Method for synthesizing tobermorite whiskers with fly ash as raw material

A technology of tobermullite and fly ash, which is applied in the field of synthesizing tobermullite whiskers, can solve the problems of harsh raw materials and reaction conditions, unsatisfactory structure and morphology of whisker products, etc., and achieve relief The effects of environmental pressure, crystallinity and crystallization rate increase, and complete crystallization plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

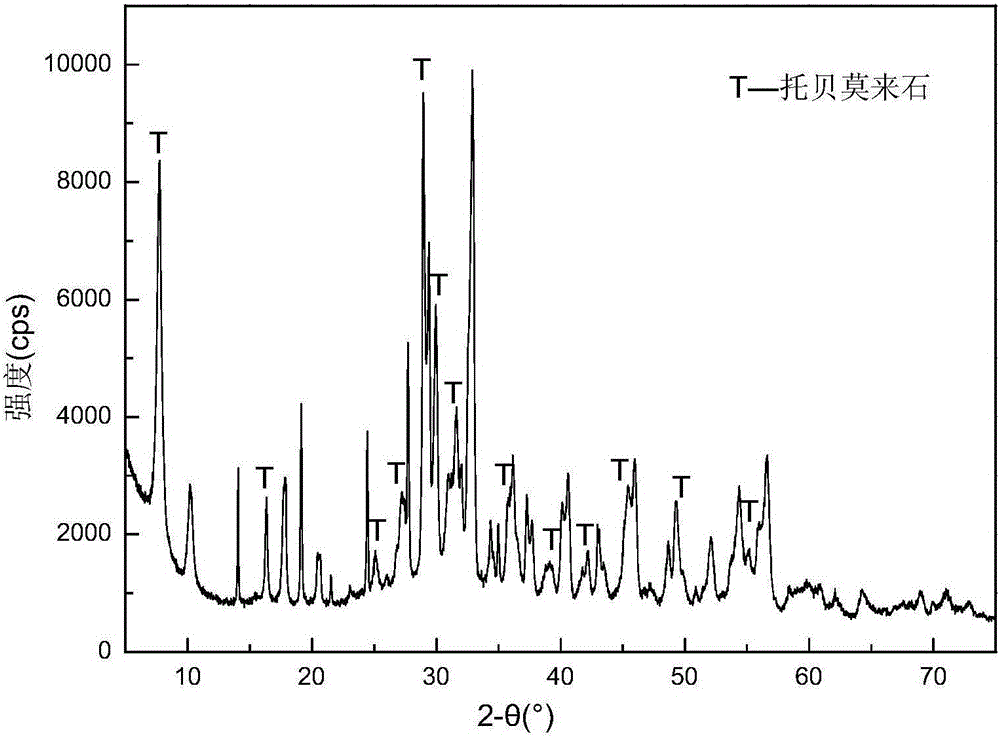

[0038] Embodiment 1: After the quicklime is digested, according to the Ca / N molecular ratio, it is 1000 to add the surfactant dodecylamine, and then it is 30ml / g and the calcium-silicon molar ratio with the fly ash to prepare the suspension slurry according to the liquid-solid ratio of 1.2. Adjust the pH value to 13 with caustic alkali, put it into the reaction kettle after stirring and mixing, and react at a constant temperature of 250 rpm at 240° C. and 3.2 MPa pressure for 3 hours. After the reaction, cool down to room temperature naturally, then filter and wash the reacted slurry, dry the filter cake at a temperature of 75°C and perform XRD analysis. The results show that calcium silicate hydrate gel (CSH) in the product decreased, while the generation of tobermolite increased.

Embodiment 2

[0039] Embodiment 2: After the quicklime is digested, according to the Ca / N molecular ratio, it is 100 to add the surfactant dodecylamine, and then it is 20ml / g and the calcium-silicon molar ratio with the fly ash to prepare the suspension slurry according to the liquid-solid ratio of 0.8. Adjust the pH value to 13 with caustic alkali, put it into the reaction kettle after stirring and mixing, and react at a constant temperature of 200 rpm at 220° C. and 2.5 MPa pressure for 6 hours. After the reaction was completed, it was rapidly cooled to room temperature, and then the reacted slurry was filtered and washed, and the filter cake was dried at a temperature of 75°C for XRD analysis. The main phase of the product was tobermullite.

Embodiment 3

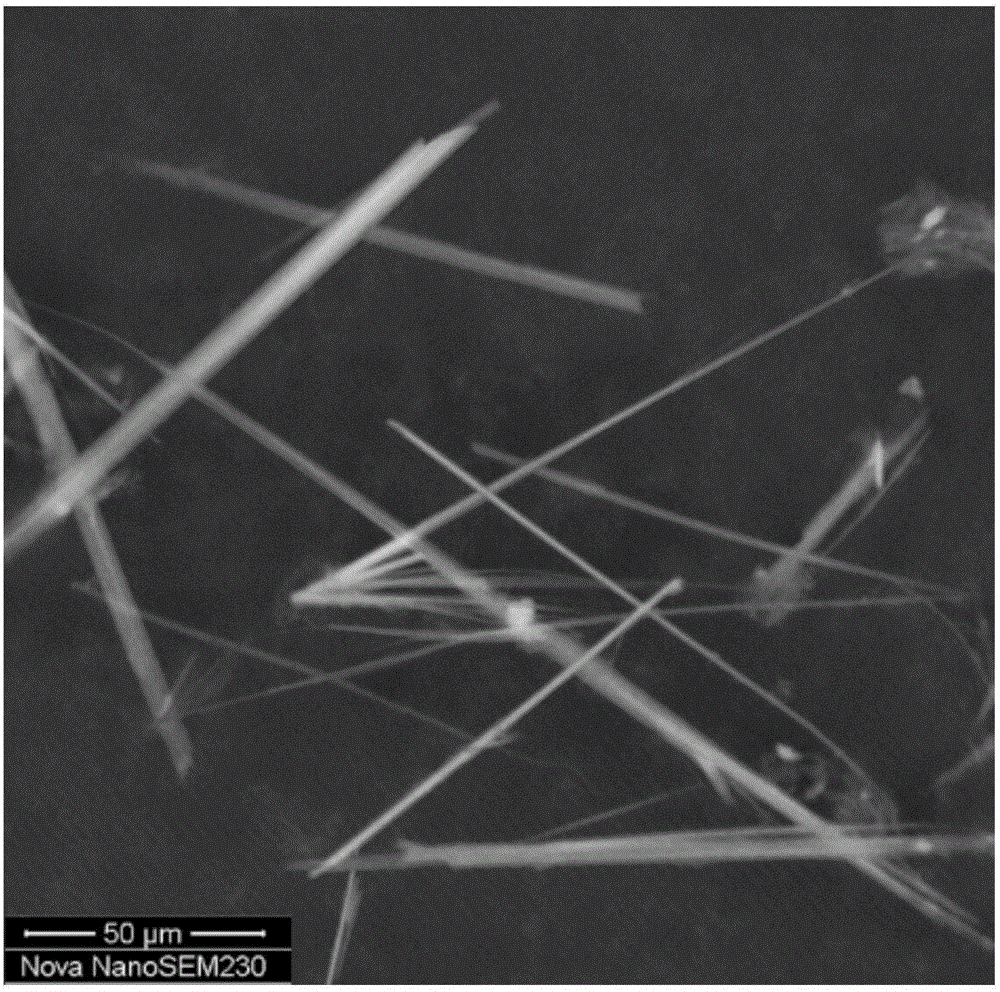

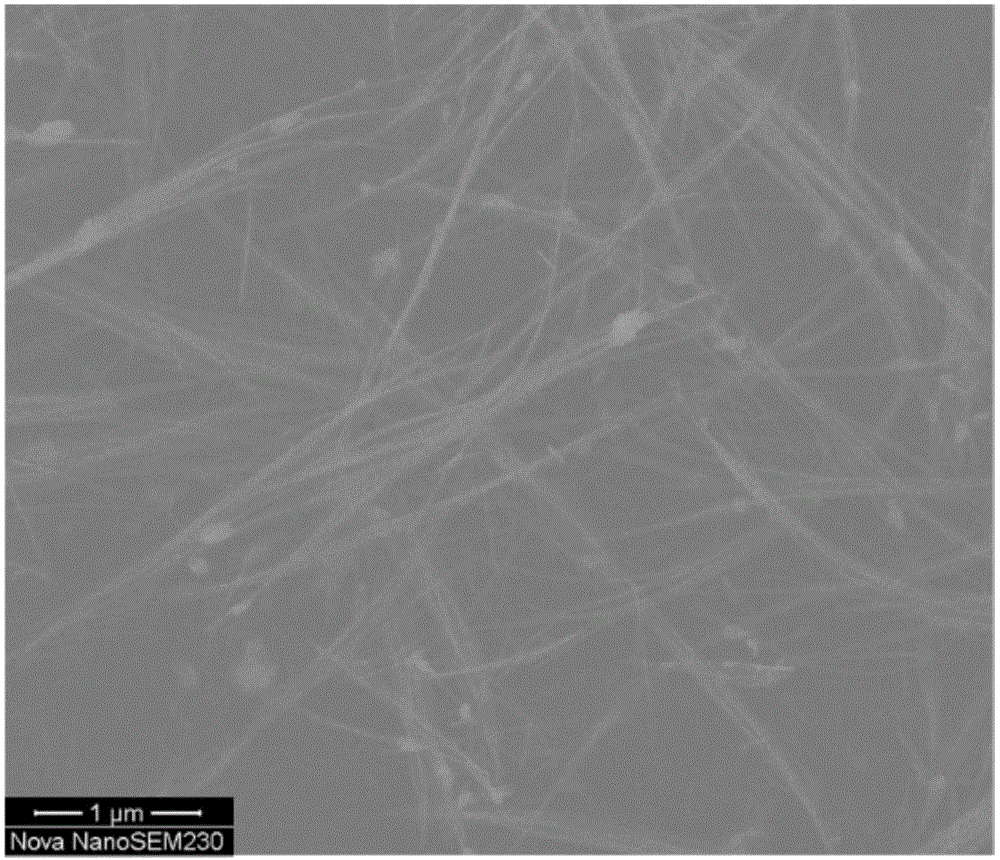

[0040] Example 3: after the quicklime is digested, the surfactant organic amine dodecylamine is added according to the Ca / N molecular ratio of 10, and the suspension slurry is prepared with fly ash according to the liquid-solid ratio of 15ml / g and the calcium-silicon molar ratio of 1.0 , use caustic soda to adjust the pH value to 14, stir and mix evenly, put it into a reaction kettle, and react at a constant temperature of 100 rpm at 180° C. and 1.8 MPa pressure for 8 hours. After the reaction, quickly cool to room temperature, then filter and wash the reacted slurry, dry the filter cake at a temperature of 75°C and perform XRD analysis. The product is mainly 1.1nm tobermullite, which is found by SEM detection Its morphology is obviously needle-shaped, and the crystal plane is relatively complete. The average length of tobermullite whiskers is about 100 μm, and the diameter is about 0.1 μm. Among the obtained products, the aspect ratio of a single whisker can reach up to 3000....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com