Sugar production clarifying production line

A production line and heating device technology, applied in the production of sucrose, sugar production, purification of sugar juice, etc., can solve the problems of high sulfur content of finished sugar, high color value of finished sugar, poor clarification effect, etc. The effect of high separation efficiency and less auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

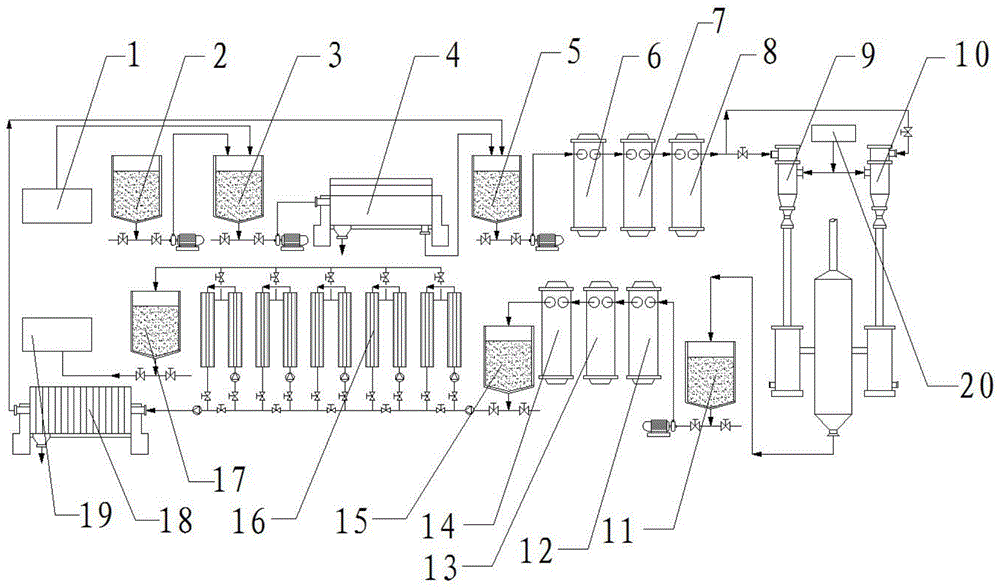

[0027] A sugar clarification production line, including a mixed juice box 3, a decanter centrifuge 4, a first heating device, a sulfur fumigation device, a second heating device, a multi-stage ceramic membrane ultrafiltration system 16, and a plate and frame filter press connected in sequence Machine 18.

[0028] A first buffer tank 5 is connected between the decanter centrifuge 4 and the first heating device, a second buffer tank 11 is connected between the sulfur fumigation device and the second heating device, and the second heating device and the multi-stage ceramic membrane A third buffer tank 15 is connected between the ultrafiltration systems.

[0029] The inlet of the mixed juice box 3 is connected with the pressing and extracting section 1 of the sugarcane sugar factory and the lime milk tank 2, the outlet of the mixed juice box 3 is connected with the inlet of the decanter centrifuge 4, and the outlet of the decanter centrifuge 4 is connected with the inlet of the fi...

Embodiment 2

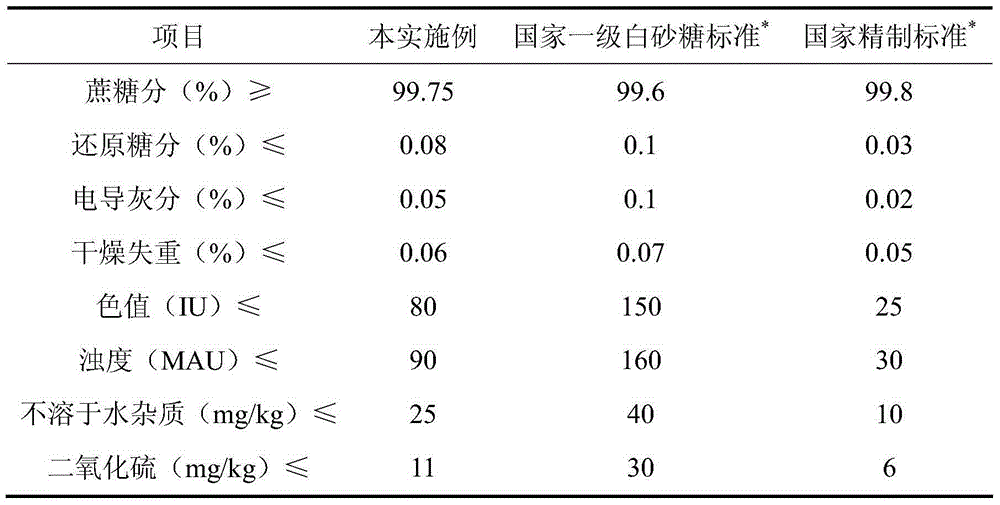

[0036] This embodiment is an example of actual production using the sugar clarification production line described in Example 1, and the specific steps are as follows:

[0037] (1) Liming: adding milk of lime with a concentration of 8.0 ° Be to the mixed juice of the sugarcane sugar factory, adjusting the pH value of the sugarcane juice to 7.6, preventing the sucrose in the sugarcane juice from converting under acidic conditions, resulting in the loss of sucrose, and obtaining limed cane juice;

[0038] (2) Coarse filtration: Utilize a decanter centrifuge with an aperture of 50.0 μm to filter the ash-added sugarcane juice to obtain the coarsely filtered sugarcane juice;

[0039] (3) The first heating: heat the coarsely filtered sugarcane juice to 55°C with a tube-and-tube heat exchanger, which is beneficial to the sulfur fumigation process of the next step on the SO 2 The absorption of sugarcane juice is obtained by heating for the first time;

[0040] (4) Sulfur fumigation: ...

Embodiment 3

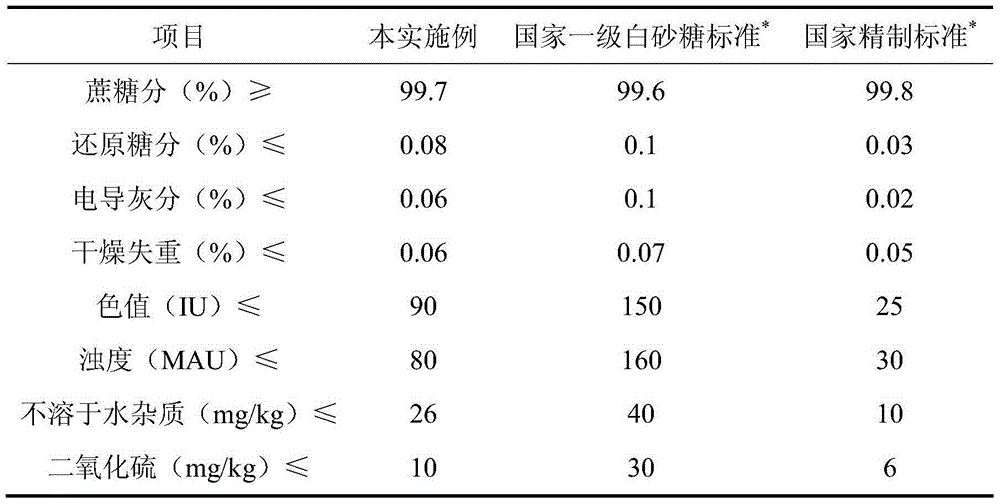

[0053] This embodiment is another example of actual production using the sugar clarification production line described in Embodiment 1, and the specific operation steps are as follows:

[0054] (1) Liming: adding milk of lime with a concentration of 8.5 ° Be to the mixed juice of the sugarcane sugar factory, adjusting the pH value of the sugarcane juice to 7.5, preventing the sucrose in the sugarcane juice from converting under acidic conditions, resulting in the loss of sucrose, and obtaining limed cane juice;

[0055] (2) Coarse filtration: Utilize a decanter centrifuge with an aperture of 150.0 μm to filter the ash-added sugarcane juice to obtain the coarsely filtered sugarcane juice;

[0056] (3) The first heating: heat the coarsely filtered sugarcane juice to 65°C with a tube-and-tube heat exchanger, which is beneficial to the sulfur fumigation process of the next step on the SO 2 The absorption of sugarcane juice is obtained by heating for the first time;

[0057] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com