Method for manufacturing perforated brick by using red mud

A technology of porous bricks and red mud, applied in clay products, ceramic products, applications, etc., can solve the problems of large consumption of land resources and high energy consumption of solid blocks, and achieve the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

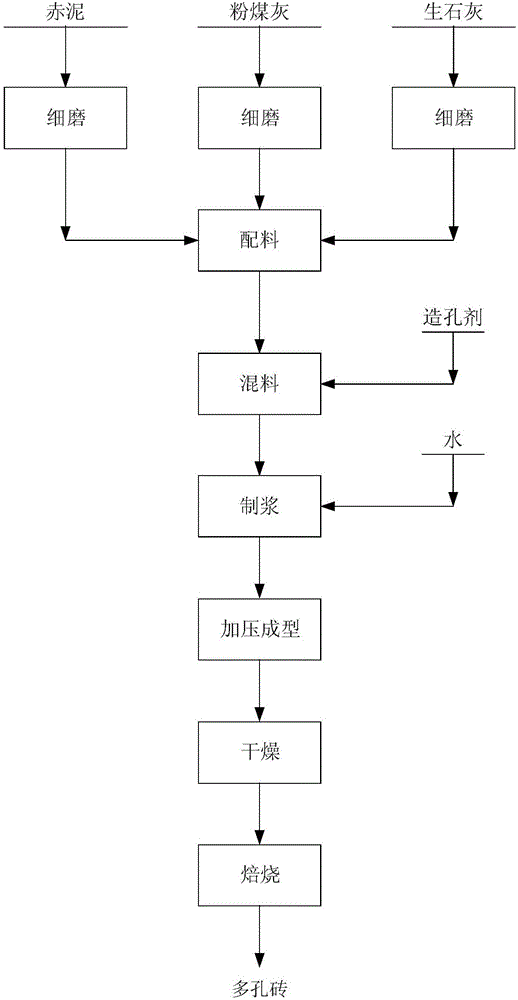

[0033] Such as figure 1 As shown, 5000kg of red mud (Bayer process red mud) and 2000kg of fly ash and 3000kg of quicklime are dried and then finely ground respectively. %above. After fine grinding, the fly ash, quicklime and red mud are mixed evenly, and a pore-forming agent with a volume fraction of 50% of the total volume of the mixture of fly ash, quicklime and red mud is added, and the pore-forming agent is 20 parts by weight of starch , 20 parts by weight of cellulose and 60 parts by weight of sawdust are mixed, and the average particle size of the pore-forming agent is 1mm. Fly ash, quicklime, red mud and pore-forming agent are fully mixed, then add 1000kg of water for stirring, and stir evenly to obtain a slurry, which is transported to a pressure molding machine and pressed at a pressure of 10MPa to form 200mm*100mm* 60mm shape adobe. The bricks are sent to the drying oven through the conveyor belt. The temperature in the drying box is 120°C, the drying time is 2 ho...

Embodiment 2

[0035] Such as figure 1 As shown, 5000kg red mud (sintered red mud) is dried with 2000kg of fly ash and 3000kg of quicklime, and then finely ground respectively. %above. After fine grinding, the fly ash, quicklime, and red mud are mixed evenly, and a pore-forming agent with a volume fraction of 60% of the total volume of the mixture of fly ash, quicklime, and red mud is added, and the pore-forming agent is 20 parts by weight of starch , 30 parts by weight of polystyrene foam particles and 50 parts by weight of sawdust are mixed, and the average particle size of the pore-forming agent is 2 mm. Fly ash, quicklime, red mud and pore-forming agent are fully mixed, then add 1000kg of water for stirring, and stir evenly to obtain a slurry, which is transported to a pressure molding machine and pressed at a pressure of 10MPa to form 200mm*100mm* 60mm shape adobe. The bricks are sent to the drying oven through the conveyor belt. The temperature in the drying oven is 120°C, and the d...

Embodiment 3

[0037] Such as figure 1 As shown, 4000kg of red mud (the mass ratio of Bayer red mud to sintering red mud is 1:1), 1000kg of fly ash and 2000kg of quicklime are dried and then finely ground respectively. Those below 200 mesh account for more than 90% of the overall quality. After fine grinding, the fly ash, quicklime and red mud are mixed evenly, and a pore-forming agent with a volume fraction of 40% of the total volume of the mixture of fly ash, quicklime and red mud is added, and the pore-forming agent is 20 parts by weight of starch , 30 parts by weight of polystyrene foam particles and 50 parts by weight of sawdust are mixed, and the average particle size of the pore-forming agent is 2 mm. Fly ash, quicklime, red mud and pore-forming agent are fully mixed, then add 700kg of water for stirring, and stir evenly to obtain a slurry, which is transported to a pressure molding machine and pressed at a pressure of 1MPa to 200mm*100mm* 60mm shape adobe. The bricks are sent to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com