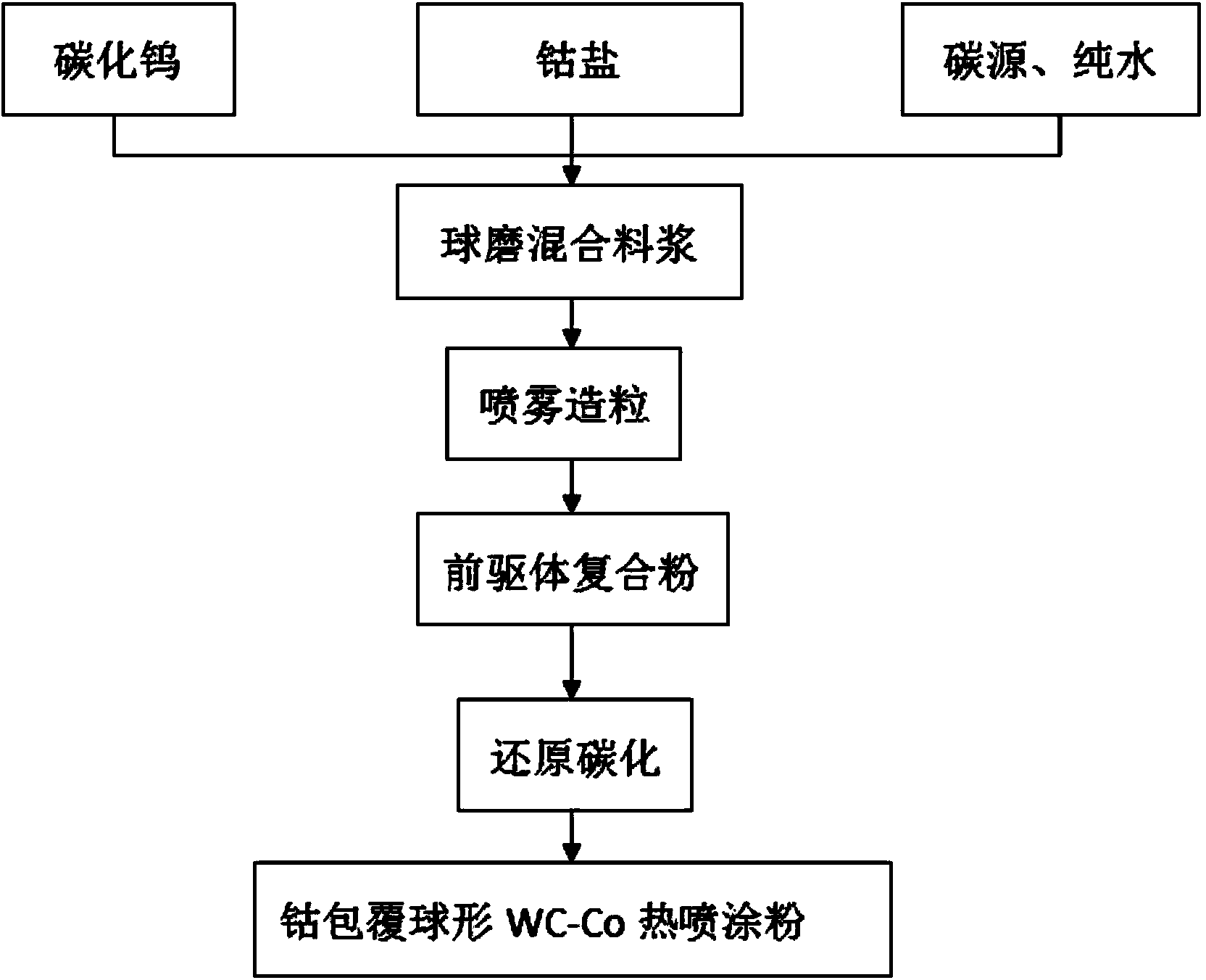

Method for preparing WC-Co powder used for thermal spraying

A technology of thermal spraying and powder, which is applied in the direction of coating, fusion spraying, metal material coating process, etc. It can solve the problems of increasing dewaxing process, crushing and screening, environmental pollution, etc., and achieves high sphericity and fluidity Good, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) 50Kg of tungsten carbide powder, 21Kg of cobalt acetate and 560g of carbon nanotubes with a particle size of 0.5 μm to 0.6 μm are dissolved in pure water whose mass is 1.5 times that of the total solid mass, and prepared into a mixed slurry with a cobalt content of 10 wt %;

[0047] 2) After ball milling the mixed slurry obtained in step 1) for 6 hours, perform spray granulation. During the spray granulation process, the inlet air temperature is 260°C, the outlet air temperature is 160°C, and the centrifugal atomization speed is 12000r / min , to obtain cobalt salt-coated WC precursor powder;

[0048] 3) Put the precursor powder obtained in step 2) at 1150°C under H 2 :CH 4 Reductive carbonization was carried out for 60 min in an atmosphere of (volume ratio)=98.5:1.5 to obtain WC-Co powder.

[0049] The present invention detects the physical properties and chemical composition of the obtained WC-Co powder, and the results are shown in Table 1. Table 1 shows the physi...

Embodiment 2

[0051] 1) Dissolve 50Kg tungsten carbide powder, 29Kg cobalt acetate, and 600g carbon black with a particle size of 0.5 μm to 0.6 μm in pure water whose mass is 1.8 times the total solid mass, and prepare a mixed slurry with a cobalt content of 12 wt %;

[0052] 2) After ball milling the mixed slurry obtained in step 1) for 8 hours, perform spray granulation. During the spray granulation process, the inlet air temperature is 260°C, the outlet air temperature is 140°C, and the centrifugal atomization speed is 10000r / min , to obtain cobalt salt-coated WC precursor powder;

[0053] In the present invention, the obtained precursor powder is subjected to scanning electron microscope scanning analysis, and the results are as follows: figure 2 as shown, figure 2 The SEM photo enlarged 2000 times for the precursor powder obtained in Example 2 of the present invention, by figure 2 It can be seen that the particle size of the precursor powder obtained by the present invention is un...

Embodiment 3

[0061] 1) 50Kg tungsten carbide powder, 43.5Kg cobalt acetate, and 1.4Kg sucrose with a particle size of 0.5 μm to 0.6 μm were dissolved in pure water whose mass was 3.0 times the total solid mass, and prepared into a mixed slurry with a cobalt content of 17 wt %;

[0062] 2) After ball milling the mixed slurry obtained in step 1) for 8 hours, carry out spray granulation. In the spray granulation, the inlet air temperature is 260°C, the outlet air temperature is 160°C, and the centrifugal atomization speed is 10000r / min , to obtain cobalt salt-coated WC precursor powder;

[0063] 3) Put the precursor powder obtained in step 2) under the condition of 1250°C, in H 2 :CH 4 (Volume ratio)=98.5:1.5 reduction carbonization was performed for 30 minutes to obtain cobalt-coated nano WC-Co powder.

[0064] The present invention detects the physical properties and chemical composition of the obtained WC-Co powder, and the results are shown in Table 1. Table 1 shows the physical propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com