Anti-yellowing amide wax and preparation method thereof

A technology of yellowing amide and amide, which is applied in the field of anti-yellowing amide wax and its preparation, can solve the problems of affecting product color, yellowing, and affecting the application of amide wax, achieve low color value, solve easy yellowing, and resist Excellent effect of yellowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

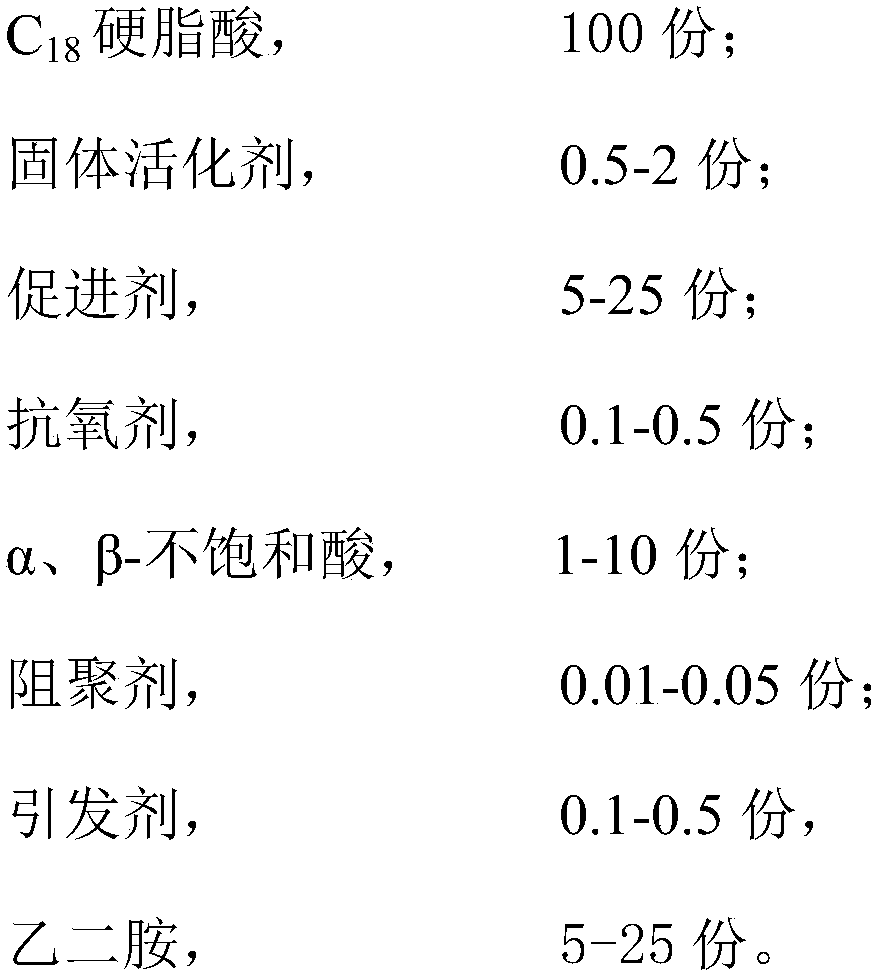

[0020] Take 100 grams of AS1801, 0.5 grams of solid activator, 5 grams of accelerator, 0.1 gram of antioxidant, 1 gram of α, β-unsaturated acid, 0.01 gram of inhibitor and 0.1 gram of initiator tape In a four-necked flask with a stirrer, a thermometer, a condenser and an equal pressure funnel, place the four-necked flask in a programmed temperature-controlled oil bath. Get 5 grams of ethylenediamine and place it in an equal pressure funnel. With the agitator in a stirring state and the system under nitrogen protection, turn on the programmed temperature control device to heat the oil bath, and when the temperature of the system rises to 110°C, add ethylenediamine dropwise. During the dropwise addition of ethylenediamine, the temperature in the reaction system should be controlled below 150°C. After the ethylenediamine is added dropwise, keep it at about 150°C for 1 hour, then raise the temperature of the system to 190°C, and keep it for 6 hours. The temperature of the system...

Embodiment 2

[0022] Take 100 grams of AS1801, 2 grams of solid activators, 25 grams of accelerators, 0.5 grams of antioxidants, 1-10 grams of α, β-unsaturated acids, 0.05 grams of inhibitors and 0.5 grams of initiator A four-necked flask equipped with a stirrer, a thermometer, a condenser and an equal pressure funnel was placed in a programmed temperature-controlled oil bath. Get 25 grams of ethylenediamine and place it in an equal pressure funnel. With the agitator in a stirring state and the system under nitrogen protection, turn on the program temperature control device to heat the oil bath, and when the system temperature rises to 130°C, add ethylenediamine dropwise. During the dropwise addition of ethylenediamine, the temperature in the reaction system should be controlled below 150°C. After the ethylenediamine is added dropwise, keep it at about 150°C for 2 hours, then raise the system temperature to 200°C, keep it for 6 hours, then lower the system temperature to below 160°C and di...

Embodiment 3

[0024] Take 100 grams of AS1840, 0.5 grams of solid activator, 5 grams of accelerator, 0.1 gram of antioxidant, 1 gram of α, β-unsaturated acid, 0.01 gram of inhibitor and 0.1 gram of initiator tape In a four-necked flask with a stirrer, a thermometer, a condenser and an equal pressure funnel, place the four-necked flask in a programmed temperature-controlled oil bath. Get 5 grams of ethylenediamine and place it in an equal pressure funnel. With the agitator in a stirring state and the system under nitrogen protection, turn on the programmed temperature control device to heat the oil bath, and when the temperature of the system rises to 110°C, add ethylenediamine dropwise. During the dropwise addition of ethylenediamine, the temperature in the reaction system should be controlled below 150°C. After the ethylenediamine is added dropwise, keep it at about 150°C for 2 hours, then raise the temperature of the system to 190°C, and keep it for 6 hours. The temperature of the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com