Process for producing arc quartz crucible by vacuum plus coating, equipment, product thereof

A quartz crucible and coating technology, which is applied in the field of crucible manufacturing, can solve the problems that the quartz crucible cannot be solved, and the uniform high-purity quartz layer cannot be sprayed uniformly, so as to improve the crystallization rate, reduce the consumption of coating, increase the strength and durability The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

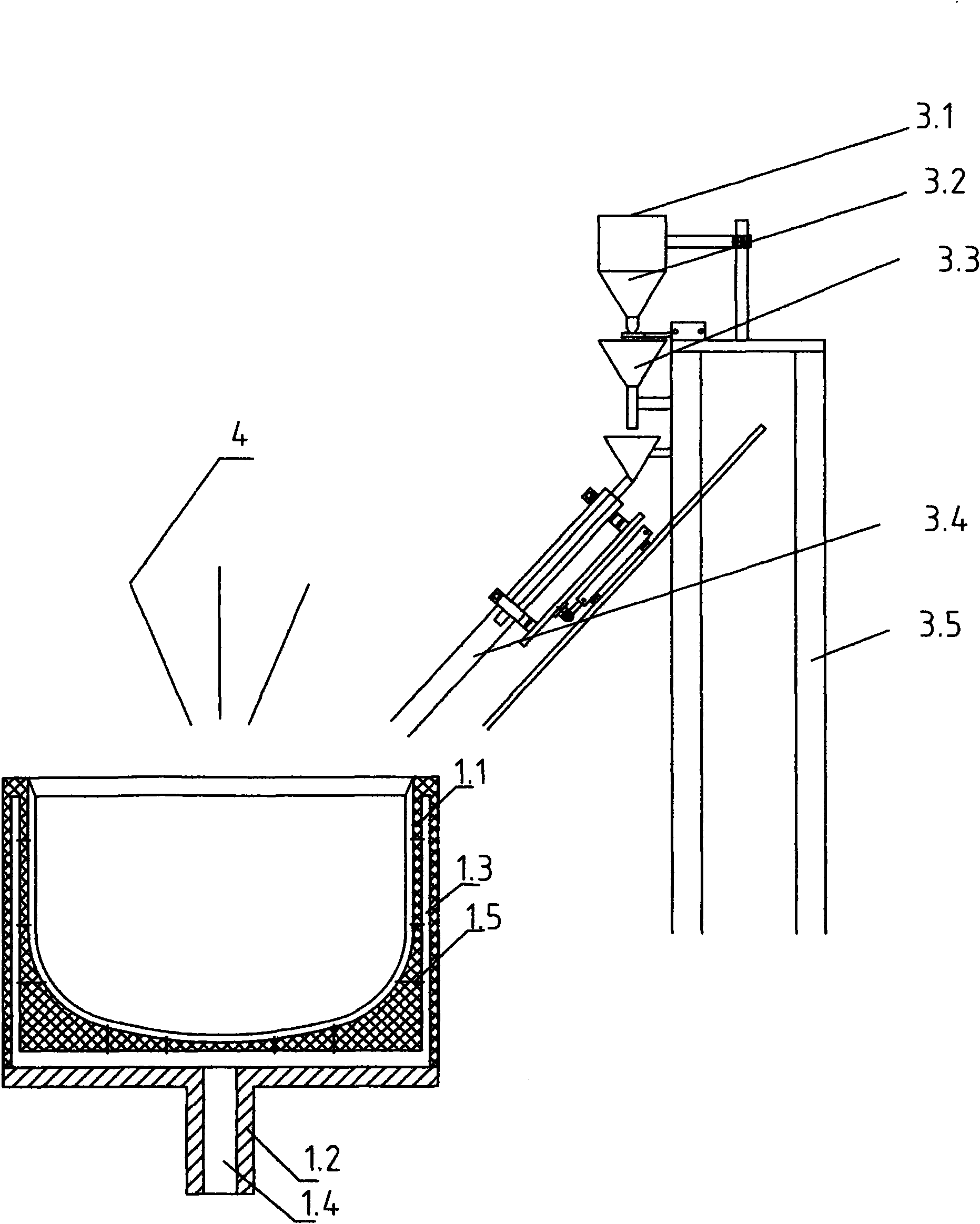

[0087] To produce 20-inch quartz crucible, the process of vacuum coating to produce arc quartz crucible is as follows:

[0088] 1) Pour the quartz sand into the vacuum mold and scrape out the prefabricated shape with a forming rod. The mold enters the melting chamber, and the vacuum pump is turned on. The vacuum degree is controlled at 200-500Pa;

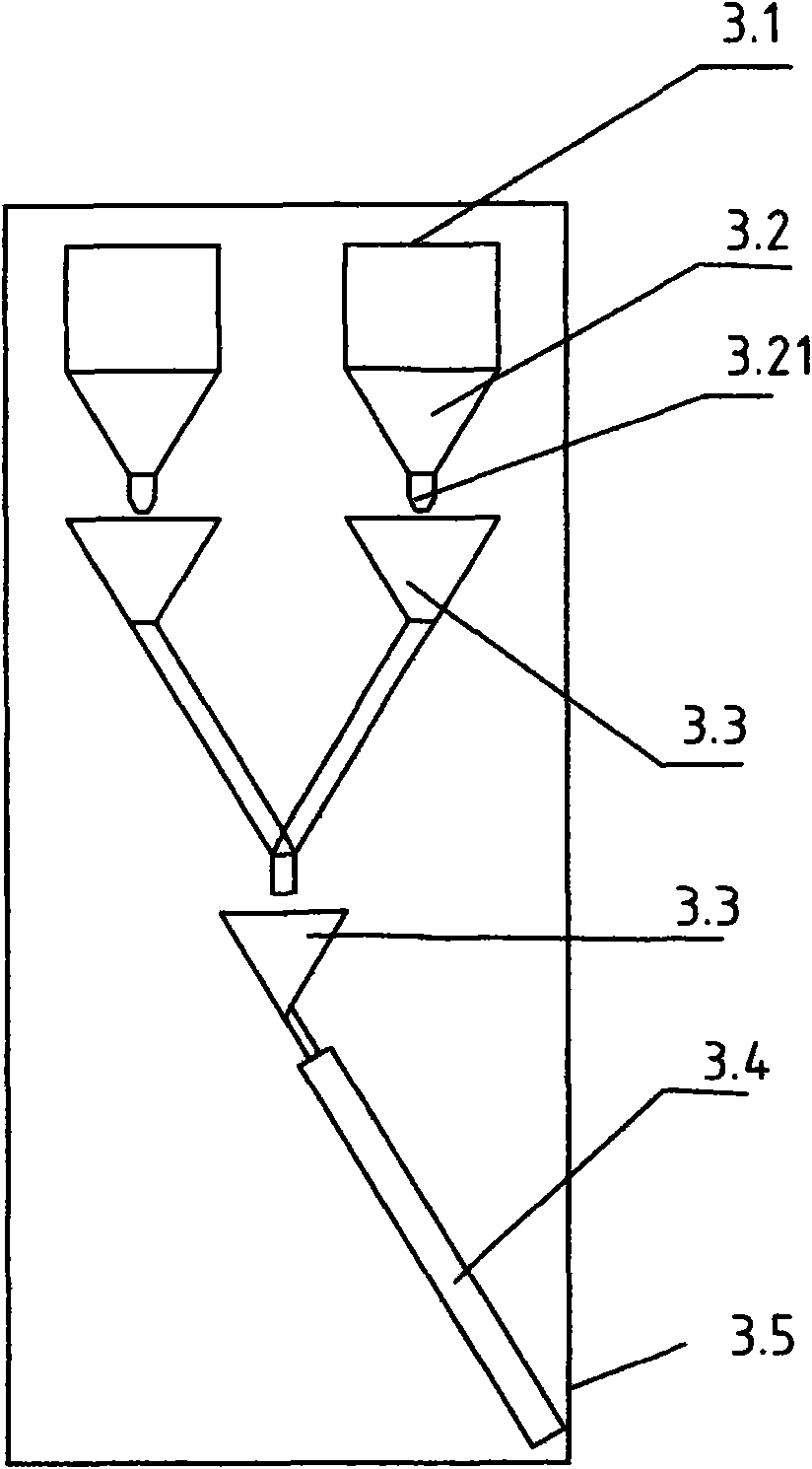

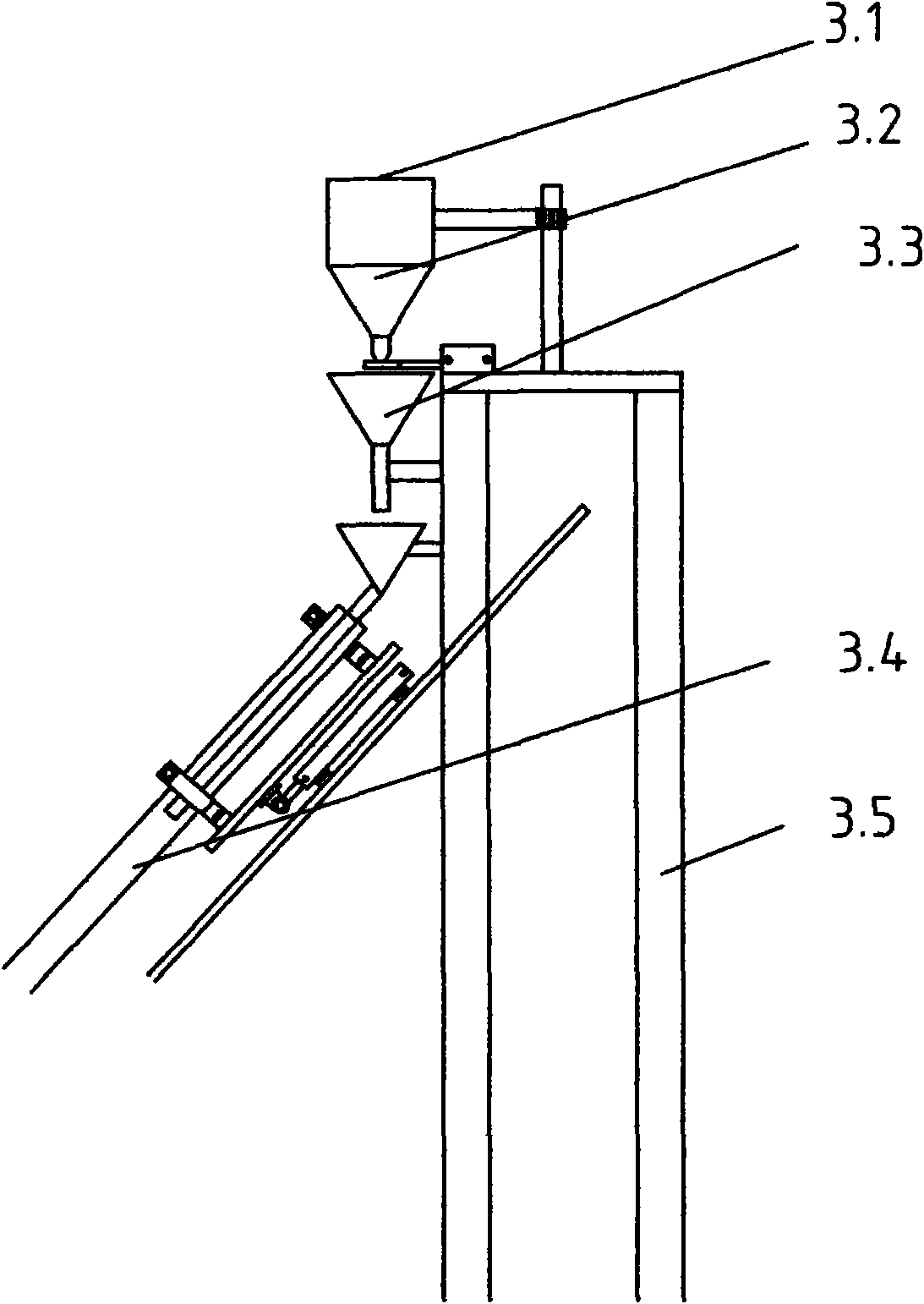

[0089] 2) Power on the electrodes, control the temperature at 1700°C to 1750°C and start melting, preheat for 9-12 minutes, when the quartz sand melts to a molten state, start the coating feeder, and control the high Spray the pure quartz sand paint into the melting quartz crucible at 3000℃-3500℃, melt for 5-10 minutes, and close the feeding port;

[0090] 3) Spray the mixed spray paint into the quartz crucible that has been sprayed with silica paint by controlling another hopper of the double-bucket feeder and melt it for 3 to 5 minutes, then close the feed port;

[0091] 4) Turn off the vacuum pump while maintaining the temperature...

Embodiment 2

[0099] To produce 18-inch quartz crucible, the process of vacuum coating to produce arc quartz crucible is as follows:

[0100] 1) Pour the quartz sand into the vacuum mold and scrape out the prefabricated shape with a forming rod. The mold enters the melting chamber, and the vacuum pump is turned on. The vacuum degree is controlled at 200Pa;

[0101] 2) The electrode is energized, and the temperature is controlled to start melting at 1700°C. Preheat for 9 minutes. When the quartz sand melts to a molten state, start the coating feeder, and control a hopper of the double-bucket feeder to paint high-purity quartz sand. Spray into a melting quartz crucible at 3000°C, melt for 5 to 10 minutes, and close the feeding port;

[0102] 3) Spray the mixed spray paint into the quartz crucible that has been sprayed with silica paint by controlling another hopper of the double-bucket feeder and melt it for 3 to 5 minutes, then close the feed port;

[0103] 4) Turn off the vacuum pump while...

Embodiment 3

[0107] To produce 16-inch quartz crucible, the process of vacuum coating to produce arc quartz crucible is as follows:

[0108] 1) Pour the quartz sand into the vacuum mold and scrape out the prefabricated shape with a forming rod. The mold enters the melting chamber, and the vacuum pump is turned on. The vacuum degree is controlled at 500Pa;

[0109] 2) The electrode is energized, and the temperature is controlled to start melting at 1750°C. Preheat for 12 minutes. When the quartz sand melts to a molten state, start the coating feeder, and control a hopper of the double-bucket feeder to paint high-purity quartz sand. Spray into a melting quartz crucible at 3500°C, melt for 5 to 10 minutes, and close the feeding port;

[0110] 3) Spray the mixed spray paint into the quartz crucible that has been sprayed with silica paint by controlling another hopper of the double-bucket feeder and melt it for 3 to 5 minutes, then close the feed port;

[0111] 4) Turn off the vacuum pump whil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com