Patents

Literature

92results about How to "Reduce color value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

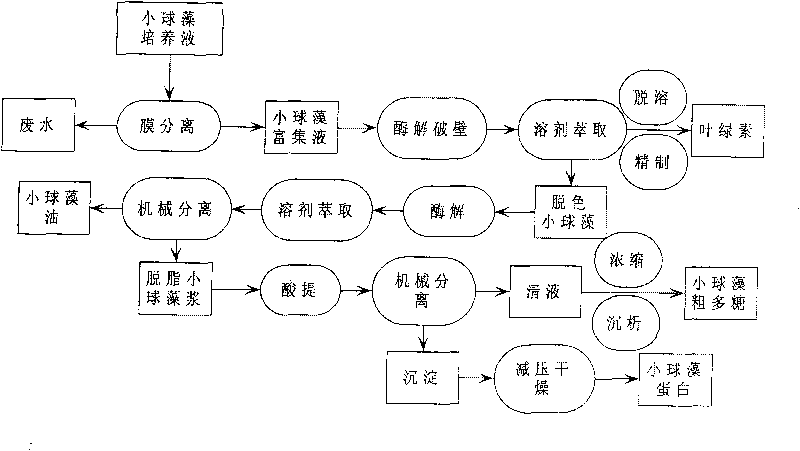

Method for continuously extracting functional components of chlorella vulgaris

InactiveCN101736045AEasy to keep activeReliable operationPeptide preparation methodsNatural dyesSolventChemistry

The invention relates to a method for continuously extracting functional components of chlorella vulgaris, which comprises the steps of enriching the chlorella vulgaris through the membrane separation technology, obtaining concentrated slurry of the chlorella vulgaris, adding a proper enzyme in a liquid phase system for wall-breaking, and using a solvent for extracting chlorophyll from chlorella vulgaris solution after wall-breaking, thereby being capable of obtaining a functional pigment product and reducing the color value of follow-up products; and firstly carrying out enzymatic hydrolysis on a water phase of the chlorella vulgaris after decoloring, then using the solvent for extracting functional grease, extracting active polysaccharides from the obtained degreased chlorella vulgaris by using the acid method, and then drying the other parts for obtaining crude proteins of the chlorella vulgaris. The main products comprise the chlorophyll, the active polysaccharides of the chlorella vulgaris, the functional grease of the chlorella vulgaris, the proteins of the chlorella vulgaris and the like, and the method optimizes the process on the basis of ensuring the activity of the functional components of the chlorella vulgaris, thereby obtaining high yield and reducing production cost.

Owner:BOHAI UNIV

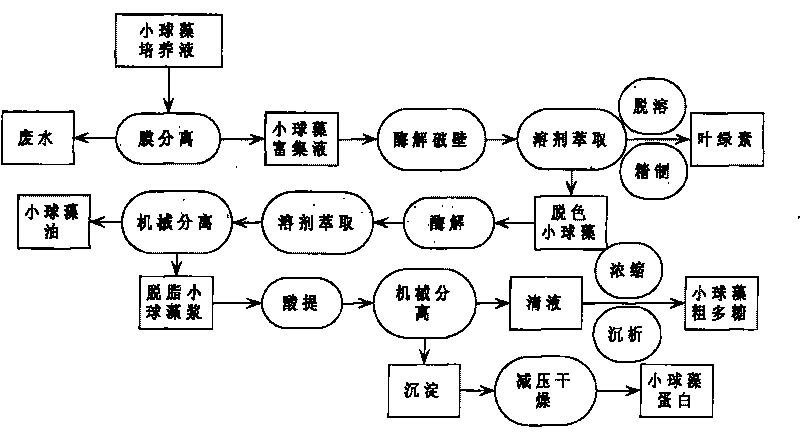

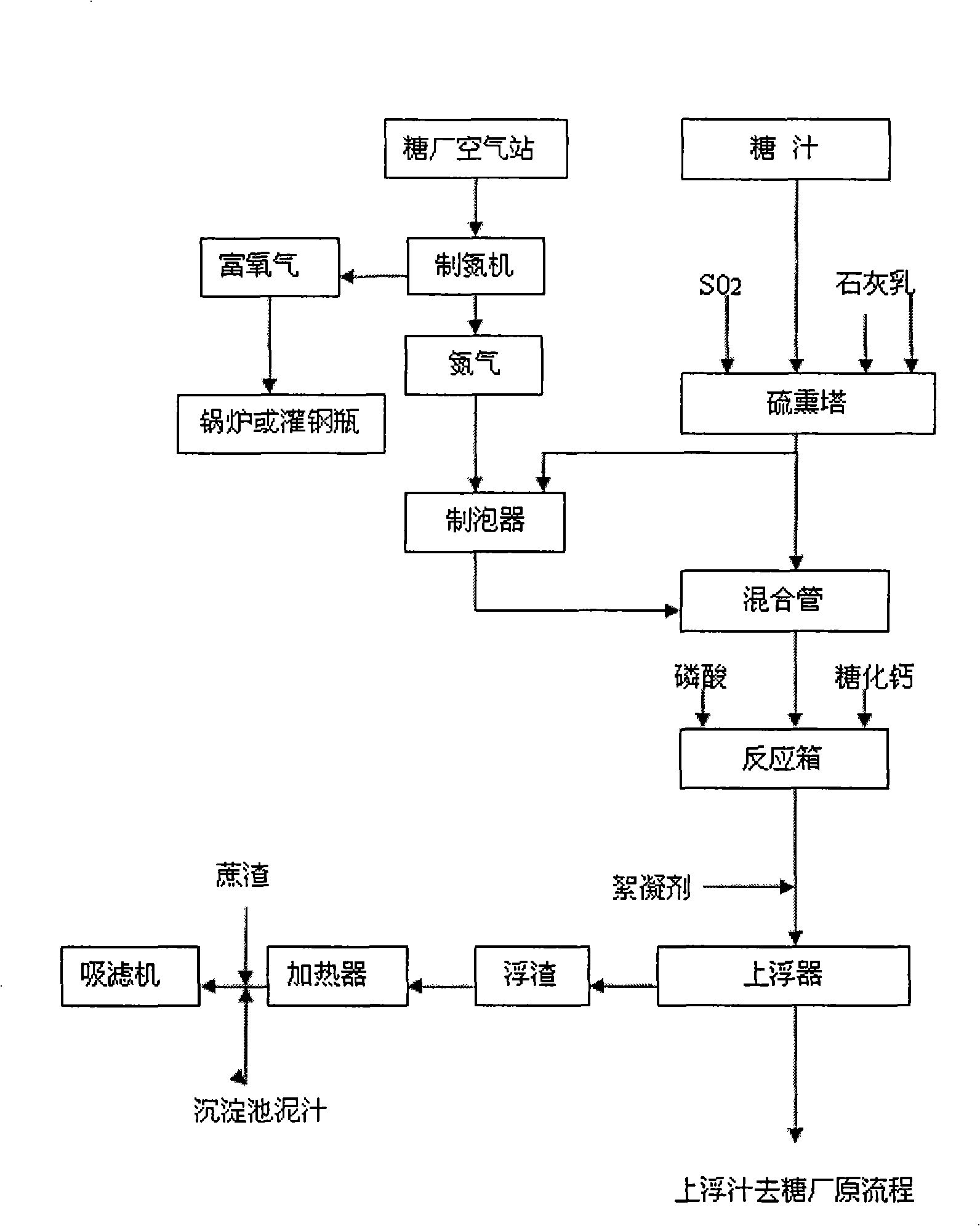

Sugar juice air-float clearing method

InactiveCN101294227AHighlight substantive featuresSignificant progressSugar juice purificationNitrogenNitrogen gas

The invention discloses an air floatation lustration method of sugar juice. Nitrogen is used as foaming air supply instead of air; thin juice (such as mixed juice, diffusion juice, neutral juice, clear juice and filtered juice) and concentrated sugar juice (such as syrup and molasses) in a sugar-refinery are processed through floatation lustration. The lustration method solves the problems that oxygen generated in the air floatation lustration method which takes the air as the foaming air supply has the oxidation encolouration side effects on the phenols in the sugar juice, the intensity of sulfitation is reduced, the sugar juice is fermented under the low temperature, etc., the sugar juice with better quality is obtained, and the product quality of the sugar-refinery is increased.

Owner:GUANGXI NANNING HUAXIN SUGAR IND TECH

Floating method of brown granulated sugar dissolved by a-wash

The invention discloses a floating method for A-wash remelting brown granulated sugar, in the method, A-wash is added while remelting brown granulated sugar to enable the purity of mixed syrup to reach or near the purity of rough syrup, and then the mixed syrup is treated by the syrup floating method. Not only the product quality is guaranteed, the color value is lowered and reducing sugar, color elements and impurities are removed, but also the back boiling amount of low purity materials is increased, the rearward shift of the materials is reduced, the yield and the purity of waste molasses are effectively lowered to achieve the purposes of improving the yield of white granulated sugar, increasing the product recovery and improving the economic benefits of the sugar factories.

Owner:GUANGXI YONGXINHUA SUGAR GROUP

Sugar manufacture clarification process

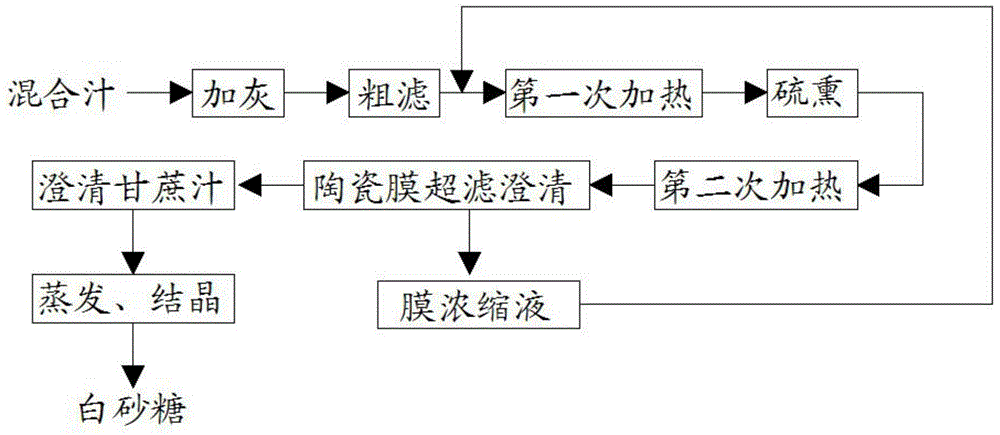

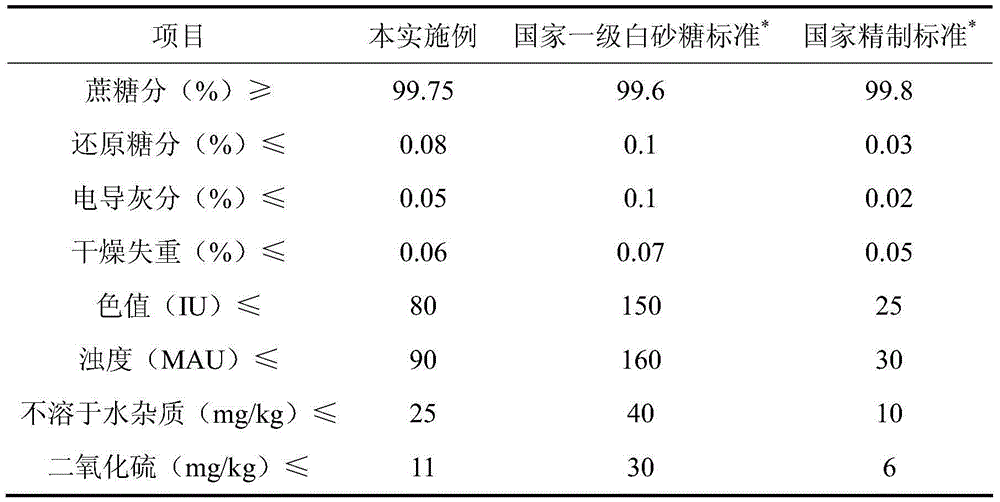

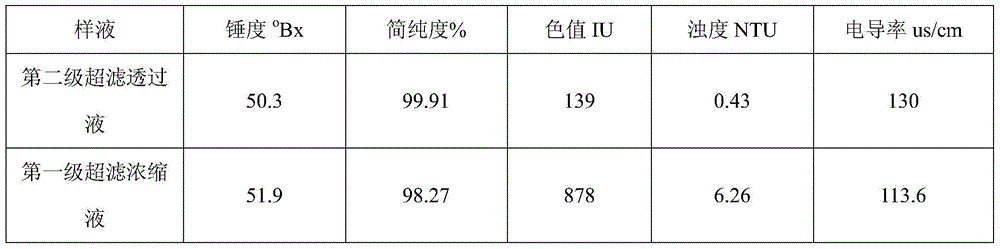

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

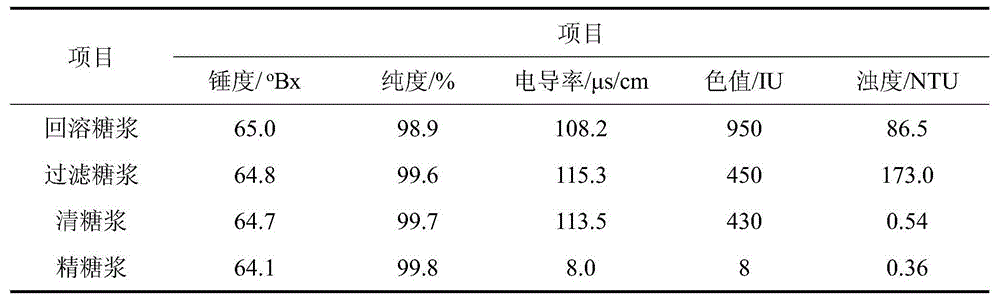

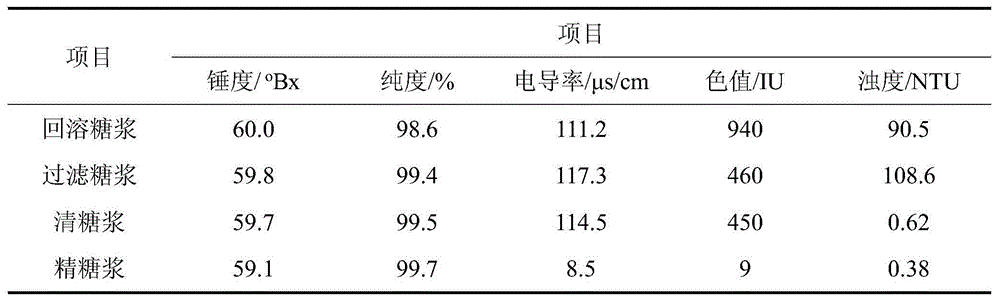

Membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology

InactiveCN104404174AReduce turbidityHigh purityPurification by physical meansFiltrationMembrane technology

The invention discloses a membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology. The technology comprises the following steps of carrying out press filtration on syrup to obtain clear syrup, before evaporation, feeding the clear syrup to a microfiltration device, carrying out microfiltration on the clear syrup by a microfiltration device to obtain a microfiltred concentrate liquid and a microfiltred penetrating liquid, removing the microfiltred concentrate liquid, collecting the microfiltred penetrating liquid, feeding the microfiltred penetrating liquid into a ultrafiltration device, carrying out further condensation treatment on the primary ultrafiltration concentrate liquid, carrying out sterilization to obtain a sugar liquid, and feeding the last ultrafiltration concentrate liquid into follow-up processes of sugar refining. The technology does not produce a waste liquid, is free of a chemical reagent, has no damage to the human body, improves syrup purity, reduces syrup turbidity and is conducive to crystallization.

Owner:GUANGXI UNIV

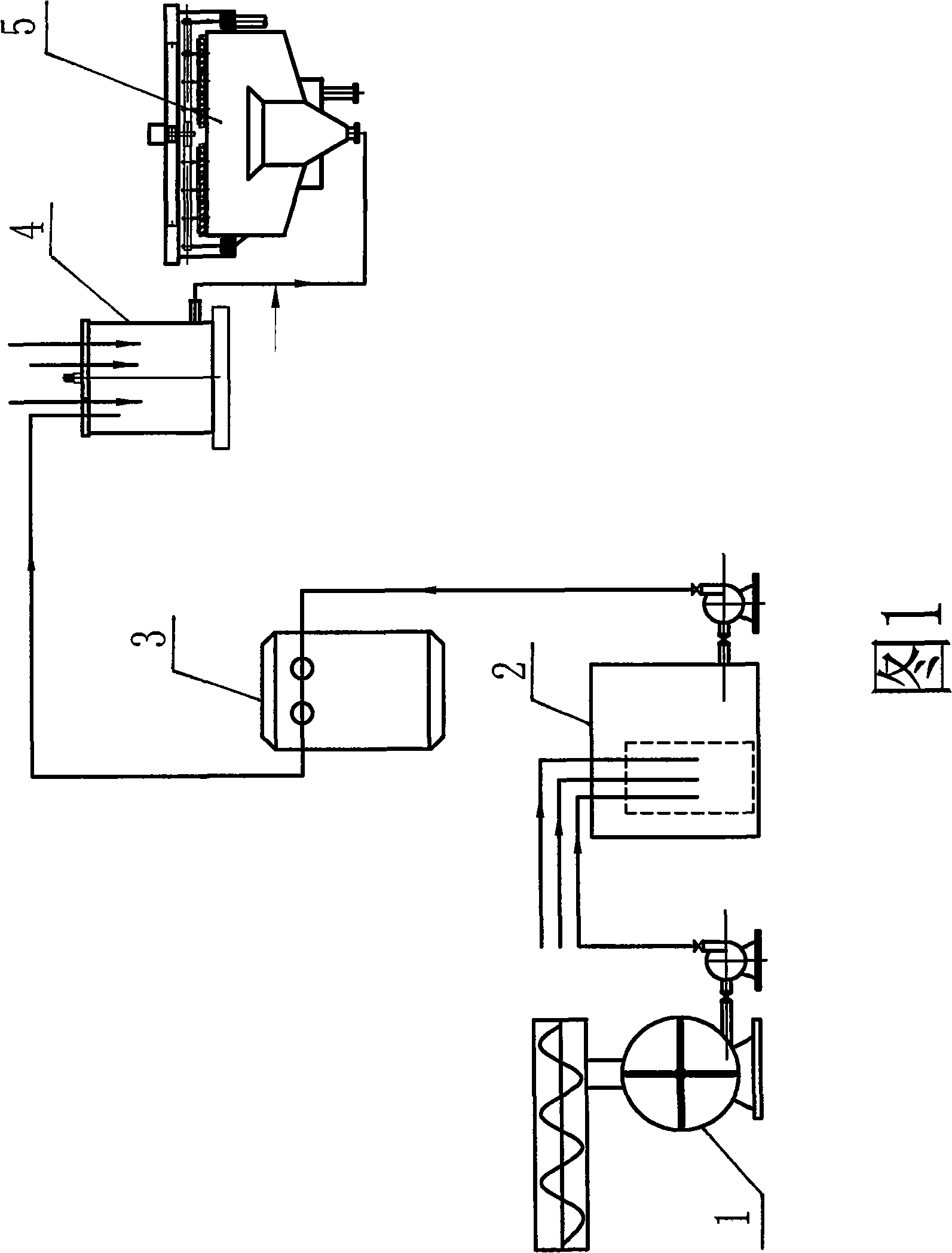

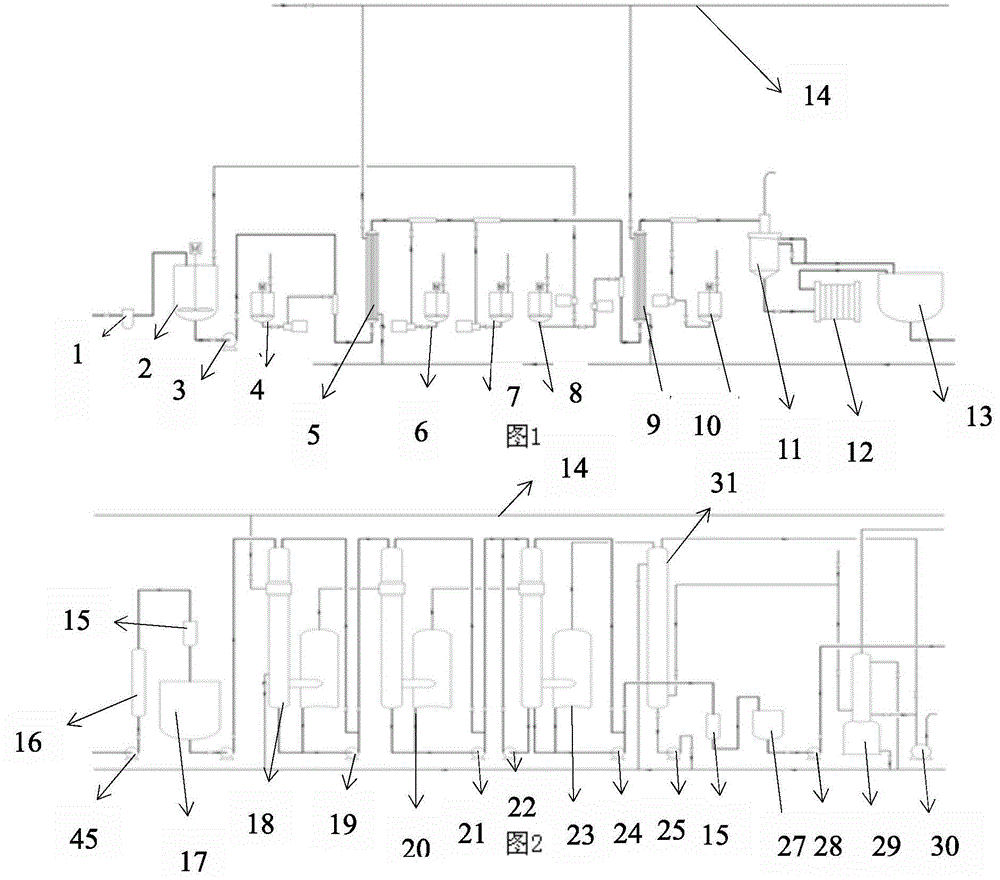

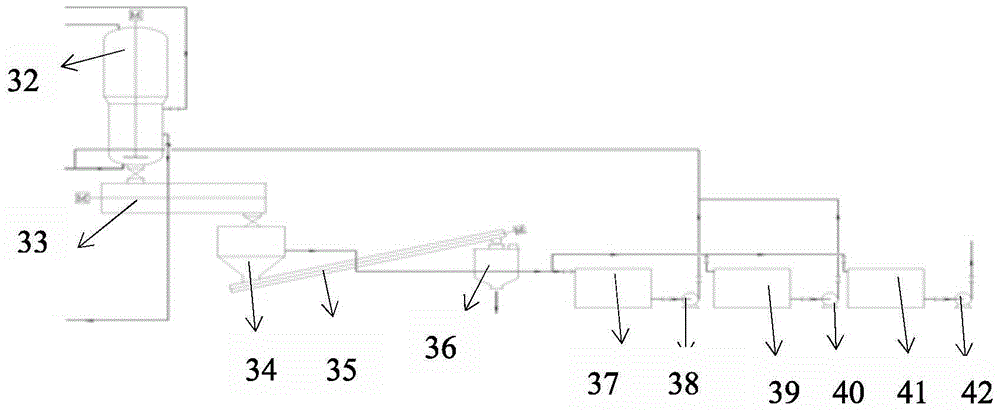

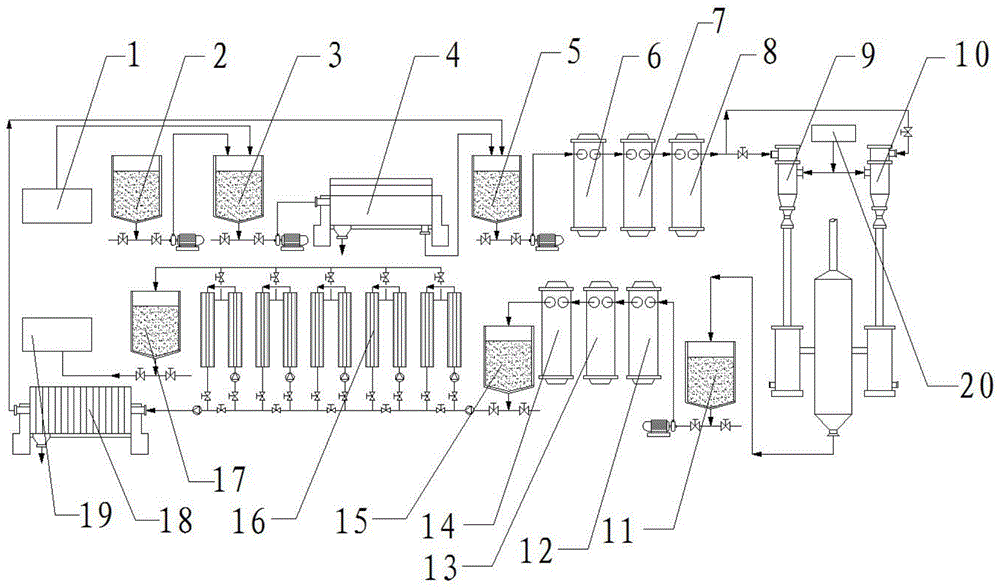

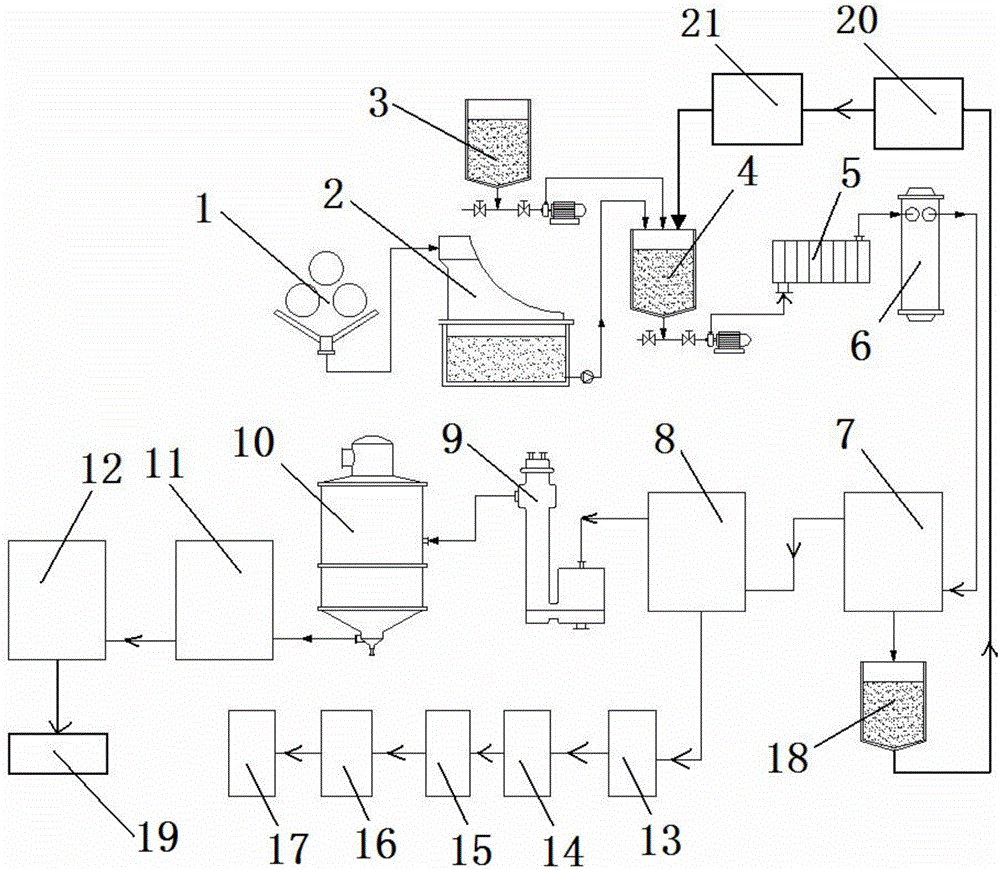

Cane sugar manufacture production system

InactiveCN103981291ALow investment costReduce manufacturing costSucrose extractionSugar juice boiling/evaporationIndustrial equipmentSettling basin

The invention discloses a cane sugar manufacture production system. The production system is characterized by comprising a cleaning system, a discoloring system, an evaporation system, a sugar boiling system and a purging and drying system; the system device comprises a pipeline filter, a mixed juice tank, a mixed juice pump, a static mixer, a heater, a rapid settling basin, a dosing storage tank, a filter press, a falling film evaporator, a condenser, a discoloring column, a bag filter, a sugar boiling crystallizing tank, a syrup tank, a help-crystallization box, a purging box, a conveyor, a drying machine, a gas-liquid separator, a honey jar, a clear juice pump, a syrup pump, a circulating pump and a vacuum pump. According to the cane sugar manufacture production system, a stove drying system and a carbonation system in the original sugar refining design are canceled, a novel process is adopted, novel industrial equipment is introduced, and the system can serve as a scientific research platform for performing a novel cane sugar manufacture process or an industrial production line for producing raw sugar, primary white granulated sugar, high-grade sugar and refined sugar.

Owner:GUANGXI UNIV +1

Decolourization method for producing sucrose mix juice

InactiveCN101082065AHigh purityReduce color valuePurification using adsorption agentsSaccharumSucrose

The sucrose juice decolorizing process includes the following steps: low temperature phosphoric acid floating treatment of mixed juice in the purity of 78.19 AP and through preheating to 50 deg.c, adding phosphoric acid mixture, neutralizing with lime milk, inflating, adding flocculant and separating out neutral slime, to obtain clear juice of purity raised to 80.66 AP and color value lowered to 92.66 st deg; pre-decolorizing the clear juice heated to 75 deg.c with diatomite in 1.0 wt% of sucrose for 60 min to lower the color number to 75.23 st deg; and decolorizing the clear juice with active carbon in 1.0 wt% of sucrose for 30 min to further lower the color number to 30.70 st deg. The process has the advantages of no production of alkali slime, short technological process, high purity of obtained sucrose juice and greatly lowered color number.

Owner:TIANJIN HANGU DISTRICT FUXIANG FERTILIZER PROCESSING FACTORY

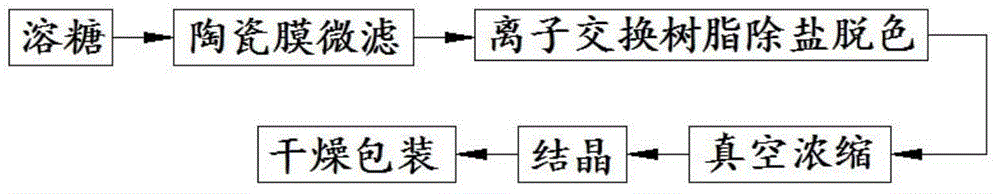

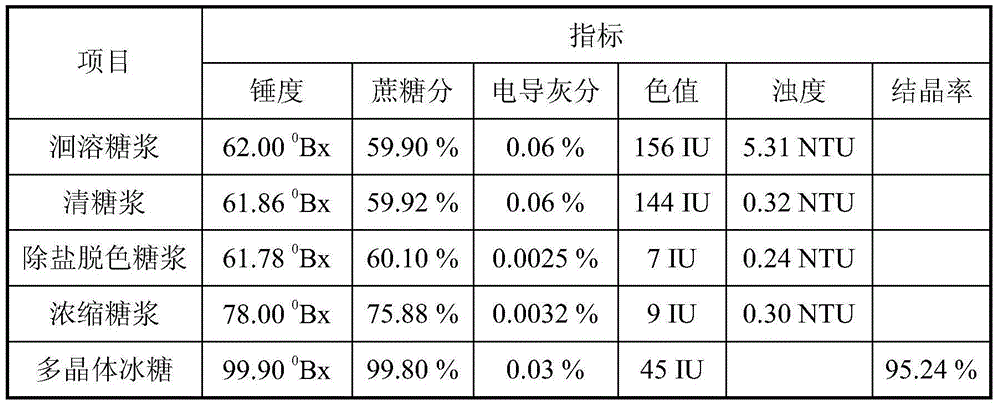

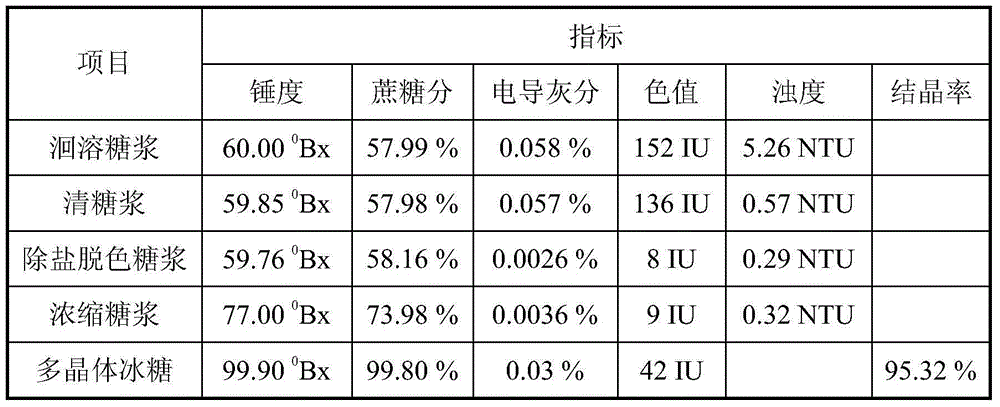

Production process of poly-crystal rocky candy

The invention discloses a production process of poly-crystal rocky candy. The production process comprises the following six steps: by taking first-grade white sugar as a raw material, dissolving the sugar, micro-filtering and clarifying, desalting and decolorizing by using ion exchange resin, concentrating in vacuum, charging seeds for crystallization, drying and packaging to produce the poly-crystal rocky candy. The poly-crystal rocky candy produced by the method disclosed by the invention is sweet and delicious in taste and white and transparent in color and luster; no sodium hydrosulfite is added for color protection during the overall production, so the product is environmental friendly and safe; the crystallization rate of the rocky candy is above 95%; the problem of low crystallization rate during production of the poly-crystal rocky candy for a long time is solved.

Owner:GUANGXI UNIV

Cleaing method of sulfurous acid method produced syrup

A clean process for preparing syrup by sulfurous acid method features that the mixture of fume and fermenting gas, is used as the aerating gas for lower cost, a carbon method for aerating gas is used, which features that the pH value in aerating tank is controlled by the quantity of added lime for preventing high-temp strong-alkaline environment, and the adding lime and aerating are performed in short time for fully saturation of syrup mixture and CO2 and preventing decomposition of reducing sugar. Its advantages are high clean effect and efficiency.

Owner:王兆群

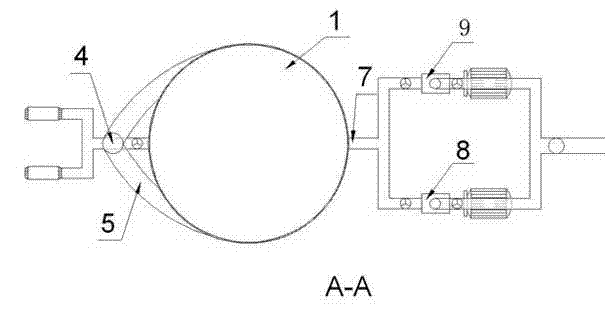

Stoving neutralizing auxiliary reaction tower

InactiveCN103173579AControl dwell timeControl unit controls dwell timePurification by oxidation/reductionPurification using alkaline earth metal compoundsChemical reactionSulfur

The invention aims to provide a stoving neutralizing auxiliary reaction tower. The stoving neutralizing auxiliary reaction tower comprises a cylindrical tank body, a stoving neutralizing reactor, a tube diffuser, a juice outlet pipe, a variable frequency juice outlet pump and a liquid level control device. By using the stoving neutralizing auxiliary reaction tower, the defects of the conventional neutralizing reaction device in a sugar refinery are overcome, and the problem of incomplete chemical reaction of the cane juice subjected to stoving liming is solved. The invention also provides a method for carrying out stoving neutralizing reaction by using the stoving neutralizing auxiliary reaction tower. According to the method, the stoving neutralizing auxiliary reaction tower is reasonably utilized, so that the standing time of the cane juice subjected to stoving liming is greatly increased, the uniformity of the cane juice is improved, the reaction of neutralized juice is more complete, and remarkable effects of improving the syrup purity, reducing the color value of white sugar and turbidity and lowering the sulfur dioxide residues are achieved.

Owner:南宁苏格尔科技有限公司

Method for absorbing and activating carbon dioxide in boiler flue gas and application of method

ActiveCN103007727AReduce emissionsSimplified absorption and activation application processCalcium/strontium/barium carbonatesProductsActivated carbonHigh concentration

The invention discloses a method for absorbing and activating carbon dioxide in boiler flue gas and application of the method. The method comprises the following steps of: 1, replacing cane juice through lime milk with the concentration of 8-15-degree Be for absorbing the carbon dioxide in boiler flue gas and generating by-products of a calcium carbonate solution in the decarbonization process in a two-stage spray packing absorption tower; 2, reacting phosphoric acid and one part of calcium carbonate solution, and generating a monocalcium phosphate solution and high-concentration carbon dioxide gas when the PH is controlled to be less than 3; 3, excessively injecting the high-concentration carbon dioxide gas into the calcium carbonate solution through an ejector, dissolving and activating the calcium carbonate into calcium bicarbonate solution, and controlling the PH to be less than 6; and 4, respectively filling the monocalcium phosphate solution and calcium bicarbonate solution generated in the decarburization and activation processes in the steps 2 and 3 into a storage box for later use. The method has the advantages of reducing the retention time of the cane juice in the carbon absorption process and saving the investment, along with high absorption rate and the like.

Owner:GUANGXI NANNING HUAXIN SUGAR IND TECH

Process for preparing modified polyisocyanate

InactiveCN101553517AReduce color valueImprove thermal stabilityOrganic chemistrySilica particleSilicon dioxide

A process for preparing a liquid organic isocyanate having a carbodiimide group and / or an uretonimine group, excellent in storage stability. In a process for preparing a modified polyisocyanate by carbodiimidizing an organic polyisocyanate in the presence of a phospholine-based catalyst, silicon dioxide particles having a specific surface area of at least 400 m / g and an oil absorption of at least 180 ml / 100 g are used to adsorb and inactivate the catalyst to thereby terminate the carbodiimidization reaction.

Owner:BAYER MATERIALSCIENCE AG

Method for storage and green processing of bee honey

InactiveCN104381781AReduce colorReduce production capacityFood preservationFood preparationBiotechnologyMass content

The invention discloses a method for storage and green processing of bee honey. The method comprises the following steps: firstly heating raw material-bee honey for decrystallization, controlling the heating temperature to be 40-50 DEG C, and controlling the heating time to be 2-4 hours to ensure that crystallized bee honey is fully dissolved; then performing first-stage filtration, resin decolorization and second-stage filtration, and then concentrating treated bee honey by adopting a falling film concentration evaporator in sterile conditions to obtain a solid matter with the mass content of 70-90%; controlling the vacuum evaporation temperature to be 50-60 DEG C, and controlling the vacuum degree to be 0.90-0.10MPa; and finally cooling and packaging. The bee honey produced by adopting the green processing method disclosed by the invention has the relatively high quality and the relatively high international competitiveness; natural active components in the bee honey cannot be damaged by virtue of low-temperature processing, and the hydroxymethyl furfural content (less than 10mg / kg) is far lower than the national standard (less than 40mg / kg); and the bee honey is low in color value, can realize the energy-saving and environment-friendly effects in production process and is high in production efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Method for Producing Sugar

InactiveUS20120225455A1Efficient removalReduce color valueSugar derivativesPurification using chemicalsSugarChemistry

Disclosed is a process for producing a sugar, whereby any non-sugar component can be removed from a sugar solution with high efficiency and the color value of the sugar solution can be reduced. Specifically disclosed is a process for producing sugar, which is characterized by comprising: adding ethanol to a sugar solution produced by squeezing a plant; removing precipitates produced by the addition of ethanol from the solution; and crystallizing sugar from the sugar solution from which the precipitates have been removed.

Owner:ASAHI BREWERIES LTD

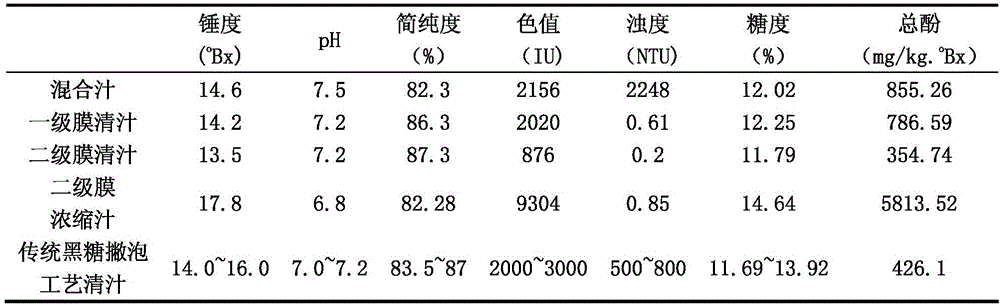

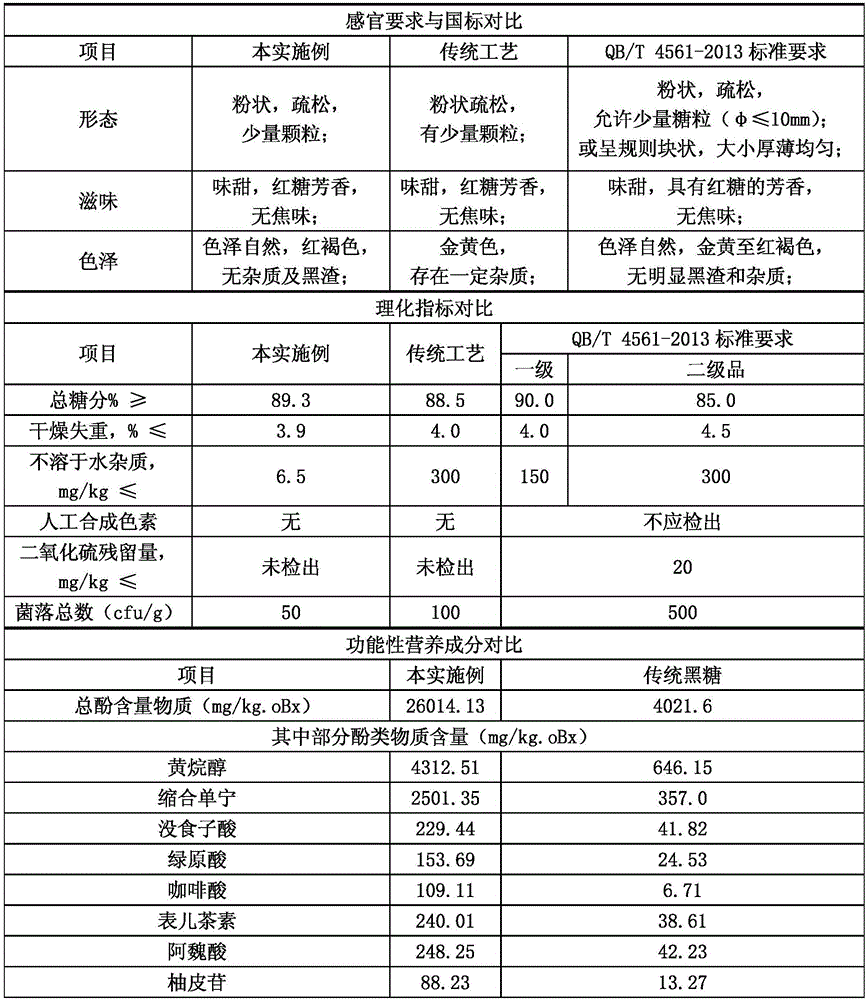

Processing method of functional brown sugar rich in polyphenols

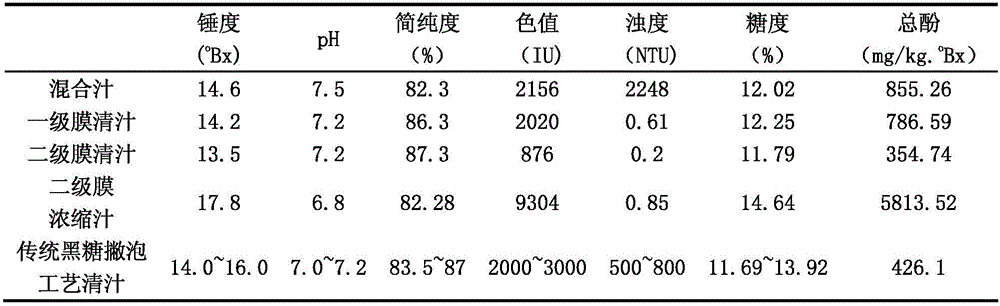

ActiveCN106167838AImprove qualityHigh nutritional valueSugar productsPurification by physical meansCodonopsisAdditive ingredient

The invention discloses a processing method of functional brown sugar rich in polyphenols. The processing method comprises following steps: sugarcane is juiced so as to obtain a raw material liquid, lime milk is added, and an obtained mixture is heated so as to obtain a heated raw material solution; a first-grade ceramic membrane is used for filtering so as to obtain a first grade membrane clear juice and a first grade membrane condensed juice; a second membrane is used for filtering so as to obtain a second membrane grade clear juice and a polyphenols-enriched second grade membrane condensed juice; and the polyphenols-enriched second grade membrane condensed juice is used for producing the functional brown sugar rich in polyphenols, wherein at least one or a plurality of ingredients selected from colla corii asini, red date, longan, Angelica sinensis, Radix Codonopsis, Chinese wolfberry, bulbus lilii, herba leonuri, and ginger are taken as functional ingredients, and are decocted with water so as to obtain a solution, or dried and smashed into powder, the polyphenols-enriched second grade membrane condensed juice is subjected to evaporation concentration and is mixed with the solution or the powder, and sugar boiling, graining, moulding, and packaging are carried out so as to obtain the functional brown sugar rich in polyphenols. According to the processing method, effective enrichment of polyphenols is realized, a plurality of functional ingredients which can be taken as both medicine and food are added, the content of polyphenols is 4 to 8 times higher than that of brown sugar obtained via traditional technology, and brown sugar quality and nutrient value are improved.

Owner:GUANGXI UNIV

Sugar juice decoloring method

InactiveCN101481746AReduce color valueQuality improvementPurification by oxidation/reductionComing outSulfur

The invention discloses a sugar juice decoloring method. The method comprises the following steps: during a sugar making process, ClO2 is used for decoloring a sugar juice; the sugar juice refers to any one, two, three or four of a clear juice coming out of a clarification section, crude syrup or re-dissolution syrup coming out of an evaporation section, or massecuite coming out of a crystallization section; CIO2 is respectively added to any one, two, three, or four of the clear juice, the syrup or the messecuite; any one, two, three or four of the four sugar juices are respectively or simultaneously oxidized and declored; the amount of CIO2 added into the sugar juice is 0.0005 percent to 0.3 percent of the weight of the sugar juice; and the adding method is that CIO2 is directly added to a corresponding sugar juice, and the sugar juice is fully mixed and reacted with CIO2 during a flow and pumping process, so as to achieve the aim of oxidation and decoloration. The sugar juice decoloring method of the invention can effectively reduce the color value of the sugar juice, reduce the color value of a product sugar and the residue of sulfur, and simultaneously improve the purity and the quality of the sugar.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Process for the production of toluene diisocyanate

ActiveUS20070287857A1Less coloringReduce colorAmino compound purification/separationOrganic compound preparationToluene diisocyanateToluenediamine

The invention relates to a process for the production of toluene diisocyanate, in which the crude toluenediamine obtained from the hydrogenation is purified and then phosgenated. The purification step reduces the total amount of cyclic ketones to less than 0.1% by weight, based on 100% by weight of the toluenediamine.

Owner:COVESTRO DEUTSCHLAND AG

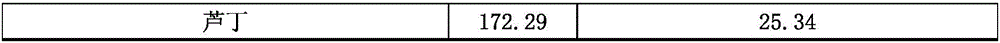

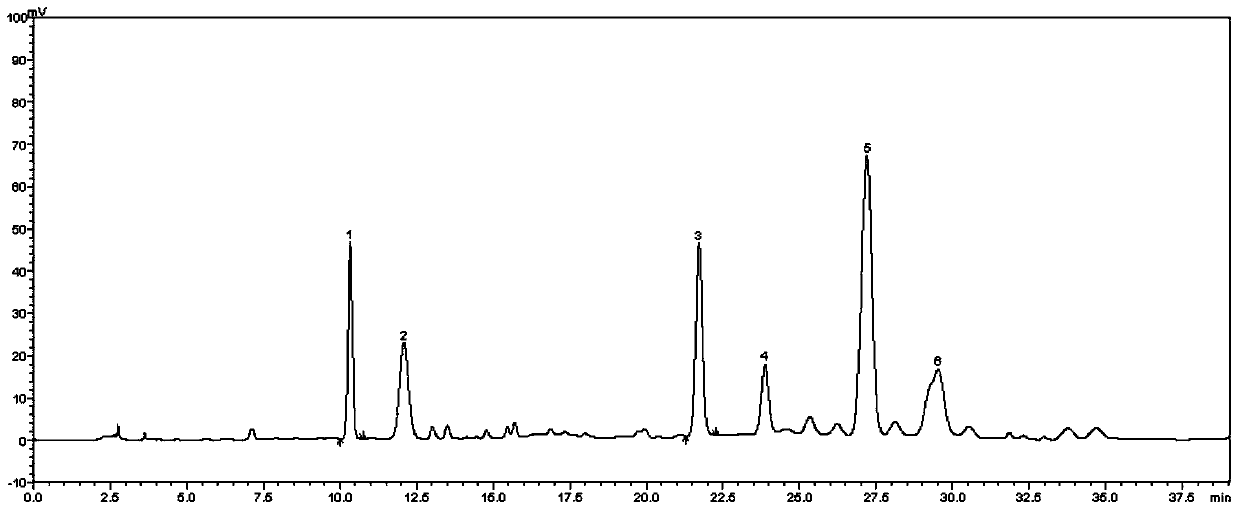

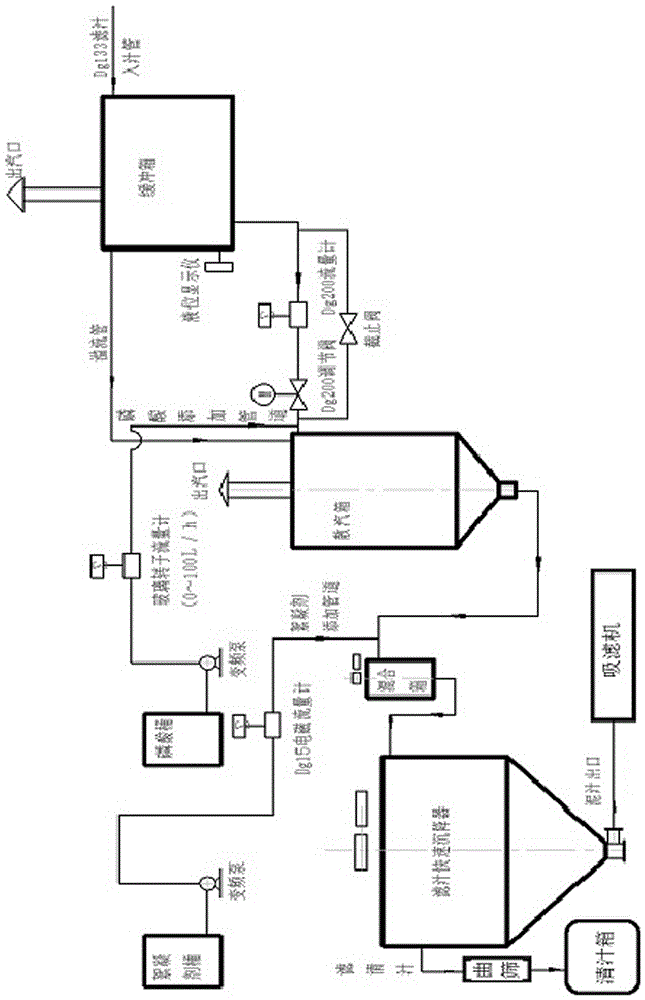

Method for rapidly preparing small peptide amino acids by microwave-assisted protein acid hydrolysis

InactiveCN103739663ALow hydrolysis efficiencyImprove hydrolysis efficiencyPeptide preparation methodsUltrafiltrationAmino acid

The invention discloses a method for rapidly preparing small peptide amino acids by microwave-assisted protein acid hydrolysis. The method comprises: in the microwave environment, performing hydrolysis on a mixed solution of a denatured protein raw material and hydrochloric acid and sulfurous acid, and performing centrifugation filtering, nanofiltration membrane deacidification and ultrafiltration separation to obtain small peptide amino acids with different molecular weight. The preparation method is mild in reaction conditions, short in production period, low in production cost and high in product recovery rate, realizes "three wastes (waste gas, waste water and industrial residue)" zero discharge, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

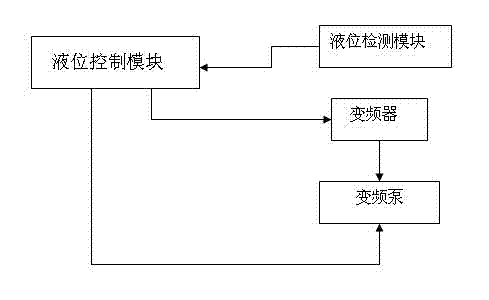

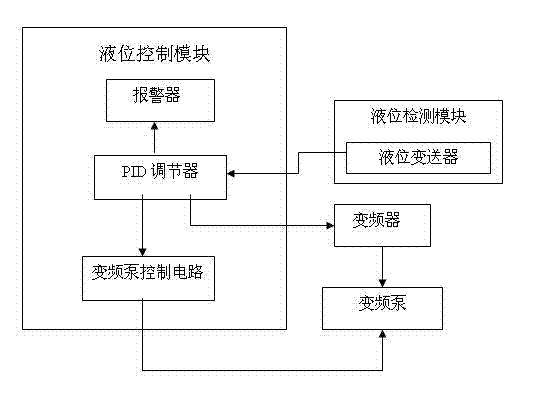

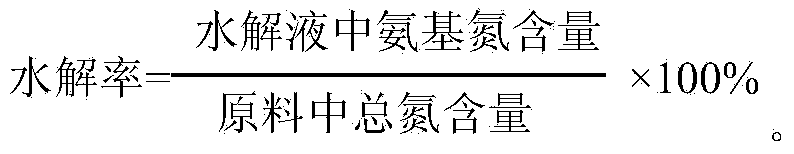

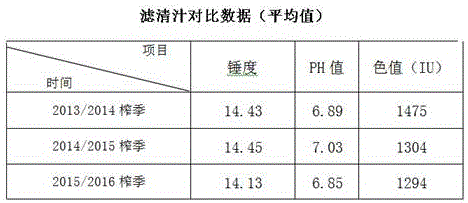

Device for fast sedimentation of filtered juice of sugar refinery and control method of device

InactiveCN105779662AImprove stabilityStable addition of excipients to achieve sedimentation separationPurification by physical meansAutomatic controlBuffer tank

The invention relates to a device for fast sedimentation of filtered juice of a sugar refinery and a control method of the device. The device comprises a buffer tank, a degassing tank, a mixing tank and a fast filtered juice sedimentation vessel, the buffer tank is connected with the degassing tank through a flowmeter and a regulating valve, a stop valve is arranged between an outlet of the buffer tank and an inlet of the degassing tank, and the top of the buffer tank is provided with an overflow pipe connected with the degassing tank; the degassing tank is connected with the mixing tank prior to being connected with the fast filtered juice sedimentation vessel. According to the control method, by arrangement of the electromagnetic flowmeter, the electric regulating valve, a liquid level display instrument, the overflow pipe and the like, the opening of a filtered juice valve can be controlled and regulated automatically online according to the liquid level, so that the amount of the filtered juice entering the fast sedimentation vessel in the sugar making process is relatively stable and smooth and auxiliary materials are added stably so as to realize stable settlement separation; therefore, quality of products is improved, and cost is lowered.

Owner:广西糖业集团良圻制糖有限公司

Process for the production of toluene diisocyanate

ActiveUS8030522B2Reduce colorReduce color valueAmino compound purification/separationOrganic compound preparationToluene diisocyanateToluenediamine

The invention relates to a process for the production of toluene diisocyanate, in which the crude toluenediamine obtained from the hydrogenation is purified and then phosgenated. The purification step reduces the total amount of cyclic ketones to less than 0.1% by weight, based on 100% by weight of the toluenediamine.

Owner:COVESTRO DEUTSCHLAND AG

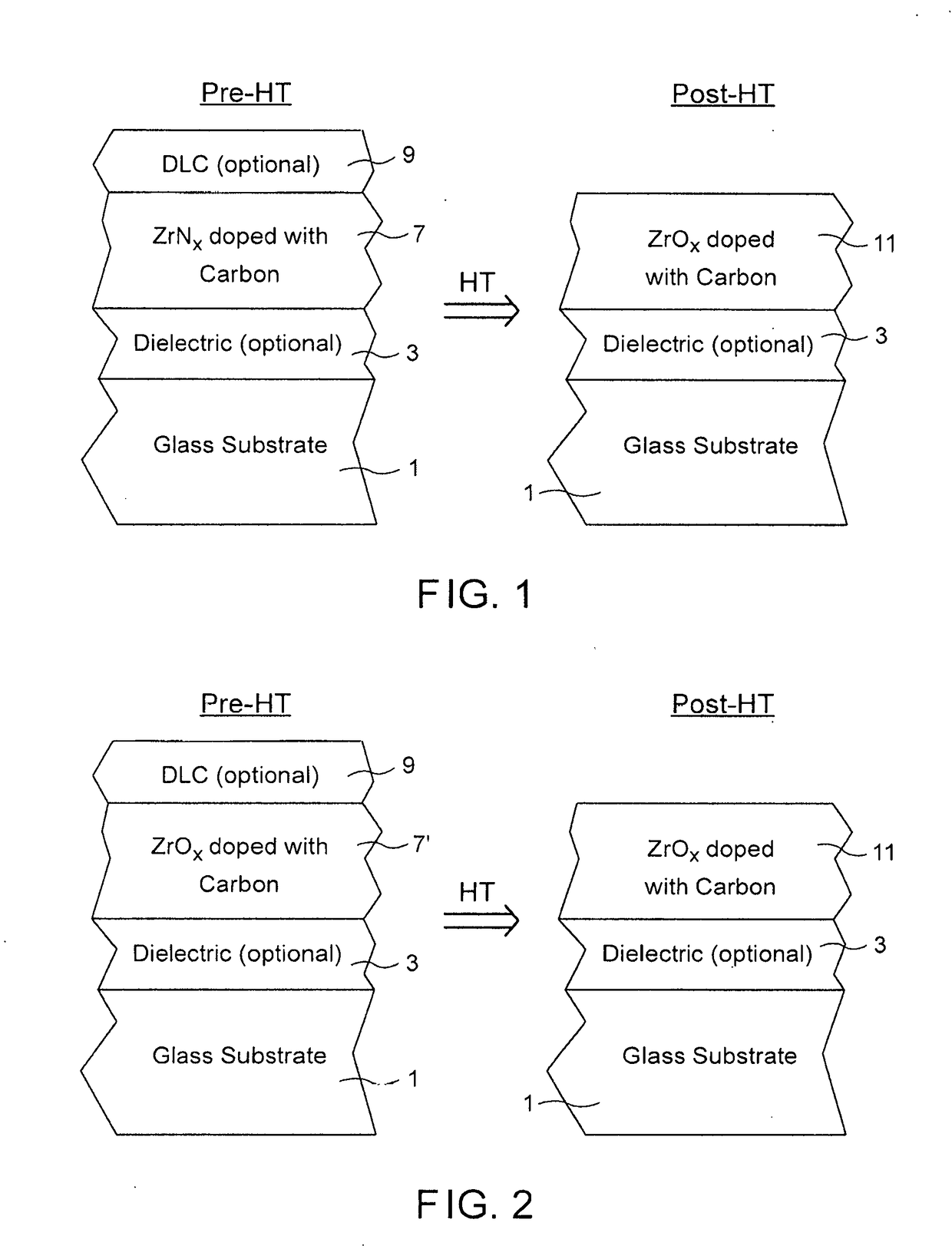

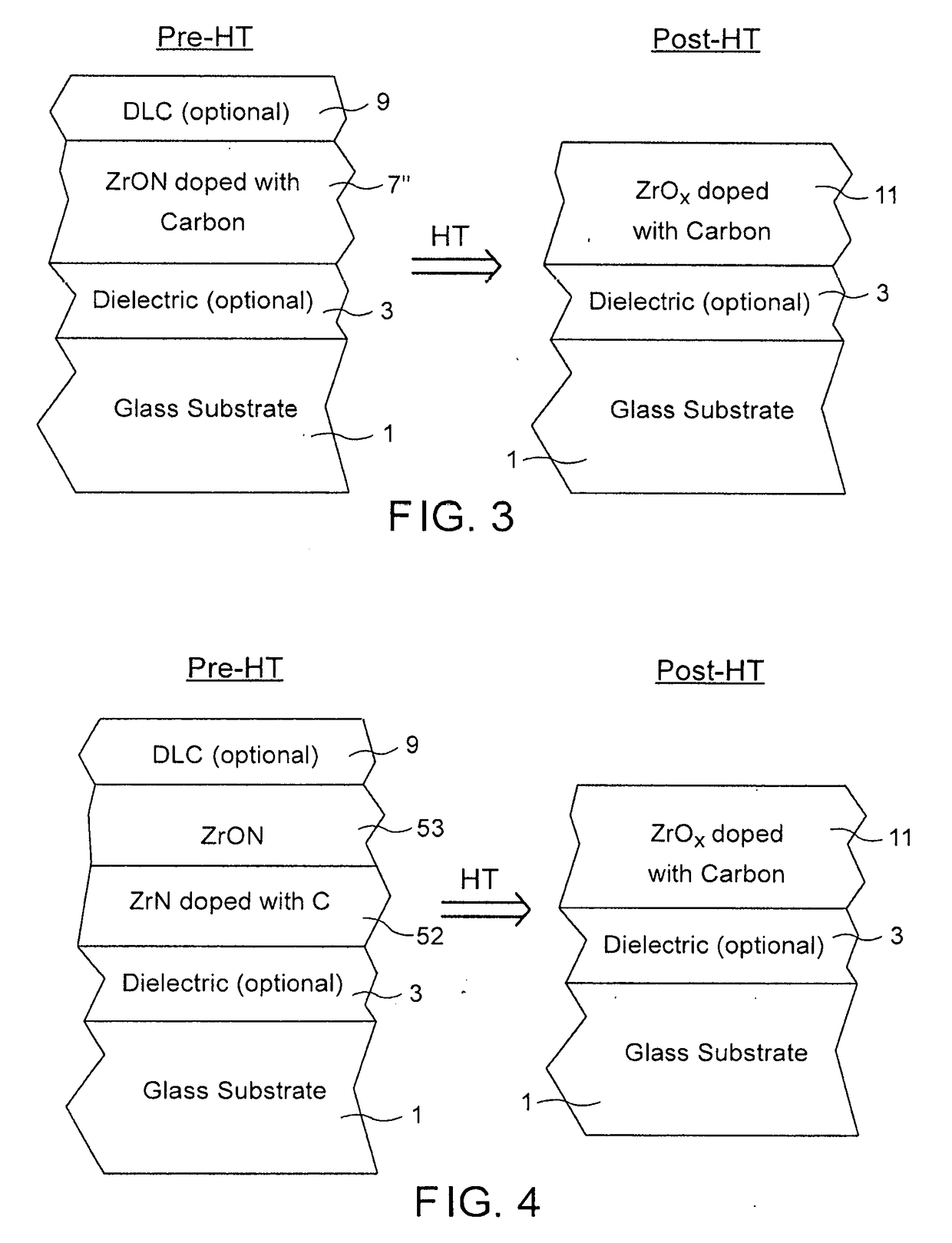

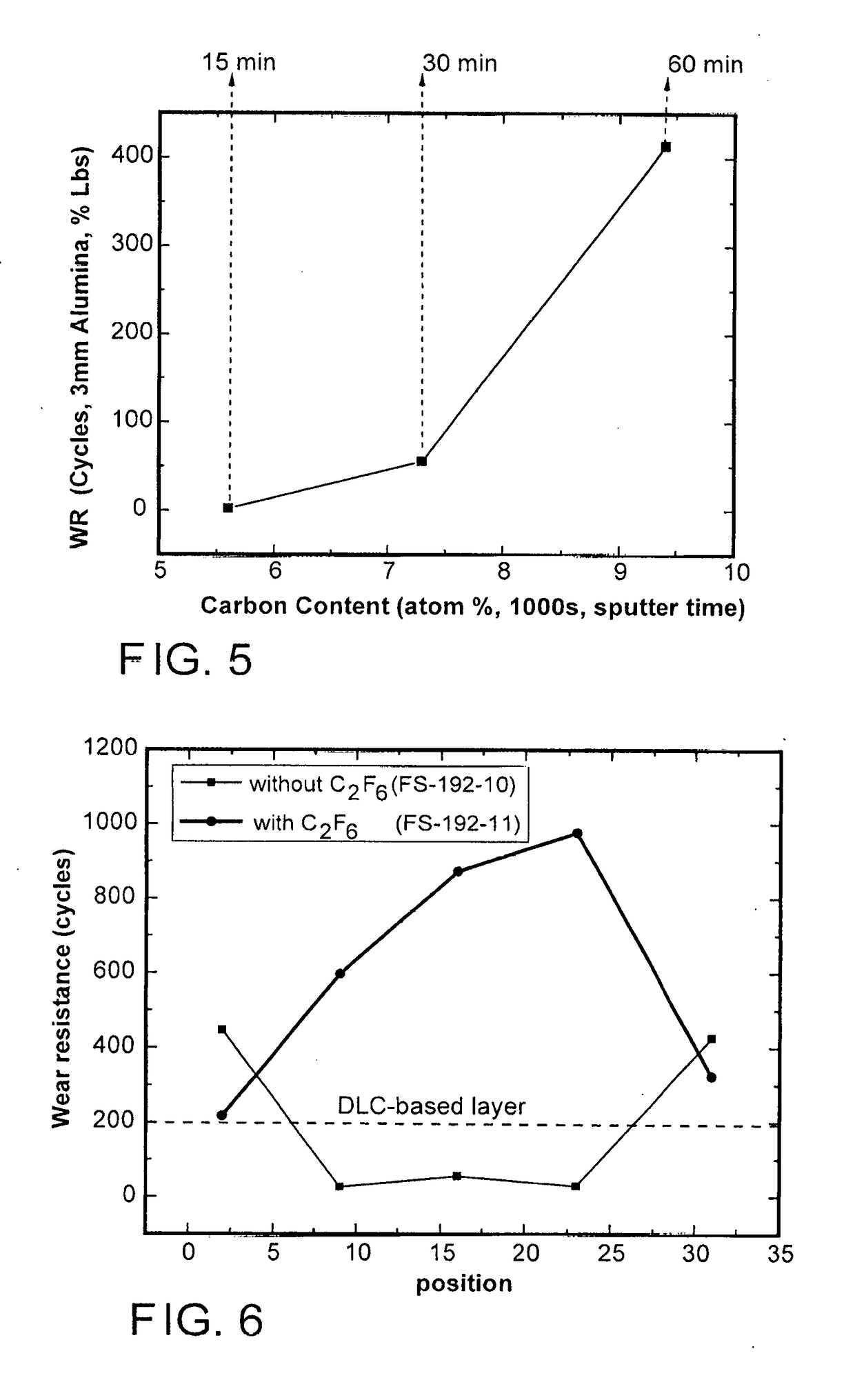

Heat treatable coated article with carbon-doped zirconium based layer(s) in coating

ActiveUS20180127307A1Improve transmission performanceImprove wear resistanceVacuum evaporation coatingSputtering coatingWear resistanceNitride

In certain example embodiments, a coated article includes a carbon-doped zirconium based layer before heat treatment (HT). The coated article is heat treated sufficiently to cause the carbon-doped zirconium oxide and / or nitride based layer to result in a carbon-doped zirconium oxide based layer that is scratch resistant and / or chemically durable. The doping of the layer with carbon (C) has been found to improve wear resistance.

Owner:GUARDIAN GLASS LLC +1

Sugar production clarifying production line

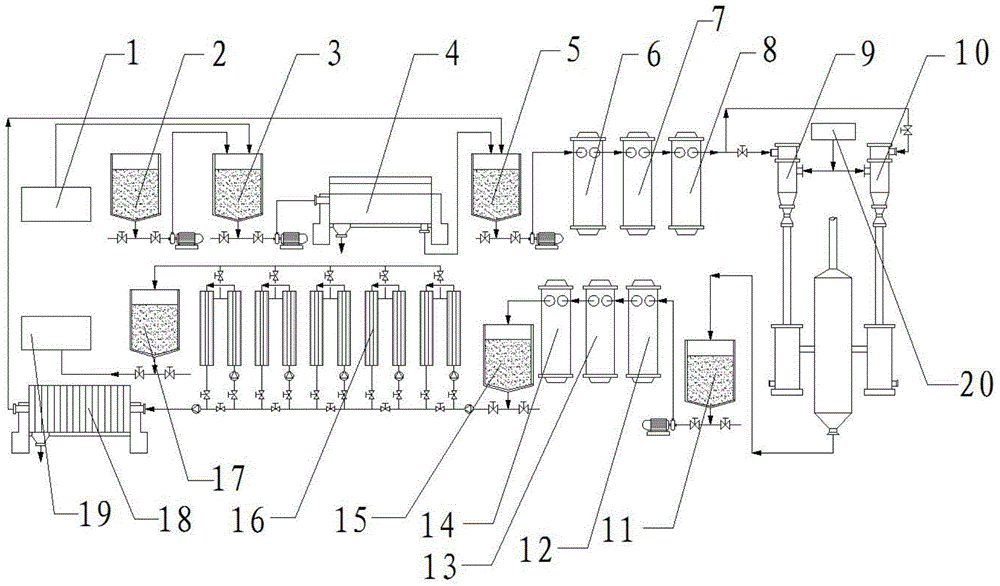

ActiveCN104831002AReduce color valueHigh purityPurification using alkaline earth metal compoundsPurification by physical meansUltrafiltrationChemistry

A sugar production clarifying production line comprises a mixed juice box, a horizontal screw-type centrifuge, a first heating device, a sulfur fumigating device, a second heating device, a multi-stage ceramic membrane ultrafiltration system, and a plate-frame filter press, which are connected in sequence. During the clarification process of mixed sugarcane juice, only a little amount of limestone and SO2 is added, so the sulfur content of finished sugar is very low, and moreover the sugar has the advantages of low color value, high purity, and low ash content, and is capable of meeting the requirements of high-end customers. Furthermore, during the sugarcane juice clarification process, a ceramic membrane is used to carry out ultrafiltration and clarification; because the membrane resistance due to the scales on the ceramic membrane is small, the membrane permeation flux is large when the ceramic membrane is used to filter sugarcane juice, moreover, the decay speed of membrane flux is slow, the high membrane flux can last for a long time, thus the membrane washing period is prolonged, and the membrane washing frequency is reduced.

Owner:GUANGXI UNIV

Method for raising yield of xylooligosaccharide

The invention discloses a method for raising the yield of xylooligosaccharide and belongs to the fields of chemical engineering and food. The method comprises of treating corn straw as the raw material, firstly, sequentially conducting air drying and pulverization, conducting soaking treatment with water and ethyl alcohol for removing water soluble impurities and fat soluble impurities in the raw material, and then conducting lignin removal treatment through a sodium chlorite method; secondly, obtaining a xylan extracting solution through an alkaline extraction method, and after pH is adjusted to be neutral, conducting concentration for removing salt; finally, conducting depolymerization treatment on xylan through an enzymolysis method and an acidolysis method in sequence, and conducting centrifugation, activated carbon treatment and freeze-drying, so that a xylooligosaccharide product is obtained. The method has the following advantages that xylan liquid obtained through the method is subjected to a hydrolysis reaction, and the complex separating and drying steps in the preparation process are omitted; enzymolysis residues are subjected to acetic acid treatment at the high temperature, the yield of the xylooligosaccharide can be raised, and no excessive influence can be caused to the acidic and basic property of the product; the straw is utilized as the raw material, so that good economic benefits and ecological significance are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

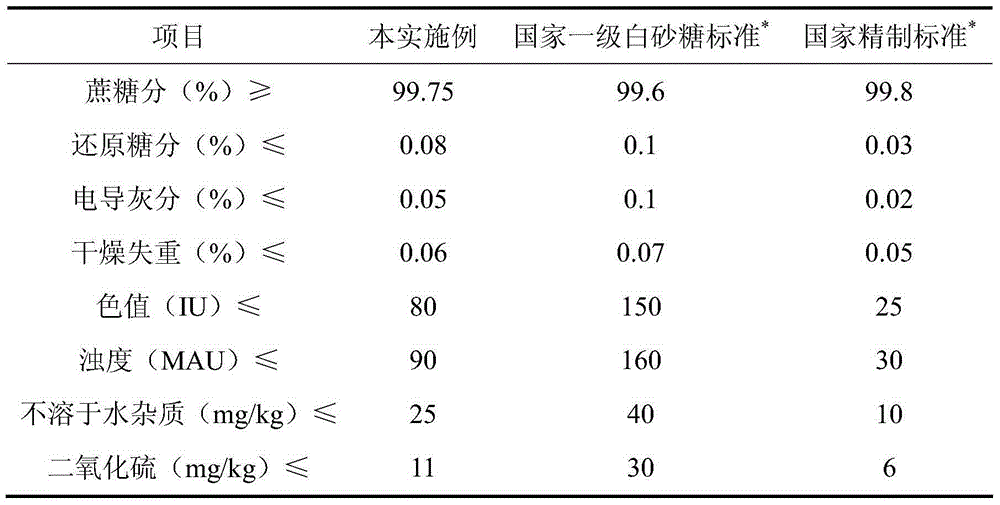

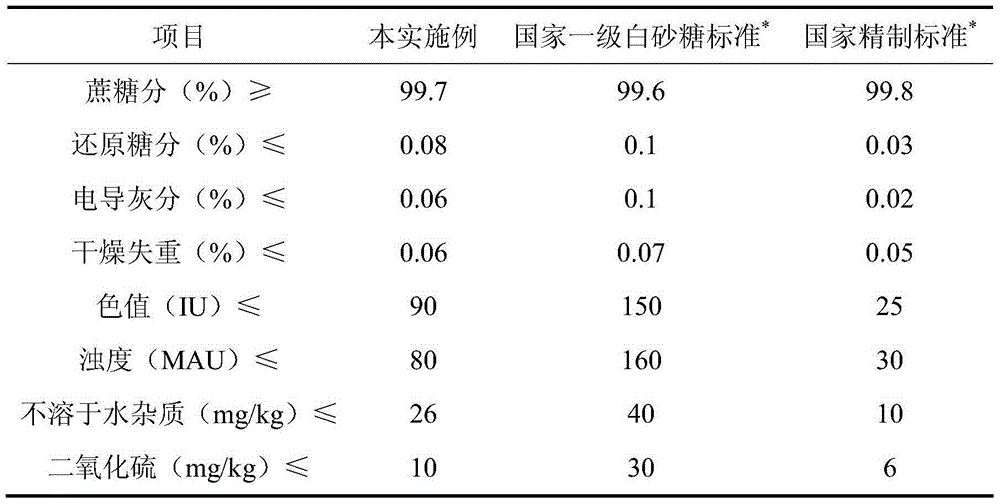

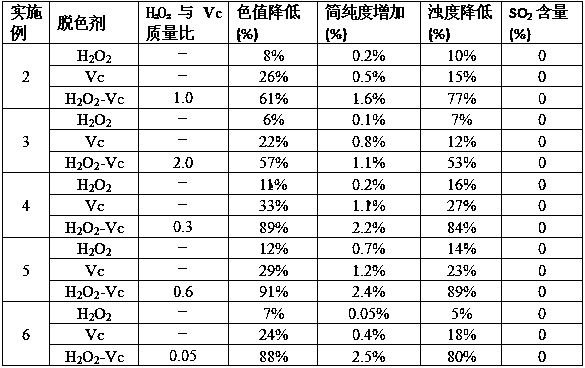

Sugar juice compound decolorizing agent and sugar juice decolorization method

ActiveCN108251564AReduce color valueQuality improvementPurification by oxidation/reductionVitamin CSulfur

The invention relates to a sugar juice compound decolorizing agent and a sugar juice decolorization method. The sugar juice compound decolorizing agent is an H2O2-Vc compound reagent composed of H2O2and vitamin C in a mass ratio of 0.01-10. The sugar juice decolorization method includes: using the H2O2-Vc compound reagent for decolorization treatment on sugar juice, which is mixed juice, clear juice, syrup or / and massecuite, wherein the adding amount of the H2O2-Vc compound reagent and the corresponding sugar juice are in a mass ratio of 10*10<-6>-2*10<-3> in the decolorization process. The method provided by the invention can greatly reduce the color value of sugar juice and sulfur dioxide residual, can effectively lower the content of colored matters and sulfur residue in the final white granulated sugar finished product, at the same time can enhance the purity of white granulated sugar, thus improving the quality of the white granulated sugar finished product; and on the other hand, the process is simple, has no need for change of the original technological process, also in low in investment and utilization cost, and can significantly improve the economic benefits of sugar factories.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

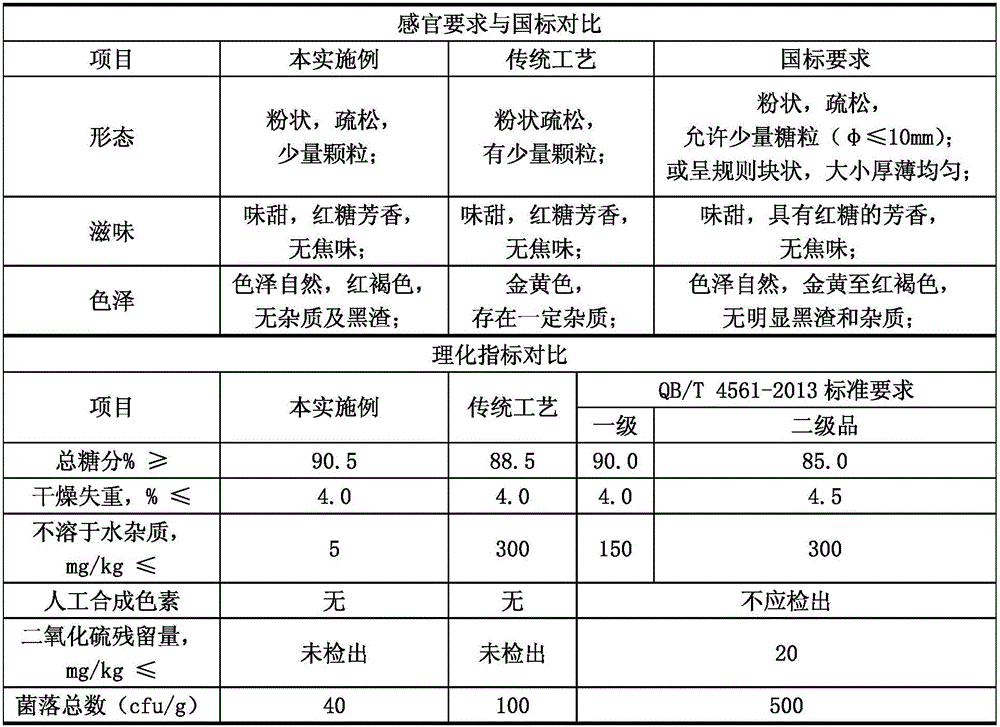

Production line of black sugar rich in polyphenol

PendingCN106119430AImprove qualityHigh nutritional valueSugar productsPurification using alkaline earth metal compoundsEngineeringPolyphenol

The invention relates to a production line of black sugar rich in polyphenol. Squeezing equipment, impurity removal and filtration equipment, a preliming cylinder, a tubular heat exchanger and a steam heater of the production line are sequentially connected, a lime milk storage cylinder is connected with the preliming cylinder, the outlet of the steam heater is connected with the inlet of a primary ceramic membrane, the concentrated solution outlet of the primary ceramic membrane is connected with the preliming cylinder by virtue of full charging equipment and a plate-and-frame filter press, and the clear solution outlet of the primary ceramic membrane is connected with the inlet of a secondary nanofiltration membrane; the concentrated solution outlet of the secondary nanofiltration membrane is connected with black sugar packaging equipment by virtue of vacuum evaporation concentration equipment, constant pressure concentration equipment, a nucleation box and a moulding die sequentially; and the clear solution outlet of the secondary nanofiltration membrane is connected with a white granulated sugar production line. The production line of the black sugar rich in polyphenol has the advantages that two stages of ceramic membranes with different membrane pore diameters are adopted for filtering sugarcane juice, concentrated juice filtered by two stages of membranes is adopted for producing the black sugar rich in polyphenol, a functional ingredient, namely polyphenol, in the concentrated juice obtained by virtue of the two stages of membranes is effectively enriched, enrichment efficiency is improved by 4-8 times compared with the traditional production technology, and quality and nutritional value of the black sugar are improved.

Owner:GUANGXI UNIV

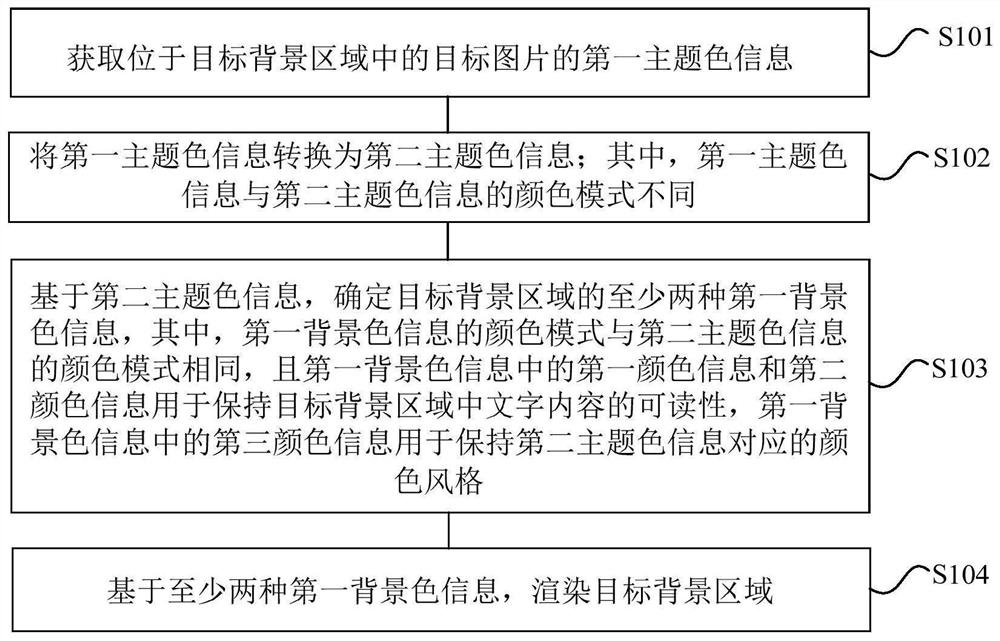

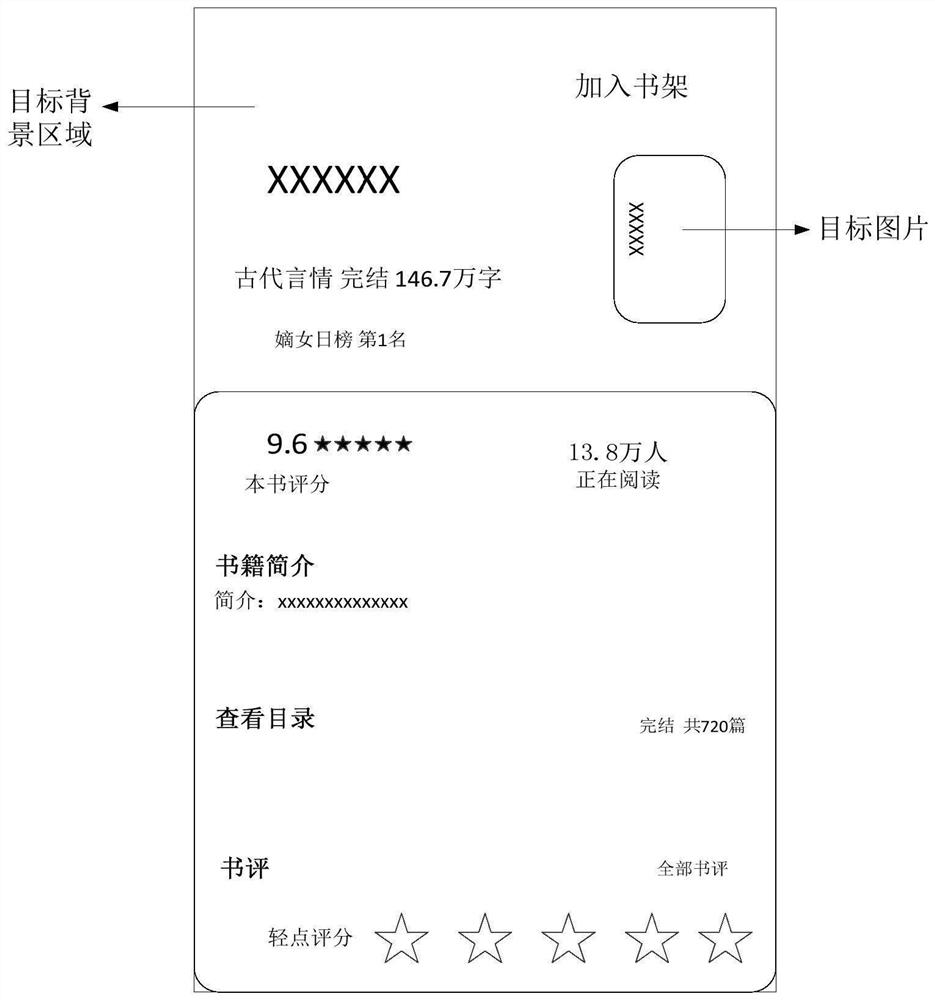

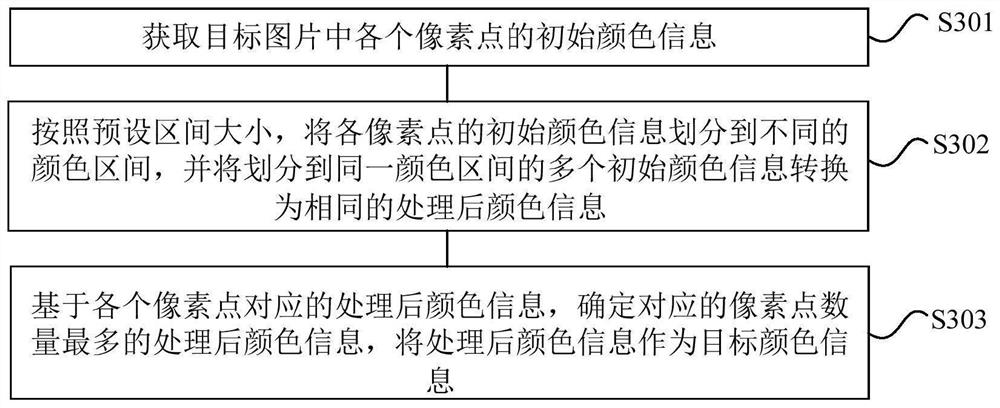

Background color generation method and device, electronic equipment and storage medium

ActiveCN113238829AConsistent readabilityConsistent color styleTexturing/coloringExecution for user interfacesComputer graphics (images)Color changes

The invention provides a background color generation method and device, electronic equipment and a storage medium. The method comprises the steps: obtaining first theme color information of a target picture located in a target background region; converting the first theme color information into second theme color information in other color modes; determining first background color information of the target background region based on the second theme color information; and rendering the target background region based on the first background color information. According to the embodiment of the invention, the color mode of the theme color is converted to obtain at least two kinds of processed background color information, and the target background region is rendered based on the two kinds of background color information, so that the background color which keeps readability of characters in the target background region, is consistent with the theme color in color style and has color change is formed.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Refined sugar clarifying method

InactiveCN104789705AExtended cleaning cycleReduce cleaning frequencyPurification using alkaline earth metal compoundsPurification using ion-exchange materialsTurbidityRefined sugar

A refined sugar clarifying method comprises steps as follows: cleaning up a pigment on the surface of raw sugar with molasses to obtain molasses-cleaned raw sugar; dissolving the molasses-cleaned raw sugar in hot water to obtain re-dissolved syrup for use; performing carbonation on the re-dissolved syrup twice to obtain second carbonation syrup; filtering the second carbonation syrup with a plate-and-frame filter press to obtain filtered syrup; pumping the filtered syrup to a ceramic-membrane microfiltration working tank, and performing microfiltration clarification on the filtered syrup with a ceramic membrane with the membrane pore diameters ranging from 0.2 mu m to 0.5 mu m to obtain a clear syrup for use; cooling the clear syrup with a plate heat exchanger and then sending the clear syrup to a first ion exchange resin column to obtain a first infiltration liquid, and then sending the first infiltration liquid to a second ion exchange resin column to obtain a second infiltration liquid, that is, refined sugar. The re-dissolved syrup subjected to carbonation and filtration by the aid of the plate-and-frame filter press is clarified by the ceramic microfiltration membrane, so that the turbidity of the re-dissolved syrup before the re-dissolved syrup enters ion exchange resin is reduced, and the service life of the ion exchange resin is prolonged.

Owner:GUANGXI UNIV

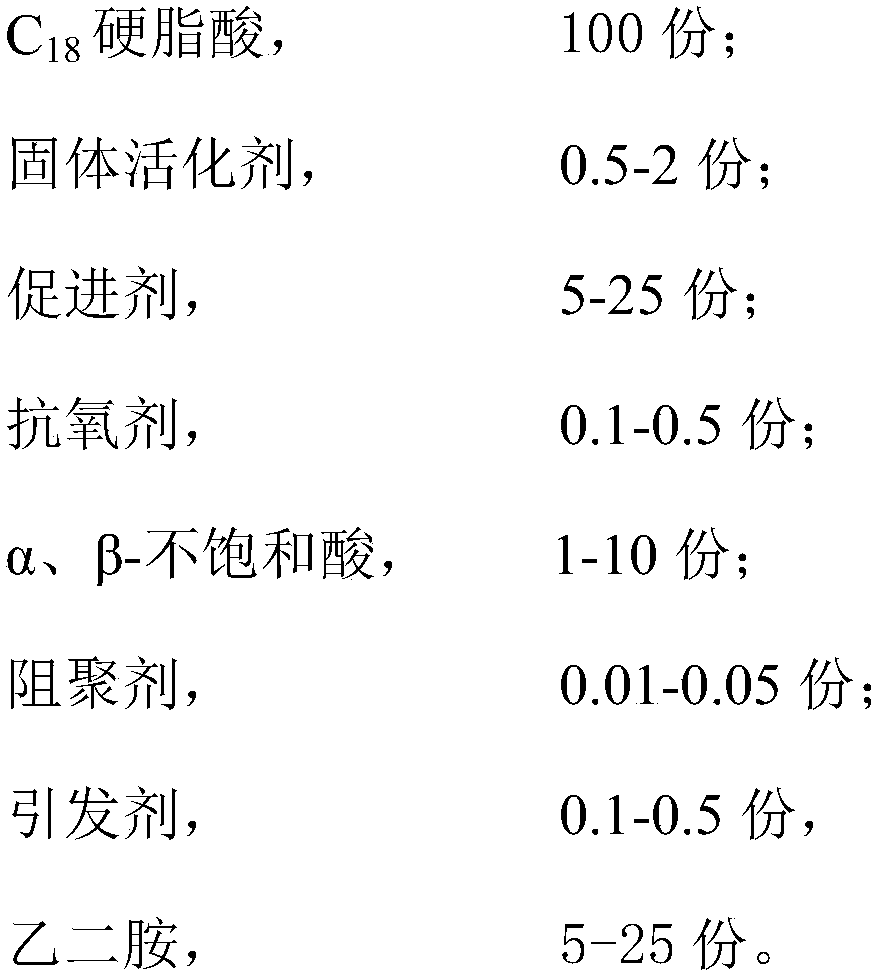

Anti-yellowing amide wax and preparation method thereof

InactiveCN108976143AHigh whitenessReduce color valueOrganic compound preparationCarboxylic acid amides preparationWaxAntioxidant

The invention provides anti-yellowing amide wax and a preparation method thereof. The anti-yellowing amide wax is prepared from the following raw materials in parts by weight: 100 parts of C18 stearicacid, 0.5-2 parts of a solid activator, 5-25 parts of an accelerant, 0.1-0.5 part of an antioxidant, 1-10 parts of alpha,beta-unsaturated acid, 0.01-0.05 part of a polymerization inhibitor, 0.1-0.5 part of an initiator and 5-25 parts of ethanediamine. According to the anti-yellowing amide wax and the preparation method thereof, compared with amide wax prepared by a conventional process, the prepared anti-yellowing amide wax is high in whiteness, low in color value, few in by-products and high in purity, and has excellent anti-yellowing property in the using process.

Owner:苏州联胜化学有限公司

Preparation method of hydrolysis-resistant PBT polyester resin

ActiveCN111303388AImprove hydrolysis resistanceReduce carboxyl end contentPhosphoric Acid EstersPolymer science

The invention relates to a preparation method of hydrolysis-resistant PBT polyester resin. The preparation method comprises the following steps: mixing terephthalic acid, 1, 4-butanediol, an organic titanate compound and magnesium phosphate to prepare slurry; carrying out esterification reaction to obtain a prepolymer; carrying out melt phase polycondensation reaction to obtain a PBT polyester resin substrate; and finally, mixing the PBT polyester resin substrate, an end-capping modifier and an organic phosphate compound in a twin-screw extruder, thereby obtaining the hydrolysis-resistant PBTpolyester resin. 97-99 parts by mass of the PBT polyester resin substrate, 0.5-1 part by mass of the end-capping modifier and 0.01-1 part by mass of the organophosphate compound are added in the mixing process. The end capping modifier is hyperbranched polyester of which the number of terminal hydroxyl groups is 6-100 and a branch unit contains 2, 2-dimethylolpropionic acid. The preparation methodis simple, and the prepared hydrolysis-resistant PBT polyester resin has excellent comprehensive performance.

Owner:DONGHUA UNIV

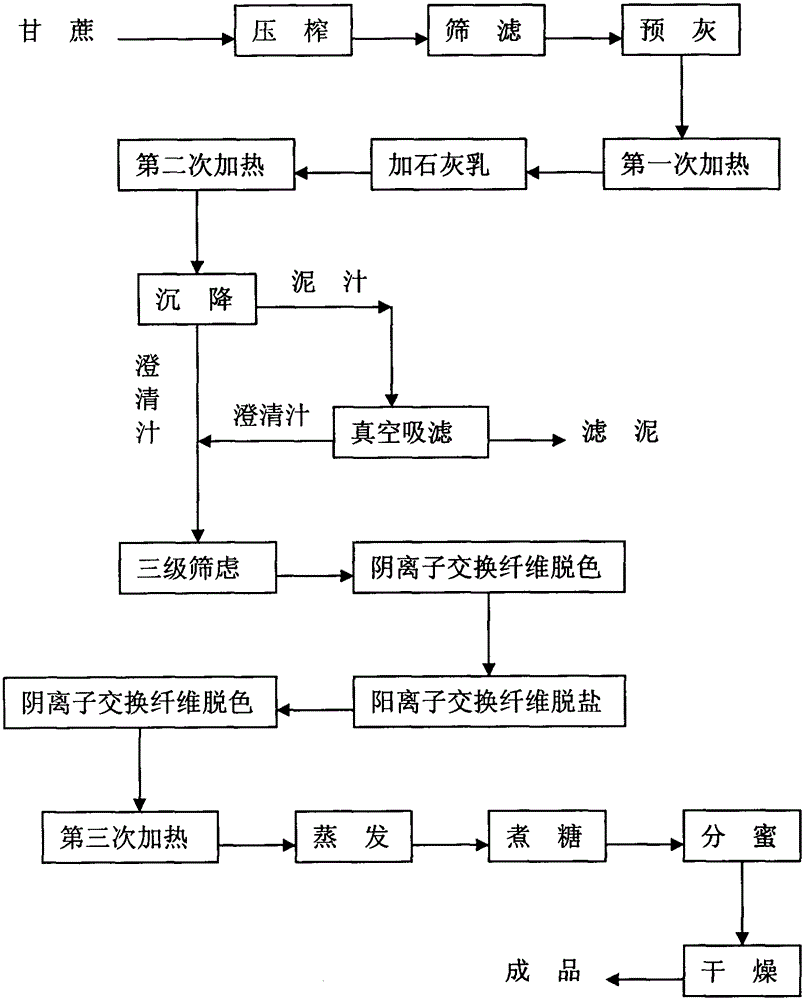

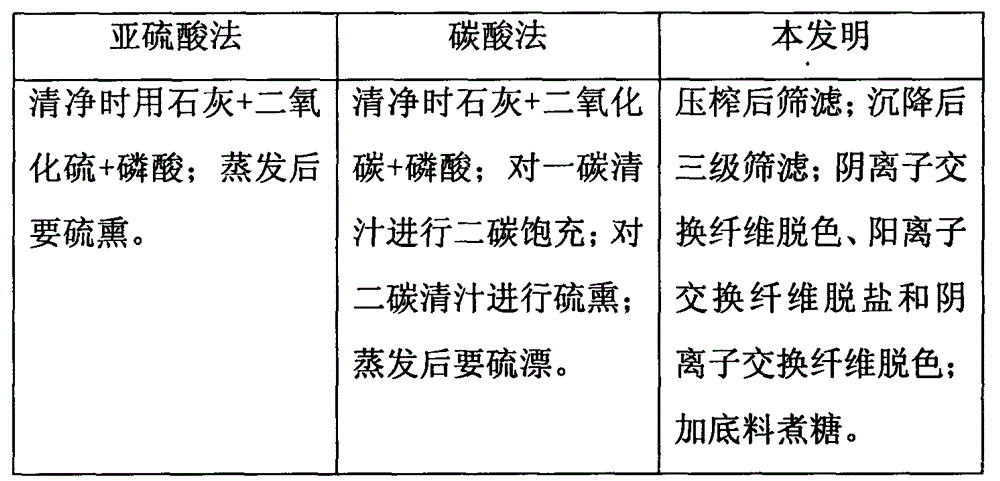

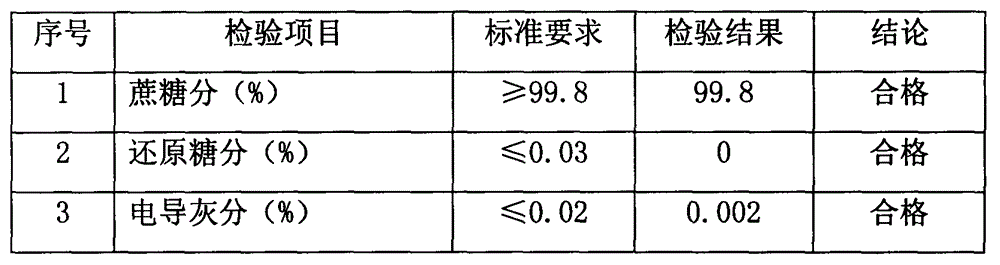

New highly efficient ion-exchange fiber decoloring sulfur-free phosphorus-free sugar-making technology

InactiveCN105002307AShort processEasy to controlSugar productsPurification using ion-exchange materialsFiberSulfur

A new highly efficient ion-exchange fiber decoloring sulfur-free phosphorus-free sugar-making technology comprises the following steps: 1) squeezing, screening, pre-liming, first heating, addition of lime milk and second heating; 2) settlement and tertiary screening; 3) anion-exchange fiber decoloring, cation exchange fiber desalination and anion-exchange fiber decoloring; and 4) third heating, evaporation, sugar boiling, sugar separating and drying. Finally, a finished production is obtained. According to the new technology, sulfur-free and phosphorus-free purposes are realized by advantages of ion-exchange fiber. The technology is simple and is adopted to raise quality index of sugar juice. Quality of the product is good. In addition, energy is saved and environmental pollution is minimized.

Owner:GUANGXI HUAZHENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com