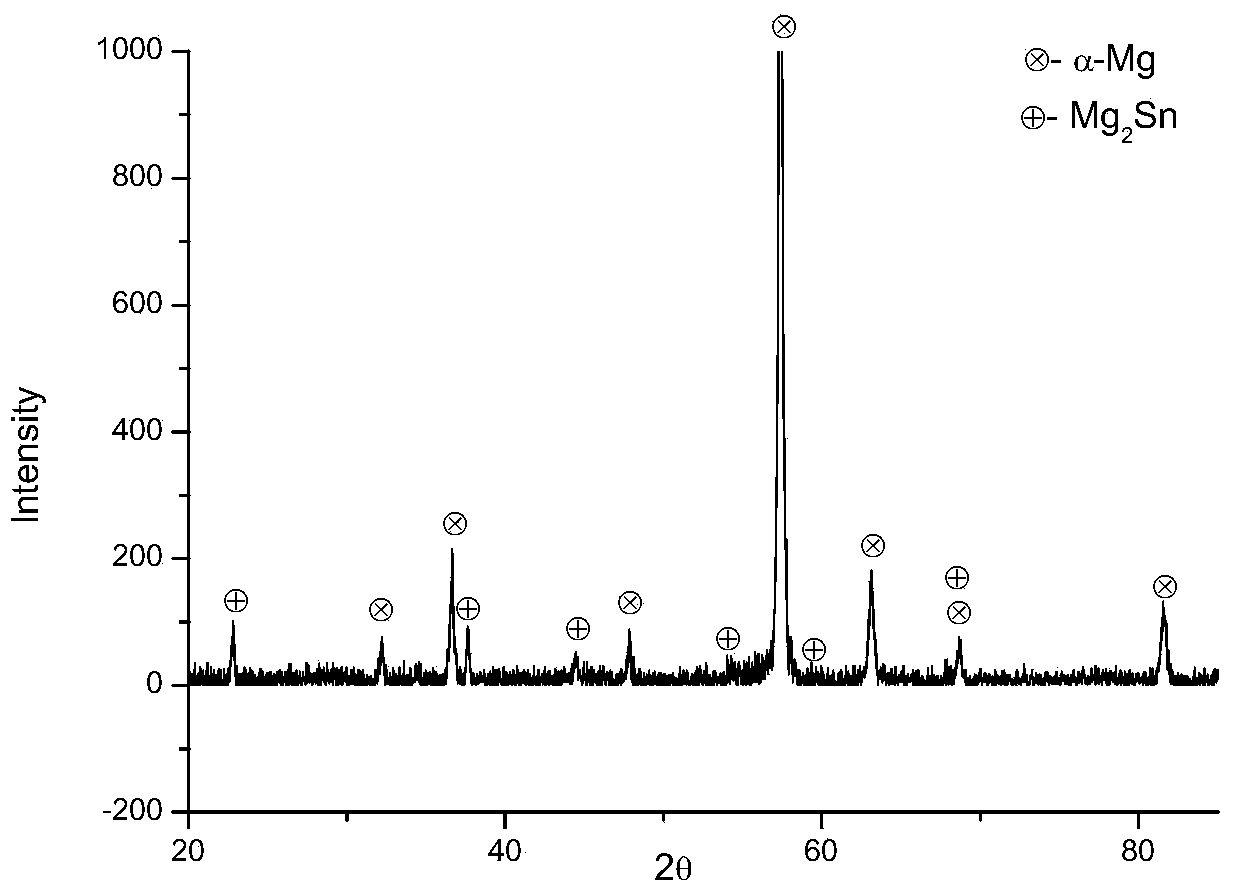

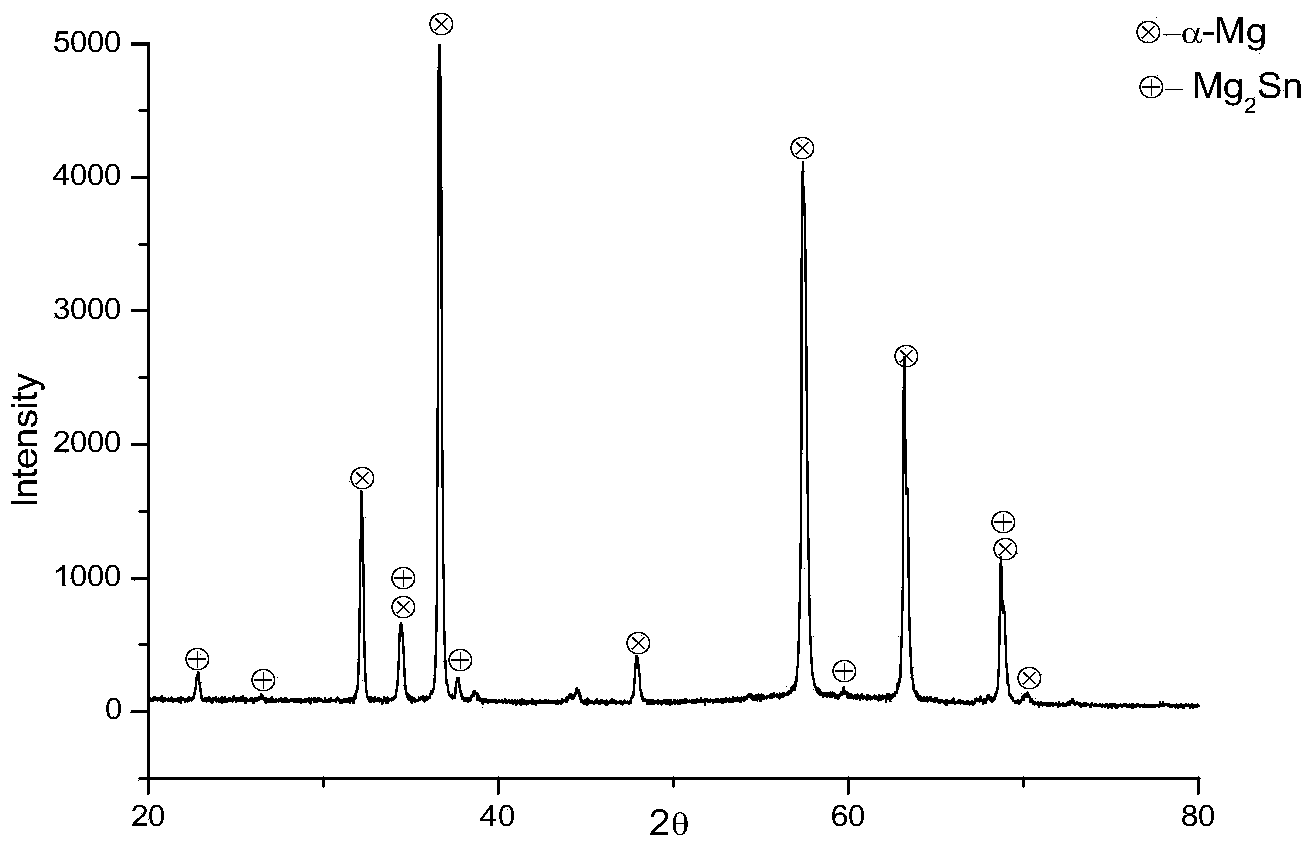

Image

Examples

Embodiment Construction

[0047] The percentage by weight of each component in the magnesium-tin-zinc-aluminum wrought magnesium alloy is shown in Table 1:

[0048] Table 1 % by weight %

[0049]

sn

Zn

Al

Impurities

Mg

Example 1

3.0

0

1.0

0.053

95.947

Example 2

3.0

0.5

1.0

0.076

95.424

Example 3

3.0

1.0

1.0

0.072

94.928

Example 4

3.0

1.5

1.0

0.063

94.437

Example 5

3.0

2.0

1.0

0.045

93.955

[0050] According to the composition in the example 1-5, select the required raw material of the present invention, the preparatory work before preparing the alloy comprises: grinding, removes the oxide, the impurity on the surface of the raw material, then according to the ratio of the example batching and respectively packed in the steel crucible . After the raw materials are ready, put the steel crucible into a vacuum electromagnetic induction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com