Phosphorus removing method from waste water and preparation method of ferrous phosphate

A technology for ferrous phosphate and wastewater, applied in water treatment parameter control, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of pipeline blockage, difficulty, fouling, etc., and achieve low water content, high crystallization rate, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

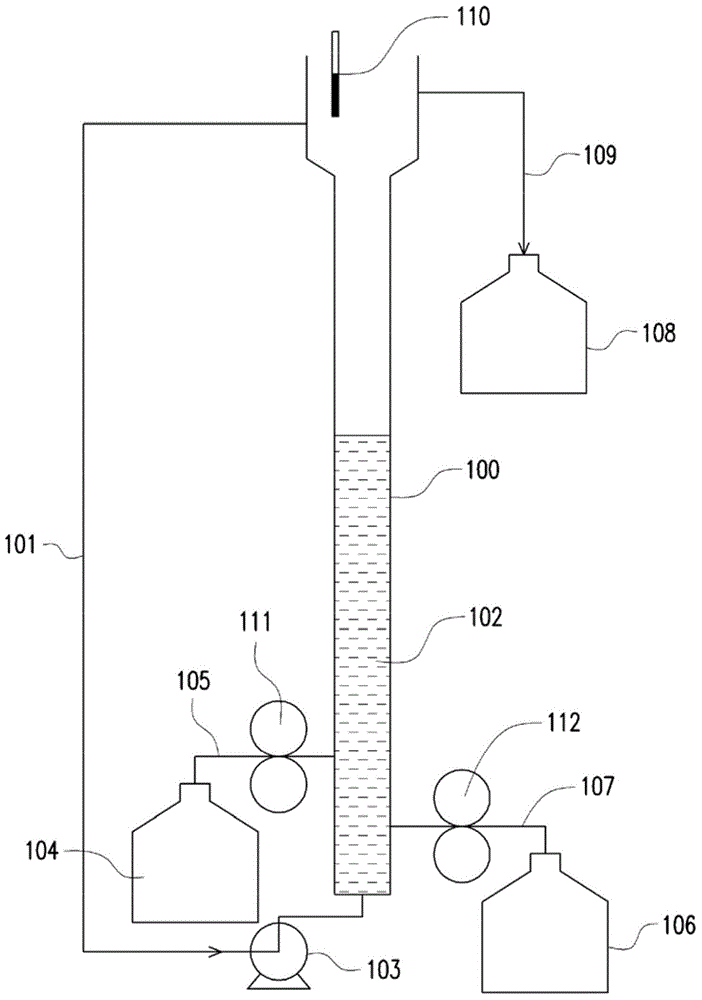

Method used

Image

Examples

experiment example 1

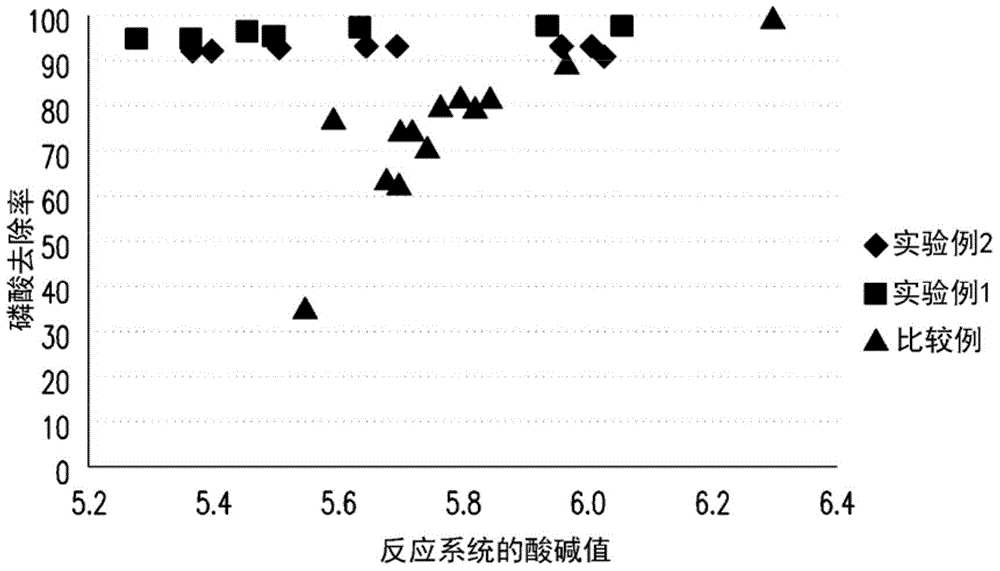

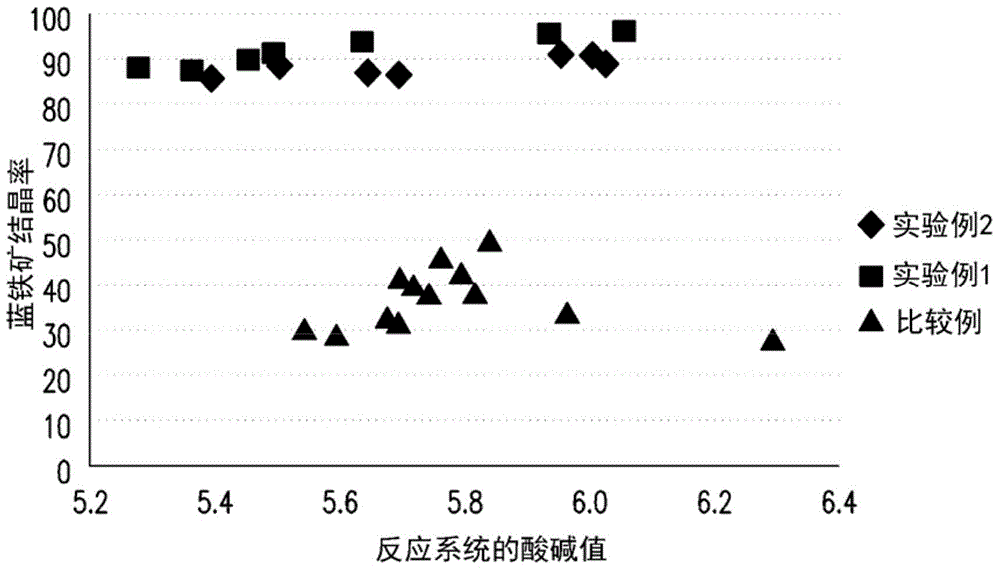

[0053] First, after injecting the ferrous sulfate solution of 0.008M and the phosphate solution of 0.008M in the fluidized bed crystallization tank and mixing, to carry out the fluidized bed crystallization reaction, wherein the ferrous sulfate solution is made of ferrous sulfate (purchased from Bixing Industrial Co., Ltd.) and water. The solution containing phosphate ions is prepared from raw phosphoric acid water provided by Longke Factory of AU Optronics Co., Ltd. The fluidized bed crystallization tank is made of SiO as the main component. 2 The ceramic tile powder was used as the support, the feed rate of the phosphate ion-containing solution was 30ml / min, the feed rate of the ferrous sulfate solution was 6ml / min, and the reflux rate was 124mL / min. Next, take 50ml of the sample solution in the water sample storage tank, and record the pH value at the backflow port (at this time, it is 5.28 to 6.06). After that, 50ml of the sample solution was left to stand for more than 12...

experiment example 2

[0056] The experimental method of Experimental Example 2 is roughly the same as that of Experimental Example 1, except that the ferrous sulfate solution is 0.16M, the feed rate of the ferrous sulfate solution is 3mL / min and the reflux rate is 127ml / min. In addition, the obtained results are also shown in figure 2 and image 3 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com