Patents

Literature

344results about How to "Increase crystallization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester compositions and laminates and processes for producing biaxially stretched polyester bottles

InactiveUS6485804B1Increase crystallization rateMaintain good propertiesBottlesSynthetic resin layered productsCarboxylic acidDicarboxylic acid

The novel polyester (first polyester [A]) of the invention comprises dicarboxylic acid constituent units derived from at least one dicarboxylic acid selected from terephthalic acid, isophthalic acid and naphthalenedicarboxylic acid and diol constituent units derived from diols comprising ethylene glycol and a polyalkylene glycol having a C2-C10 alkylene chain, wherein the proportion of constituent units derived from the polyalkylene glycol is 0.001 to 10% by weight based on the diol constituent units. The polyester [A] has an excellent crystallization rate, is suitably used, singly or as compositions together with another polyester [B] and / or other polymers, for production of molded products such as films, sheets, laminates, preforms and bottles, which have excellent thermal, gas barrier and transparency properties.

Owner:MITSUI PETROCHEMICAL INDUSTRIES LTD

Microcrystalline glass and preparation method thereof

The invention relates to a kind of microcrystalline glass and a preparation method thereof. The preparation raw materials include 10-90wt% of iron, vanadium and titanium-containing tailings, 5-50wt% of fluorite tailings, 1-50wt% of dolomite and 0-20wt% of soda ash. The preparation method of the microcrystalline glass comprises the following steps: uniformly mixing and fusing raw materials in proportion so as to obtain fused glass fluid; and shaping the fused glass fluid, then cooling the shaped glass fluid, and carrying out heat treatment on the obtained product so as to obtain the microcrystalline glass. The microcrystalline glass provided by the invention can be widely used for manufacturing high wear-resisting, acid and alkali erosion resistant and impact resistant products, and the performance of the microcrystalline glass is far higher than that of cast stone, thereby not only solving the pollution problem of tailings and manufacturing high-technical-content and high value-added products.

Owner:承德华富玻璃技术工程有限公司

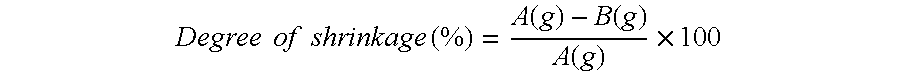

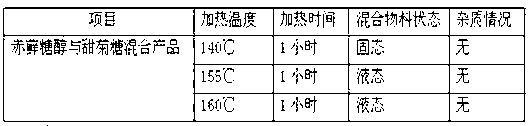

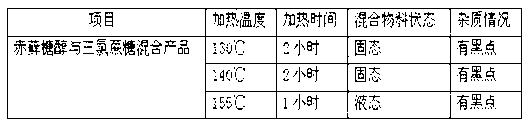

Erythritol crystal and preparation method of erythritol crystal

The invention relates to the technical field of compound sugar, in particular to an erythritol crystal, which comprises erythritol and sweet agents accounting for 1 to 2.5 percent of the weight of the erythritol. A preparation method of the erythritol crystal comprises the following steps that the erythritol and the sweet agents are mixed and dissolved to obtain liquid solution, the solution is simultaneously evaporated and crystallized, and the erythritol crystals are obtained; the erythritol and the sweet agents are mixed and are dissolved to obtain liquid solution, the liquid solution is subjected to non-evaporation crystallization, the filtering is carried out after the crystallization completion, and the erythritol crystals are obtained; the erythritol and the sweet agents are mixed in a solid from; and the mixed solids are subjected to melting, crystallization, crushing and drying to obtain the erythritol crystals. The sweetness of the erythritol is improved and reaches more than 80 percent of the sweetness of the cane sugar, the consistency of ingredients of compound products of the erythritol and the sweet agents is realized, the problem of cocrystallization of the erythritol and the sweet agents easily carbonized at high temperature is solved, the crystallization rate is improved to the maximum degree, the crystallization efficiency is 5 to 20 percent higher than that of the traditional crystallization technology, and the application field of the product is enlarged.

Owner:BAOLINGBAO BIOLOGY

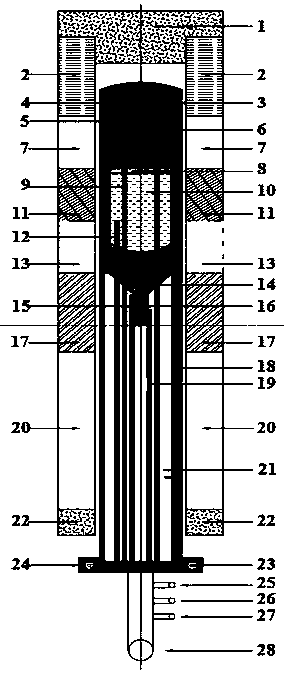

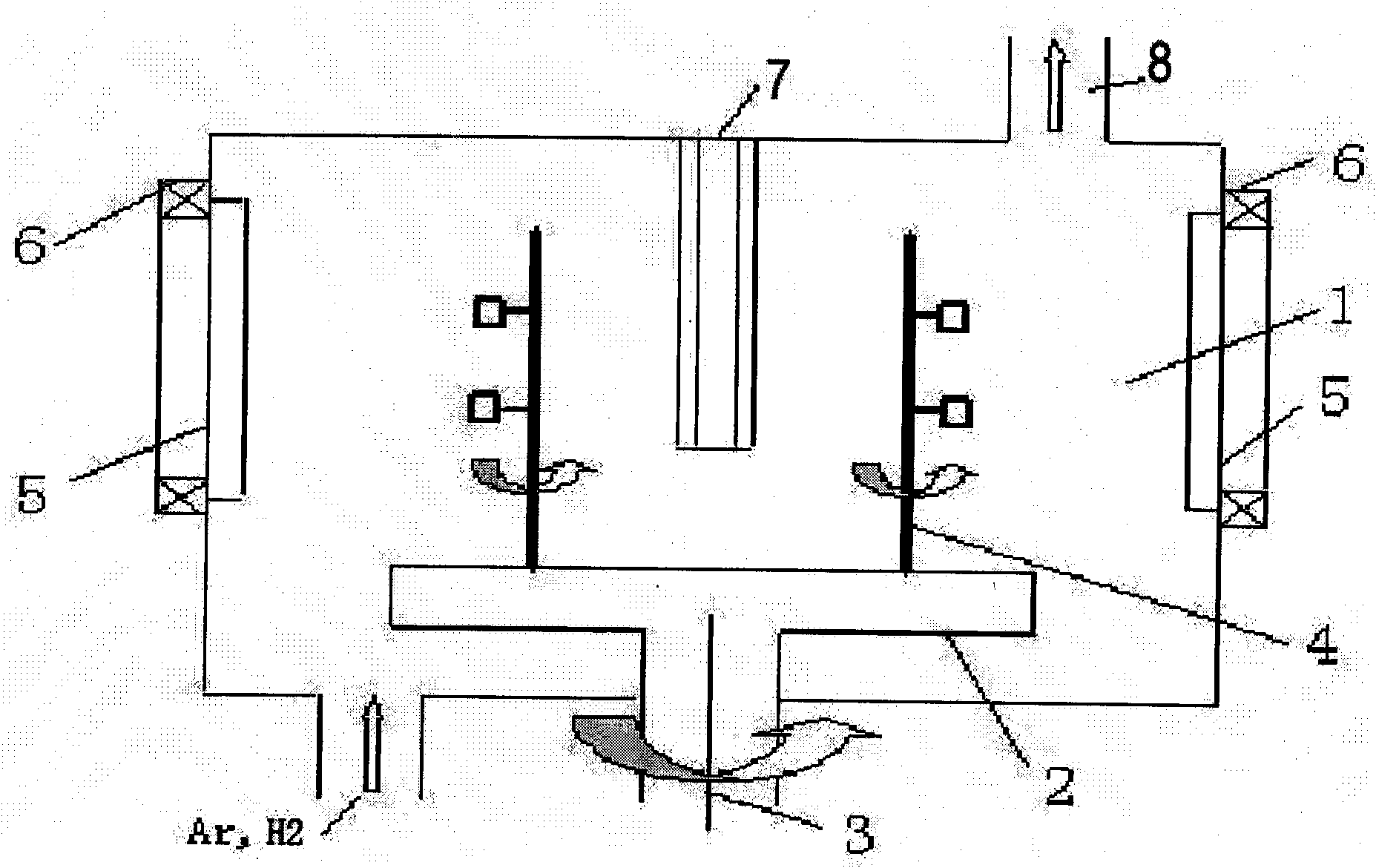

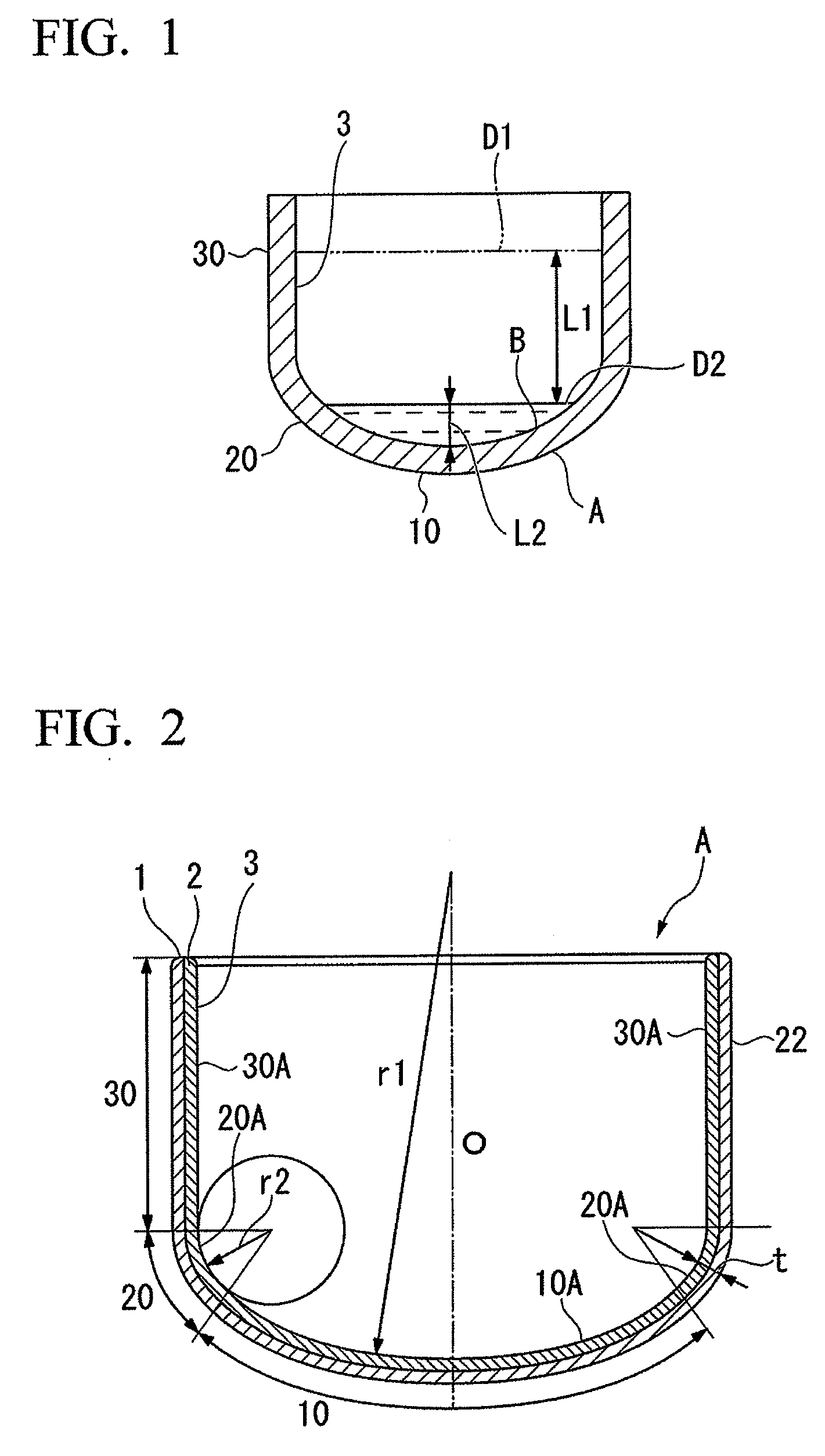

VGF/VB gallium arsenide single-crystal furnace structure and growing method

InactiveCN109252220AIncreased crystallization latent heat releaseIncrease crystallization ratePolycrystalline material growthFrom frozen solutionsSingle crystalMaximum size

The invention discloses a VGF / VB gallium arsenide single-crystal furnace structure and a growing method. According to the VGF / VB gallium arsenide single-crystal furnace structure, a resistance heatingfurnace which is relatively lowest in production cost and is provided with multiple temperature zones is adopted; a support structure adopts graphite; the support strength is improved; the loading amount is favorably increased; release of latent heat of growth crystallization is facilitated; the crystal yield of crystal growth is favorably improved; a sealing structure with a reusable quartz tubeand a stainless steel flange is adopted; a 1-atm air charging and discharging automatic valve is additionally arranged on an air channel pipeline, so that the balance of inner air pressure and outerair pressure of the quartz tube can be effectively guaranteed, and the influence of deformation of the quartz tube on reuse is avoided. A VGF method and a VB method are used for growing crystals; whenthe crystals are grown by the VB method, the sunken degree of a concave solid-liquid interface of the VGF growth method can be improved, so that the crystal yield is favorably improved. The single-crystal furnace and the growth method are used for growing the gallium arsenide single crystals with maximum size of 8 inches; meanwhile, the quartz tube can be reused, so that the production cost can be reduced; a CO atmosphere doping manner also can be used for controlling the resistivity and the axial resistivity uniformity of semi-insulating gallium arsenide.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

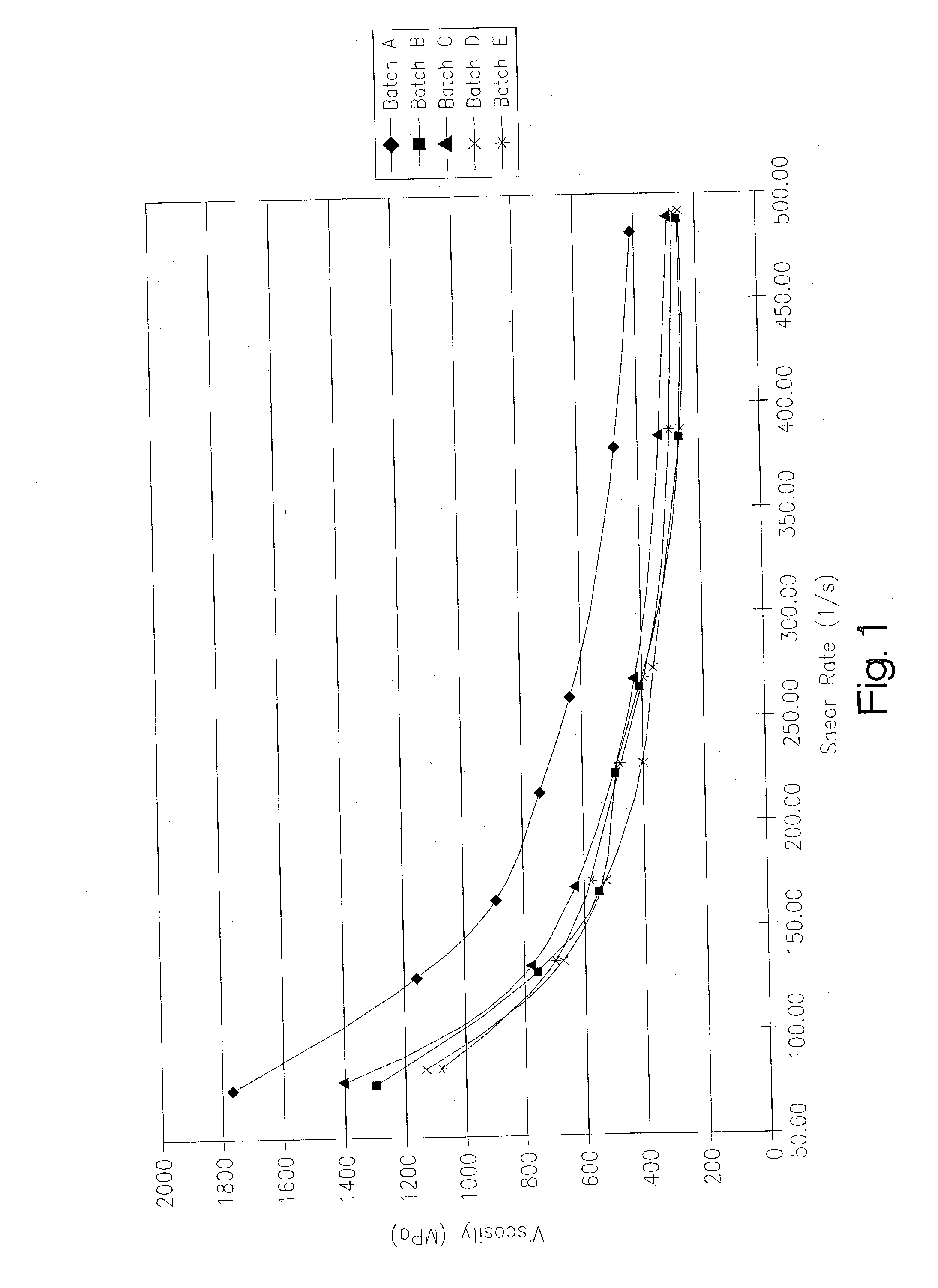

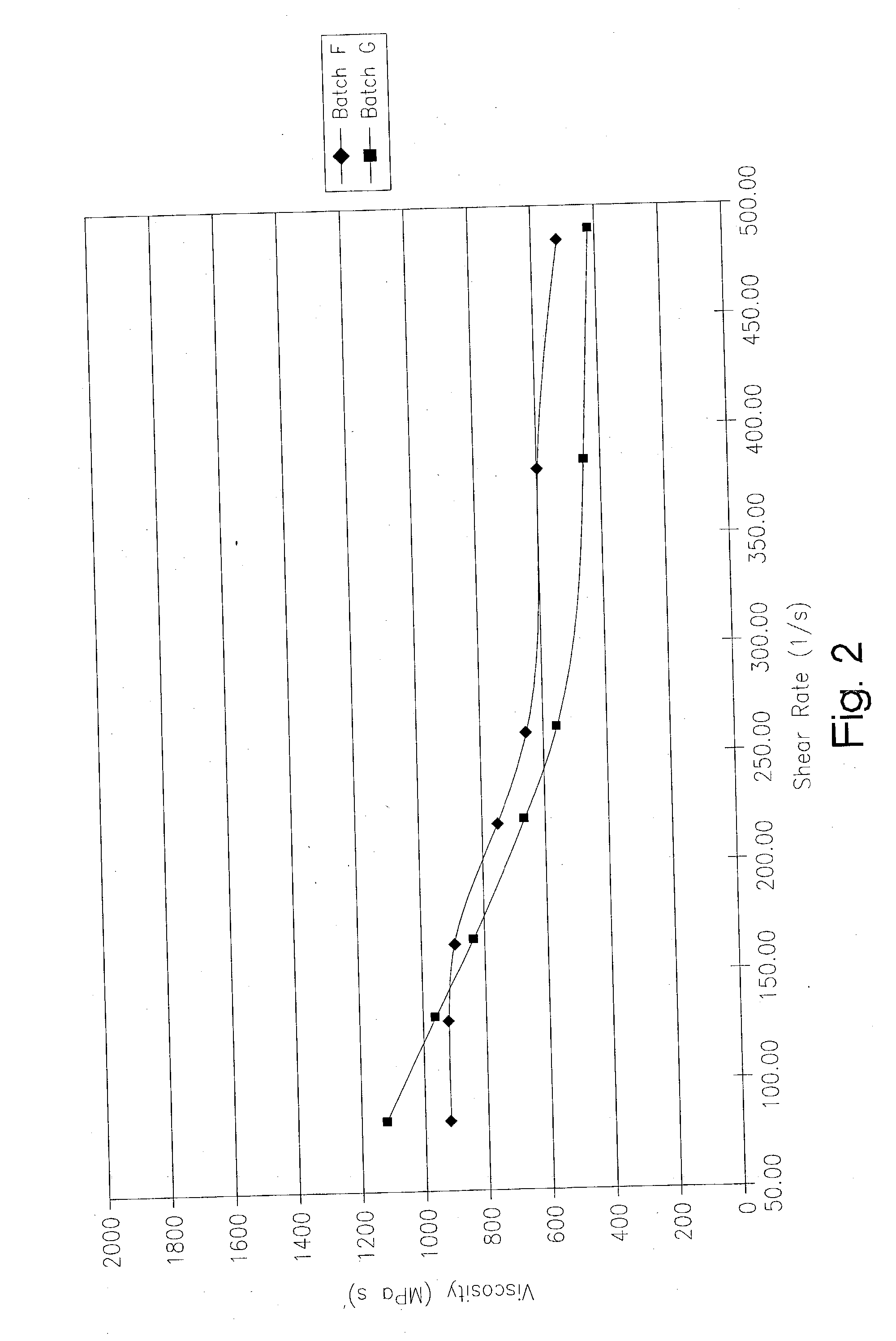

Injection-moldable, thermoplastic polyurethane elastomer

InactiveUS20030122282A1Reduces intermolecular hydrogen bondingPromote sportsCoatingsThermoplastic polyurethaneDiol

A thermoplastic polyurethane (TPU) elastomer and p-phenylene diisocyanate (PPDI) / polycaprolactone-based composition therefor having a unique chain extender combination for improved injection moldability. The elastomer is formed as the reaction product of: (A) from about 60 to 80% by weight of a hydroxyl-terminated poly(caprolactone) diol; (B) from about 17 to 22% by weight of a p-phenylene diisocyanate; (C) from about 3 to 10% by weight of a first hydroxyl-functional chain extender; and (D) less than about 2% by weight of a second hydroxyl-functional chain extender different from the first chain extender, the second chain extender being selected as effective to modify the crystallinity of the elastomer.

Owner:PARKER INTANGIBLES LLC

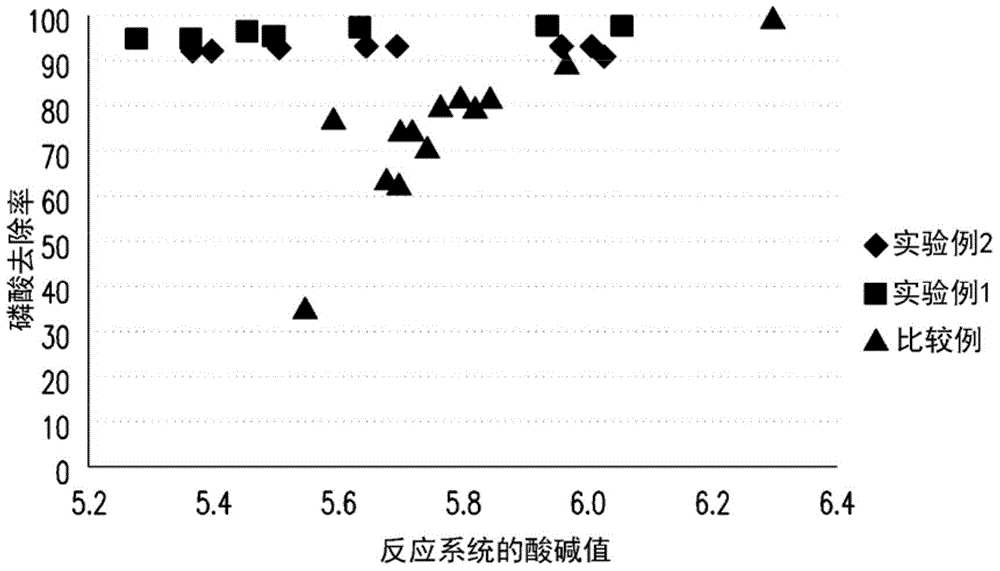

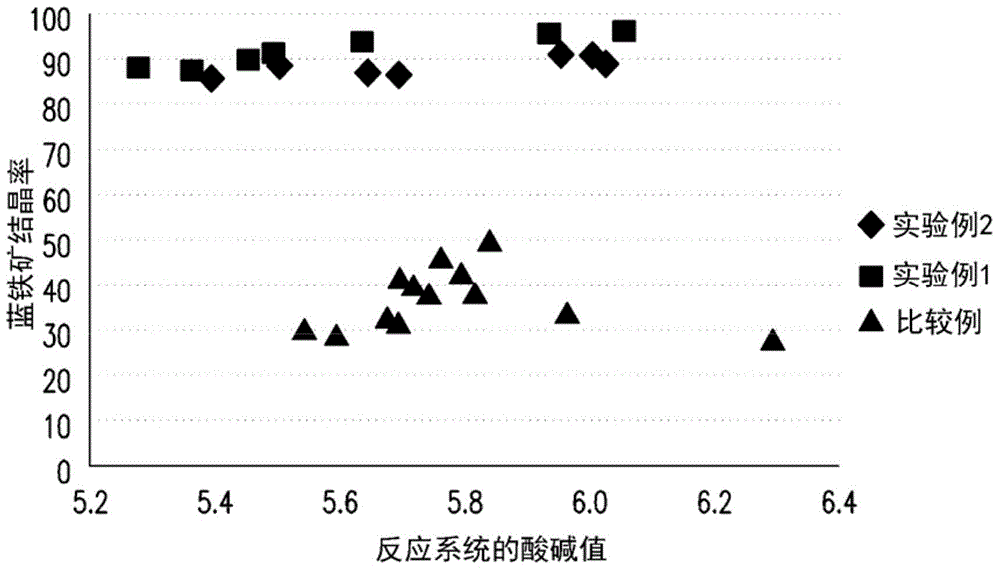

Phosphorus removing method from waste water and preparation method of ferrous phosphate

InactiveCN104445555AHigh purityIncrease crystallization rateWater treatment parameter controlWater contaminantsPhosphate ionFluidized bed

The invention provides a phosphorus removing method from waste water. The method includes following steps: providing a solution containing phosphate anion; mixing a solution containing ferrous ions and the solution containing the phosphate ion and performing fluidized bed crystallization to obtian a ferrous phosphate precipitation, wherein a pH value of the fluidized bed crystallization is 5-6 and a molar ratio of the ferrous ion to the phosphate ion is 1.5-2.5 and a volume ratio of the solution containing ferrous ions to the solution containing the phosphate ion is 10-20; and removing the ferrous phosphate precipitation. The invention also provides a preparation method of ferrous phosphate. By means of the phosphorus removing method, damage of the waste water to environment can be reduced and meanwhile economic benefit is achieved. By means of the preparation method of the ferrous phosphate, the ferrous phosphate being low in water content, being high in purity and being high in crystallization rate can be prepared.

Owner:AU OPTRONICS CORP +1

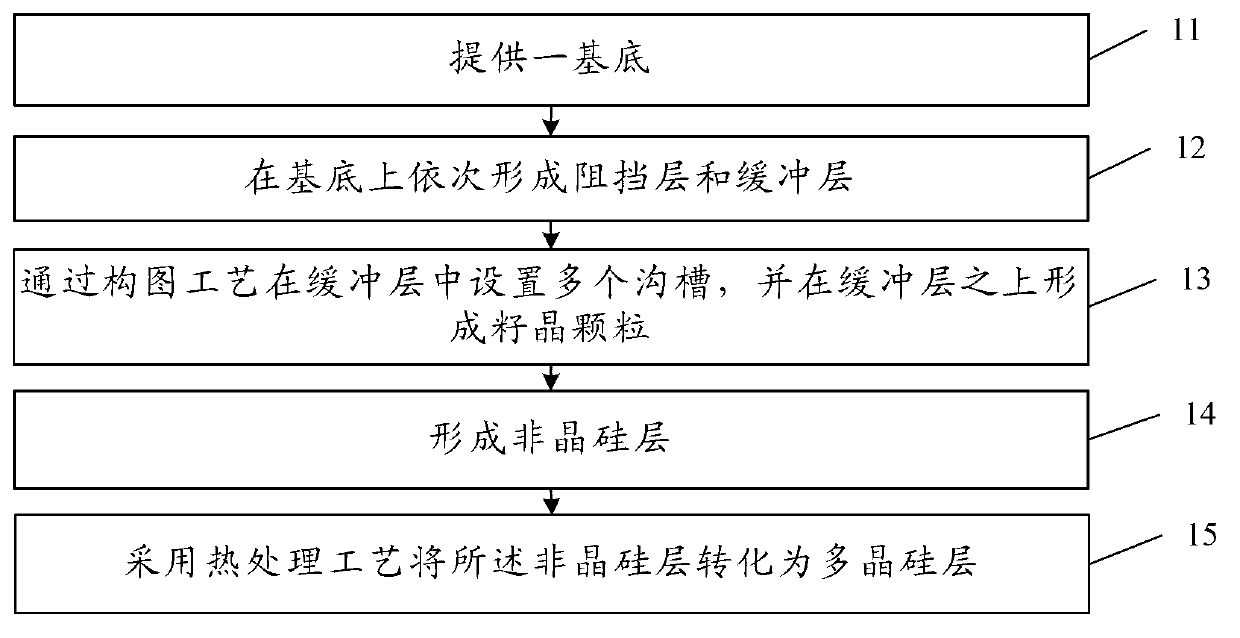

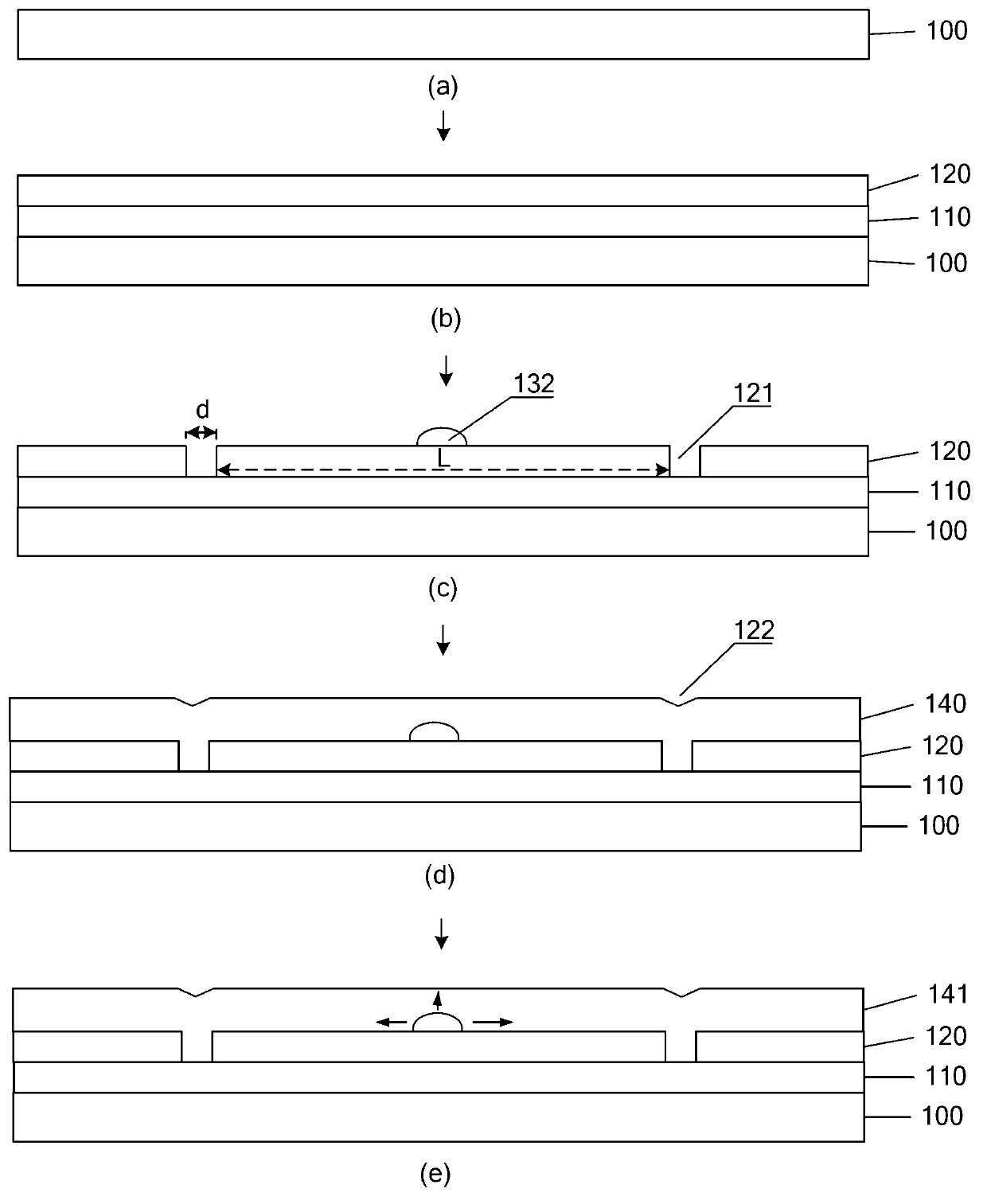

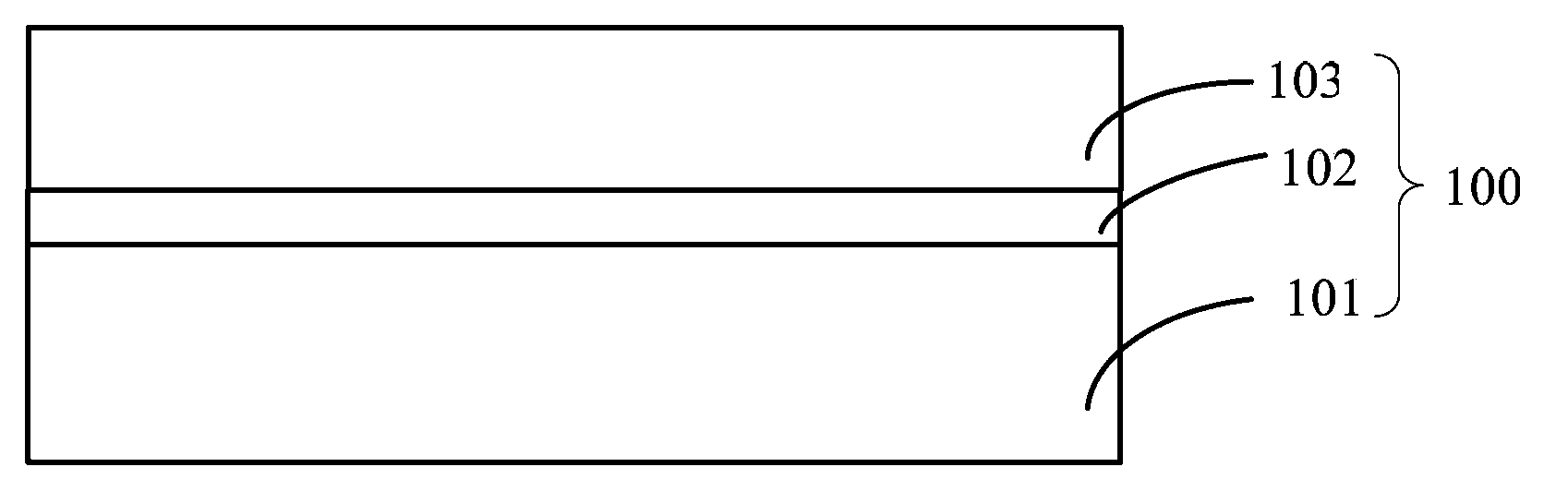

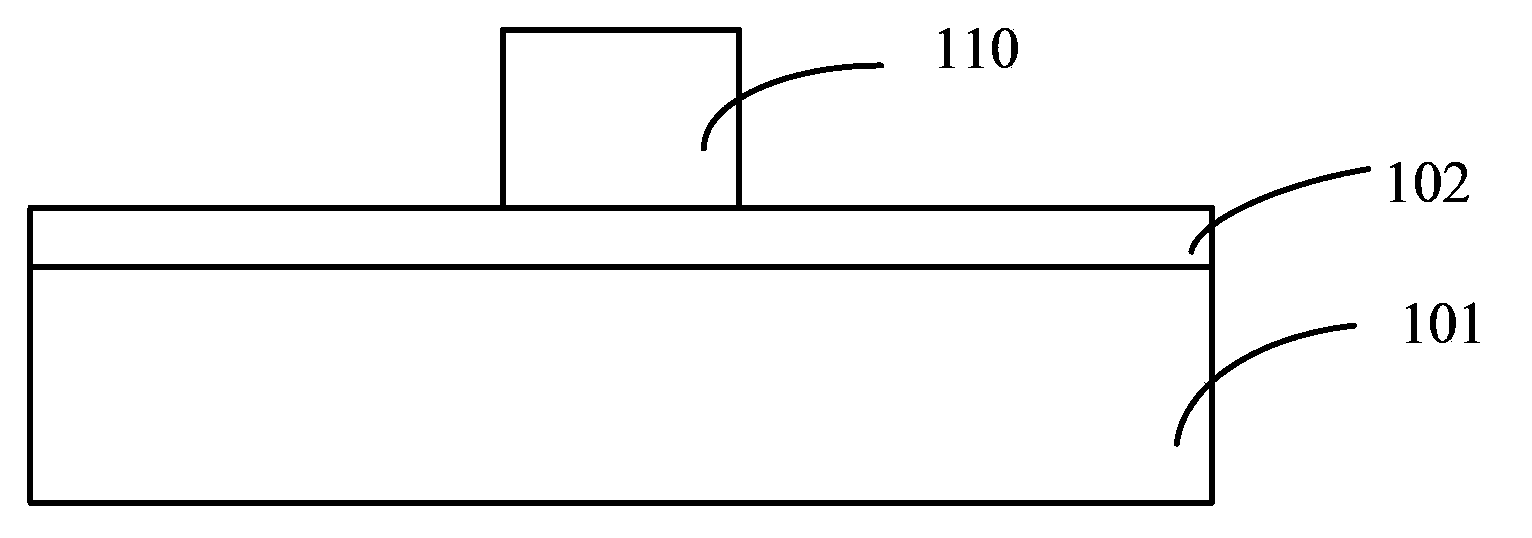

Manufacturing method of polycrystalline silicon layer and polycrystalline silicon thin film transistor and manufacturing method thereof

ActiveCN103219228AIncrease crystallization rateUniform grainTransistorSolid-state devicesAmorphous siliconComposition process

The invention discloses a manufacturing method of a polycrystalline silicon layer and a polycrystalline silicon thin film transistor and a manufacturing method thereof, and relates to the field of displaying. According to the manufacturing methods, a crystallization rate of a formed polycrystalline silicon layer is high, crystalline grains are uniform, crystal boundary defects are little, thus electrics properties of the polycrystalline silicon thin film transistor can be improved, and reliability of the polycrystalline silicon thin film transistor is improved. The manufacturing method of the polycrystalline silicon layer includes the steps that a substrate is provided; a barrier layer and a buffer layer are sequentially formed on the substrate; multiple groves are arranged in the buffer layer through a picture composition process, and seed crystals are formed on the buffer layer; an amorphous silicon layer is formed on the buffer layer provided with the grooves and the seed crystals; and the amorphous silicon layer is converted into the polycrystalline silicon layer through adoption of a heating processing process. The manufacturing method of the polycrystalline silicon layer and the polycrystalline silicon thin film transistor and the manufacturing method of the polycrystalline silicon thin film transistor are used for improving quality of polycrystalline silicon films.

Owner:BOE TECH GRP CO LTD +1

Method for improving axial resistivity uniformity of single crystal with heavily doped Ar

ActiveCN102162124AImprove axial resistivity uniformityReduce concentrationPolycrystalline material growthBy pulling from meltComposition processSingle crystal

The invention relates to a method for improving axial resistivity uniformity of a single crystal with heavily doped Ar. The method comprises the following steps in sequence: (1) regulating furnace pressure along with the growth of a silicon single crystal: gradually decreasing the furnace pressure along with the growth of the single crystal from the maximum 70torr to the minimum 10torr; and (2) regulating Ar gas flow at the same time of executing the step (1): gradually increasing the Ar gas flow to the maximum 80slpm from the minimum 20slpm. The method has the advantages that the axial resistivity uniformity of the single crystal with heavily dope Ar is improved, wherein (rhomax-rhomin) / rhomin is smaller than 28%; the concentration of the doping agent Ar of a diffusion layer is reduced; the probability of the occurrence of a composition process is decreased; and the crystal forming rate is improved.

Owner:内蒙古中环领先半导体材料有限公司 +1

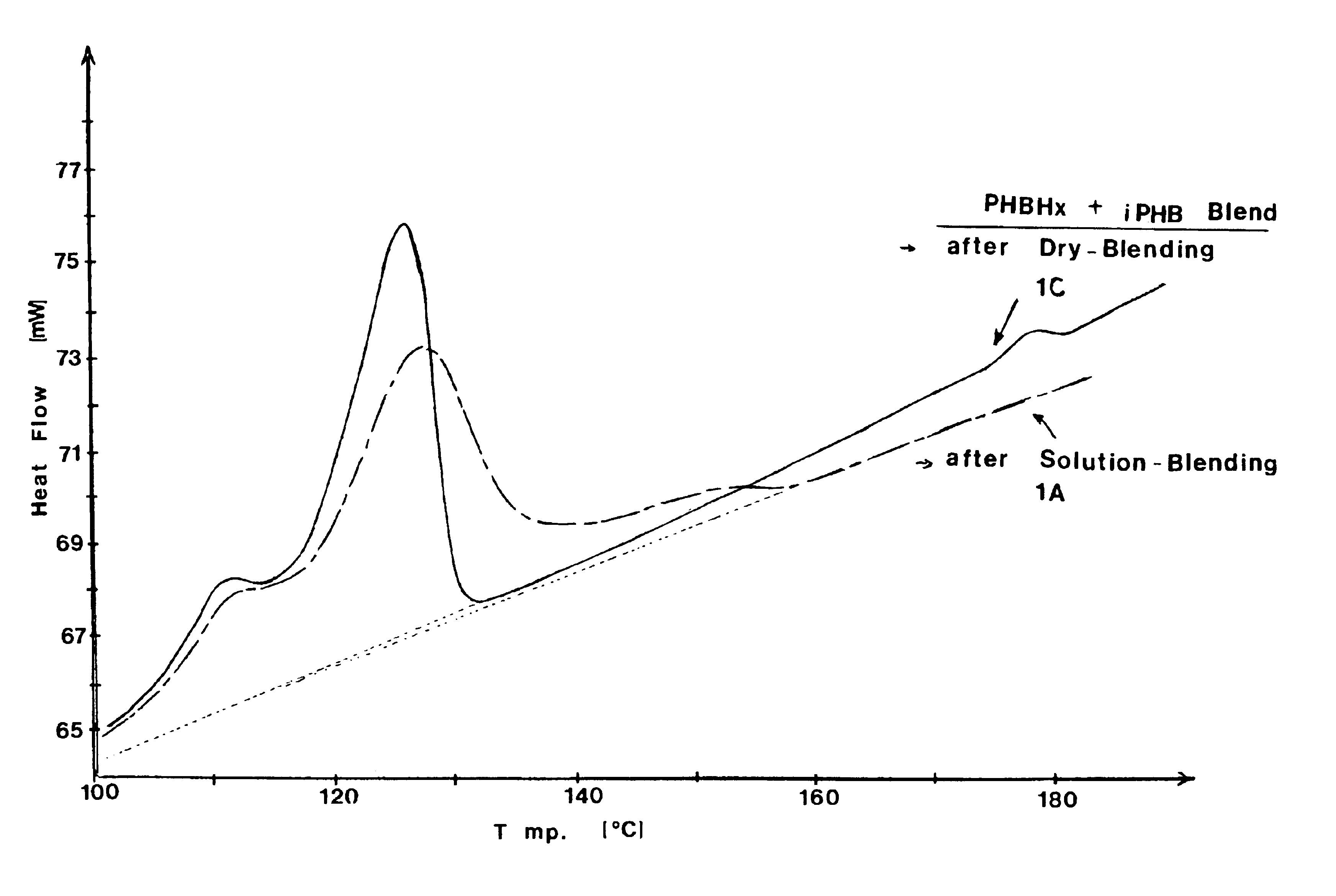

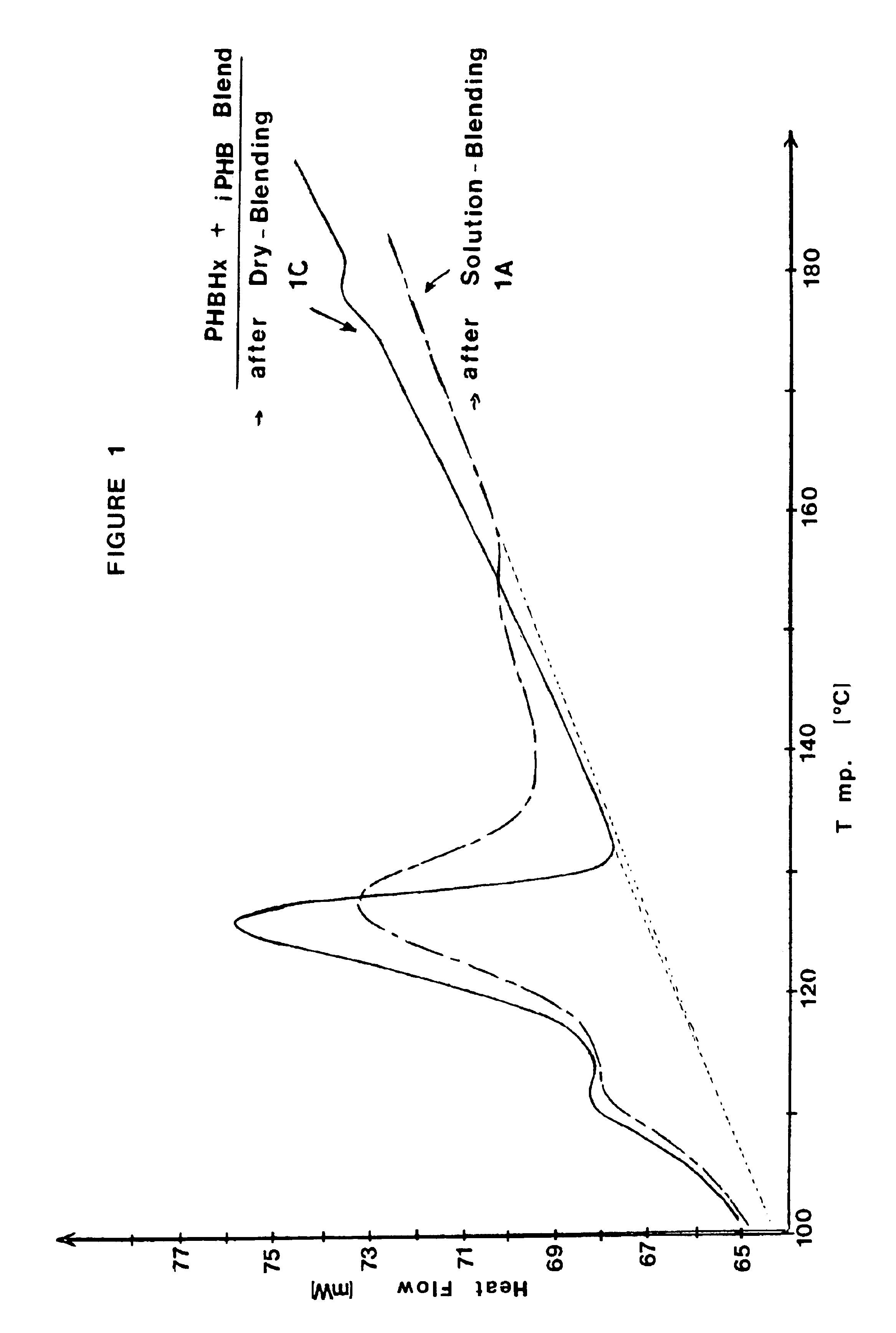

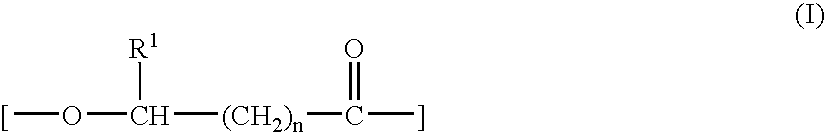

Method for making biodegradable polyhydroxyalkanoate copolymers having improved crystallization properties

InactiveUS6838037B2Extended processing methodIncrease ratingsElectric/magnetic/electromagnetic heatingPolymer scienceHydroxy group

Methods for enhancing the rate of a first biodegradable polyhydroxyalkanoate having a copolymer, or a blend thereof, of at least two randomly repeating monomer units, and has a melting point Tm1, by solution blending or melt blending the first biodegradable polyhydroxyalkanoate with a second crystallizable biodegradable polyhydroxyalkanoate homopolymer or copolymer, which has at least one randomly repeating monomer unit and a melting point Tm2, wherein Tm2 is at least about 20□C. greater than Tm1. Methods for forming shaped articles from the blending of the two polyhydroxyalkanoates.

Owner:DANIMER IPCO LLC

Metal sheet coated with thermoplastic resin and can obtained therefrom

InactiveUS20050100749A1Improve corrosion resistanceLow transparencyLiquid surface applicatorsSynthetic resin layered productsElastomerPolyolefin

A thermoplastic-resin-coated metal sheet in which the thermoplastic resin has been applied to the metal sheet without through an adhesive primer and which, even after having been formed into a can, is excellent in impact resistance at low temperatures and resistance to corrosion by acid contents; and a can obtained from the coated metal sheet. The thermoplastic-resin-coated metal sheet is obtained by coating a metal sheet with a thermoplastic resin composition comprising a blend of a polyester resin with a polyolefin resin or polyolefin elastomer. This metal sheet is formed into a can through drawing / ironing with thickness reduction.

Owner:TOYO KOHAN CO LTD

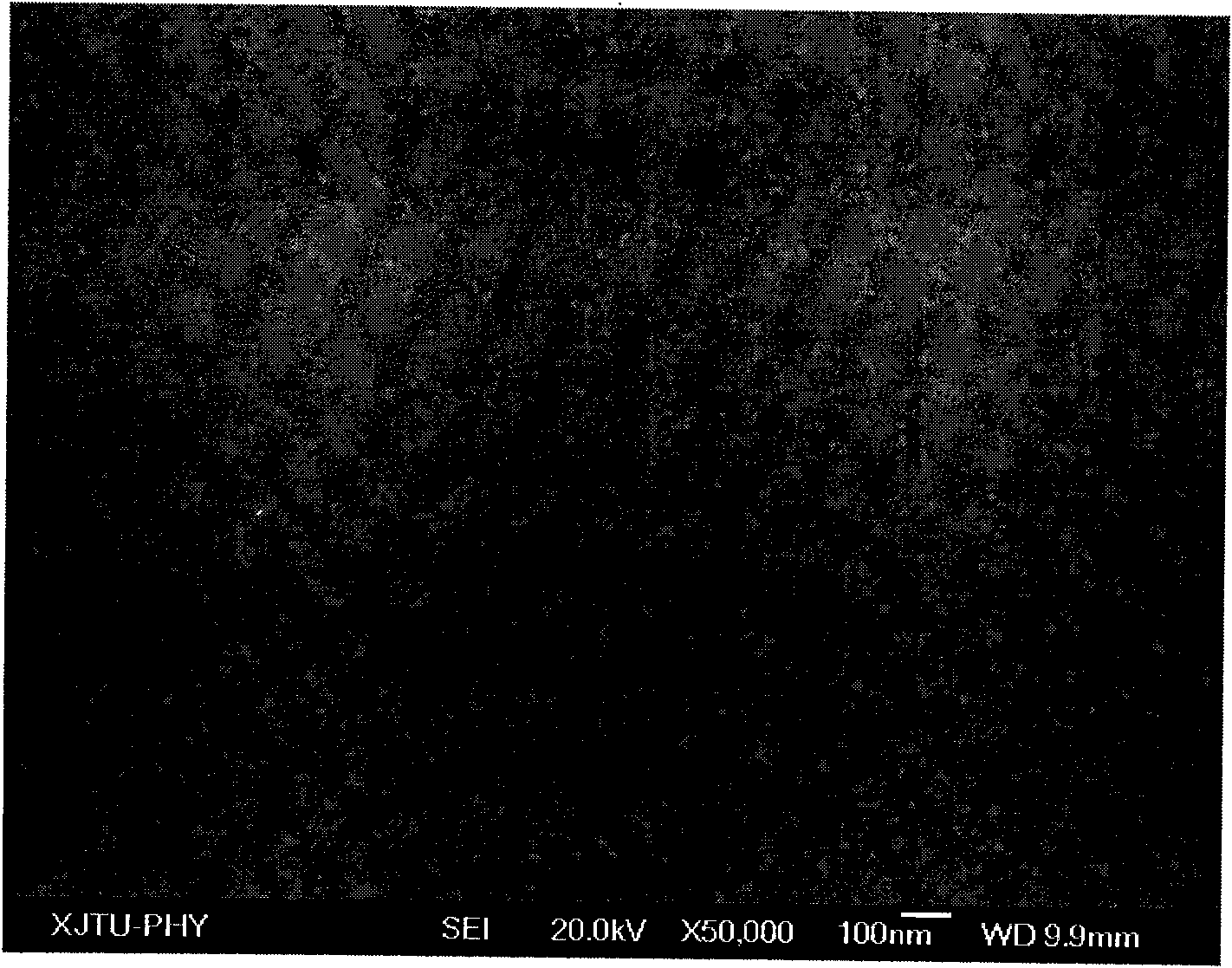

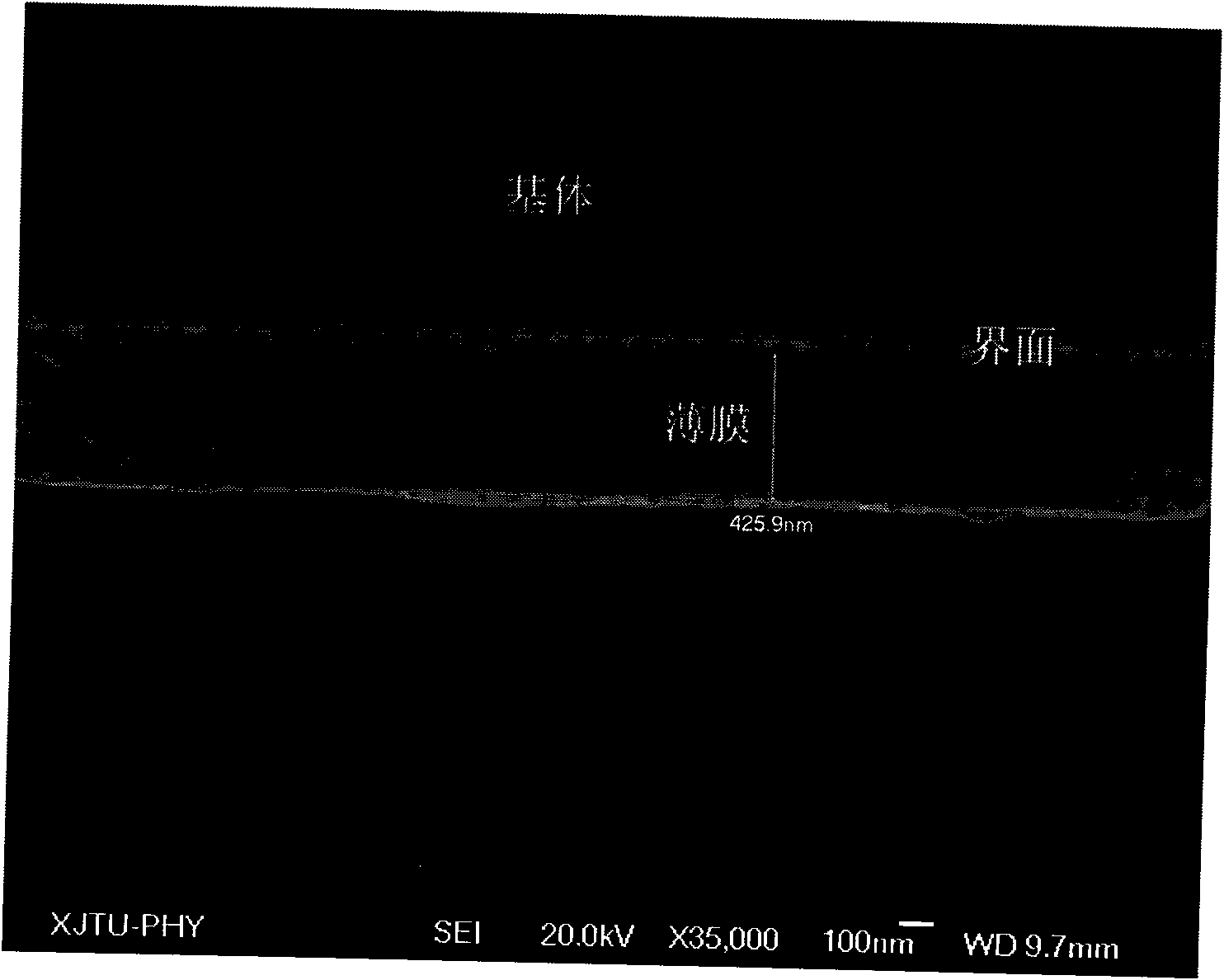

Method for preparing hydrogenated silicon film by utilizing magnetron sputtering

InactiveCN101660131AChange photoelectric propertiesFlat surfaceVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

The invention discloses a method for preparing a hydrogenated silicon film by utilizing magnetron sputtering. The method comprises the following steps, pretreating a substrate and placing the substrate in a magnetron sputtering filming device; utilizing a plane Si target as a source of Si element; adjusting the power of an intermediate frequency pulse power supply to control the sputtering rate ofthe Si target; utilizing high-purity Ar gas as main ionization gas, and ensuring the effective glow discharge process; and adopting high-purity H2 gas as reaction gas, ionizing the H2, and combiningthe H2 with the Si element, forming the hydrogenated silicon film on the surface of the substrate through deposition, and annealing the film at the temperature of 550 DEG C to 950 DEG C in vacuum to obtain the nano-crystalline / non-crystalline composite structure. The invention achieves regulation and control to microstructure of the hydrogenated silicon film by changing introduction proportion ofhydrogen so as to further change the photoelectric properties of the film. The preparation method is simple and reliable, and the prepared hydrogenated silicon film is hopeful to be applied to solar batteries.

Owner:XI AN JIAOTONG UNIV

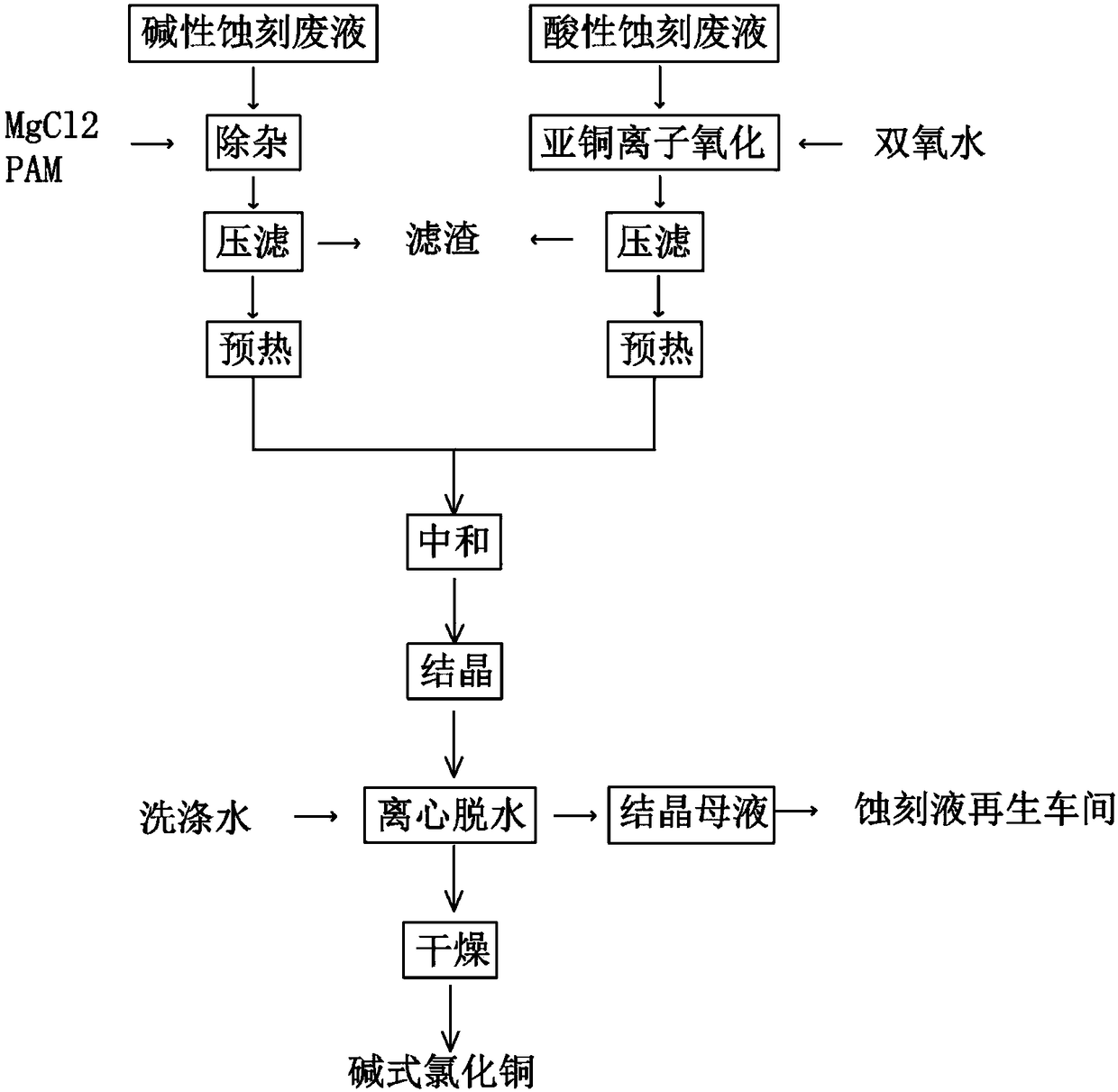

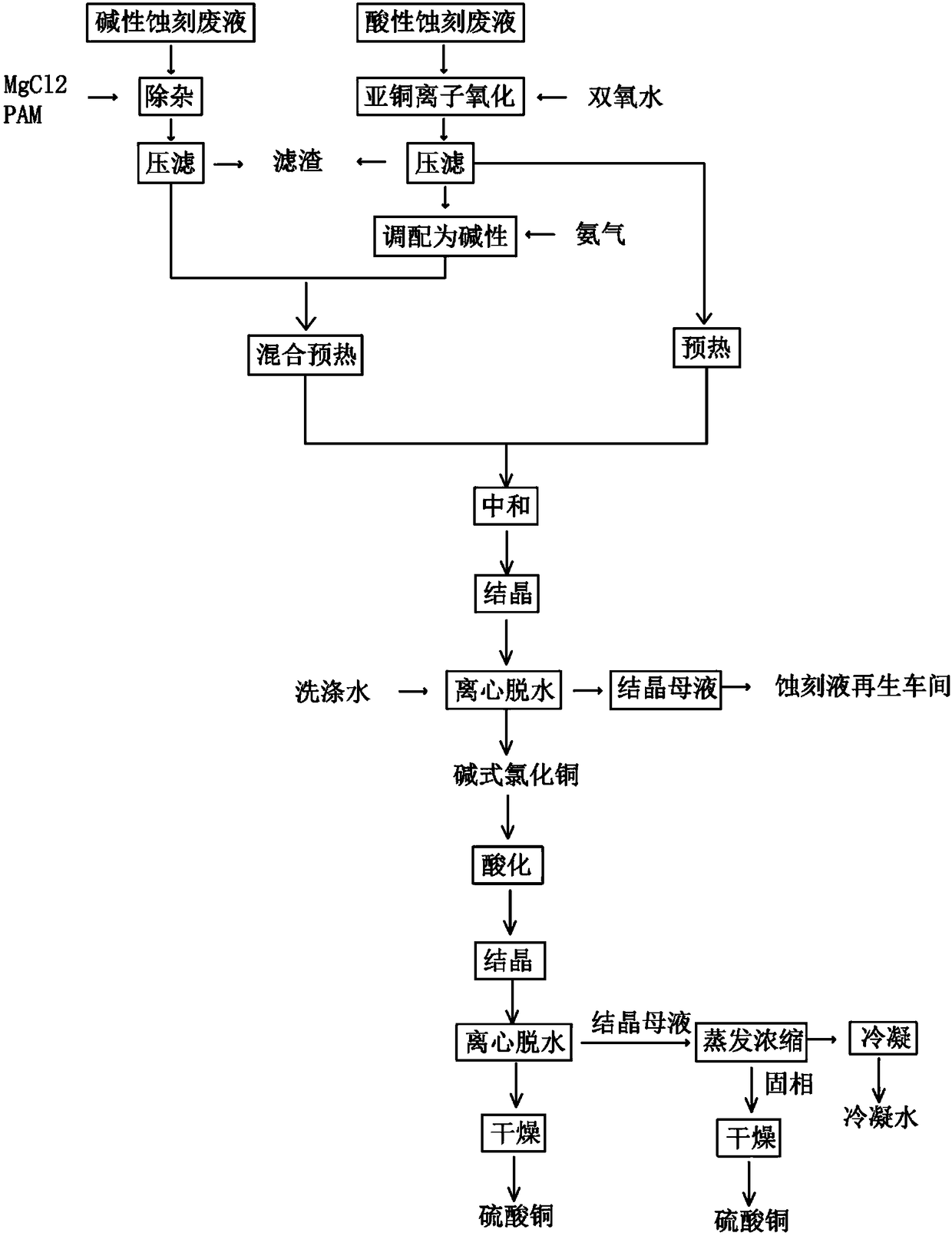

Comprehensive recycling process of copper-containing etching waste solution

InactiveCN108249472AHigh recovery rateEfficient removalCopper chloridesCopper sulfatesCopper chlorideChloride

The invention discloses a recycling process of a copper-containing etching waste solution. The recycling process comprises the following steps: removing mechanical particles and arsenic in an alkalinewaste solution by virtue of magnesium chloride, PAM and a press filtering machine, removing the mechanical particles and oil contaminants in an acid waste solution by virtue of a press filtering machine, neutralizing the acid waste solution and alkaline waste solution to obtain alkaline copper chloride, or acidifying by using sulfuric acid to obtain copper sulfate; and when the alkaline waste solution is insufficient, introducing ammonia gas into the acid waste solution with the mechanical particles and the oil contaminants removed by virtue of the press filtering machine, adjusting the solution to be alkaline, and then performing the neutralization reaction to obtain alkaline copper chloride or copper sulfate. The comprehensive recycling process is simple, low cost, capable of massivelytreating the etching waste solution, and capable of recycling the copper and realizing the safety up-to-standard treatment of the etching waste solution.

Owner:韶关鹏瑞环保科技有限公司

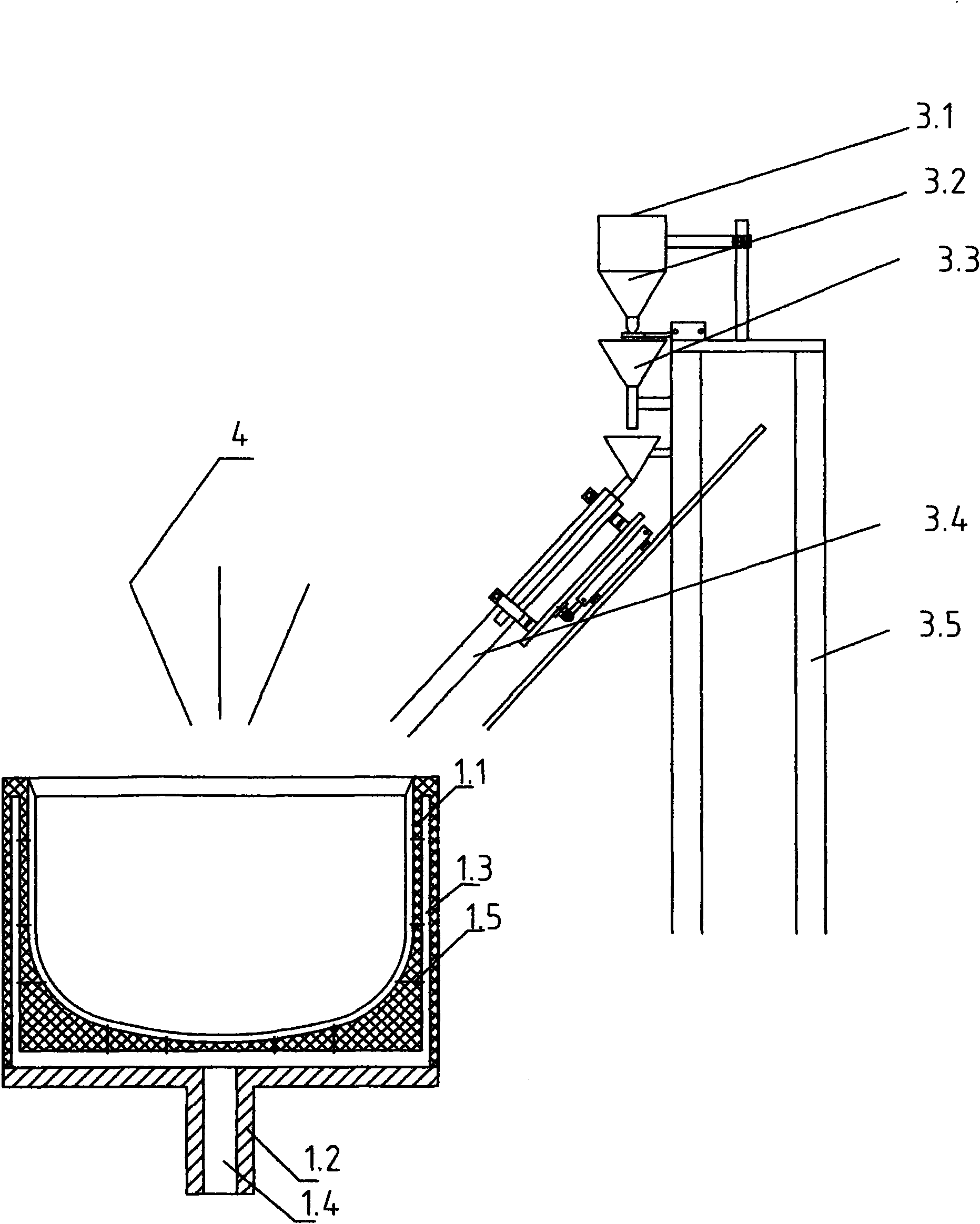

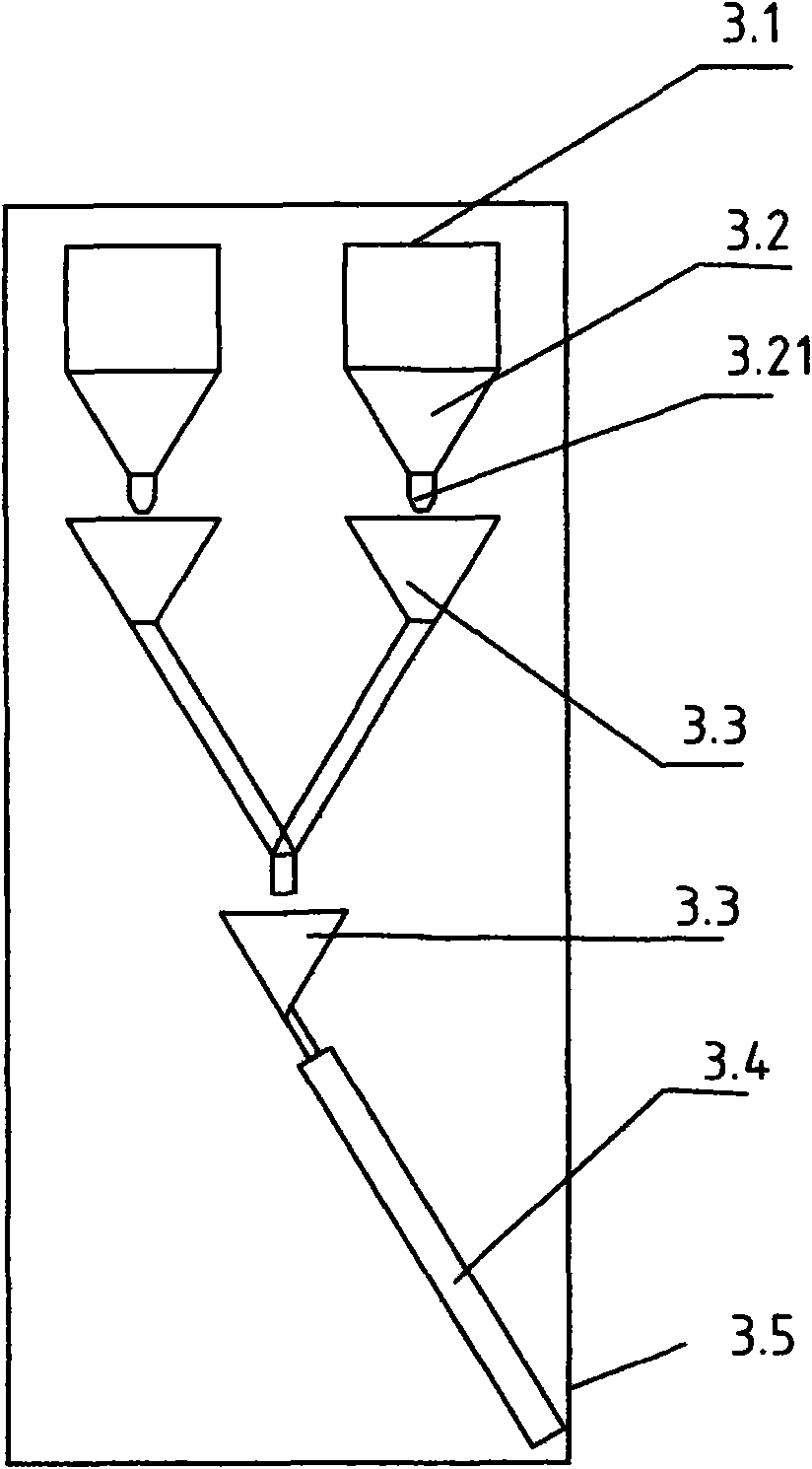

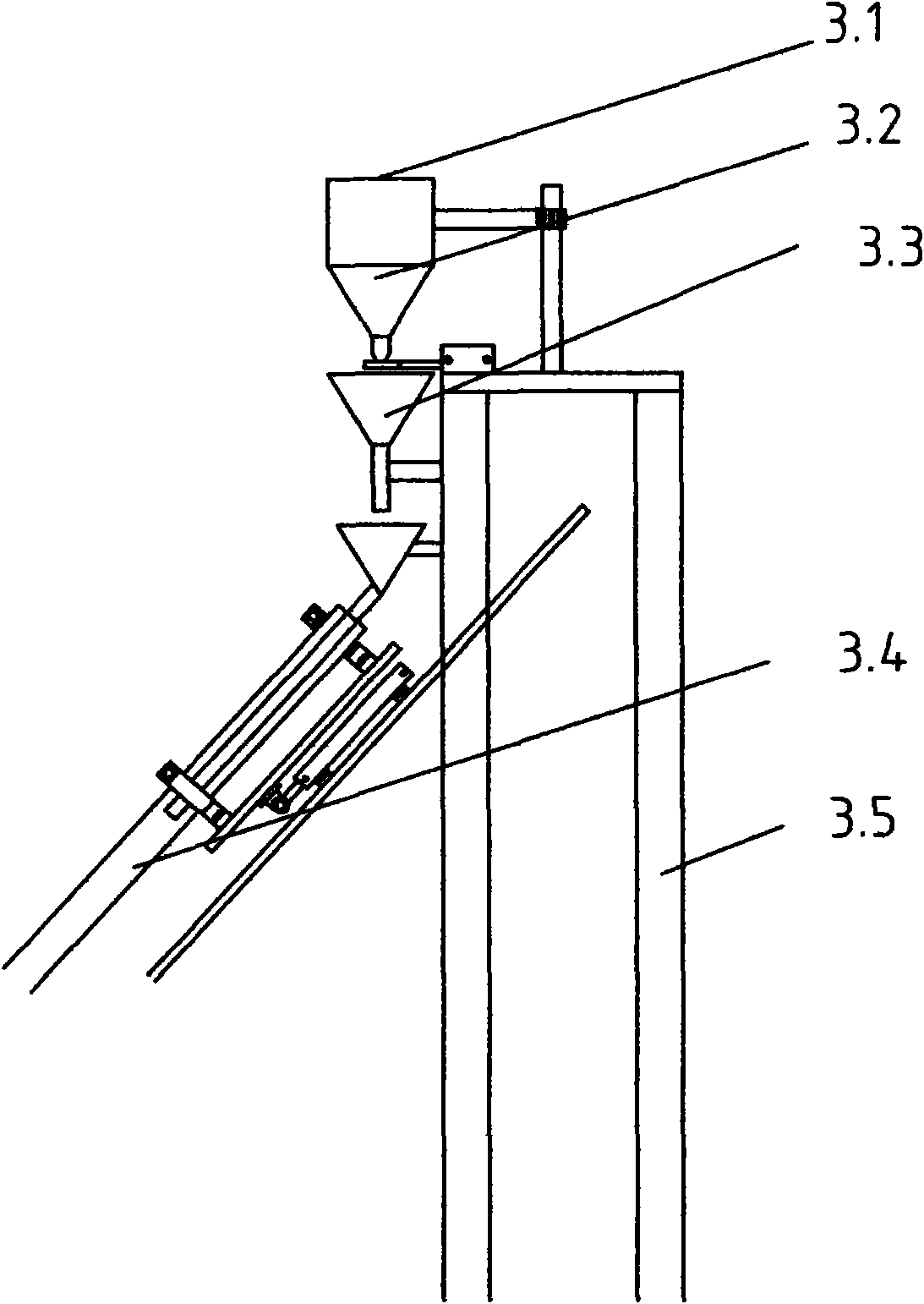

Process for producing arc quartz crucible by vacuum plus coating, equipment, product thereof

InactiveCN101570391AEasy to controlHigh strengthBy pulling from meltGlass shaping apparatusState of artSpray coating

The invention relates to the crucible manufacturing field and is a process for producing an arc quartz crucible by vacuum plus coating, equipment, products thereof. The invention solves the problems that the crucible manufacturing process in the prior art can not solve the operating requirements of long time, high temperature, and high purity of the quartz crucible, a uniform high purity quartz layer can not be formed in the vacuum state by uniform spraying, the layered spraying can not be accurately and timely carried out, and the like; therefore the process and the equipment for producing the arc quartz crucible by vacuum plus coating are provided; the quartz sand is poured into a vacuum mould to shape a prebuilt shape which is put into a founded chamber; a vacuum pump is started and the temperature is controlled, and then the melting and preheating begin; by controlling two hoppers of a double-hopper charging machine, the high-purity quartz sand is sprayed into the quartz crucible in the process of melting, and then mixing spraying coating is sprayed; the vacuum pump is closed during keeping the temperature. The quartz crucible produced by the process and the equipment of the invention has strong non-deformability of long time and exhaustion resistance in high temperature and can be used for long time.

Owner:余姚市启明石英有限公司

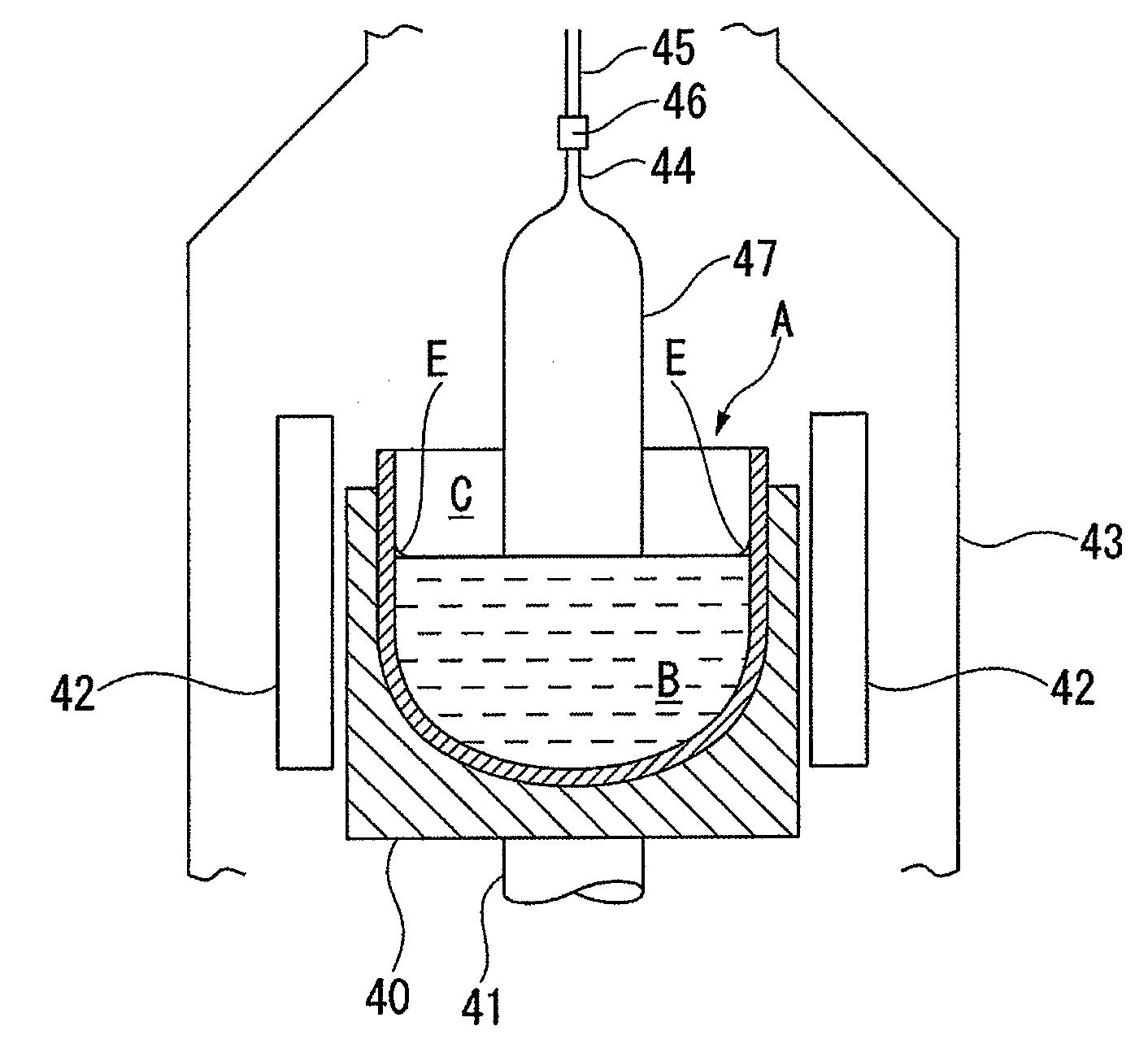

Quartz glass crucible for the pulling up of silicon single crystal

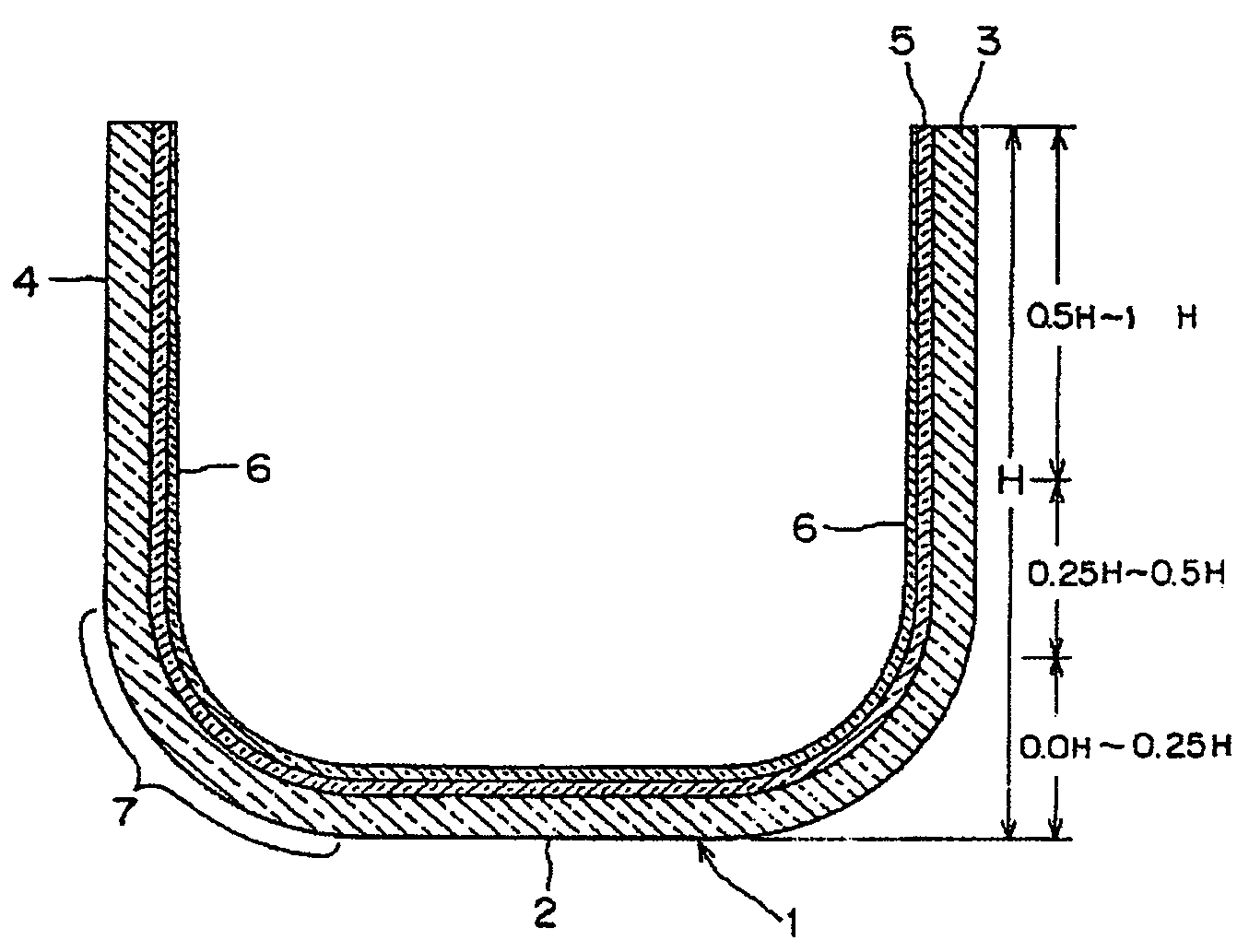

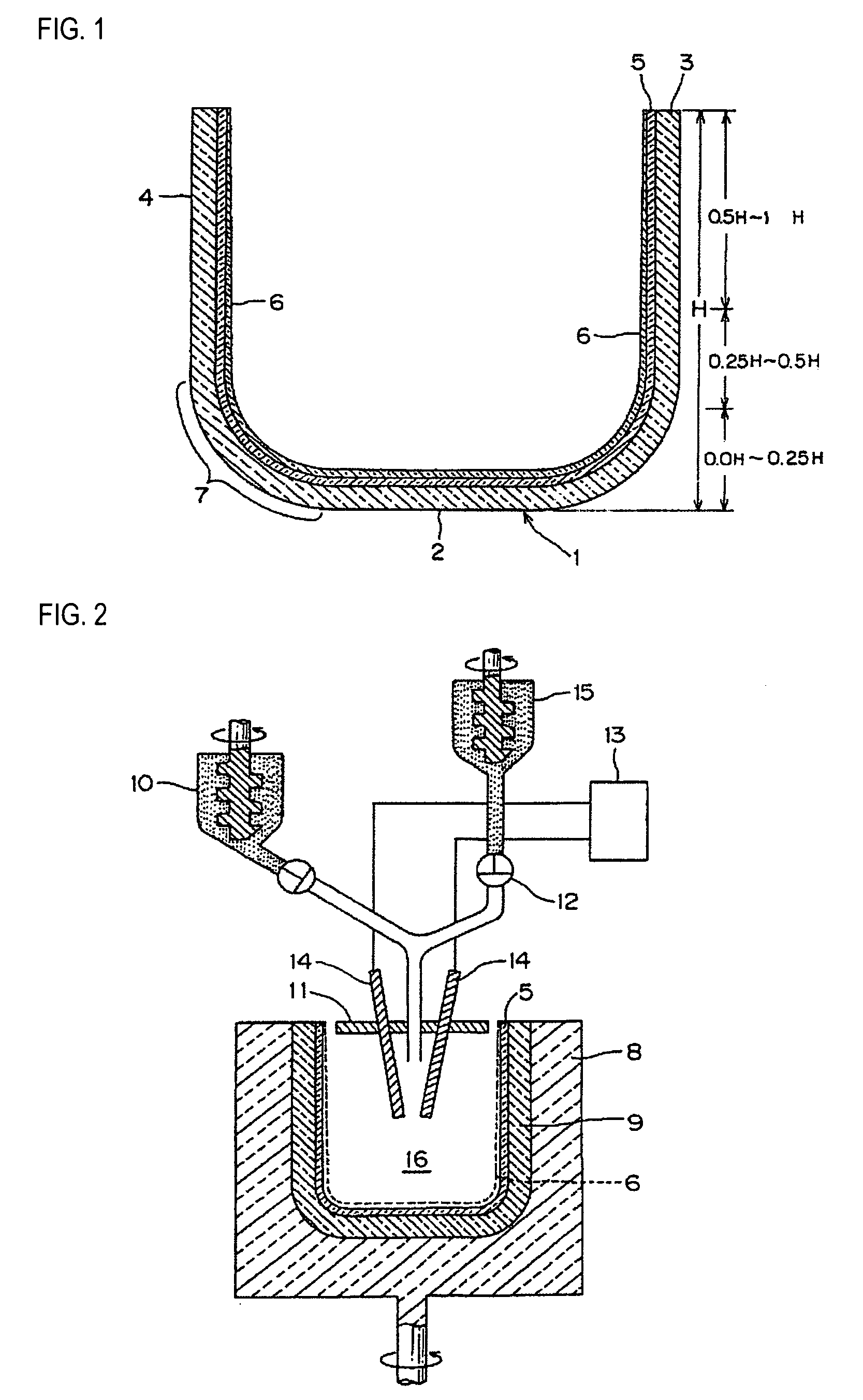

ActiveUS7299658B2Increase crystallization rateReduce thicknessAfter-treatment apparatusBy pulling from meltInter layerCrucible

A quartz glass crucible for use in pulling up a silicon single crystal, wherein it has, at least in the curved portion thereof, a three-layer structure comprising a transparent inner layer being composed of a synthetic quartz glass and having a low Al concentration, a transparent or nontransparent intermediate layer being composed of a natural quartz glass or a mixture of natural and synthetic quartz glasses and having a high Al concentration, and a nontransparent outer layer being composed of a natural quartz glass and having an Al concentration higher than that of the intermediate layer. The quartz glass crucible is reduced in the deformation of the transparent inner layer, and allows the suppression of the change in the amount of dissolution of the quartz glass crucible associated with the pull-up of a single crystal and the achievement of the uniform oxygen concentration in the longitudinal direction of a single crystal.

Owner:SHIN ETABU QUARTZ PRODS

Low-trans for confectionery fat compositions

InactiveUS7700146B2Interesting nutritional profileTrend downFatty acid hydrogenationFatty acid esterificationInteresterified fatChain length

Owner:FUJI OIL CO LTD

New stainless steel squeeze tube glass lubricant

ActiveCN102277221AGood protective lubricationLow softening pointMandrelsBase-materialsSpray coatingSteel tube

The invention provides a novel glass lubricant of a stainless steel extruded tube. The lubricant is composed of three glasses of a novel glass formulation including exterior coating powder GW8, interior coating powder GN26 and a glass pad GD19 which are respectively acted on a roller coating or spraying coating phase, a broaching phase and an extrusion phase. Compared with the traditional like products, the lubricant provided by the invention has better protecting and lubricating properties. Through utilizing the product provided by the invention, the surface defects of the stainless steel are fewer and the grinding rate can be obviously reduced.

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV +1

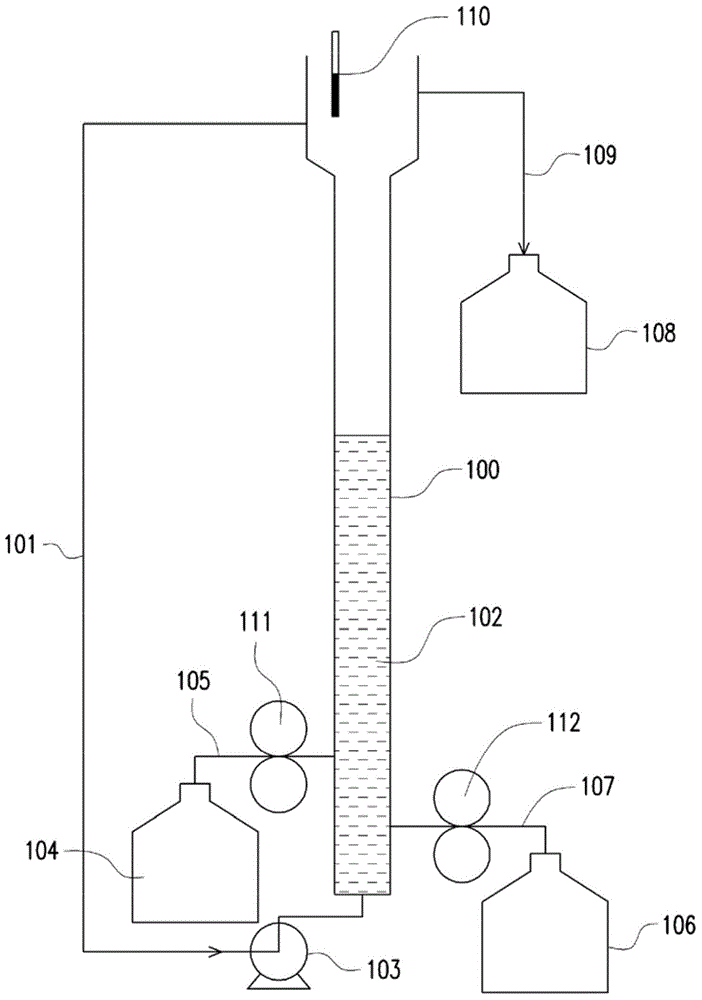

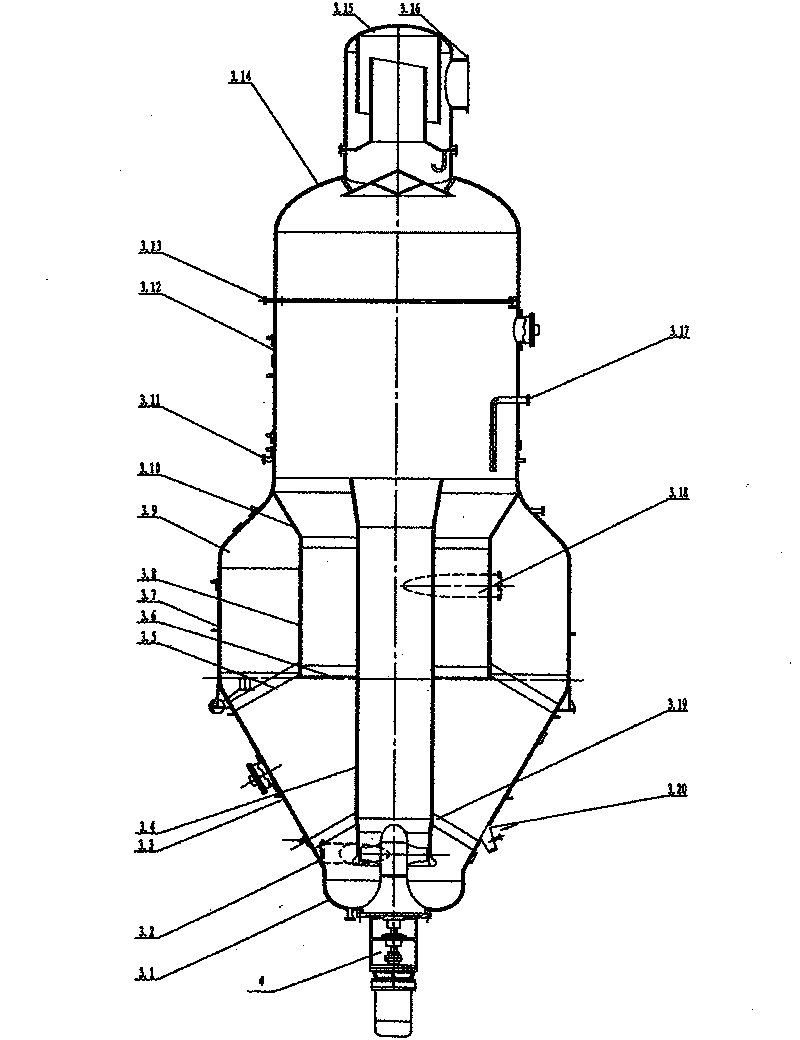

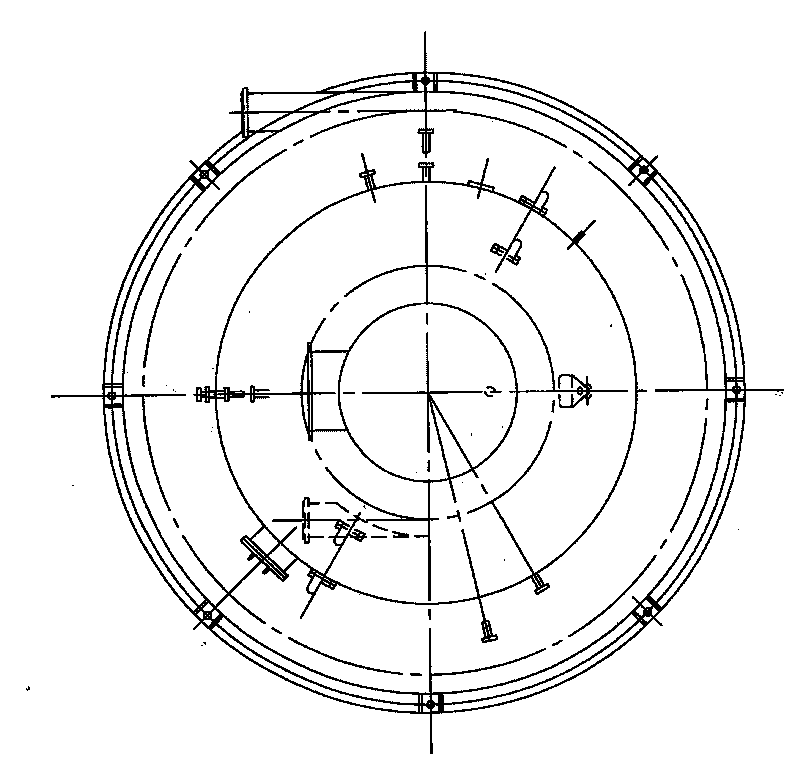

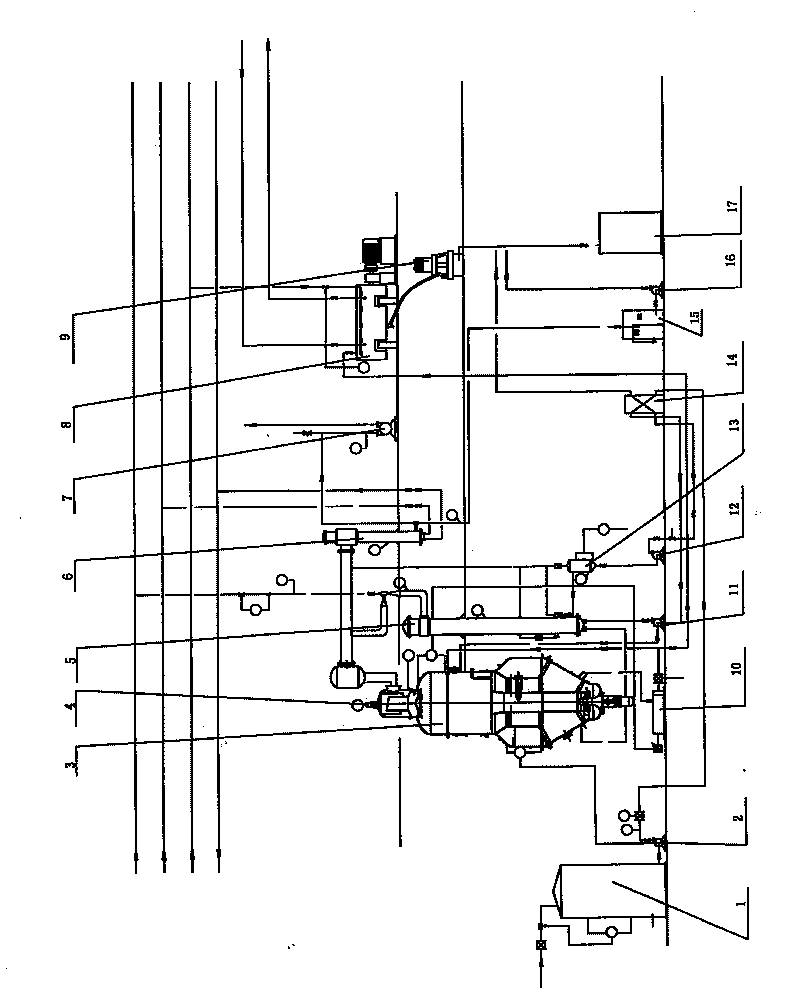

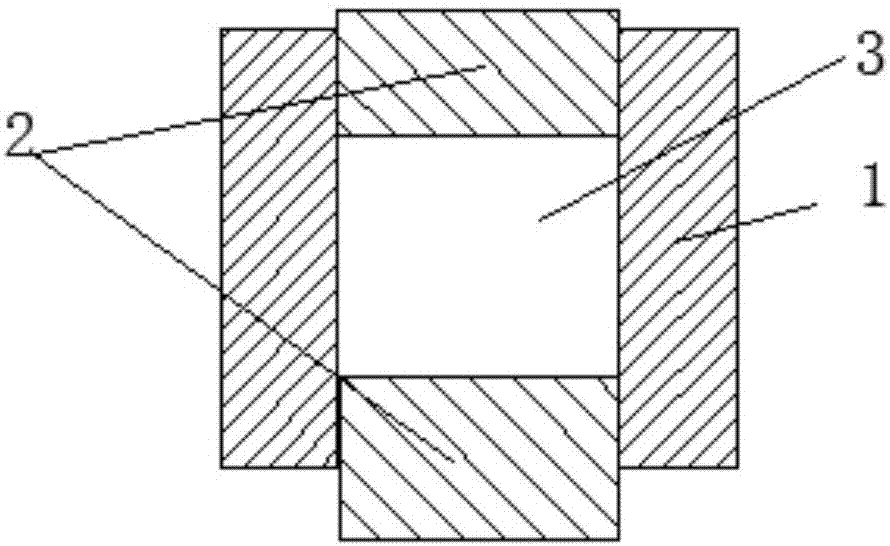

Continuous crystallizer

InactiveCN101732885AIncrease production capacityContinuous operationSolution crystallizationCirculating pumpMixing tank

The invention relates to a continuous crystallizer mainly used for concentrative crystallization in monosidum glutamate production of food industry, which comprises a crystallizer (3), a raw liquid and mother liquid mixing tank (1), a feeding pump (2), a plate type heater (14), an outer circulating pump (11), a heater (5), an inner circulating pump (4) and a discharging pump (10), wherein the raw liquid and mother liquid mixing tank (1) is connected with the feeding pump (2) connected with the plate type heater (14) which is communicated with the outer circulating pump (11), the outer circulating pump (11) is connected with the heater (5) communicated with a circulated flow returning port (3.2) of the crystallizer (3), and an circulated discharging port (3.18) of the crystallizer (3) is communicated with the outer circulating pump (11); the inner circulating pump (4) is arranged at the bottom of the crystallizer (3); and an outlet of the discharging pump (10) is respectively connected with a crystal paste circulating port (3.11) of the crystallizer (3) and a crystallization-assistant slot (8). The continuous crystallizer has the characteristics of low steam consumption, high equipment yield, high degree of the automation and the like.

Owner:江阴丰力生化工程装备有限公司

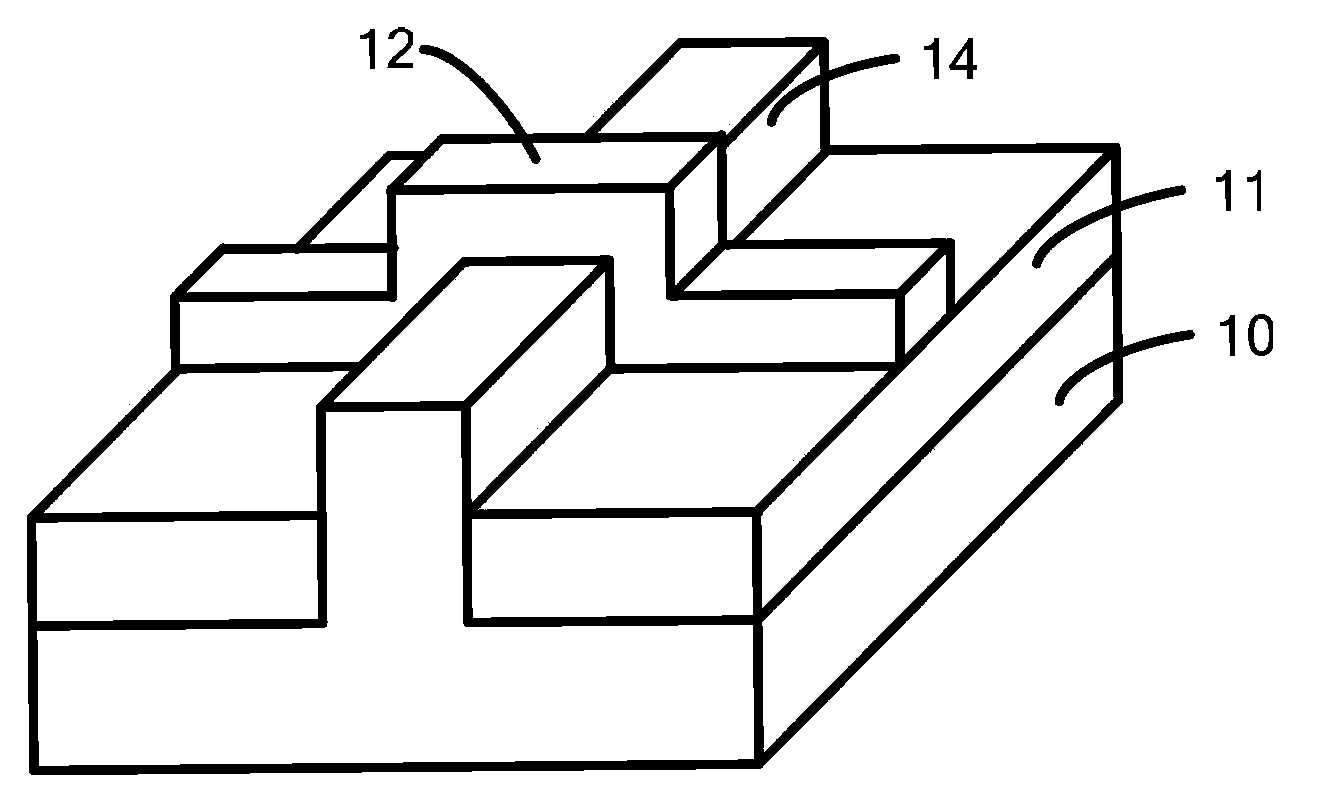

Forming method of fin-type field effect transistor

ActiveCN103855022AIncrease crystallization rateIncrease in sizeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringField-effect transistor

A forming method of a fin-type field effect transistor comprises the steps that a semiconductor substrate is provided; a fin portion is formed on the surface of the semiconductor substrate, wherein the fin portion comprises a channel area located between source and drain areas at the two ends of the fin portion; the source and drain areas of the fin portion are etched to enable the height of the source and drain areas to be reduced; non-crystalline silicon layers are formed on the surfaces of the etched source and drain areas; annealing is conducted on the non-crystalline silicon layers to form polycrystalline silicon layers, wherein the polycrystalline silicon layers generate pull stress to the channel area of the fin portion. By means of the method, the migration rate of electrons in a channel of the fin-type field effect transistor can be increased, and the performance of the N-shaped fin type field effect transistor can be improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

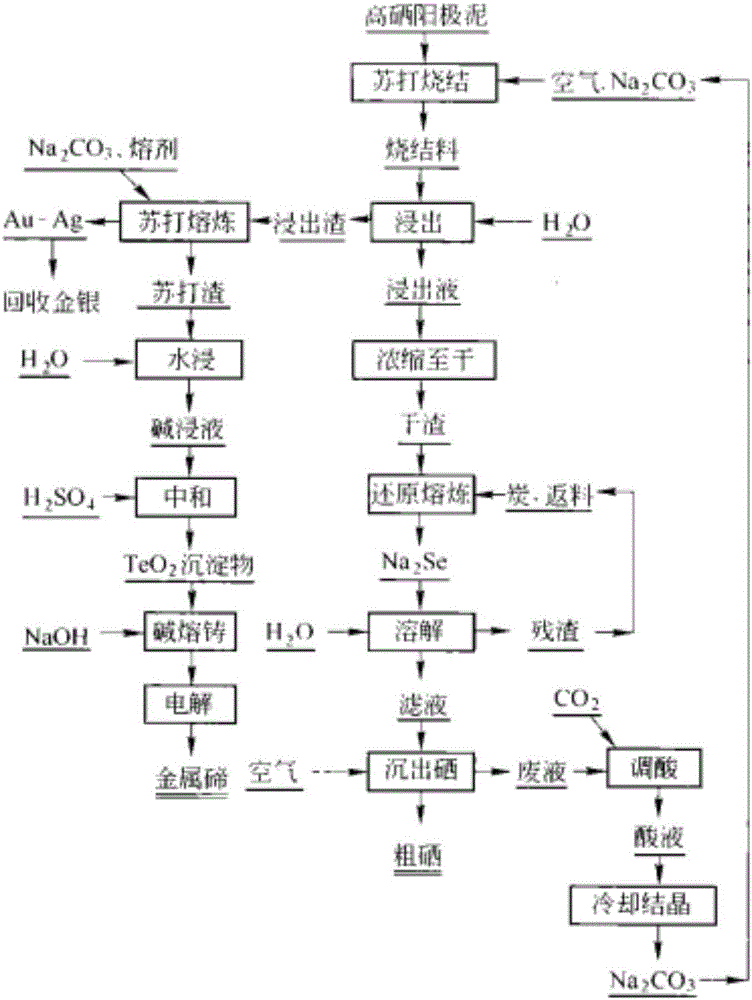

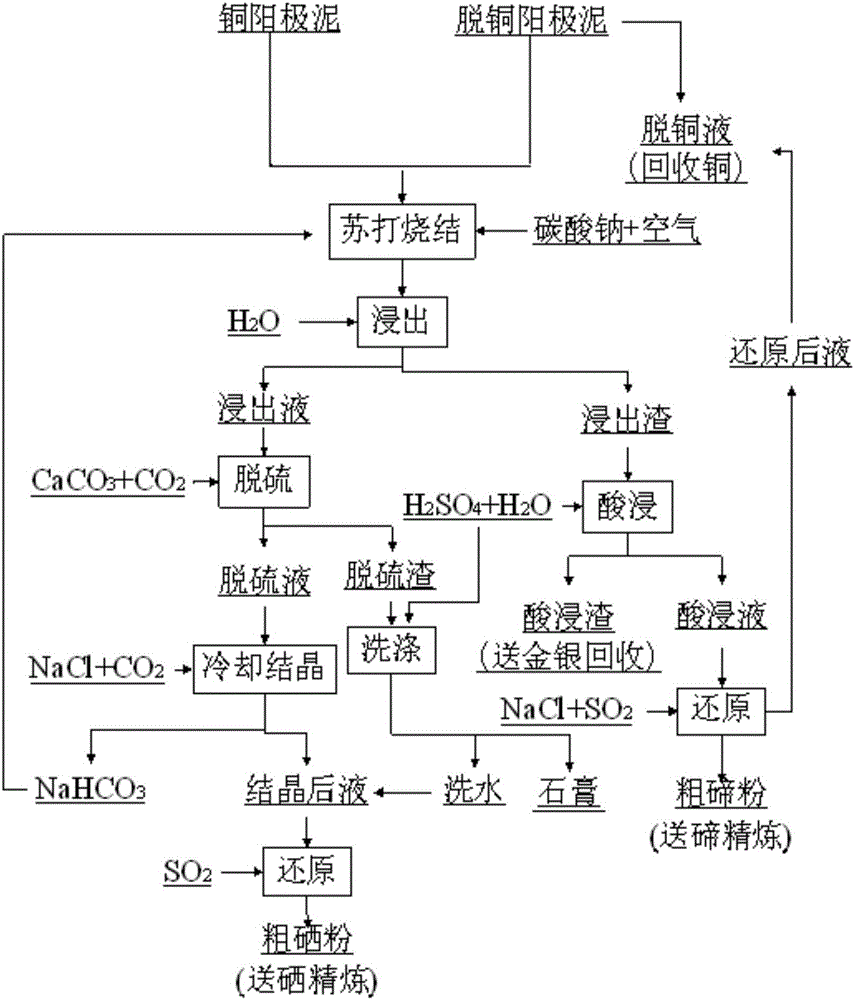

Method for separating and recycling selenium and tellurium from copper anode mud

InactiveCN106477533AReduce pressure on environmental protectionEfficient separation and recoveryElemental selenium/telluriumSulfite saltCopper

Disclosed is a method for separating and recycling selenium and tellurium from copper anode mud. The method includes: performing soda sintering on the copper anode mud or copper-removed anode mud obtained after copper removing is performed on the copper anode mud, adding water into the sintered material for leaching, and filtering to obtain selenium-rich leachate and tellurium-rich leach residues; subjecting the selenium-rich leachate to sodium carbonate separating and recycling, using sodium sulfite or SO2 to revivify and recycle selenium in the selenium-rich leachate or filtrate, filtering to obtain rough selenium powder, and further refining the rough selenium powder to obtain metal selenium; leaching the tellurium-rich leach residues via a sulfuric acid solution, filtering to obtain acid leachate and acid leach residues; subjecting the acid leachate to silver separating through chlorination, using sodium sulfite or SO2 to revivify and precipitate tellurium in the chlorinated acid leachate, filtering to obtain rough tellurium powder, and further refining the rough tellurium powder to obtain metal tellurium. The method has the advantages that by the integral redesign of the process and the mutual cooperation of the steps, the process route for separating and recycling the selenium and the tellurium from the copper anode mud is simplified greatly, environmental protection pressure during a copper anode mud processing process is alleviated greatly, and the method conforms to the development tendency of energy saving and emission reduction technical transformation; the method is simple in process, simple to operate, low in production cost, high in selenium and tellurium recycling rate, good in working environment, suitable for industrialized application, and the like.

Owner:CENT SOUTH UNIV

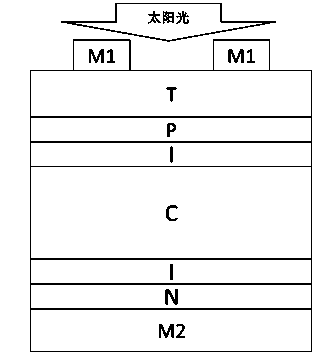

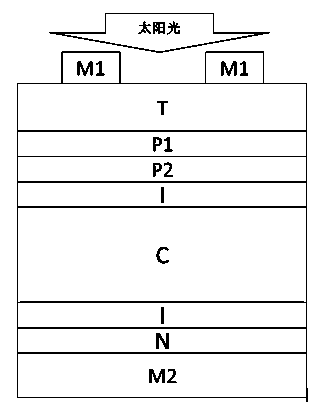

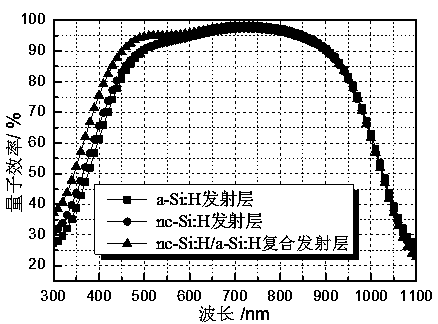

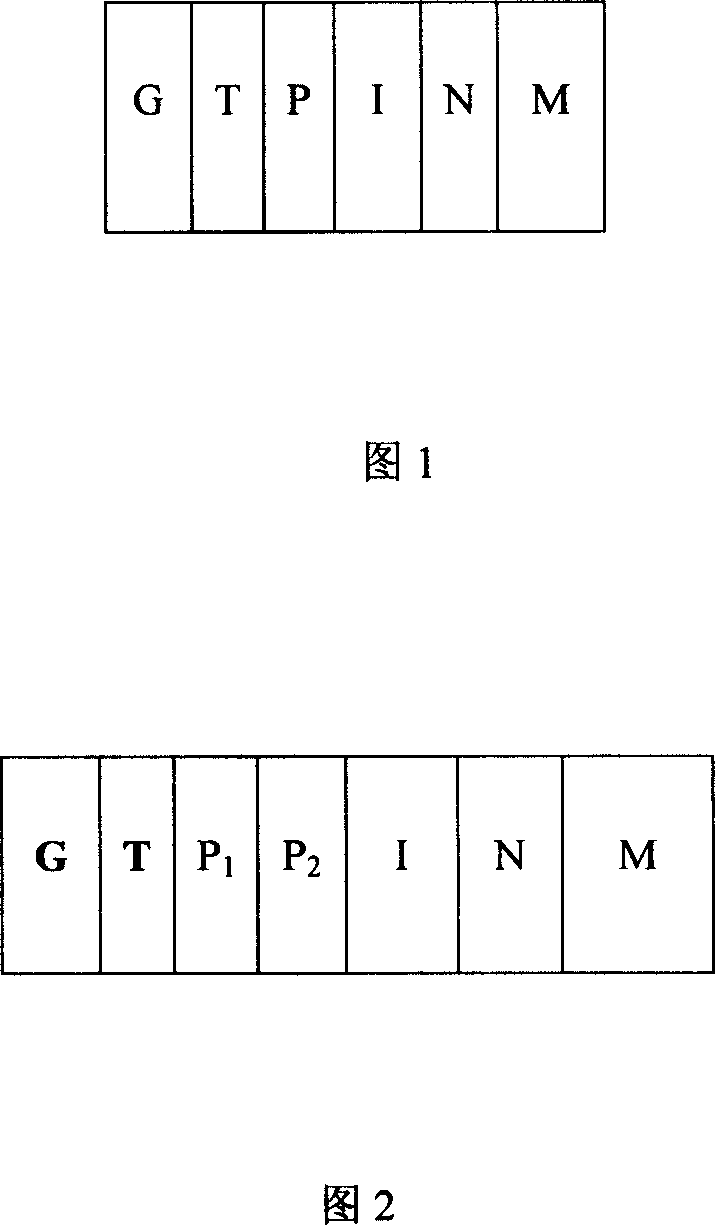

Method for preparing silicon heterojunction solar cell containing composite emission layer

ActiveCN103915523AReduced series resistanceReduce absorptionFinal product manufacturePhotovoltaic energy generationNanocrystalline siliconCrystalline silicon

The invention provides a method for preparing a silicon heterojunction solar cell containing a composite emission layer. The method includes the steps that an amorphous silicon back field N is deposited on one face of a substrate C on which a double-faced intrinsic amorphous silicon passivation layer I is deposited, an amorphous silicon layer P2 with the uniform structure is prepared on the face opposite to the amorphous silicon back field N under the conditions that doping concentration, hydrogen dilution and power density are low, a nanocrystalline silicon layer P1 with the uniform structure is prepared under the conditions that the doping concentration, the hydrogen dilution and the power density are improved, and an amorphous silicon / nanocrystalline silicon composite structure formed by the two silicon films serves as the emission layer of the silicon heterojunction solar cell. Materials have the advantages of being high in transmittance and conductivity through the structure, on the basis, the passivation effect of the surface of crystalline silicon can be improved, short wave response and output characteristics of the cell are improved, and the method for preparing the silicon heterojunction solar cell is simple and easy to carry out.

Owner:捷造科技(宁波)有限公司

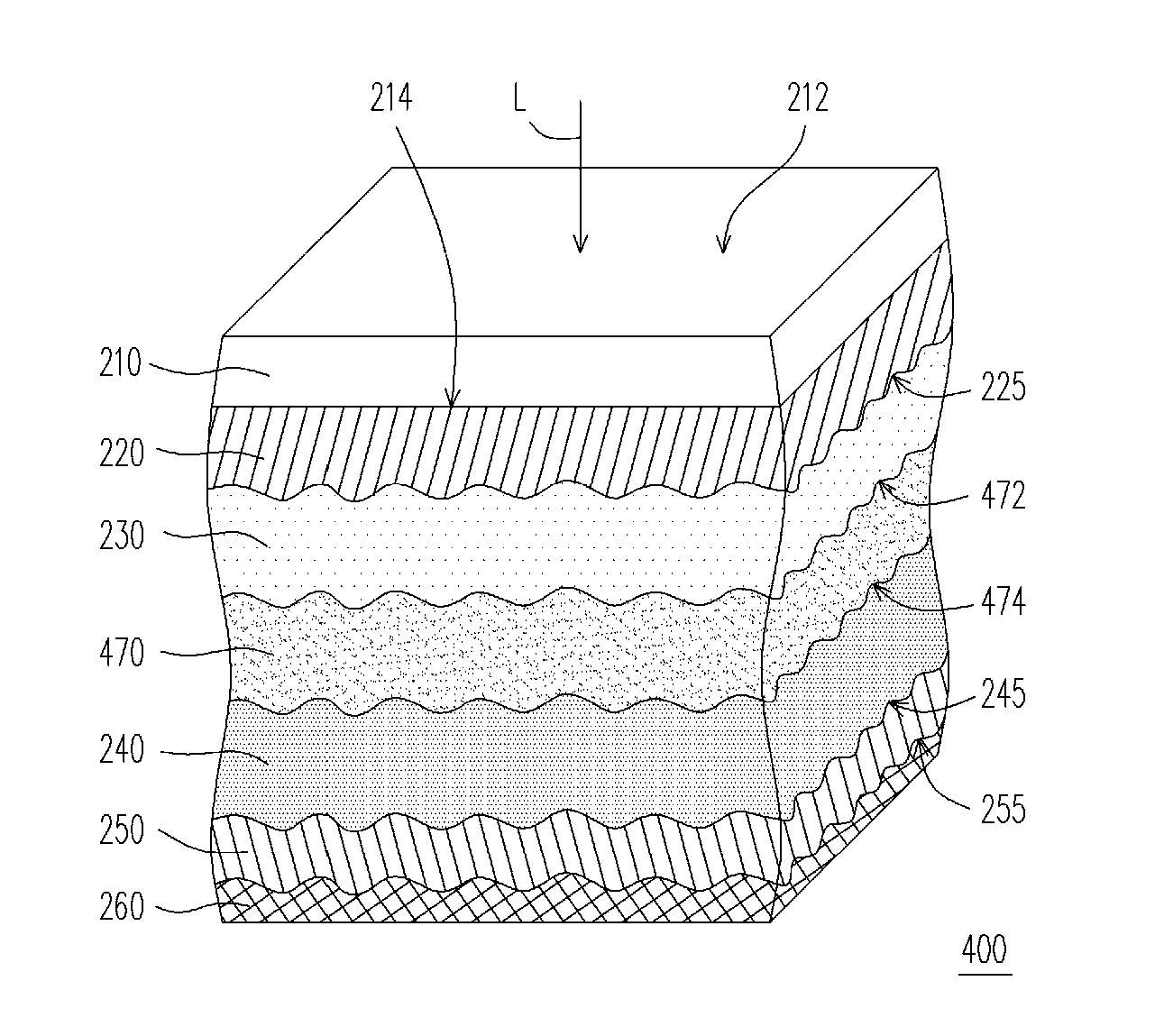

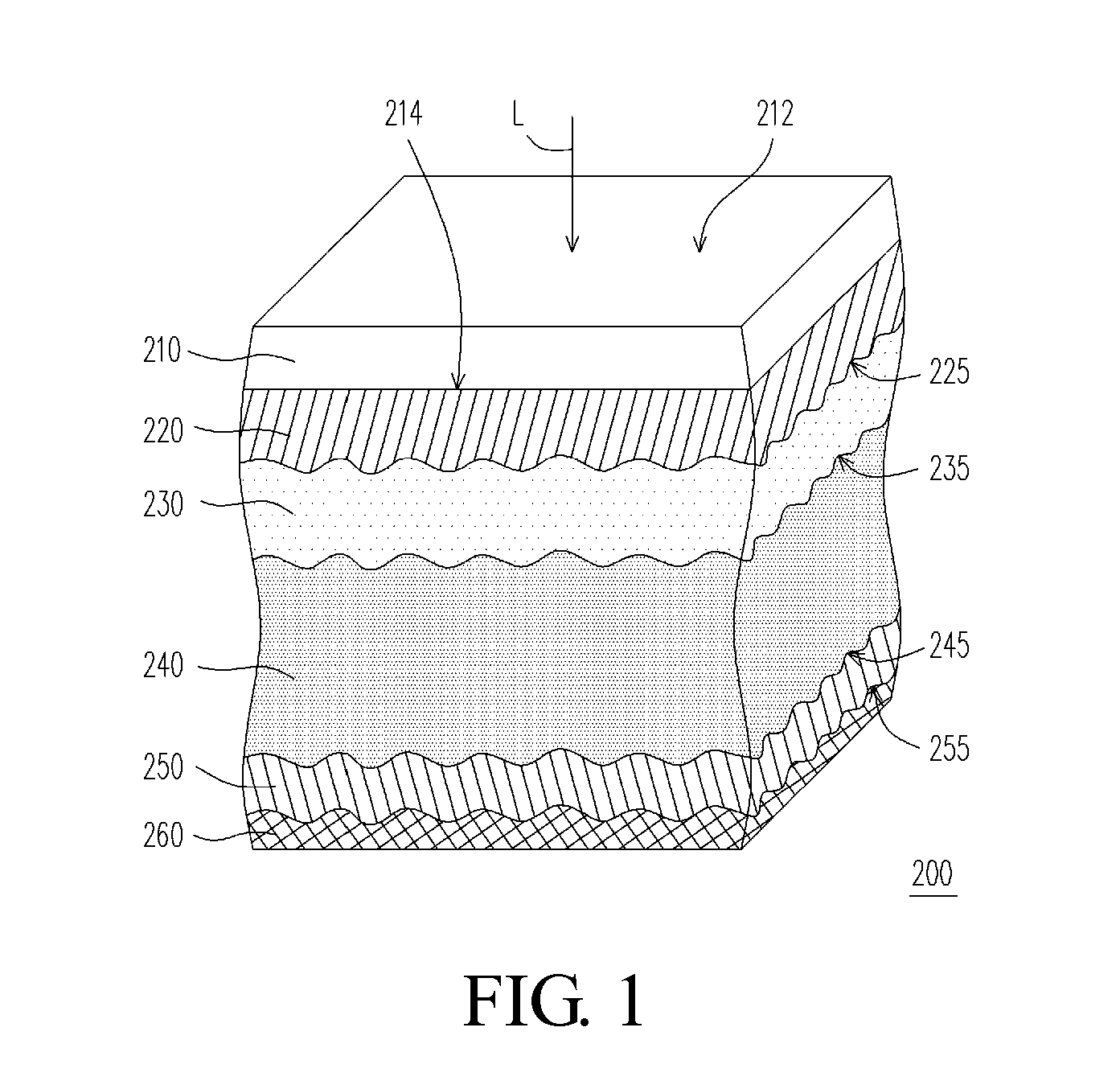

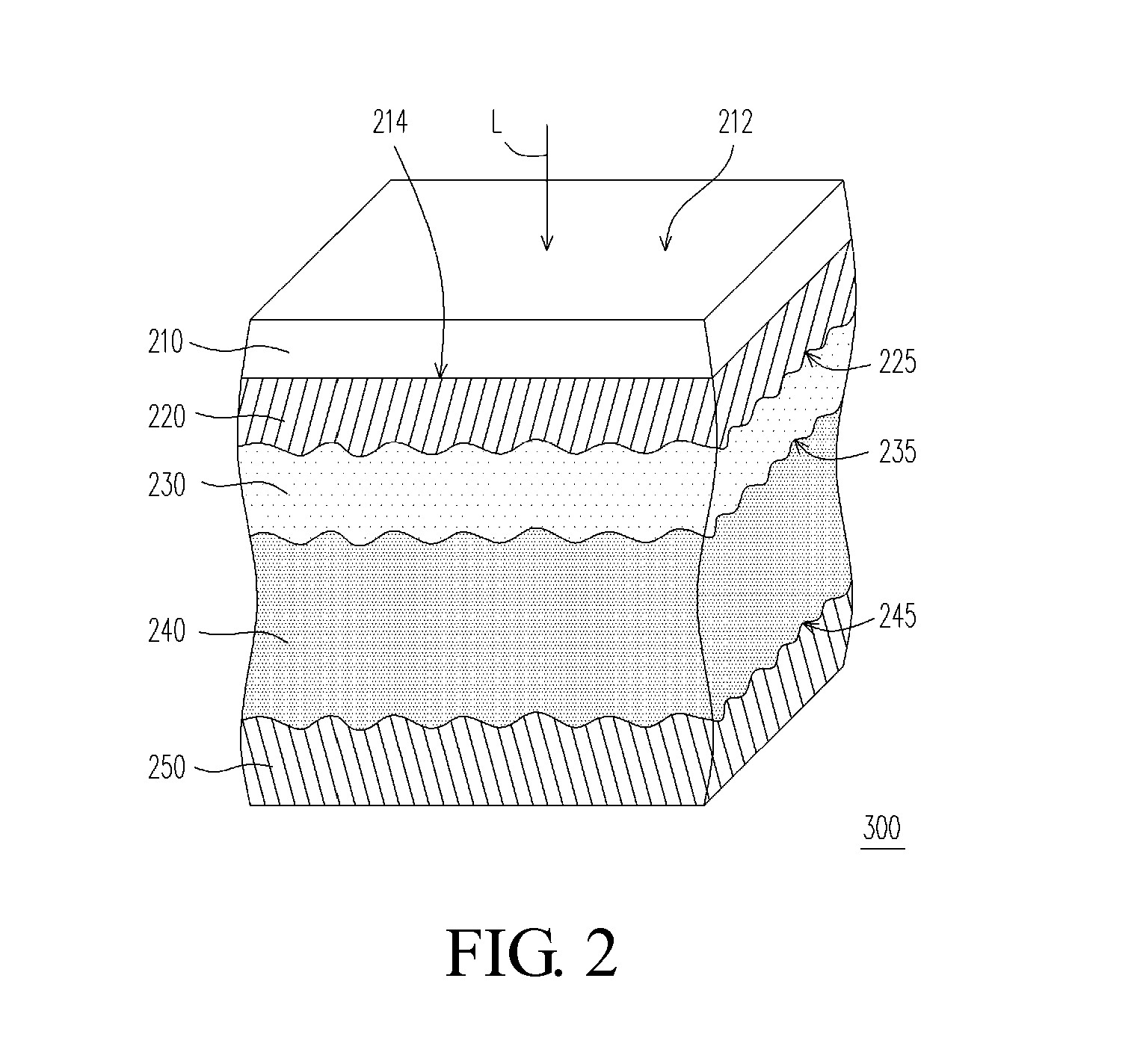

Thin-film solar cell and manufacturing method thereof

InactiveUS20110168246A1Increase profitImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingLength waveCrystalline semiconductor

A thin-film solar cell, comprising a light transmissive substrate, a transparent electrode, a first photovoltaic layer, a second photovoltaic layer and a back electrode, is provided. The light transmissive substrate has a light incident surface and a back surface opposite to the light incident surface, and the transparent electrode is disposed on the back surface. The first photovoltaic layer is disposed on the transparent electrode, and the material of the first photovoltaic layer is an amorphous semiconductor, and the first photovoltaic layer has a first energy gap. The second photovoltaic layer is disposed on the first photovoltaic layer and has a second energy gap lower than the first energy gap. The material of the second photovoltaic layer is a micro-crystalline semiconductor, and the crystallization ratio of the second photovoltaic layer is between 30%˜100%. The second photovoltaic layer can absorb a light ray with a wavelength between 600 nm-1100 nm.

Owner:AURIA SOLAR CO LTD

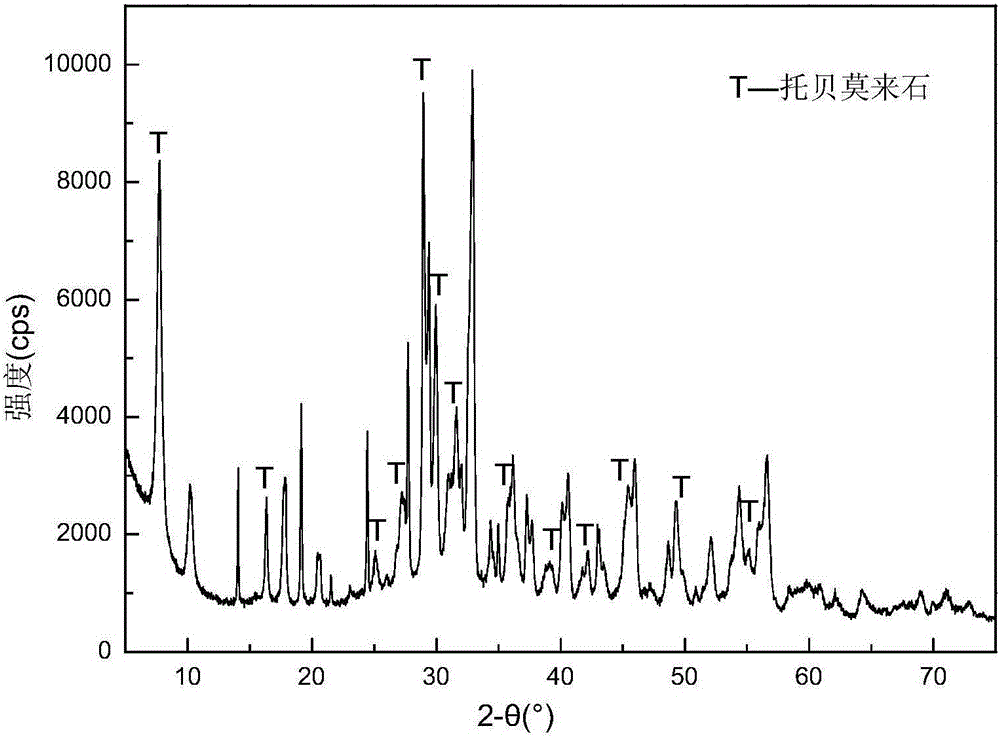

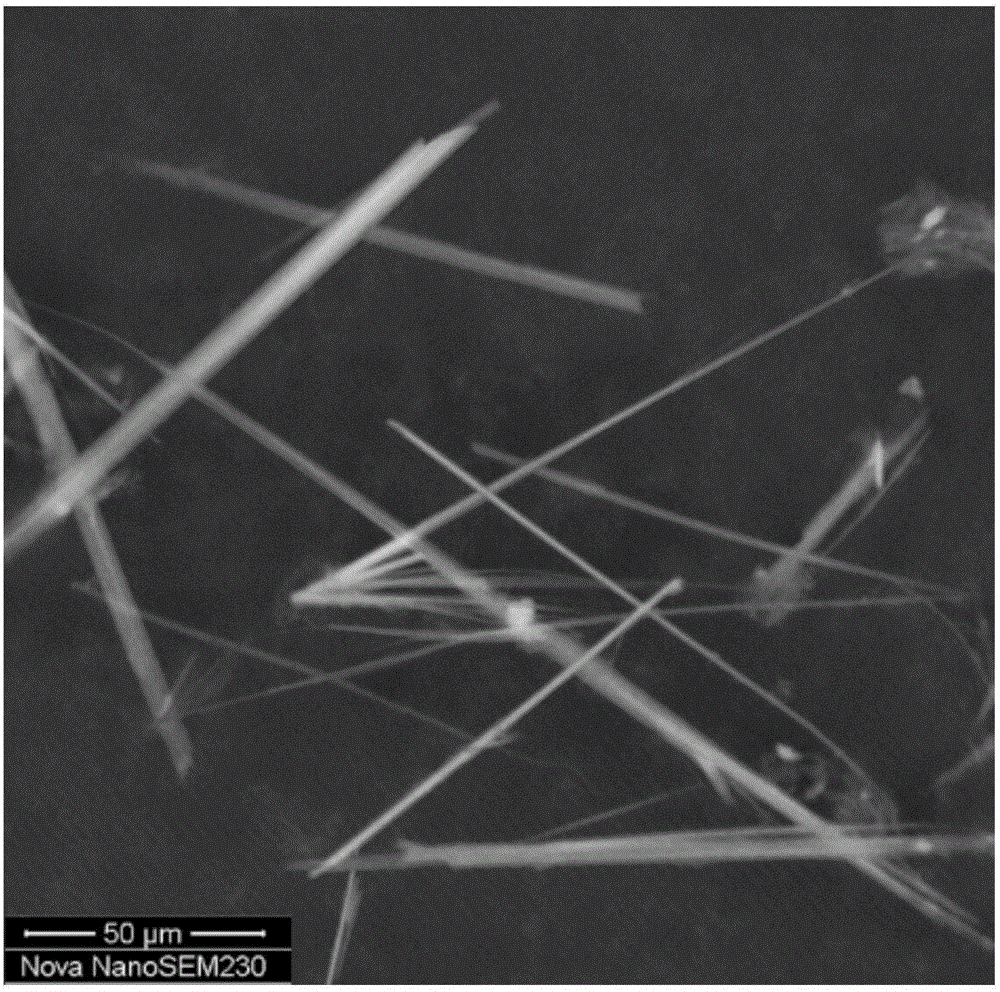

Method for synthesizing tobermorite whiskers with fly ash as raw material

ActiveCN105780121ARelieve environmental pressureImprove performancePolycrystalline material growthFrom normal temperature solutionsFireproofingSlurry

The invention relates to a method for synthesizing tobermorite whiskers with fly ash as a raw material and belongs to the technical field of nanometer whisker products. According to the method, an addition agent and a calcium resource are mixed uniformly according to the Ca / N molar ratio of (1-1000): 1 to obtain mixed slurry, after the pH value of the mixed slurry is adjusted to be 11-14, the fly ash is added, and in a high-pressure closed container, the mixture reacts at the temperature ranging from 150 DEG C to 260 DEG C, so that the tobermorite whiskers are obtained; the addition agent is a surfactant; the surfactant is an amino compound or a derivative of the amino compound. According to the method, the industrial solid waste fly ash is used as the raw material, the synthesized tobermorite whiskers can serve as a high-quality silicate heat-preserving and fireproofing material, and after being separated and purified, the tobermorite whiskers can also serve as an inorganic addition agent of a function composite material. The method is simple, feasible and beneficial for promoting high value-added utilization of the fly ash resource, and the product can be applied to the fields of building materials, metallurgy materials, chemical engineering materials and the like.

Owner:CENT SOUTH UNIV

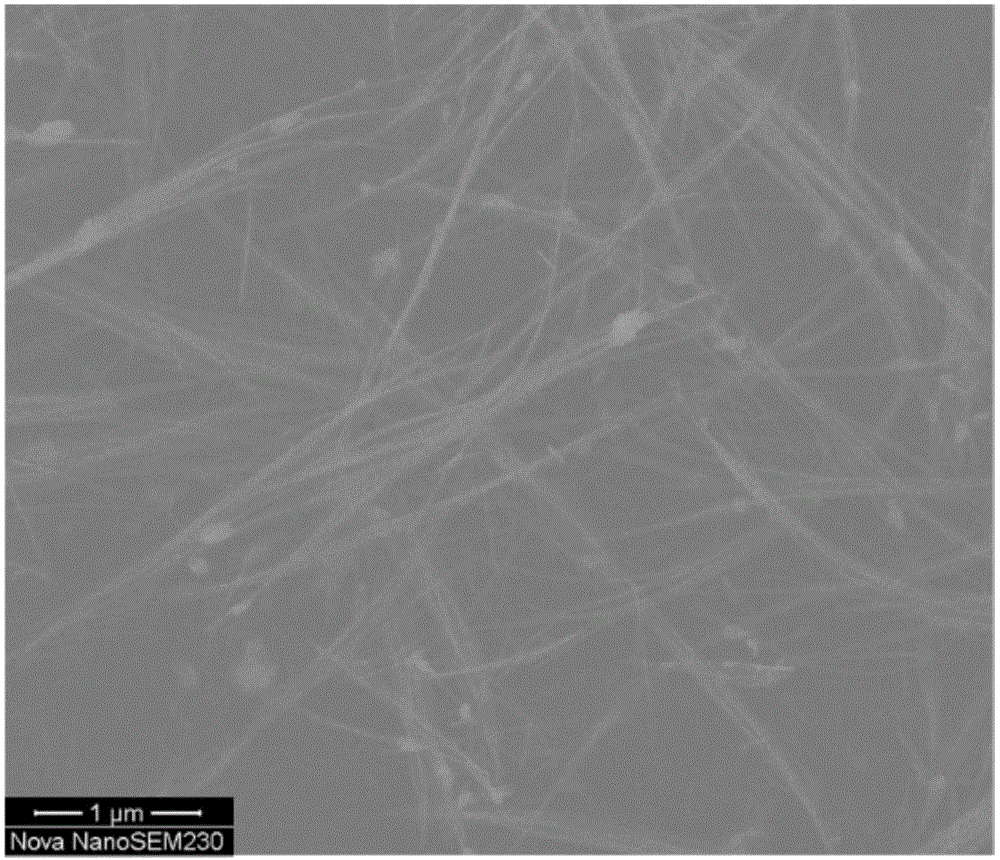

P type window layer in use for solar cell of silicon thin film, and preparation method

ActiveCN1697201AIncrease crystallization rateHigh conductanceFinal product manufacturePhotovoltaic energy generationNano siliconSolar cell

The window layer is composed of transparent substrate, transparent conductive film and P type window layer etc. Characters are that P layer is divided into P1 and P2 layers. P1 layer is thin film of Nano silicon with high crystallizing rate and wide band gap. Thickness of P1 is smaller than thickness of P2 in one order of magnitude. Two-layered P type doping layer structure is adopted in designing P type window layer. Controlling crystallizing rates, doping concentrations and thickness in two layers reaches crystallizing and doping results to be completed respectively so as to meet requirement of high conductance and high crystallizing rate. The disclosed window layer provides good basis for further growth of active layer of crystallite silicon, raises battery efficiency by high open circuit voltage and low series resistance.

Owner:GS SOLAR FU JIAN COMPANY

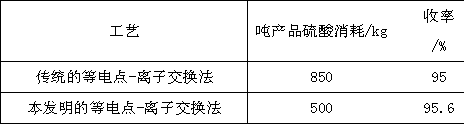

Glutamic acid separating and extracting technology

ActiveCN103224454ALow costReduce consumptionOrganic compound preparationAnimal feeding stuffIon exchangeEconomic benefits

The invention discloses a glutamic acid separating and extracting technology. The technology is characterized in that glutamic acid in the isoelectric point liquid of glutamic acid is separated and extracted through adopting an ion exchange method, an acid solution not an alkali solution is directly used to elute for generation after the ion exchange resin adsorption of the glutamic acid, and an eluate obtained after the ion exchange returns to an isoelectric operation for glutamic acid extraction. Compared with traditional technologies, the technology disclosed in the invention has the advantages of saving of a large amount of an acid and an alkali, reduction of the production cost and the environmental pollution, and economic benefit improvement.

Owner:内蒙古阜丰生物科技有限公司

Vitreous silica crucible for pulling single-crystal silicon

ActiveUS20090165701A1Suppress deterioration of quality of single crystalIncrease concentrationPolycrystalline material growthBy pulling from meltCrucibleSilicon dioxide

A vitreous silica crucible for pulling single-crystal silicon, which is formed of vitreous silica and has a bottomed cylindrical shape, wherein, in a liquid-level movement range in the inner surface of the crucible, ranging from a position corresponding to the liquid surface level of a silicon melt at the time of stating the pulling of single-crystal silicon to a position corresponding to the liquid surface level of a silicon melt at the time of finishing the pulling of single-crystal silicon, the concentration of an OH group included in the vitreous silica is higher in an erosion thickness portion of the inner surface of the crucible than that in the range lower than the liquid surface level which is positioned below the liquid-level movement range

Owner:SUMCO CORP

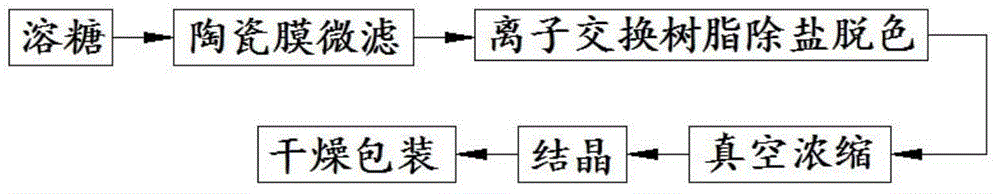

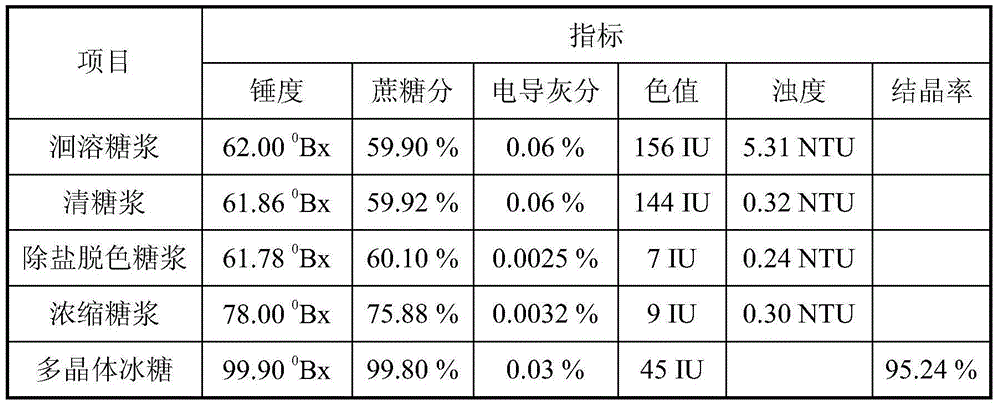

Production process of poly-crystal rocky candy

The invention discloses a production process of poly-crystal rocky candy. The production process comprises the following six steps: by taking first-grade white sugar as a raw material, dissolving the sugar, micro-filtering and clarifying, desalting and decolorizing by using ion exchange resin, concentrating in vacuum, charging seeds for crystallization, drying and packaging to produce the poly-crystal rocky candy. The poly-crystal rocky candy produced by the method disclosed by the invention is sweet and delicious in taste and white and transparent in color and luster; no sodium hydrosulfite is added for color protection during the overall production, so the product is environmental friendly and safe; the crystallization rate of the rocky candy is above 95%; the problem of low crystallization rate during production of the poly-crystal rocky candy for a long time is solved.

Owner:GUANGXI UNIV

Method for improving crystallizing rate of reused monocrystal silicon and material block for feeding barium carbonate

ActiveCN107460538AAvoid harmPut an end to ignitionPolycrystalline material growthBy pulling from meltCorrosionMonocrystalline silicon

The invention provides a method for improving a crystallizing rate of reused monocrystal silicon. Silicon material is fed into a crucible via a refeeding cylinder, when a liquid level of the silicon material in the crucible is a certain distance higher than a round corner of the bottom of the crucible, a few grams of barium carbonate are put into the crucible via the refeeding cylinder, and then the silicon material is continuously put into the crucible via the refeeding cylinder. In the method, silicon dioxide is exposed after the crucible is corroded, after barium carbonate powder is fed, barium oxide is generated after heating, the barium oxide reacts with silicon dioxide to generate BaSiO3; due to existence of barium metasilicate, a layer of compact and tiny cristobalite crystals is formed on the wall of the quartz crucible, and thus a corrosion degree of the quartz crucible corroded by solution is relieved; meanwhile, the cristobalite crystals are formed in needle holes, so that foreign gases entering silicon solution are reduced, and the purpose of directly improving the crystallizing rate of the monocrystal silicon after reusing is achieved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

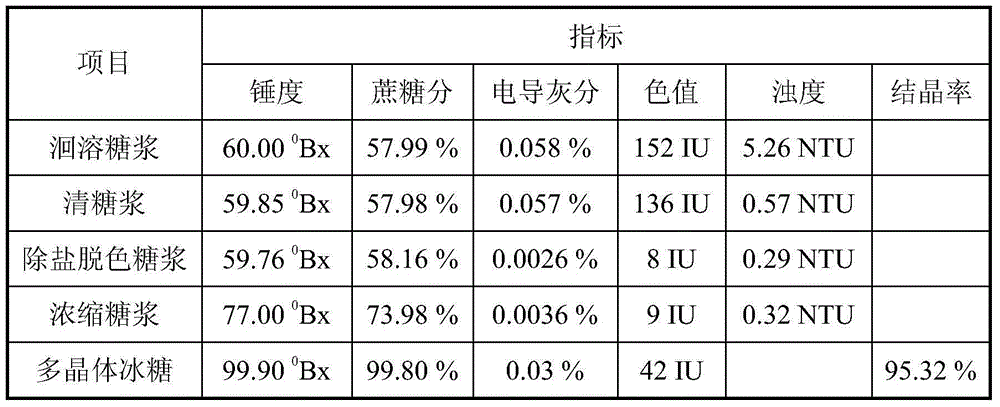

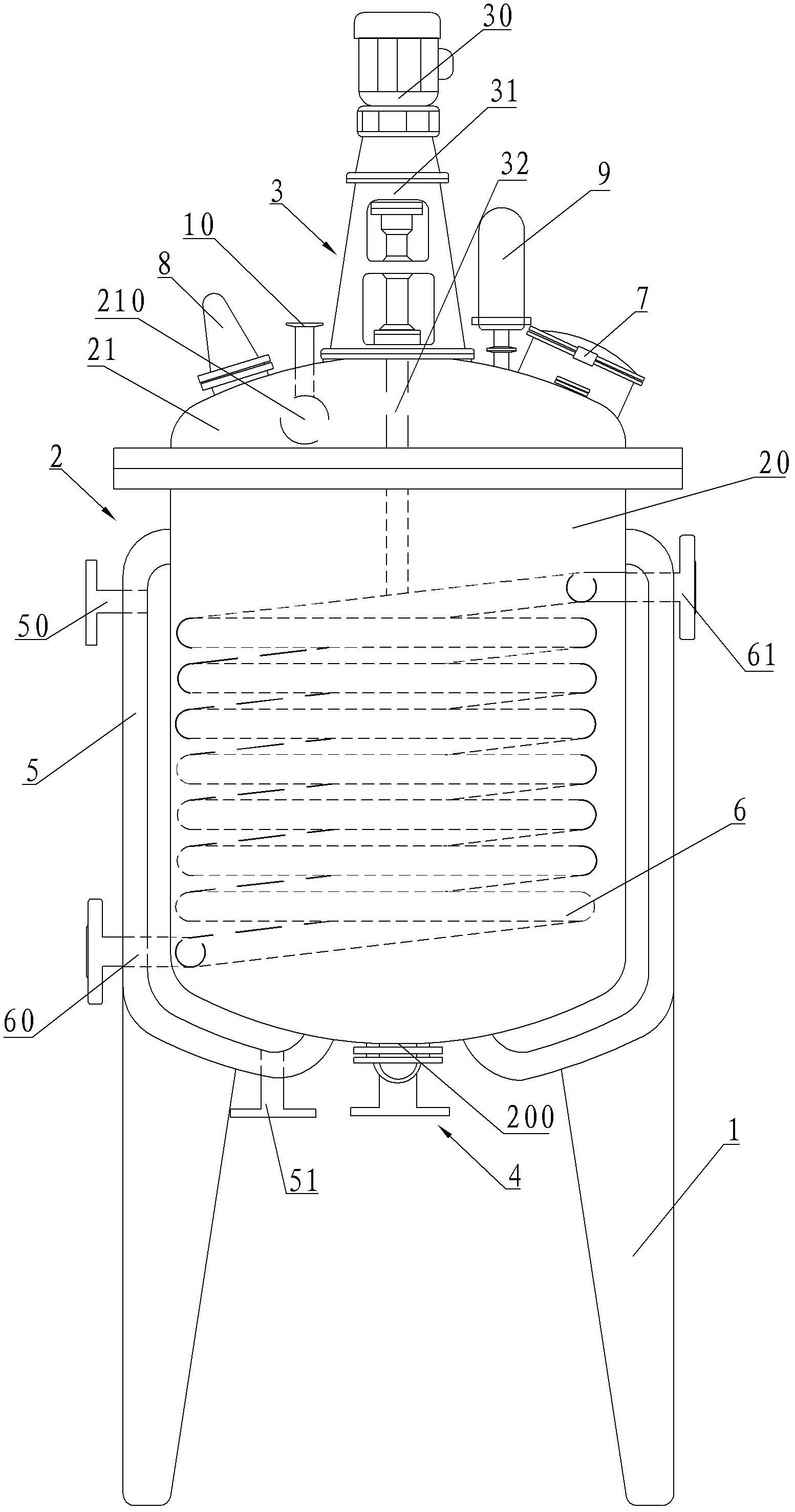

Vinpocetine special-purpose crystallization pot

InactiveCN102423543AEasy to set upEasy to operateOrganic chemistrySolution crystallizationHeat transfer efficiencyCondensed water

The invention relates to a vinpocetine special-purpose crystallization pot, which contains a pot rack, a pot and a stirring device. The pot contains a pot body and a cover. The bottom of the pot body is provided with a discharge hatch which is equipped with a discharged valve. A feed inlet is disposed on the cover. The periphery of the pot body is provided with an insulation jacket with a steam inlet and a condensed water outlet. The crystallization pot also contains a condensation coil pipe disposed inside the pot body. The condensation coil pipe is equipped with a condensate liquid inlet and a condensate liquid outlet which extend out through the pot. According to the crystallization pot, the condensation coil pipe is arranged inside the pot. As the condensation coil pipe directly contacts with a material, the heat transfer efficiency is highest, and the material can be rapidly cooled. Therefore, the vinpocetine crystallization rate can be raised and the crystallization efficiency can be improved. In addition, the invention is simple to arrange and convenient to operate.

Owner:江苏斯威森生物医药工程研究中心有限公司

Glass fiber composition and glass fiber and composite material thereof

ActiveUS20160362327A1Low molding temperatureHigh liquidus temperatureGlass/slag layered productsGlass fiberRefractive index

The present invention provides a glass fiber composition, a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 58-64% SiO2, 14-19% Al203, ≧8.8% and <11.8% CaO, 7.5-11% MgO, 0.2-2.7% SrO, 0.1-2% Na2O+K2O, 0.05-0.9% Li2O, 0.05-1% Fe2O3, 0.05-1.1% TiO2 and <0.5% F2, wherein the range of the weight percentage ratio C1=(MgO+SrO) / CaO is 0.75-1.1, and the range of the weight percentage ratio C2=CaO / MgO is less than 1.4. Said composition can effectively inhibit the crystallization tendency of glass, significantly decrease the liquidus temperature and crystallization degree of glass and also has an outstanding glass refractive index and outstanding modulus.

Owner:JUSHI GRP CO

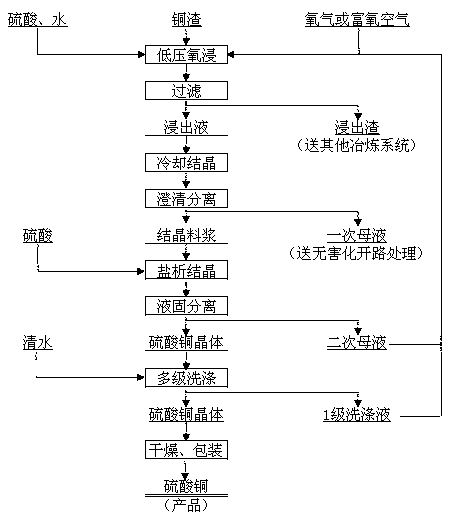

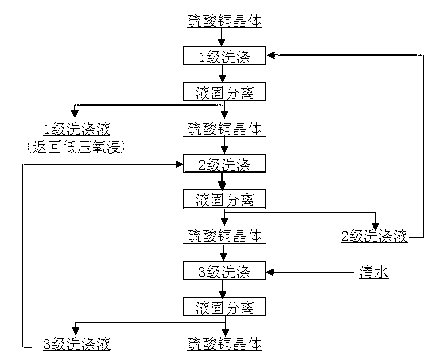

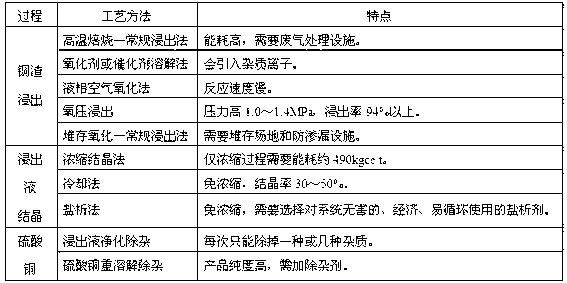

Method for producing high-quality copper sulfate through low-pressure oxygen leaching of copper slag

ActiveCN103074499AHigh product purityNo addedProcess efficiency improvementCopper sulfatesCOPPER SULFATE CRYSTALSLeaching (metallurgy)

The invention relates to a method for producing high-quality copper sulfate through low-pressure oxygen leaching of copper slag. A copper-bearing material with metallic copper or cuprous oxide content greater than 15wt% serves as a raw material, and the method comprises the steps of copper slag or spongy copper slag pickling of zinc hydrometallurgy. A dilute sulphuric acid solution is adopted for low-pressure oxygen leaching of the raw material, an obtained leachate is subjected to combined crystallization including cooling crystallization and salting-out crystallization, a copper sulfate crystal is obtained after liquid-solid separation, and dried after multistage washing, and copper sulfate meeting requirements of above a premium grade specified in YS / T 94-2007 is obtained.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com