Preparation method of phytic acid and KH550 modified biomass derived porous carbon nanosheets

A porous carbon and nanosheet technology, applied in the directions of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve problems such as corrosion of metal substrates and coating failures, simplify the use process, increase applicability, and relieve environmental pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

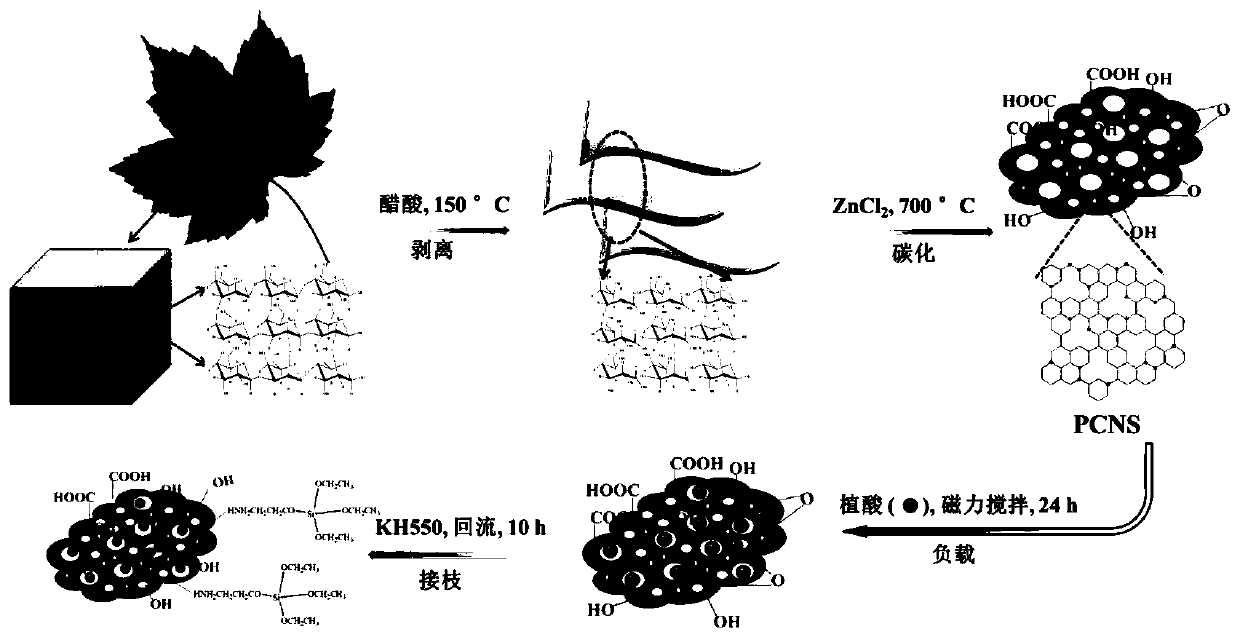

[0032] The preparation method of a phytic acid, KH550 modified biomass-derived porous carbon nanosheets involved in this embodiment comprises the following steps:

[0033] (1) 1g sycamore leaf and 150ml concentration are mixed homogeneously with 10% aqueous acetic acid solution, transferred to a polytetrafluoroethylene reactor and reacted at 150°C for 5 hours, then the product was cleaned with distilled water, centrifuged and dried to obtain water heat products;

[0034] (2) Mix 0.5g hydrothermal product with 1gZnCl 2 Mix evenly and react in a tube furnace at 700°C for 3 hours under the protection of nitrogen, then the product is washed with hydrochloric acid and distilled water in sequence, centrifuged, and dried to obtain biomass porous carbon nanosheets;

[0035] (3) Add 0.1g of biomass porous carbon nanosheets to 20ml 45wt% phytic acid aqueous solution and react under magnetic stirring for 12 hours, then wash with ethanol, centrifuge, and dry to obtain porous carbon nanos...

Embodiment 2

[0040] The preparation method of a phytic acid, KH550 modified biomass-derived porous carbon nanosheets involved in this embodiment comprises the following steps:

[0041] (1) Mix 1.5g lotus pod shells with 100ml 15% acetic acid aqueous solution, transfer to polytetrafluoroethylene reactor and react at 180°C for 5 hours, then the product is washed with distilled water, then centrifuged, dried to obtain hydrothermal product;

[0042] (2) Mix 0.5g hydrothermal product with 1.5gZnCl 2 Mix evenly and react at 700°C for 5 hours under the protection of nitrogen in a tube furnace, then wash the product with hydrochloric acid and distilled water in sequence, centrifuge, and dry to obtain biomass porous carbon nanosheets;

[0043] (3) Add 0.1g of biomass porous carbon nanosheets to 20ml of 60wt% phytic acid aqueous solution and react under magnetic stirring for 12 hours, then wash with ethanol, centrifuge, and dry to obtain porous carbon nanosheets loaded with phytic acid;

[0044] (...

Embodiment 3

[0046] The preparation method of a phytic acid, KH550 modified biomass-derived porous carbon nanosheets involved in this embodiment comprises the following steps:

[0047] (1) Mix 1g of corn stalks with 100ml of 5% acetic acid aqueous solution, transfer to a polytetrafluoroethylene reactor and react at 150°C for 3 hours, then wash the product with distilled water, then centrifuge and dry to obtain a hydrothermal product ;

[0048] (2) Mix 0.5g product with 1.5gZnCl 2 Mix evenly and react in a tube furnace at 700°C for 3 hours under the protection of nitrogen, then the product is washed with hydrochloric acid and distilled water in sequence, centrifuged, and dried to obtain biomass porous carbon nanosheets;

[0049] (3) Add 0.1g of biomass porous carbon nanosheets into 20ml 70wt% phytic acid aqueous solution and react under magnetic stirring for 12 hours, then wash with ethanol, centrifuge, and dry to obtain porous carbon nanosheets loaded with phytic acid;

[0050] (4) Add 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com