A special continuous casting crystallizer functional protection material for plastic mold steel

A continuous casting crystallizer and plastic mold steel technology, which is applied in the field of steelmaking, can solve the problems of strong heat penetration ability of slag film and low binary alkalinity, achieve good fluxing effect, weak electron repulsion, and reduce mixing failure. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with some specific embodiments.

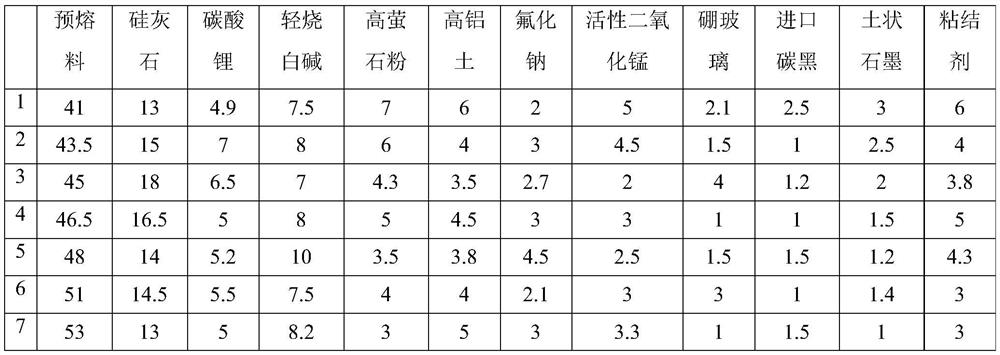

[0025] The raw materials and weight percentages of the special continuous casting crystallizer functional protection materials for plastic mold steel in Examples 1-7 of the present invention are shown in Table 1, wherein the chemical composition and weight percentages of the binder are: starch 92- 99.95%, Fe≤0.001%, oxalate≤0.05%, and reducing sugar≤8%.

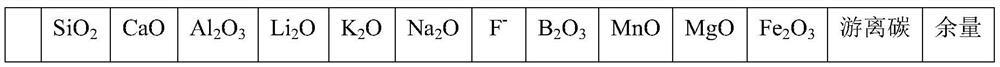

[0026] The chemical components and weight percentages of the premelts in Examples 1-7 of the present invention are shown in Table 2 below.

[0027] The chemical composition and weight percentage of the β-type acicular wollastonite in Examples 1-7 of the present invention are shown in Table 3 below.

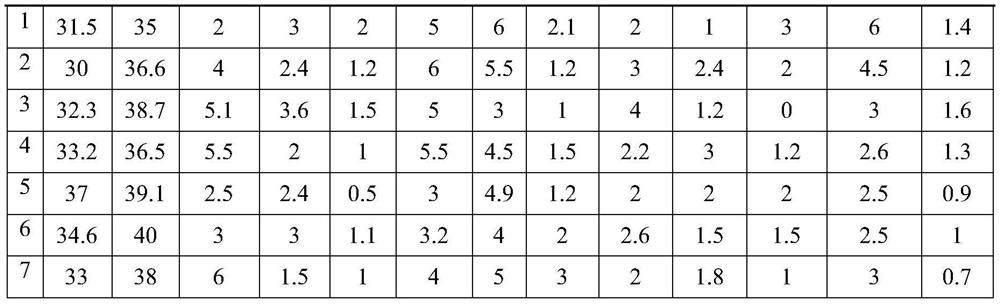

[0028]The chemical composition and weight percentage of the special continuous casting crystallizer functional protection material for plastic mold steel in Examples 1-7 of the present invention are shown in Table 4 belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com