P type window layer in use for solar cell of silicon thin film, and preparation method

A solar cell and window layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as rarely seen P-type window layers, and achieve the effects of improving cell efficiency, high conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of p-type window layer for thin film solar cell, it comprises following 3 steps:

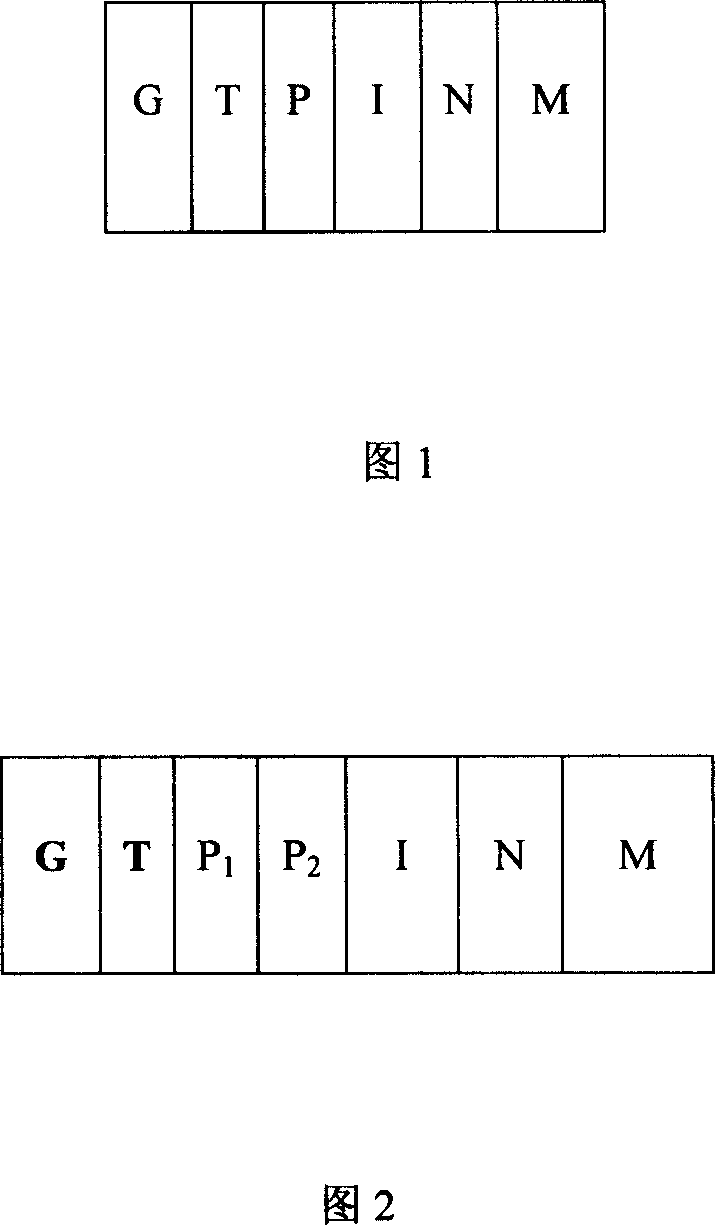

[0015] 1) Put the glass substrate G with T in the vacuum chamber, the background vacuum is lower than 10 -3 support;

[0016] 2) Plasma-enhanced chemical vapor deposition (PECVD) was used to deposit P 1 and P 2 Thin film, the glow excitation frequency used is: 13.56MHz-100MHz:

[0017] 3) The reaction gas introduced into the reaction chamber is: silane, hydrogen, borane or trimethyl boron, P 1 and P 2 Thin film reactive deposition parameters are as follows:

[0018] The reaction gas pressure is above 0.1 Torr (Torr);

[0019] Glow power density: 40 milliwatts (mW)-500 milliwatts (mW);

[0020] Substrate surface temperature: 100-260°C;

[0021] Hydrogen diluted silane concentration SC=([SiH 4 ] / ([SiH 4 ]+[H 2 ]))%≤5%;

[0022] Ratio of boron-containing gas to silane (boron dopant concentration): BS≤3%.

[0023] By adjusting the boron dopant concentration...

Embodiment 1

[0036] On Corning7059 glass substrate, adopt silane, hydrogen, borane as reaction source gas, by VHF-PECVD method, glow excitation frequency is 60MHz, according to the preparation method that this patent thin film solar cell uses p-type window layer included in The steps are to select the deposition process parameters and prepare the microcrystalline silicon p-layer material. Under the premise that the thickness is 20-30nm, its conductance can be at 10 -1 On the order of s / cm, the crystallization rate reaches 40%-50%.

Embodiment 2

[0038] On the glass substrate covered with ZnO transparent conductive film, silane, hydrogen, borane and phosphine are used as reaction source gases, and the glow excitation frequency is 60MHz by VHF-PECVD method. According to the p-type thin film solar cell of this patent The steps included in the preparation method of the window layer select the deposition process parameters, and prepare the p-type window layer and the microcrystalline silicon thin film solar cell according to the steps shown in Figure 2 of the specification. When the cell area is 0.253 square centimeters, the efficiency of the prepared single-junction pin type microcrystalline silicon thin film solar cell reaches 9.2% (when carrying out J-V test, the used light intensity is AM1.5, 100mW / cm 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com