Patents

Literature

302results about How to "Less by-products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS20070232481A1High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium Compounds1-Octene

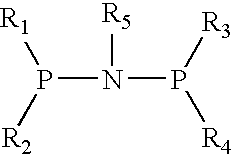

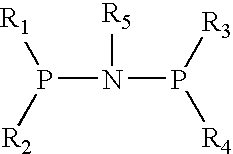

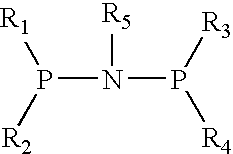

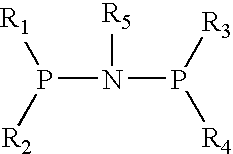

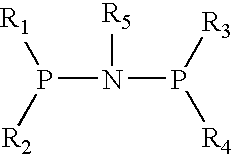

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and / or Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as: in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; general formula of the accelerator is X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkyl or aryl; the molar ratio of a, b, c and d is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·mol−1 Cr ·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

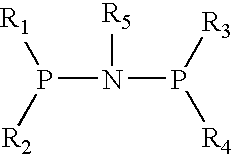

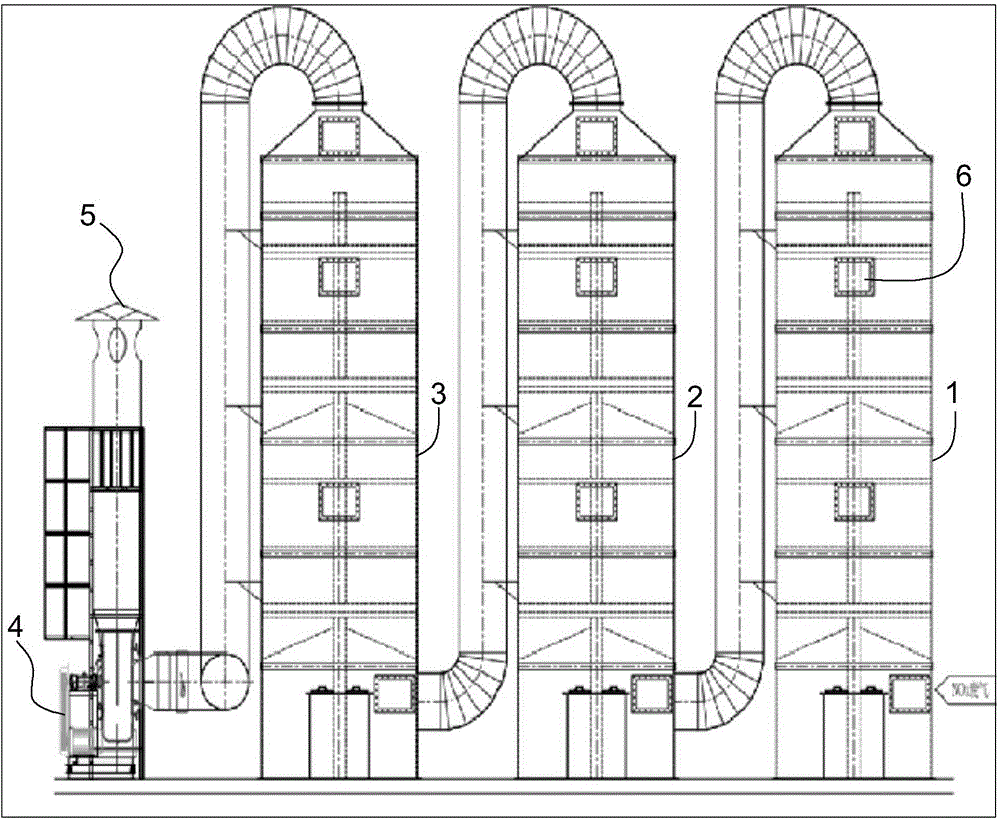

Nitrogen oxide waste gas treatment method and treatment system thereof

InactiveCN104906931AImprove processing efficiencyLess by-productsDispersed particle separationResidual nitrogenChemistry

The invention relates to a nitrogen oxide waste gas treatment method and a treatment system thereof. The method includes: introducing nitrogen oxide containing waste gas into a first stage washing tower to conduct oxidation treatment to oxidize nitric oxide into nitrogen dioxide, introducing waste gas mainly containing nitrogen dioxide into a second stage washing tower to conduct reduction treatment to convert nitrogen dioxide into nitrogen, finally introducing the treated waste gas into a third stage washing tower, spraying a sodium hydroxide test solution to absorb the residual nitrogen dioxide gas in the waste gas, performing defogging treatment and then conducting emptying. The method and the system provided by the invention employs three-stage washing towers to treat nitrogen oxide waste gas, effectively improve the treatment efficiency of waste gas, and reduce the treatment cost.

Owner:TOT HUANGSHI TECH CO LTD

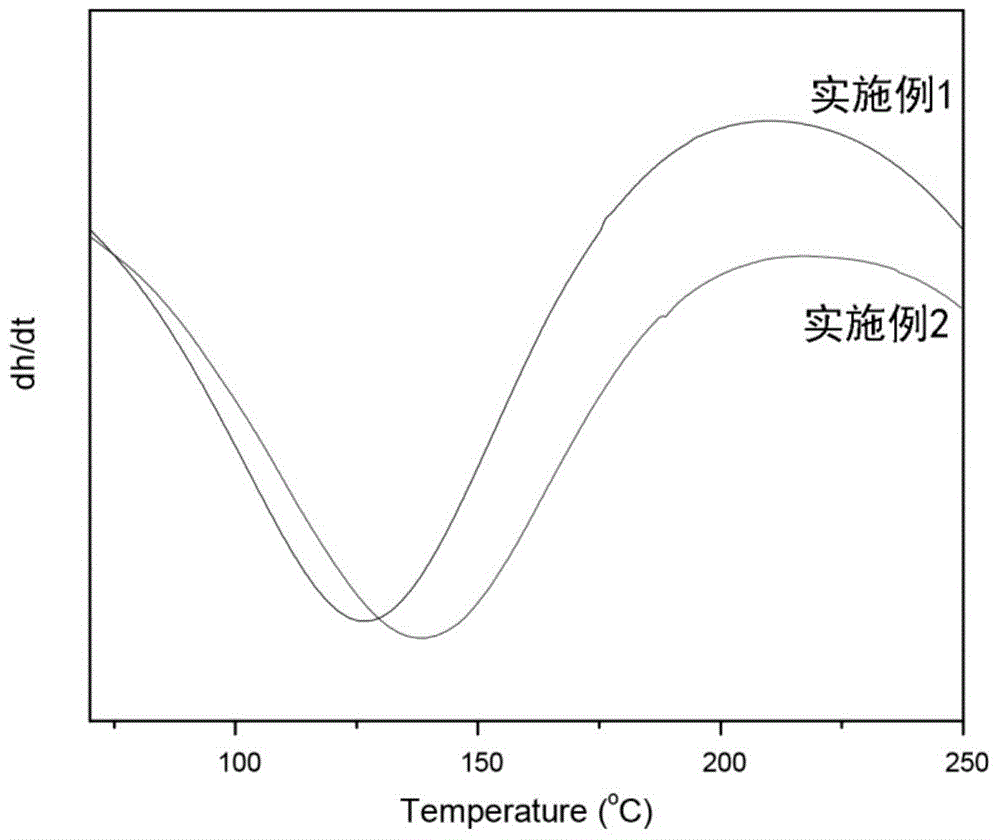

Method for degrading epoxy resin carbon fiber composite material

The invention discloses a method for degrading an epoxy resin carbon fiber composite material. The method comprises the following steps of: preparing a reaction solution by adding a metal salt into water, methanol, ethanol or propanol which is taken as the solvent; dipping the epoxy resin carbon fiber composite material in the reaction solution, and carrying out degradation at 160-240 DEG C for 1-20 hours; and separating and recycling the metal salt and obtaining the epoxy resin degraded product and the carbon fiber. The method disclosed by the invention has the advantages of simple process, mild condition, low cost and low damage on carbon fiber strength.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Metal palladium nano-material catalyst and preparation and application thereof

InactiveCN101972651ASingle sizeGood lookingOrganic compound preparationAmino compound preparationNitrobenzeneAniline

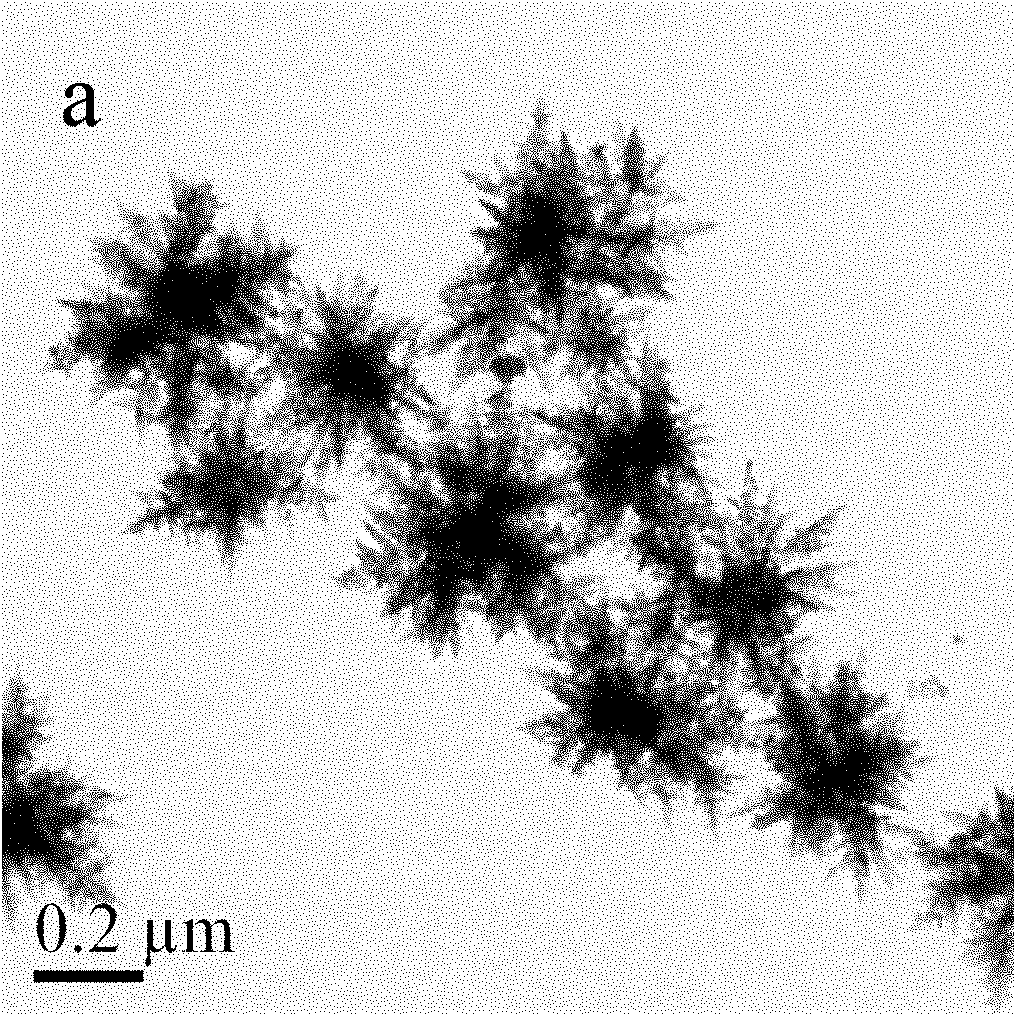

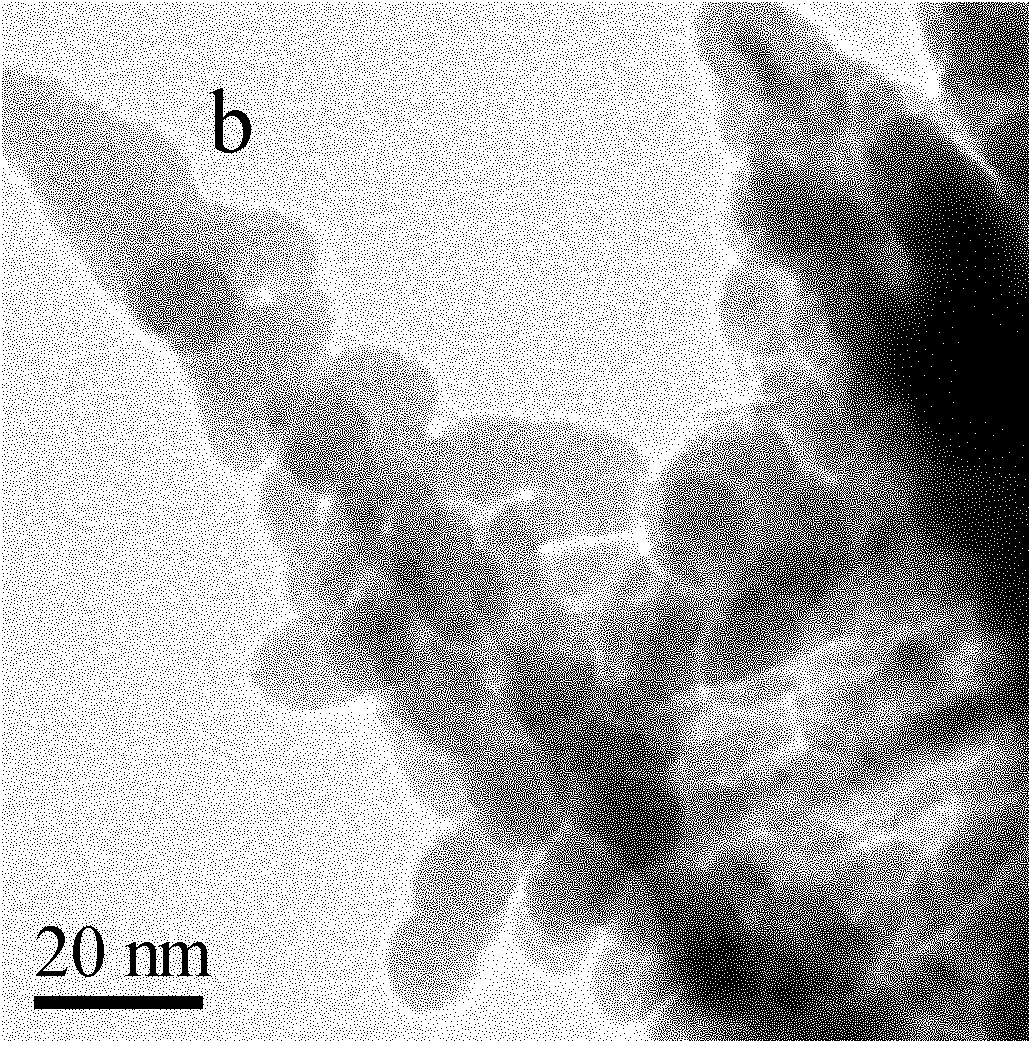

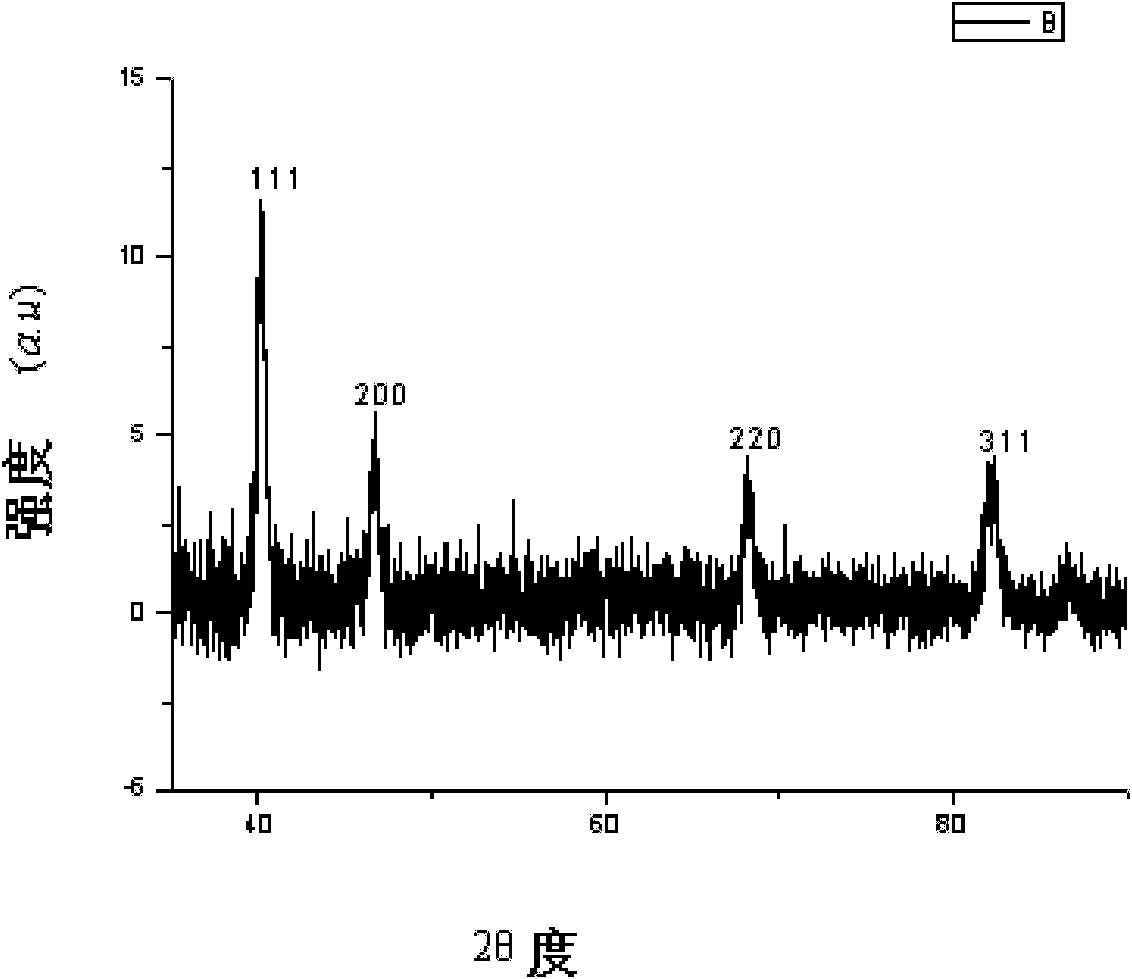

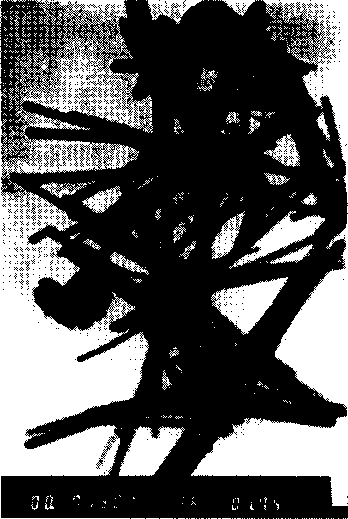

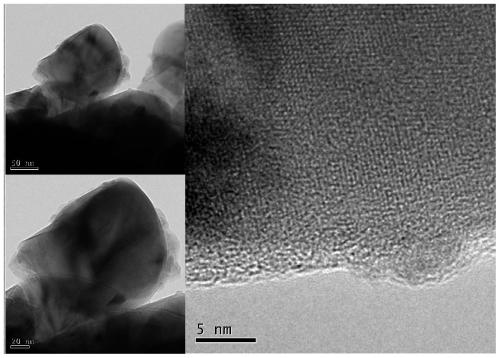

The invention provides a metal palladium nano-material catalyst and preparation and application thereof. The catalyst is a self-assembly snowflake metal Pd nano-material for preparing phenylamine by catalytic hydrogenation of nitrobenzene. The preparation method of the catalyst comprises the following steps: dissolving palladium chloride into hydrochloric acid for fully reacting to generate palladium chlorate hydrate colloidal solution; adding benzyl alcohol to the obtained palladium chlorate hydrate to obtain benzyl alcohol solution of palladium chlorate; adding the H2PdC14-benzyl alcohol solution and directing agent PVP-benzyl alcohol solution to a round-bottom flask, adding benzyl alcohol as a solvent, transferring the flask into a microwave oven, rapidly heating while stirring rapidly until the solution is changed into dark brownish black from brown yellow, thus obtaining snowflake metal Pd nano-colloidal solution with stable PVP; and standing the colloidal solution to obtain sticky black precipitate, washing and drying the precipitate to obtain the self-assembly snowflake metal Pd nano-material. The snowflake metal Pd nano-material is mixed with the nitrobenzene and then transferred into a high-pressure reaction kettle, and then hydrogen is introduced into the kettle for hydrogenation of the nitrobenzene to obtain the phenylamine, wherein, the conversion rate of the nitrobenzene can reach up to 100%.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

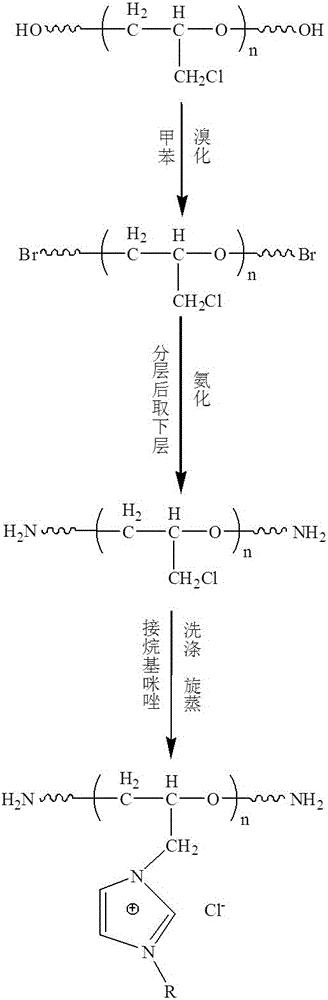

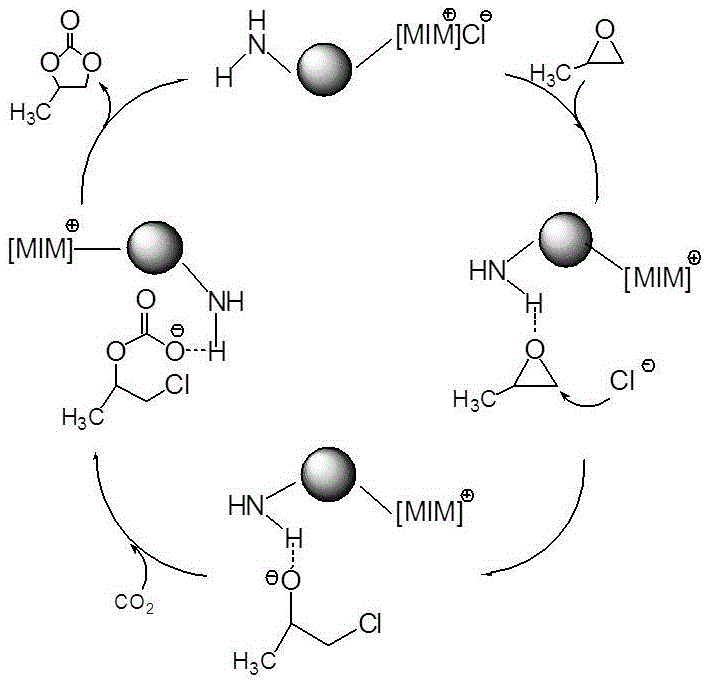

Preparation method of 1-aminopolypropylether-3-methylimidazolium chloride ion liquid catalyst

ActiveCN106040296AGood synergyHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIsolation effectSide effect

The invention relates to a 1-aminopolypropylether-3-methylimidazolium chloride ion liquid catalyst and a preparation method thereof. The prepared catalyst makes an ion liquid structure contain an active amino-terminated functional group and a polyether large-molecular chain at the same time in a chemical bonding mode, the coordinative catalysis effect, base position isolation effect and infinite dilution effect of the catalyst are well achieved, the generation of byproducts is effectively reduced, and the catalyst has the excellent advantages of being high in activity and selectivity, stable in active component, small in consumption, easy to separate and recover, recyclable, long in service life, friendly to the environment and the like; no side effects happen in the catalysis process, and a new propylene carbonate product high in purity, yield, selectivity and transformation frequency can be obtained at low temperature and pressure.

Owner:SHENYANG POLYTECHNIC UNIV

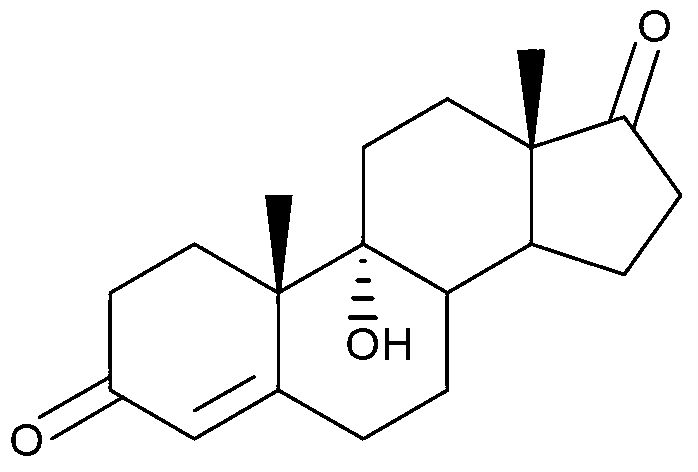

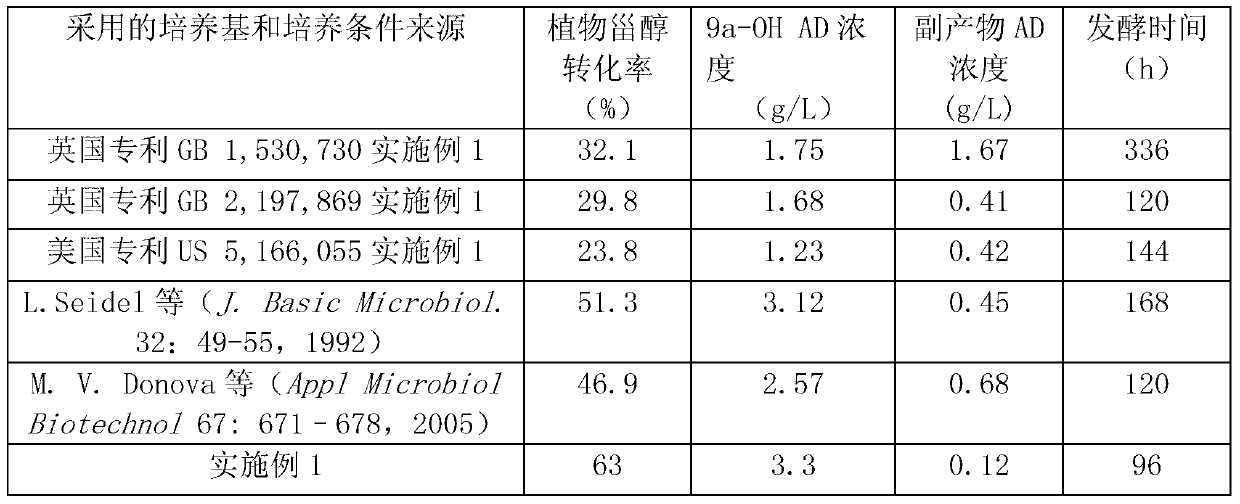

Method for preparing 9a-hydroxy androstendione

InactiveCN103343155AReduce generationShorten fermentation timeMicroorganism based processesFermentationBiotechnologyMicrobiology

The invention provides a method for preparing 9a-hydroxy androstendione, which comprises a step of performing fermentation culture on phytosterol by use of mycobacterium fortuitum ATCC 35855 so as to convert the phytosterol into 9a-hydroxy androstendione. The method is used for preparing 9a-hydroxy androstendione by use of mycobacterium fortuitum ATCC 35855 and corresponding fermentation liquid and fermentation technology; the cheap phytosterol can be adopted as a substrate; and moreover, the yield of the prepared 9a-hydroxy androstendione is high, a few byproducts are produced, the fermentation time is short, and a good way is provided for high-efficiency industrial production of 9a-hydroxy androstendione.

Owner:SHANXI ZUYUAN IND & TRADE CO LTD

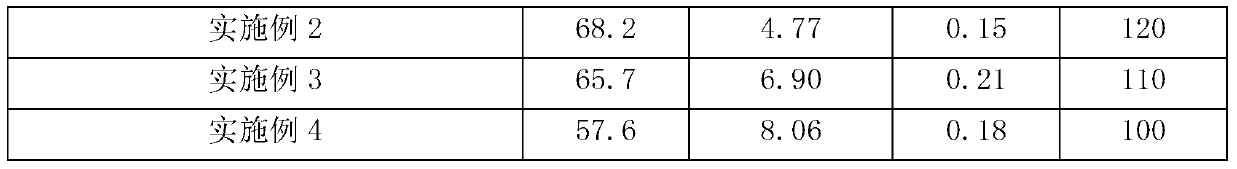

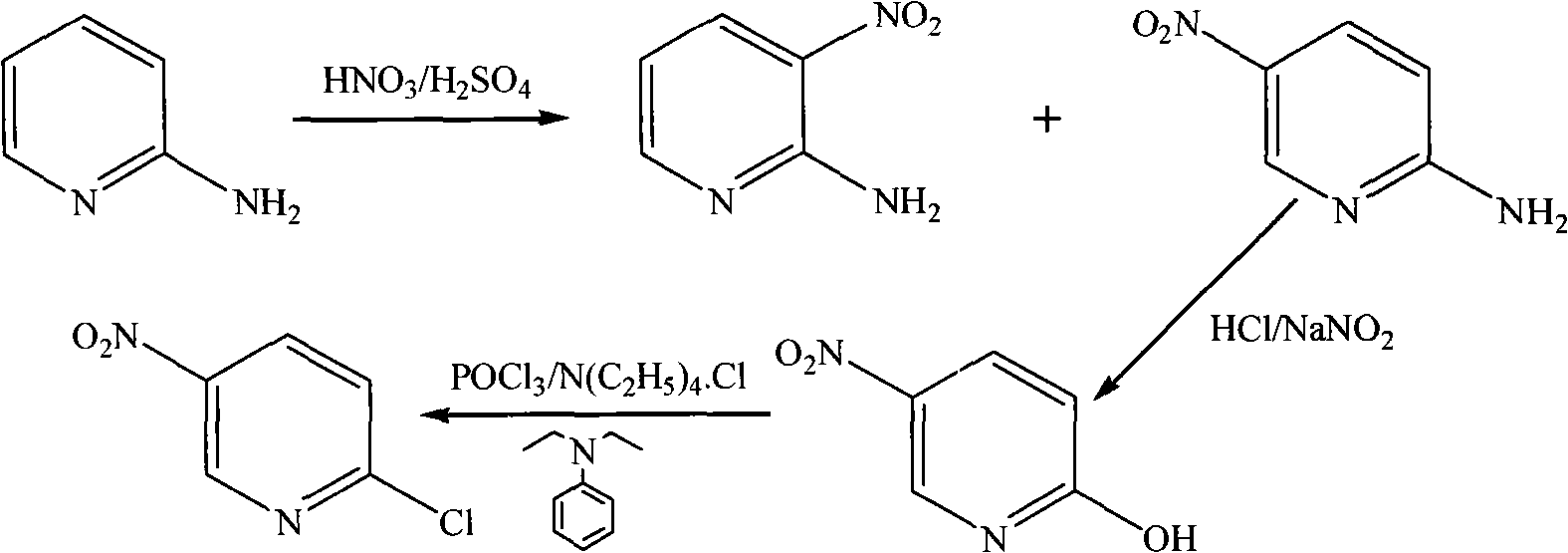

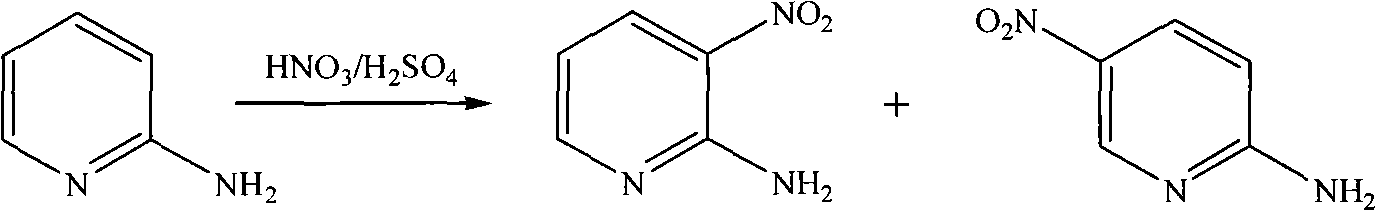

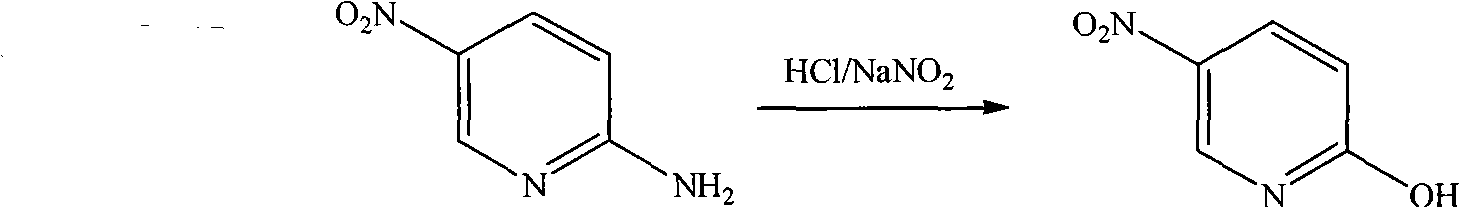

Method for preparing 2-chloro-5-nitropyridine

InactiveCN102040554ALess by-productsMild responseOrganic chemistryStereochemistryReaction conditions

The invention discloses a method for preparing 2-chloro-5-nitropyridine, which comprises the following steps of: 1, synthesizing 2-amino-5-nitropyridine; 2, synthesizing 2-hydroxy-5-nitropyridine; and 3, synthesizing the 2-chloro-5-nitropyridine. By the method for preparing the 2-chloro-5-nitropyridine, few byproducts are produced in a digestion process, reaction conditions are mild and total yield is high.

Owner:张家港任发化工材料有限公司

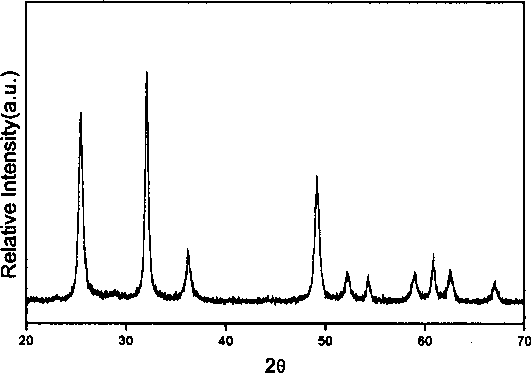

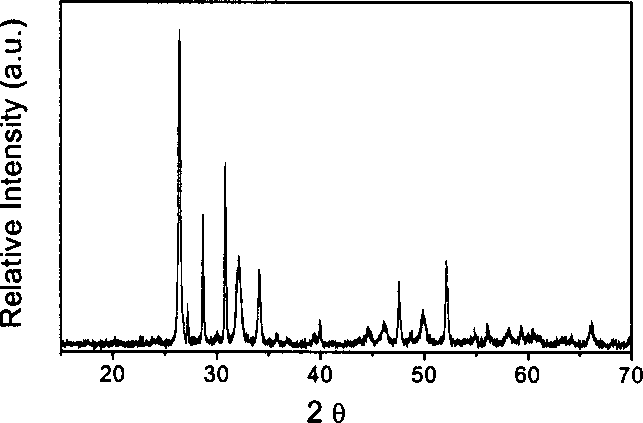

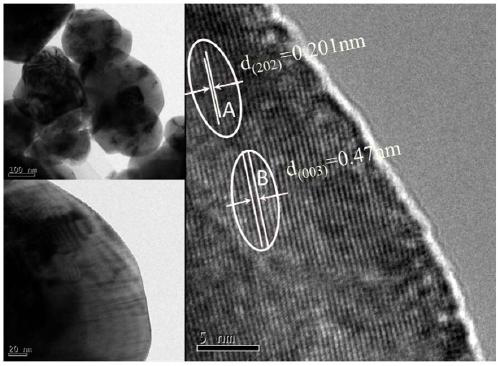

Process for synthesizing alpha, beta type lead dioxide and leadleaden oxide naon crystal

The method for synthesizing alpha and beta type lead dioxide nano crystal and lead tetraoxide nano crystal includes the following steps: adding lead salt or lead oxide into water to prepare solution, adding sodium hydroxide, regulating pH value of solutino to 9-14, making said solution produce liquid-phase reaction with oxidants of chlorine gas, etc., under the condition of 30-60 deg.C can obtain alpha type lead dioxide nano crystal, under the condition of 60-200 deg.C can obtain beta type lead dioxide nano crystal, then pyrolyzing the obtained lead dioxide nano crystal at 410-430 deg.C and can obtain lead tetraoxide nano crystal.

Owner:TSINGHUA UNIV

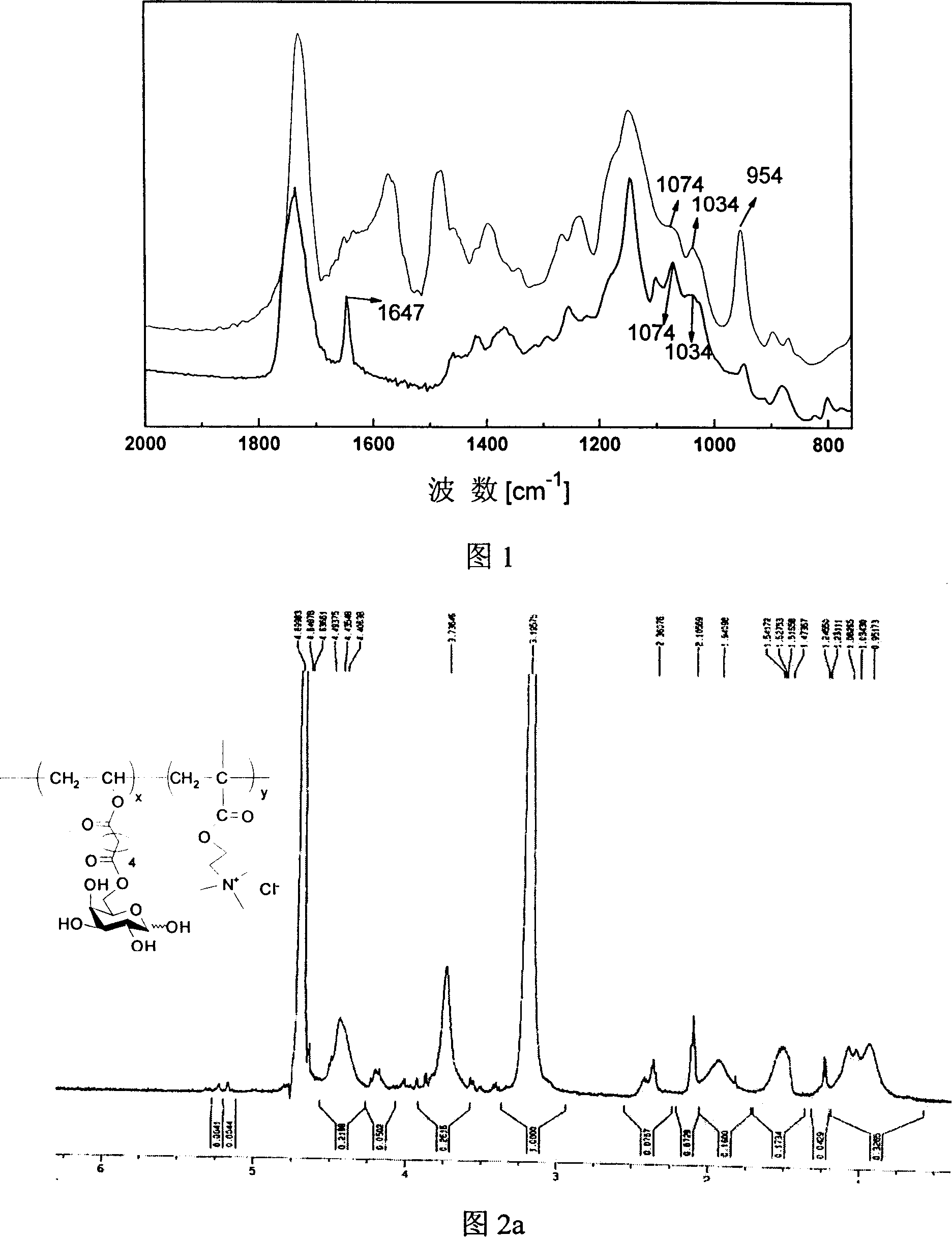

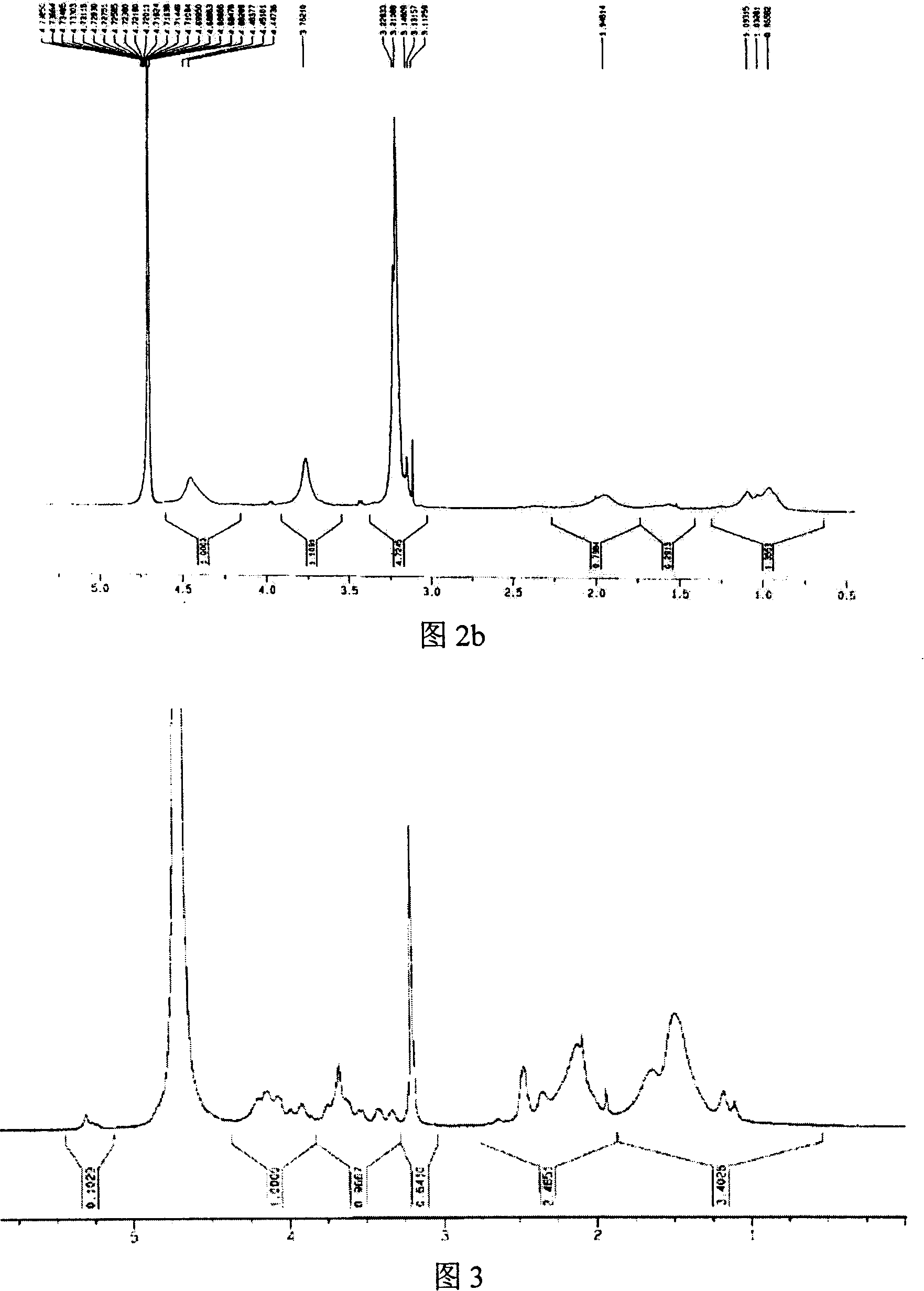

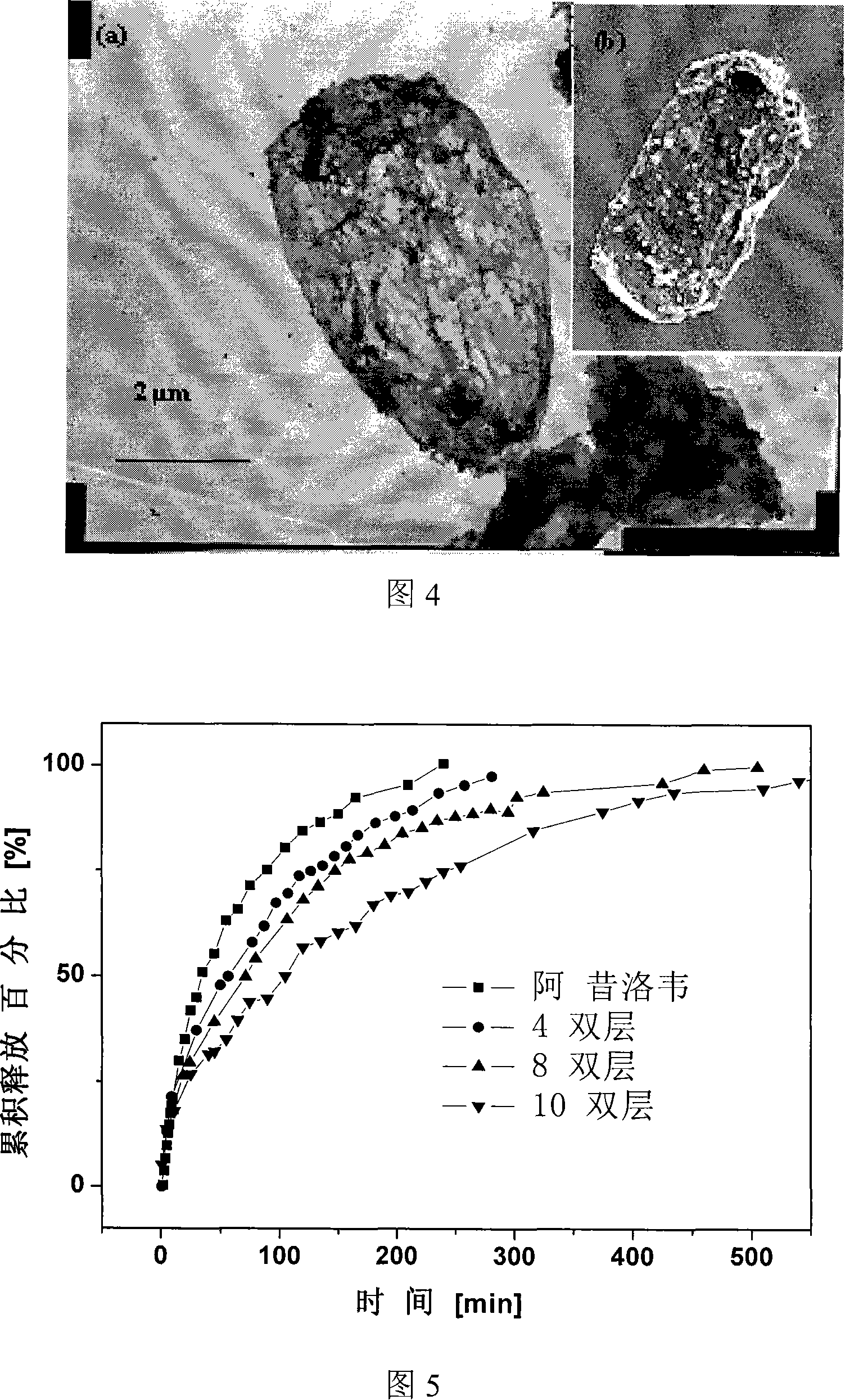

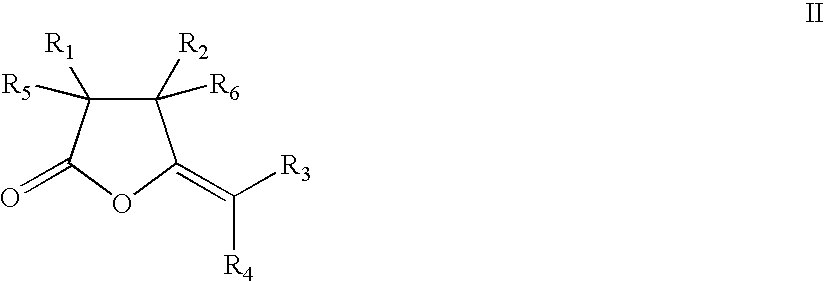

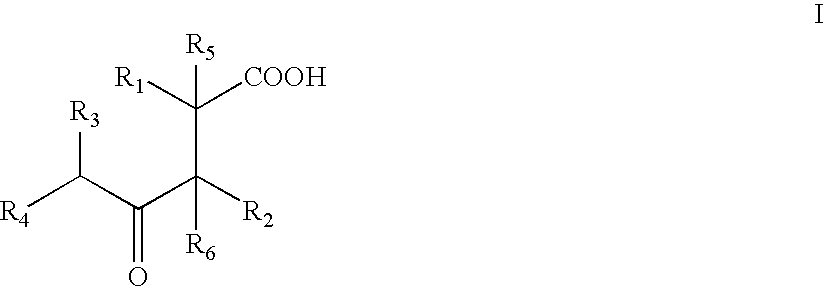

Method of producing hepatic targeting drug microcapsule

InactiveCN101129342AHigh selectivityLess by-productsPharmaceutical non-active ingredientsMicroballoon preparationDrug capsuleVinyl ester

The invention discloses a method for preparing a medicine with liver target taxis for slow-releasing the nanometer microcapsule. The method comprises the following steps: proceeding with enzymatic reaction of liver target taxis gene with sugar monomer of cerebrose residue and ethylated carboxylate; copolymerizing vinyl ester with glycosyl and unsaturated cationic or anion; getting liver target taxis polyelectrolyte; getting the medicinal microcapsule with liver target taxis by multilayer packaging polyelectrolyte on the surface of medicine by electrostatic action, wherein the deactivation speed of microcapsule medicine can be controlled. The polymerization method is simple, high effective and non-toxicity. The coating method has the high efficient, the simple operation and the mild technology, which can cycle several times. The preparing medicine can save for a long time, which can release step by step, can accumulate in the liver, improves the medicinal effect of disease portion, reduces the toxic effect of the other healthy organ, and has the good application prospect.

Owner:ZHEJIANG UNIV

Synthesis of cyclic compounds

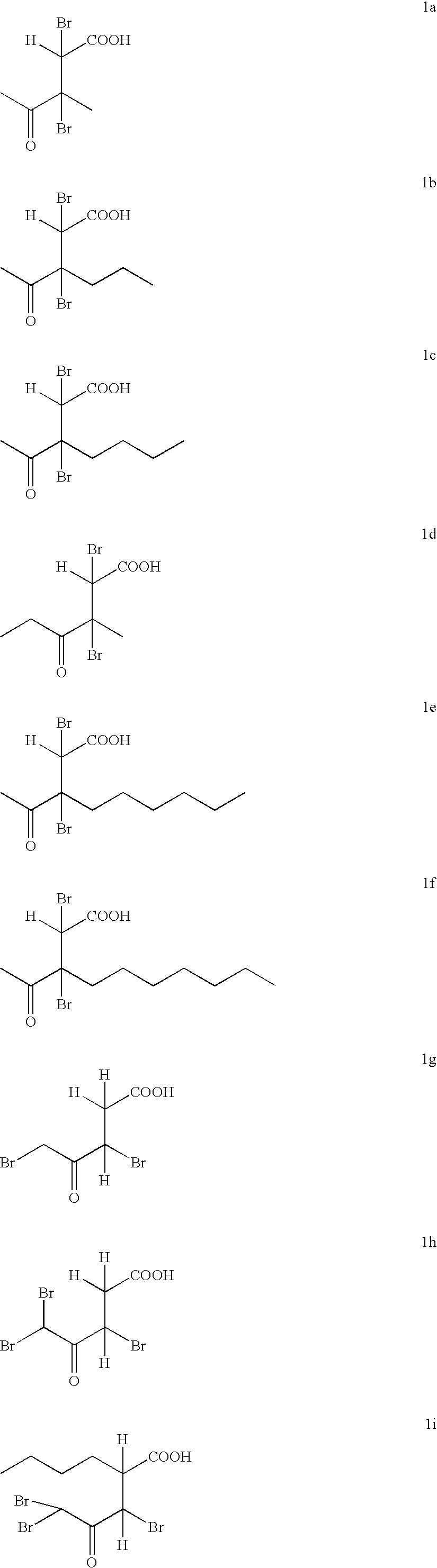

InactiveUS20040110966A1Less by-productsHigh yieldAntibacterial agentsOrganic active ingredientsArylHydrogen

A method for the preparation of a compound of formula (II) wherein R1 and R2 are independently H, alkyl, alkoxy, oxoalkyl, alkenyl, aryl or arylalkyl whether unsubstituted or substituted, optionally interrupted by one or more hetero atoms, straight chain or branched chain, hydrophilic, hydrophobic or fluorophilic; R3, R4, R5 and R6 are independently or all hydrogen or halogen; provided that at least two of the R3, R4, R5 and R6 are halogens.

Owner:UNISEARCH LTD

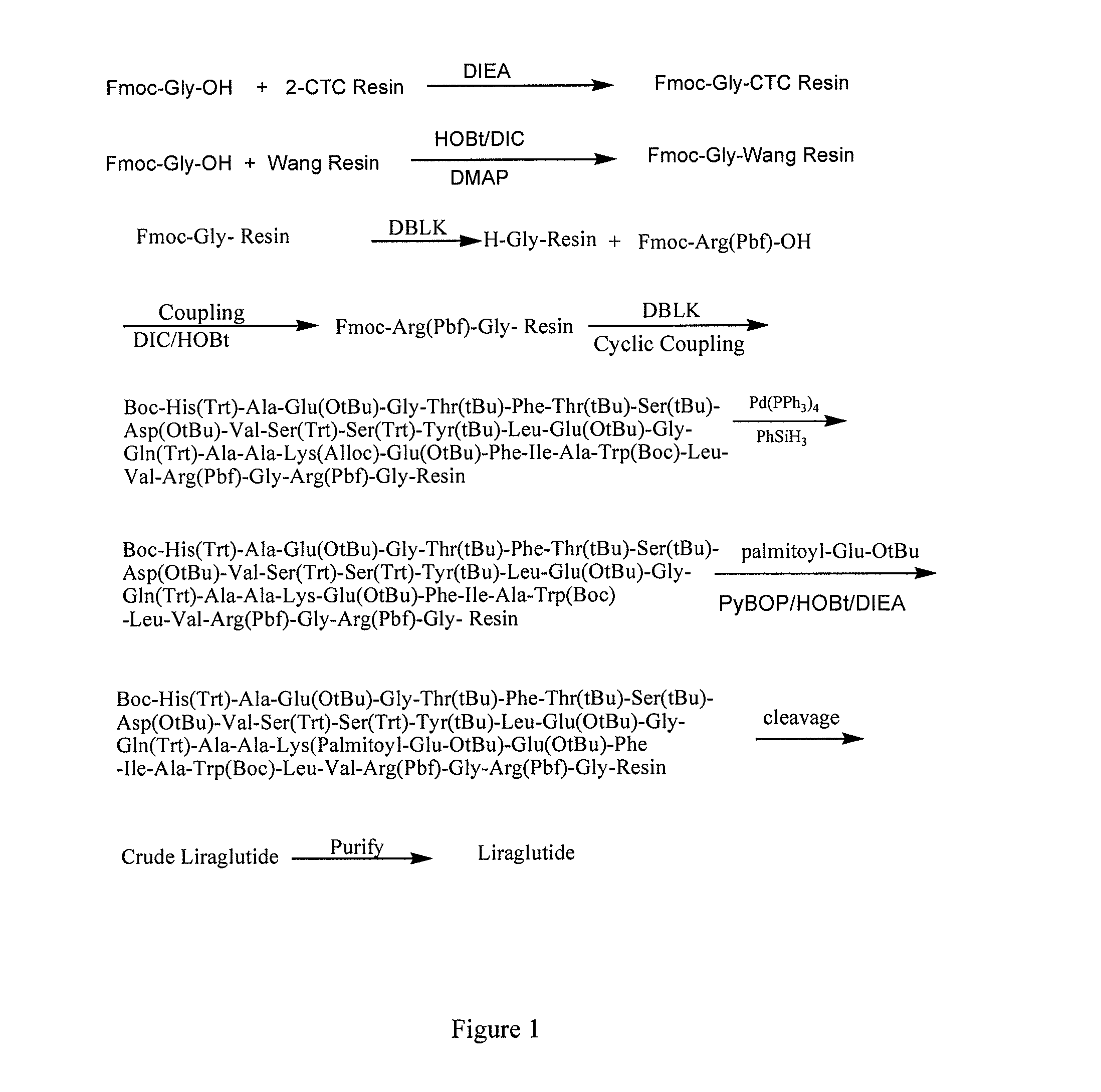

Method for solid phase synthesis of liraglutide

ActiveUS20140350219A1Easy to operateShort synthesis cyclePeptide/protein ingredientsMetabolism disorderGlycineSide chain

Provided is a method for solid phase synthesis of liraglutide, comprising the following steps: A), Fmoc-Gly-resin being obtained by coupling resin solid phase carrier with glycine with N-end protected by Fmoc(Fmoc-Gly-OH) in the presence of activator system; B) according to the peptide sequence of the main chain of liraglutide, successively coupling with amino acids with N-ends protected by Fmoc and protected side chains by the method for solid phase synthesis, wherein lysine employs Fmoc-Lys(Alloc)-OH; C) removing the protective group, Alloc, from the side chain of lysine; D) couplilng the side chain of lysine with Palmitoyl-Glu-Offiu by the method for solid phase synthesis; E) cleavage, removing protection groups and resin to obtain crude liraglutide; F) purifying and lyophilizing to obtain liraglutide.

Owner:HYBIO PHARMA

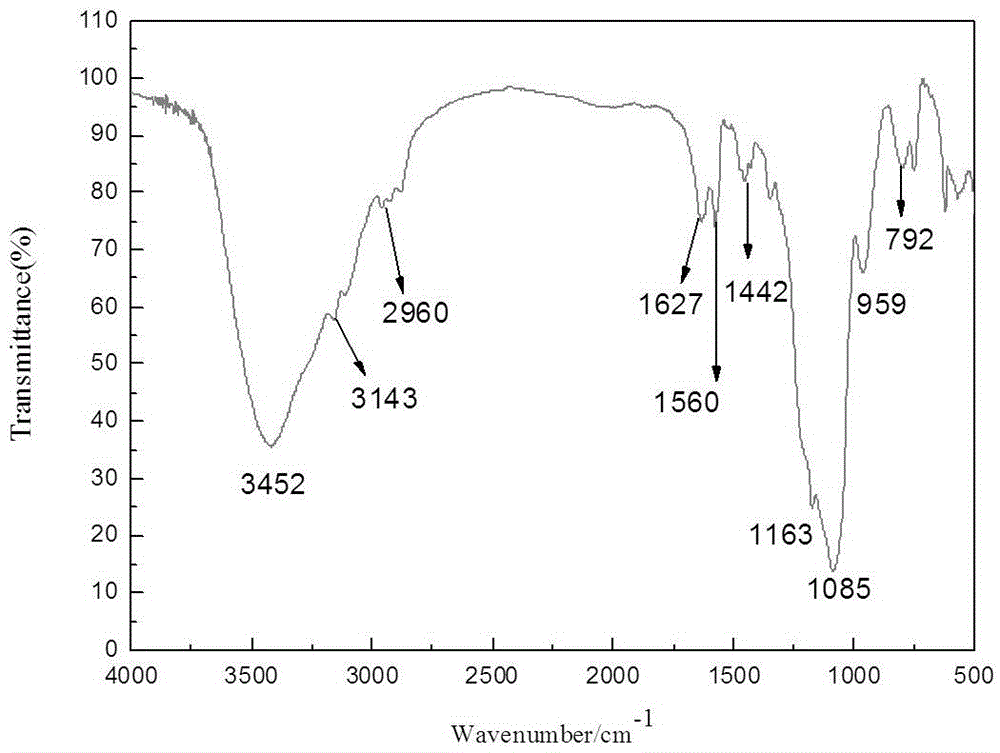

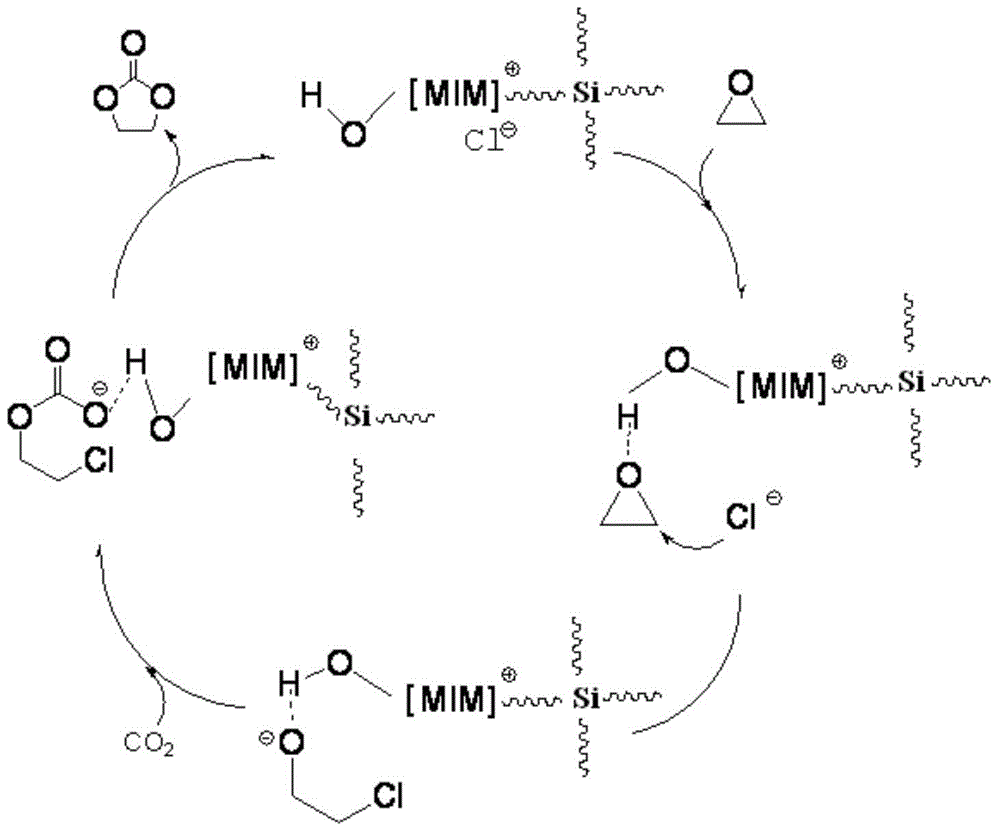

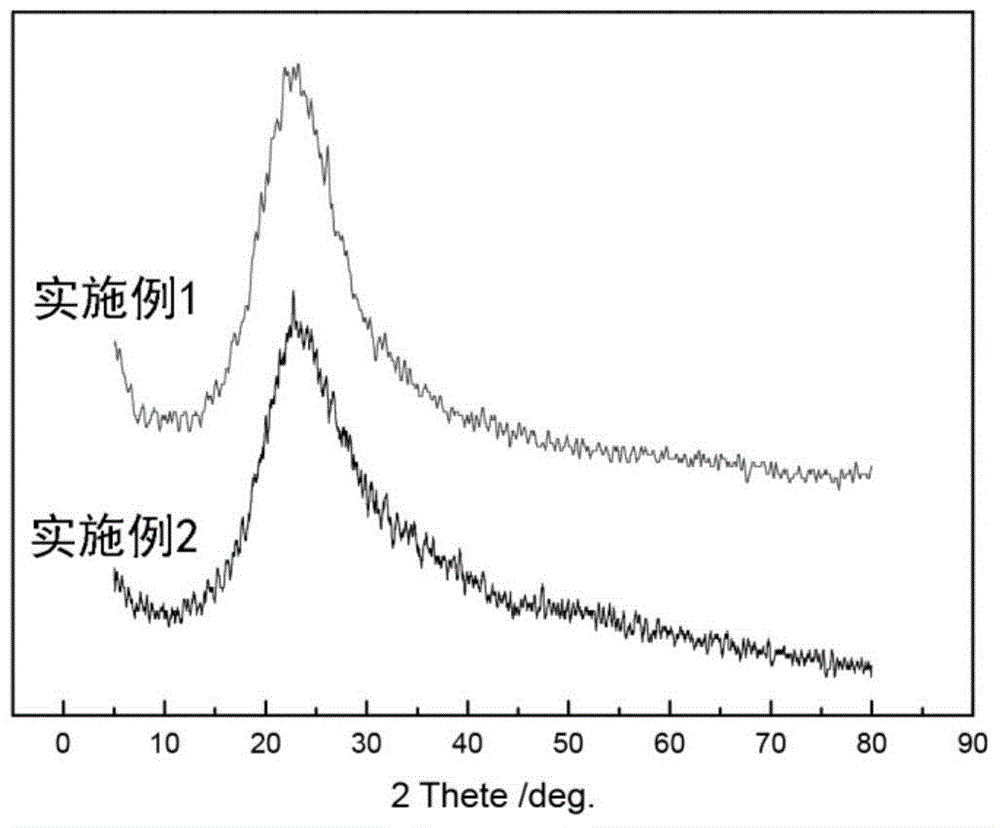

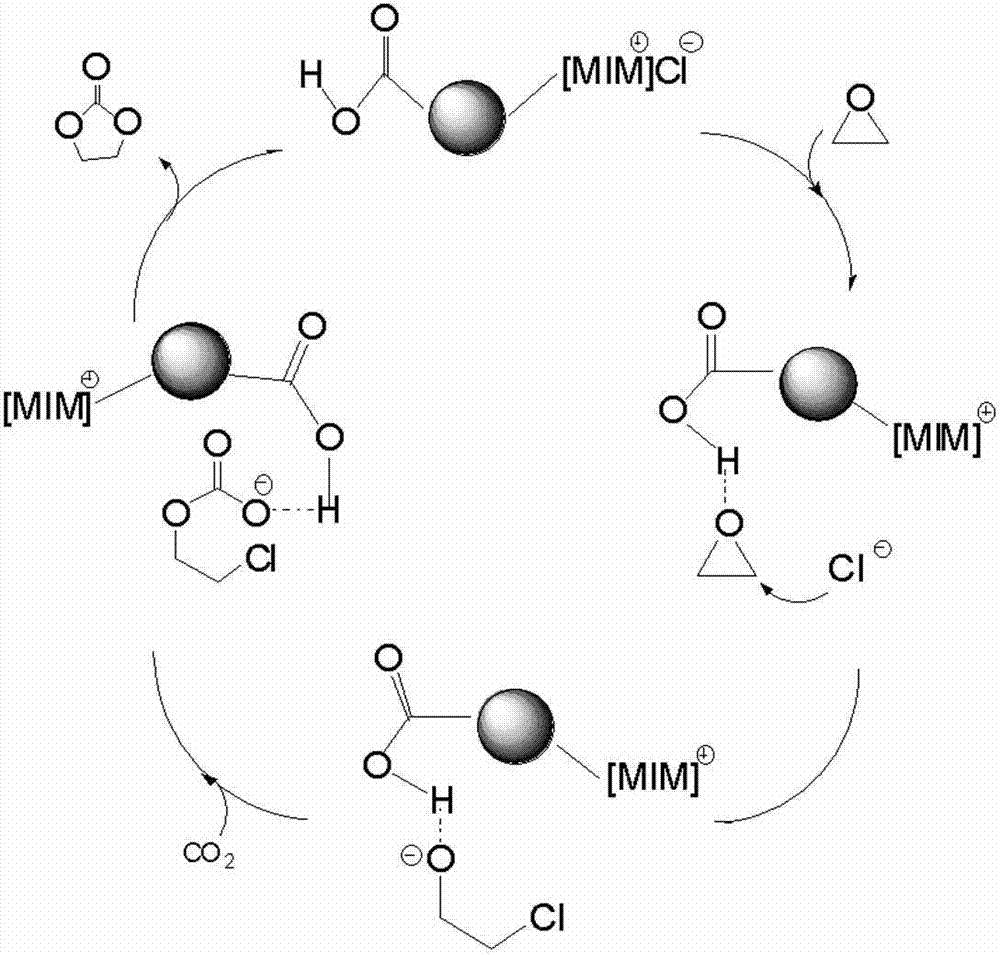

Silicon-supported ionic liquid catalyst

ActiveCN105642343ASolution to short lifeReduce dosageOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIsolation effectSolvent

The present invention belongs to the technical field of catalysts, and relates to a silicon-supported ionic liquid catalyst. First methylimidazole or alkyl imidazole is reacted with a halogen-substituted alkyl alcohol / acid to prepare an imidazole ionic liquid with reactive groups for standby use; then tetraethylorthosilicate and ethanol are added into a fixed volume container for mixing and heating, then stirred, and then added dropwise into a mixed ionic liquid solution, hydrochloric acid is added dropwise while stirring into a suspension system, and the suspension system is gradually solidified into a gel; and finally at 60 DEG C the gel is aged for 2-6h, the gel-like system is dried to give a solid product, and the solid product is ground into pale yellow powder, namely the silicon-supported ionic liquid catalyst Advantages of the silicon-supported ionic liquid catalyst are as follows: the silicon-supported ionic liquid catalyst has good catalytic synergy effect and base position isolation effect, high activity and selectivity, and can be recycled. Auxiliary catalysts or solvents are not used in catalytic processes, and high yield and high purity ethylene carbonate new products can be obtained under relatively mild conditions.

Owner:PETROCHINA CO LTD

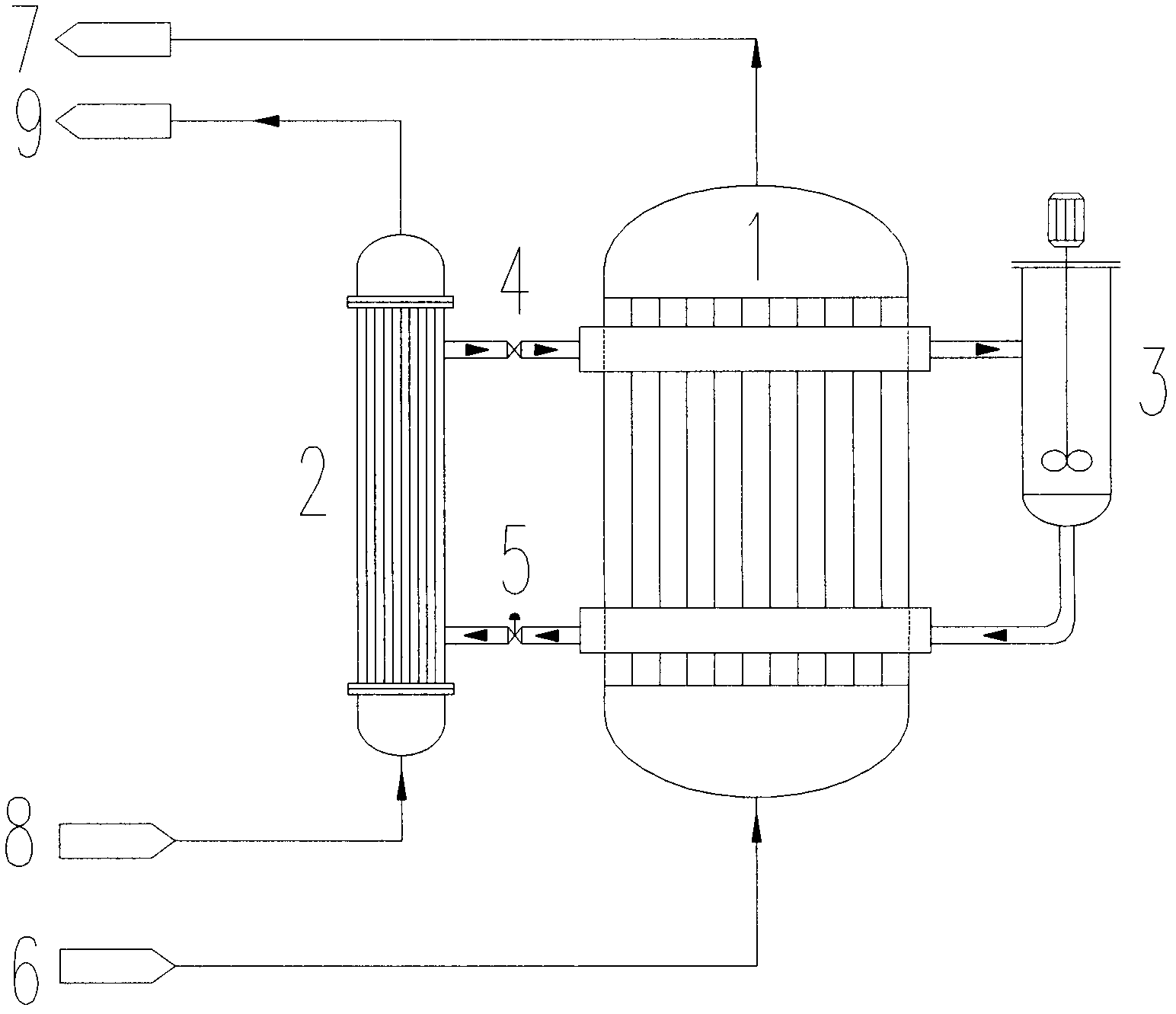

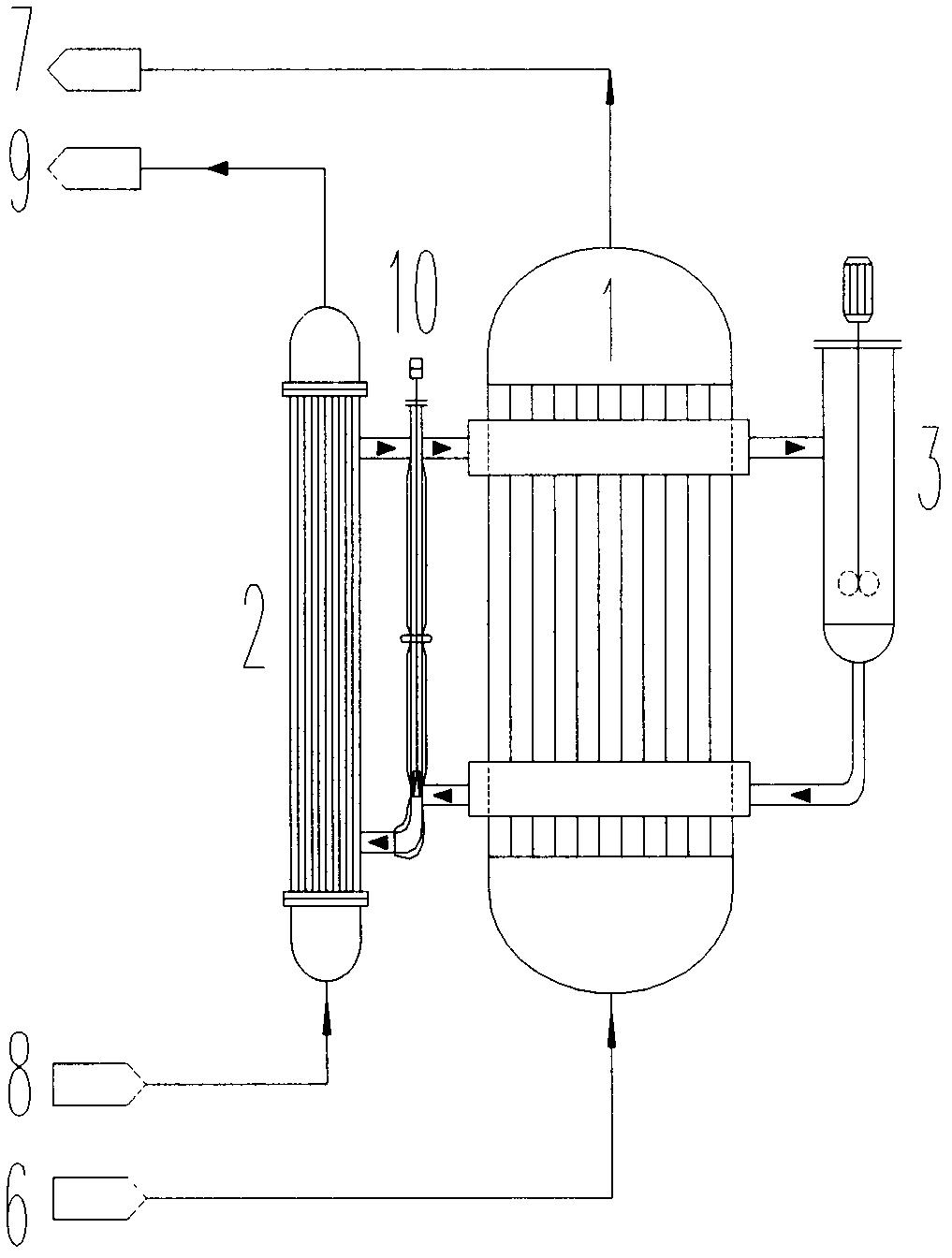

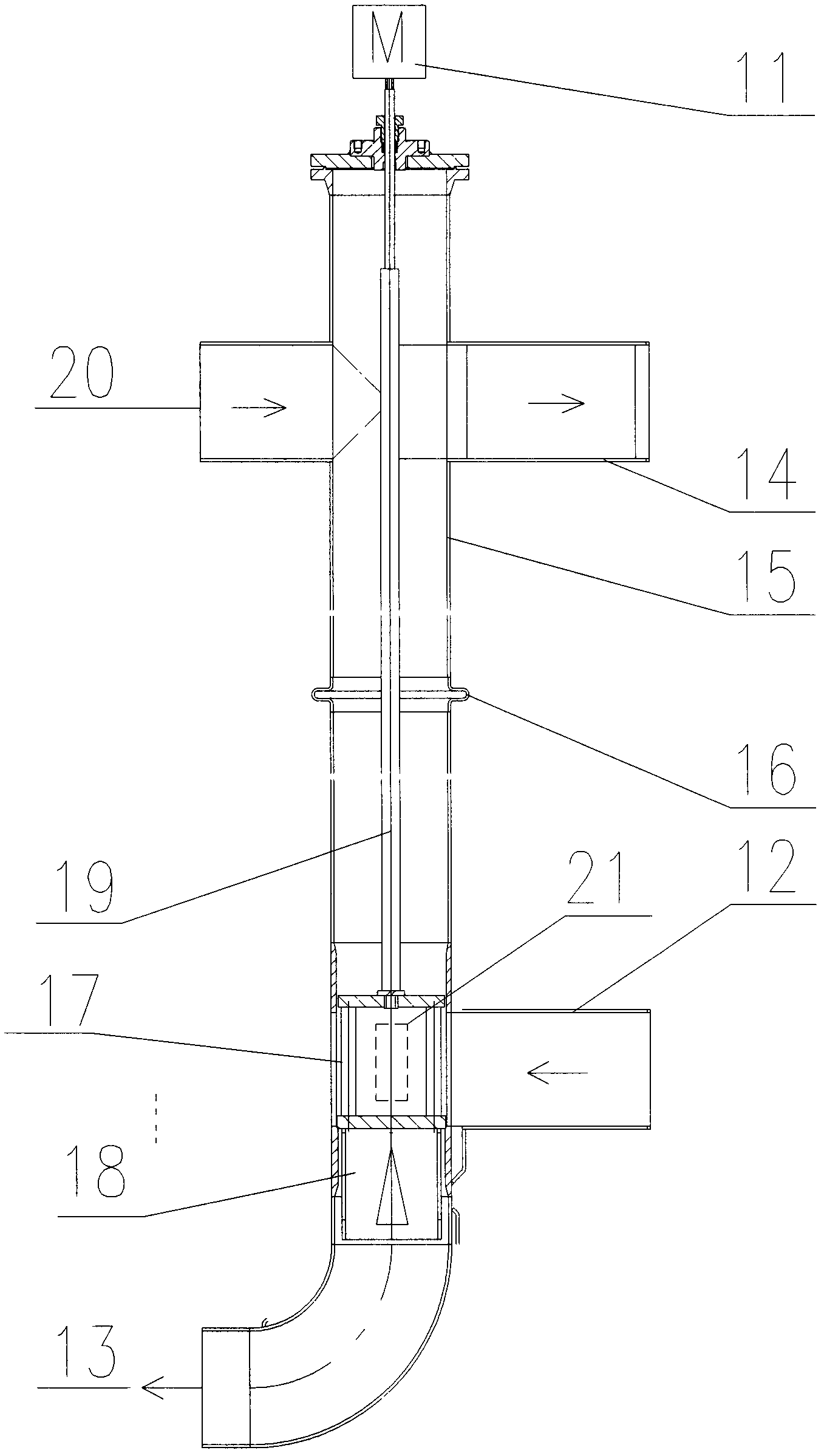

Oxidation reaction temperature regulation control device and method in fixed bed maleic anhydride production with normal butane method

ActiveCN102423666AHigh selectivityHigh yieldOrganic chemistrySlide valveMolten saltReaction temperature

The invention relates to an oxidation reaction temperature regulation control device and method in fixed bed maleic anhydride production with a normal butane method. A slide valve is arranged between a reactor and a molten salt cooler; a high-temperature molten salt inlet of the slide valve is connected with a molten salt lower circuit of the reactor; a high-temperature molten salt outlet is connected with a high-temperature molten salt inlet of the molten salt cooler; and a low-temperature molten salt returning port and a molten salt backflow port are connected with a molten salt upper circuit of the molten salt cooler and the reactor. An expansion joint is arranged at the center of the slide valve; in a valve body, a connecting rod is connected with a valve core and a self-control electric execution mechanism on the valve body; and a through hole corresponding to the valve core is arranged on the valve seat. By adopting the method, automatic regulation control on the temperature of molten salt is realized; and by accurately controlling the opening of the slide valve, stable temperature of the molten salt on the shell pass of the reactor is realized, and the fluctuation of the reaction temperature is solved and overcome. The molten salt temperature of the reactor is correct to + / -0.5 DEG C from the (+ / -)2-3 DEG C under original control. The yield of the maleic anhydride obtained by the oxidation reaction is improved by 0.5-1.0% by weight, and the byproduct in the reaction products is reduced.

Owner:天津渤化工程有限公司

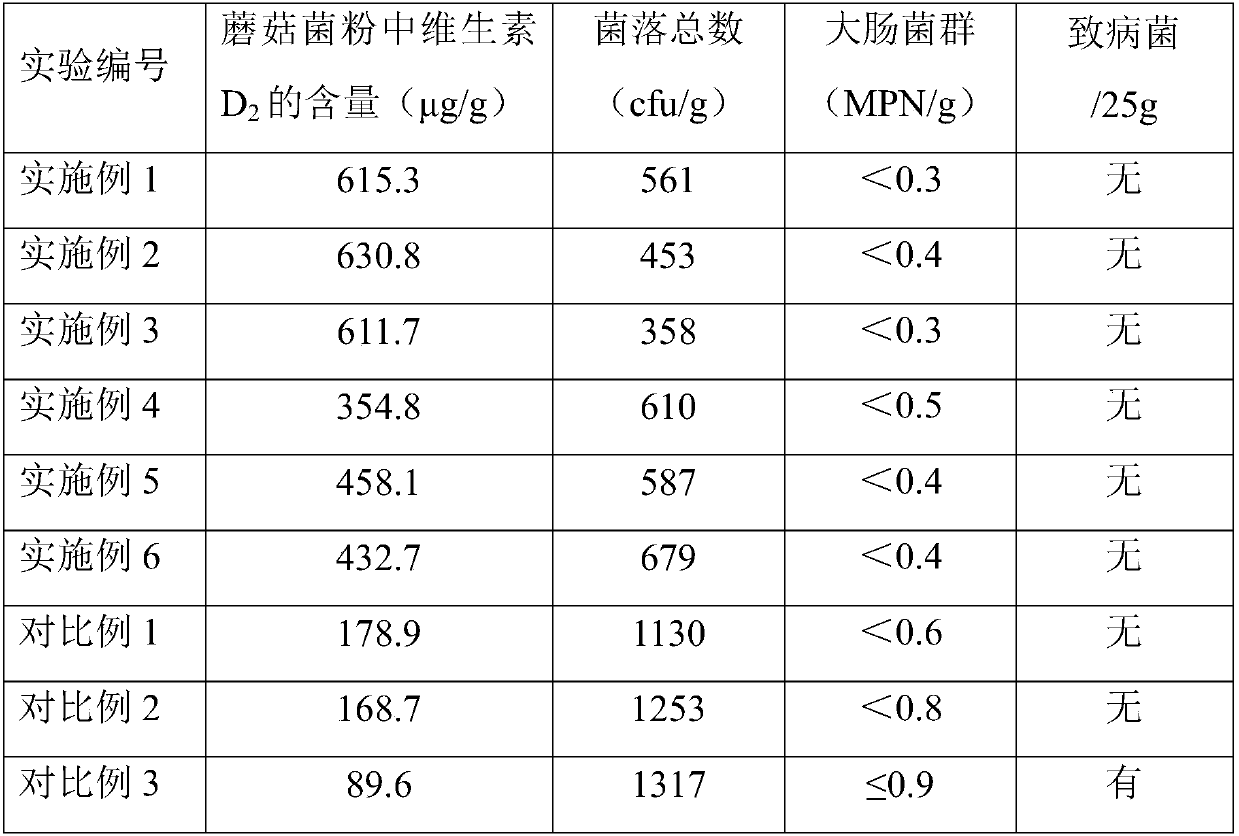

Mushroom powder rich in vitamin D2, and preparation method and application thereof

PendingCN109527530AAvoid isomeric impurities or degradation lossesLess by-productsOrganic active ingredientsFruits/vegetable preservation by irradiation/electric treatmentWater contentNitrogen gas

The invention relates to the field of domestic fungus processing, and discloses a mushroom powder rich in vitamin D2, and a preparation method and an application thereof. The preparation method comprises the following steps: slicing a mushroom raw material, and performing ultraviolet irradiation treatment in an environment having a temperature of 20-55 DEG C and a relative humidity of 50-85%, wherein the ultraviolet light irradiation is a combination of 280-315 nm UVB irradiation and 200-280 nm UVC irradiation, and the water content of the mushroom raw material is not less than 20%; drying theultraviolet-irradiated mushroom raw material under a nitrogen-filling condition; and crushing the dried mushroom raw material. The conversion rate of ergosterol into the vitamin D2 is improved by controlling the wavelength, temperature and humidity conditions during ultraviolet irradiation treatment, and a nitrogen-protected drying process is adopted to avoid the vitamin D2 from forming isomer impurities or from being degraded and lost in order to improve the quality of the mushroom powder product.

Owner:瞿瀚鹏

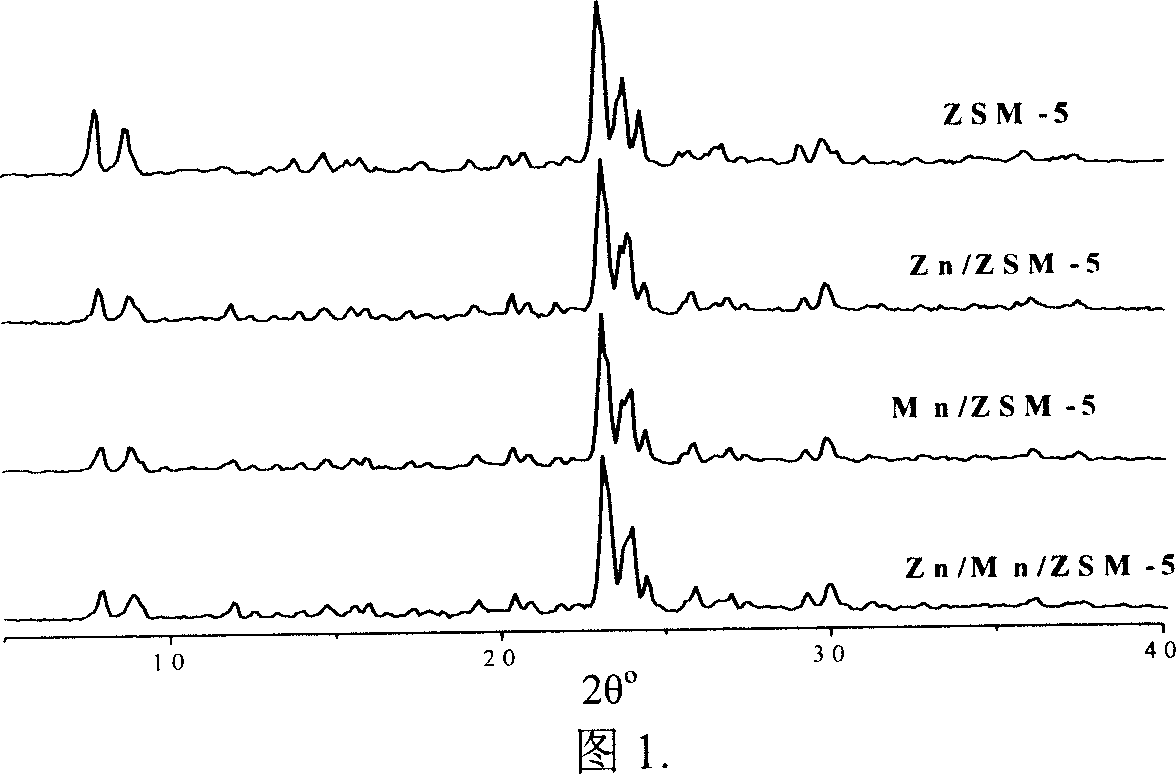

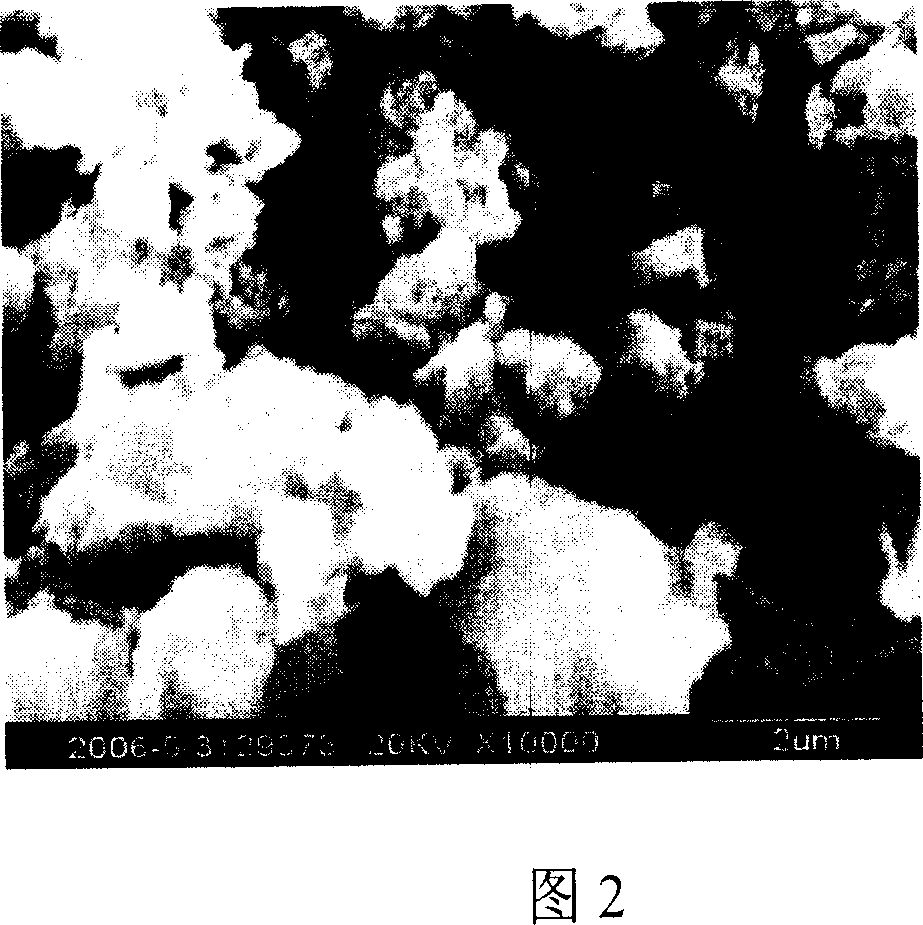

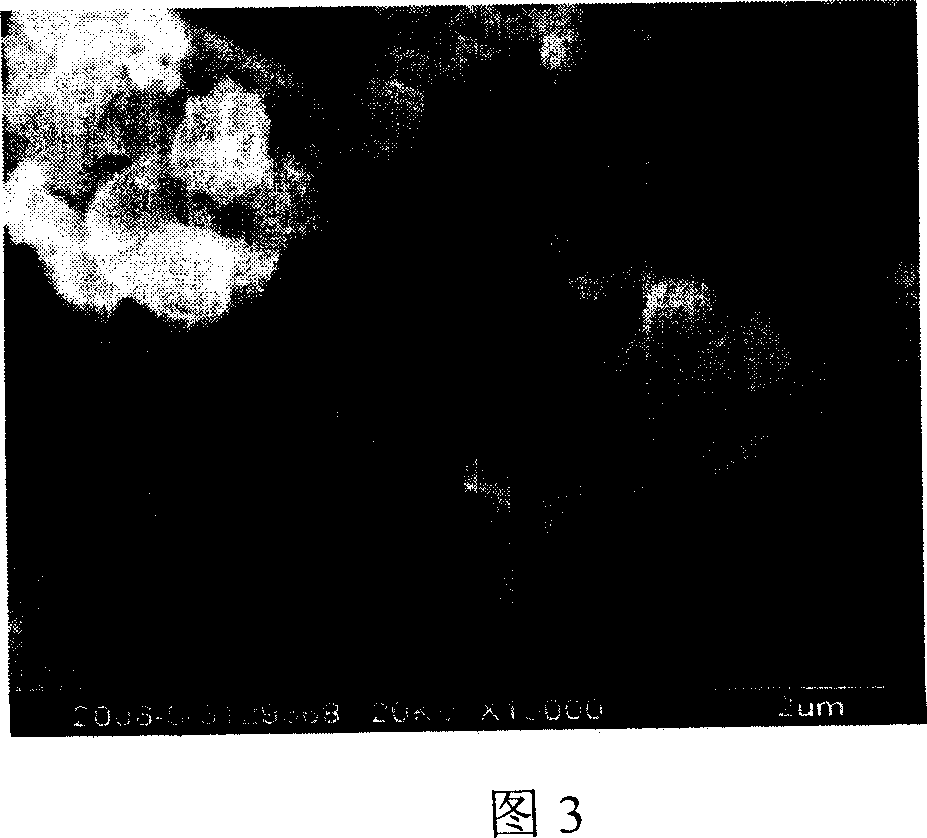

Preparation of composite modified catalyst and method for preparing biological ethane using same

InactiveCN1923367AHigh purityLess investmentMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureEthylene

The invention relates to a method for preparing composite modified catalyst, used to prepare biological ethane. Wherein, it comprises that preparing composite modified catalyst, and using said catalyst to prepare biological ethane; said catalyst uses HZSM-5 molecule screen as powder, uses emerge method to lead in Zn<2+ and Mn<2+ metal ion, to be baked, compressed, rolled, and screened, to obtain the composite modified Zn / Mn / ZSM-5 catalyst with high catalysis activity. And its application uses biological ethane as material, adds said catalyst, under normal pressure, controls airflow speed, reaction temperature and reaction time; dewaters to obtain biological ethane, while its transformation rate and selectivity are both higher then 95%. The invention has low cost and simple control.

Owner:TSINGHUA UNIV +1

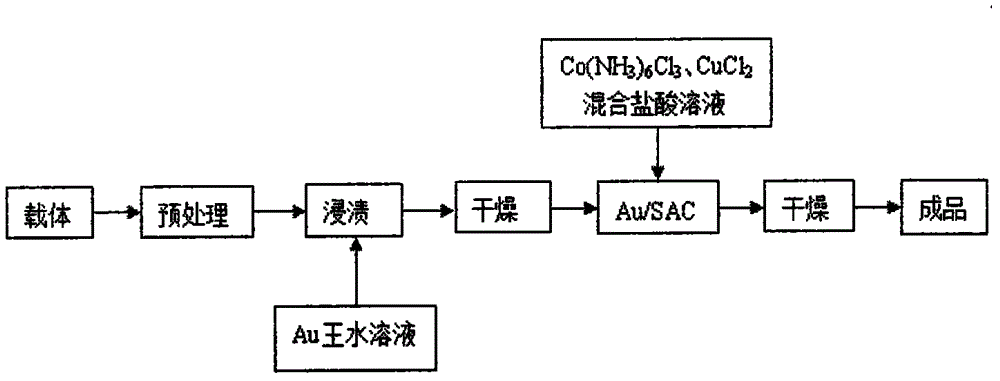

Au-Co-Cu catalyst used in synthesis of vinyl chloride by hydrochlorination of acetylene and preparation method for Au-Co-Cu catalyst

InactiveCN102794187ALow reaction temperatureLess by-productsPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsIonActivated carbon

The invention discloses a mercury-free catalyst used in the generation of vinyl chloride by the hydrochlorination of acetylene. In the catalyst, gold ions are taken as an active ingredient, and one or two transition metal elements such as copper chloride and hexaamminecobalt trichloride are added additionally; metal salts of the active ingredient can be nitrate, acetate, chloride, a complex and the like; and the active ingredient is loaded by a porous carrier, and the porous carrier is pitch-based spherical activated carbon or powdered activated carbon. The active ingredient is loaded by an impregnation method.

Owner:代斌

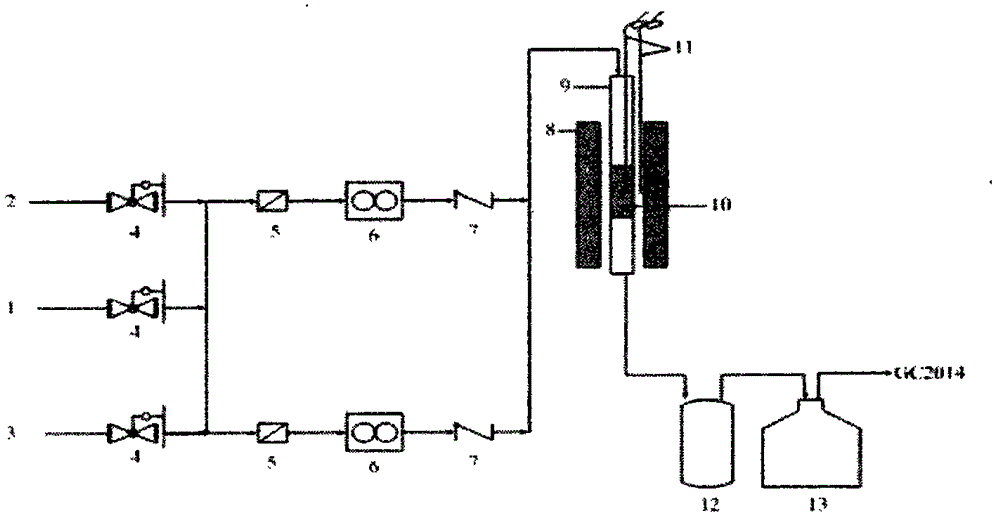

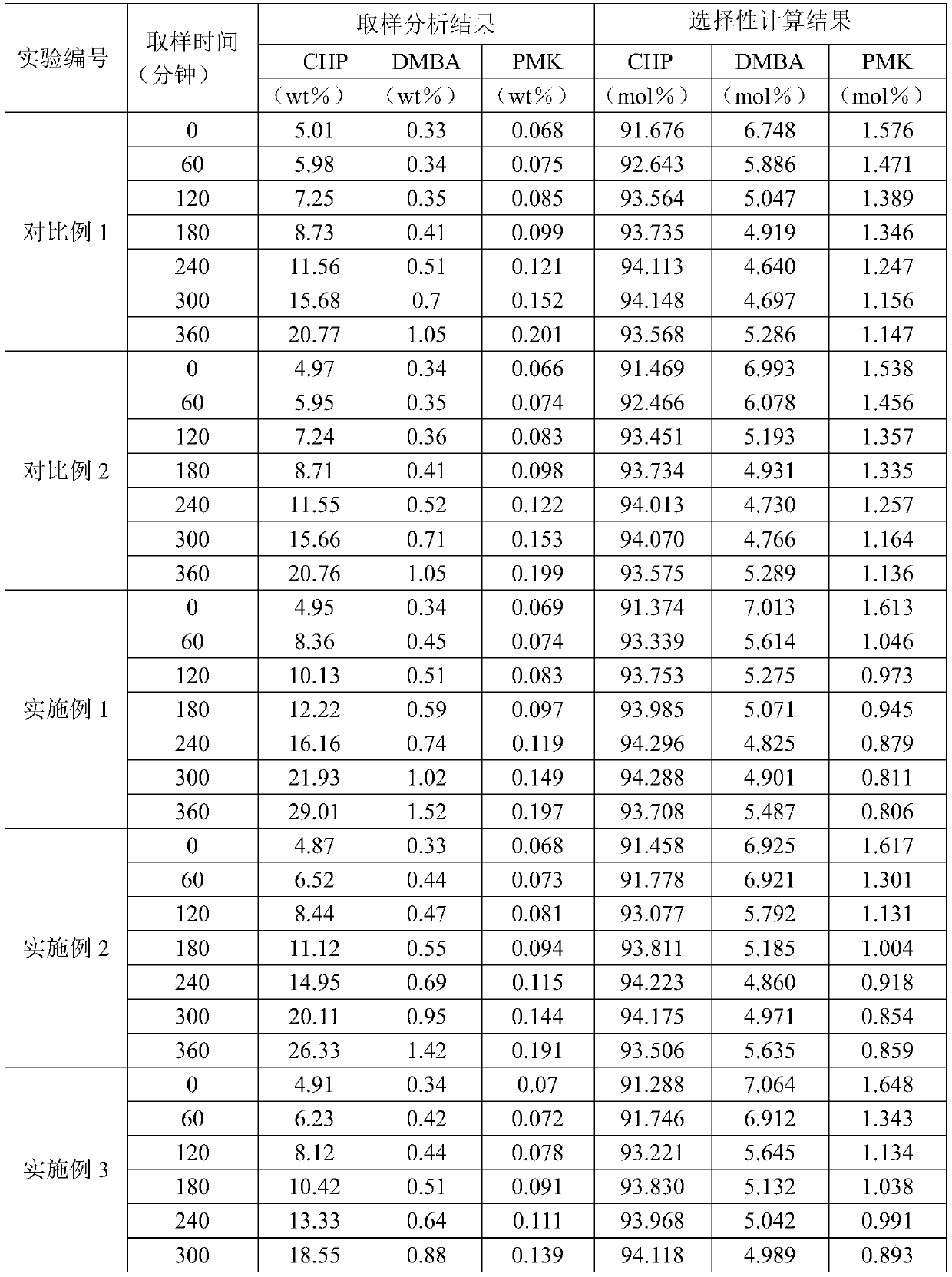

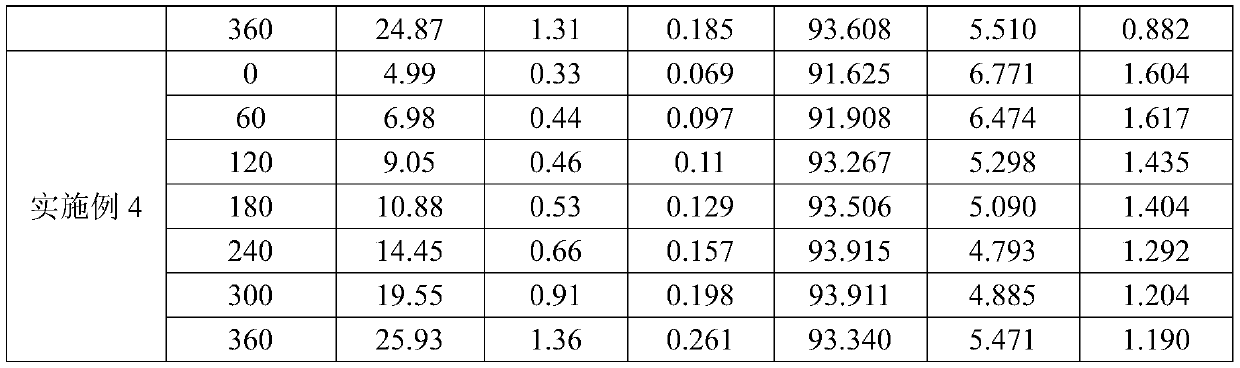

Method for preparing cumene hydroperoxide through oxidation of cumene

ActiveCN110437117AHigh yieldInhibit moving to the rightOrganic compound preparationPeroxy compound preparationBy-productCumene hydroperoxide

The present invention relates to a method for preparing cumene hydroperoxide through oxidation of cumene. The method comprises: in the presence of an alpha-methyl styrene dimer, preparing cumene hydroperoxide through oxidation of cumene, wherein preferably the method can be performed in the presence of a by-product inhibitor. According to the present invention, the conversion rate of cumene is improved when the reaction solution contains a certain amount of alpha-methylstyrene dimmers; and after the alpha-methylstyrene dimer and the by-product inhibitor are simultaneously added, the conversionrate of cumene can be increased while the selectivity of methyl phenyl ketone can be effectively reduced.

Owner:WANHUA CHEM GRP CO LTD +1

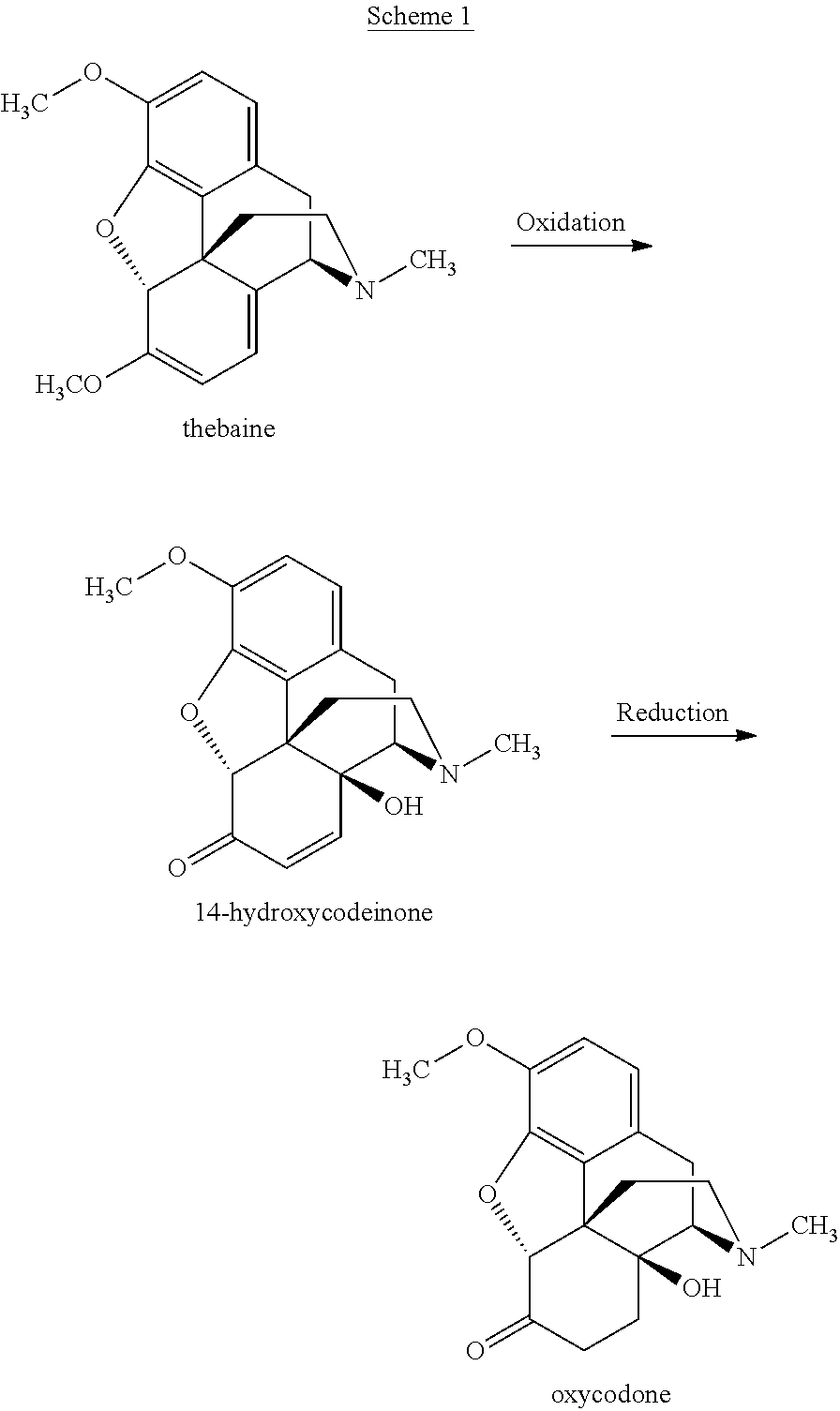

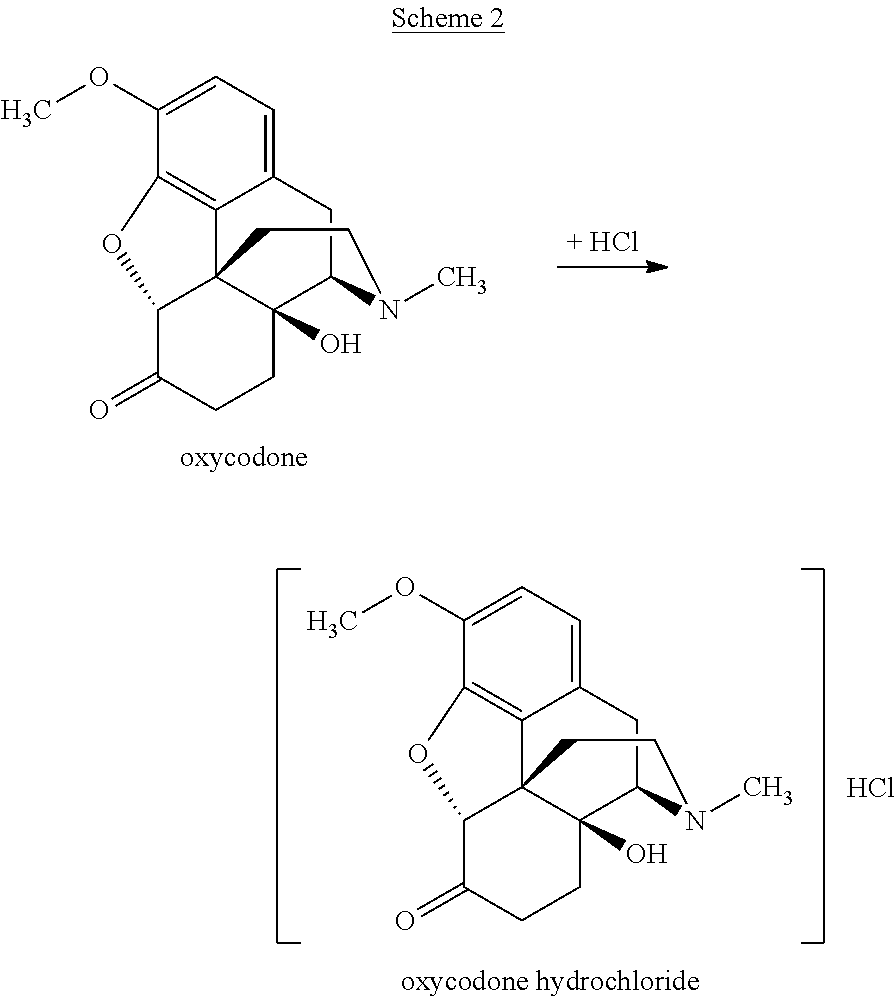

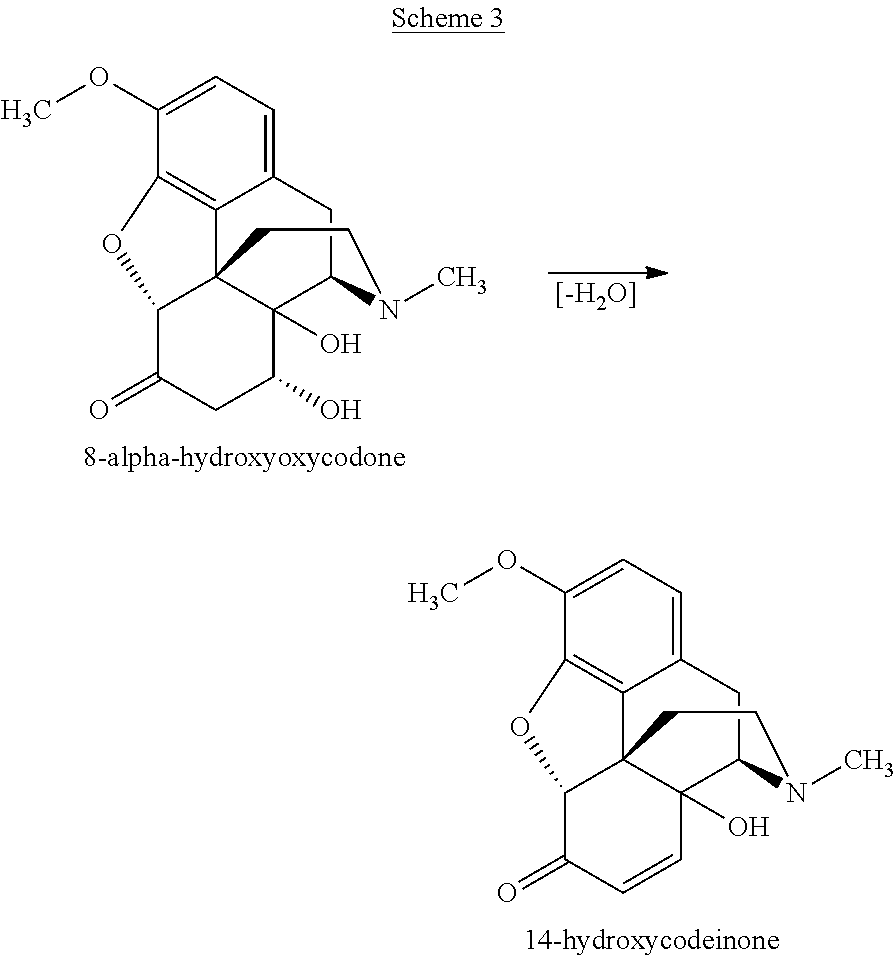

Process for improved opioid synthesis

InactiveUS20150259355A1Reduce and prevent formationReduce manufacturing costBiocideNervous disorderMedicineDosage form

Compounds and compositions for use as starting materials or intermediate materials in the preparation of opioids including, e.g., oxycodone base and / or an oxycodone salt; processes for preparing these compounds and compositions; uses of these compounds and compositions in the preparation of APIs and pharmaceutical dosage forms; and uses of said APIs and pharmaceutical dosage forms in the treatment of medical conditions.

Owner:NORDBOTICS INC

Technology for synthesizing trimethylolpropane trioleate

PendingCN107935847ALess by-productsImprove colorPhysical/chemical process catalystsOrganic compound preparationStrong acidsOleic Acid Triglyceride

The invention relates to a technology for synthesizing trimethylolpropane trioleate. The trimethylolpropane trioleate is prepared through a direct esterification method of highly pure oleic acid and trimethylol propane, a SO<4><2-> / La2O3-ZrO2@CNTS super strong acid having a high specific surface area is used as an esterification catalyst in the esterification reaction, and the catalyst has a goodcatalytic activity and an excellent reuse performance in the esterification reaction of the trihydroxymethane and the oleic acid at a lower temperature.

Owner:浙江工业大学上虞研究院有限公司

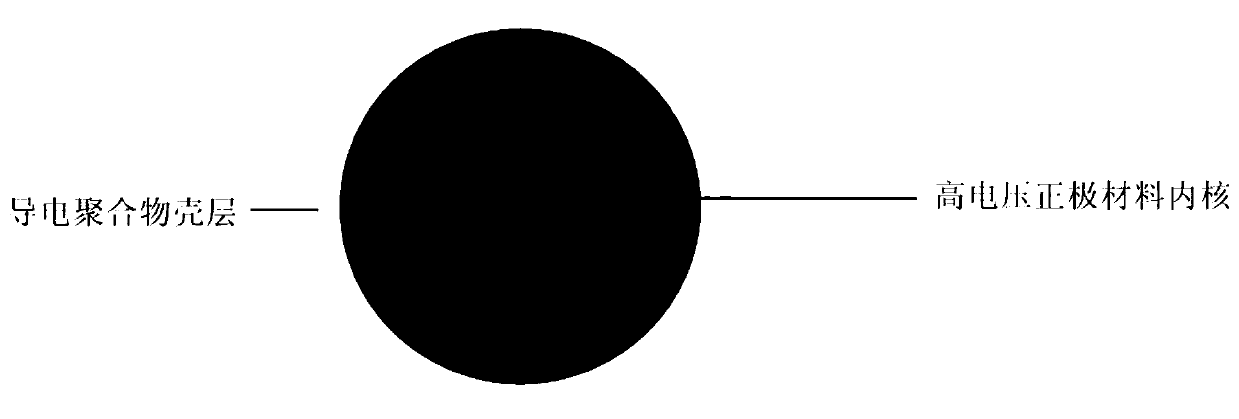

Modified high-voltage positive electrode material and preparation method and application thereof

ActiveCN111509210AImprove developmentEfficient use ofSecondary cellsPositive electrodesElectrolytic agentPtru catalyst

The invention discloses a modified high-voltage positive electrode material as well as a preparation method and application thereof. The modified high-voltage positive electrode material comprises a high-voltage positive electrode material core and a conductive polymer shell layer coating the surface of the high-voltage positive electrode material core, the preparation method comprises the following steps: carrying out in-situ reaction by adopting a high-voltage positive electrode material, a conductive polymer monomer, a catalyst and an initiator or carrying out direct coating by adopting thehigh-voltage positive electrode material, a conductive polymer and a coupling agent. The modified high-voltage positive electrode material can gradually react with an electrolyte in a battery througha controllable electrochemical activation process to form a new surface compact coating layer, the surface impedance of the battery can be effectively reduced, the ion transmission performance is improved, the rate capability of the material is improved, and the preparation method is simple to operate, high in controllability, non-toxic, harmless, few in by-product and suitable for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

Bacillus licheniformis strain and use thereof

ActiveCN102220275AImprove conversion rateLess by-productsBacteriaMicroorganism based processesSubstance contentLichen

The invention discloses a bacillus licheniformis strain MTDB-02 and use thereof. The preservation number of the strain is CGMCC NO.4825. The characteristics at bacteriology are as follows: at the initial stage, the colony form is protruded and circular, and the surface of the colonial form is smooth and has luster, at the later period of the culture, the colony edge is irregular, the surface of the colony form is flat and light yellow, and has no luster, and the 16SsDNA gene sequence has 99% homology with the 16SrDNA gene sequence of multi bacillus licheniformis strains. The strain is used for converting L-threonine to prepare 2,5-dimethyl pyrazine, the reaction condition is mild, the harmful substance content is low, the influence of plantation is free, the large scale production can be carried out, and the production cycle is short.

Owner:KWEICHOW MOUTAI COMPANY

Decolorization of amines

ActiveUS20130204044A1Less corrosiveHigh yieldAmino compound purification/separationOrganic compound preparationAcetic acidOrganic acid

The present invention provides methods that are used to decolorize compositions containing one or more amines in the presence of one or more weak acids. Significantly, the weak acids, particularly organic acids such as glacial acetic acid, when used in combination with a heat treatment produce dramatically less by-products than do the stronger mineral acids, making heat treatments and subsequent separation techniques more effective while producing less waste. In some modes of practice, the weak acids do not need to be neutralized, eliminating neutralizing steps and waste streams associated with neutralization. Low color products can be obtained easily at very high yield as a consequence.

Owner:DOW GLOBAL TECH LLC

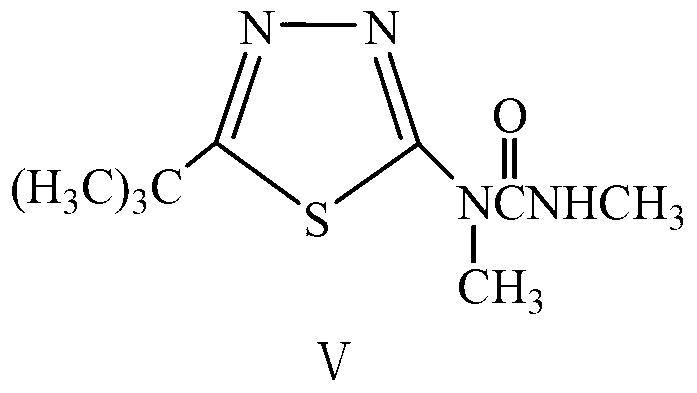

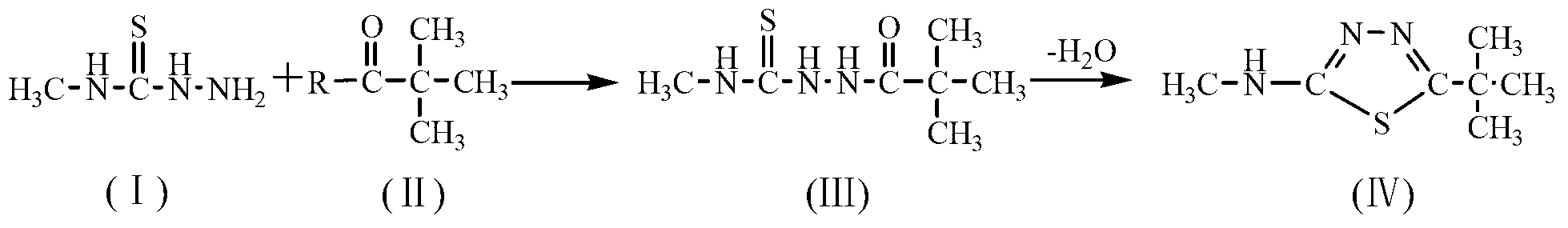

Synthesis method of key intermediate of tebuthiuron, namely 2-methylamino-5-tert-butyl-1, 3, 4-thiadiazole

The invention discloses a synthesis method of a key intermediate of tebuthiuron, namely 2-methylamino-5-tert-butyl-1, 3, 4-thiadiazole. Derivatives of 4-methyl-3-thiosemicarbazide and trimethylacetic acid are taken as raw materials, and condensation and dehydration cyclization reactions are performed under acid conditions in the presence of an organic solvent medium and a hydration agent to obtain the 2-methylamino-5-tert-butyl-1, 3, 4-thiadiazole. According to the synthesis method disclosed by the invention, environmental pollution caused by a large amount of wastewater containing phosphorus, which is produced by taking phosphoric acid, polyphosphoric acid and the like as dehydration reagents, can be effectively avoided; simultaneously, the reaction yield is high, byproducts are few, and the solvent can be recovered and applied mechanically; and the synthesis method further has the advantage of very high atom economy and is in line with the direction of green chemical development.

Owner:ZHEJIANG HETIAN CHEM CO LTD +1

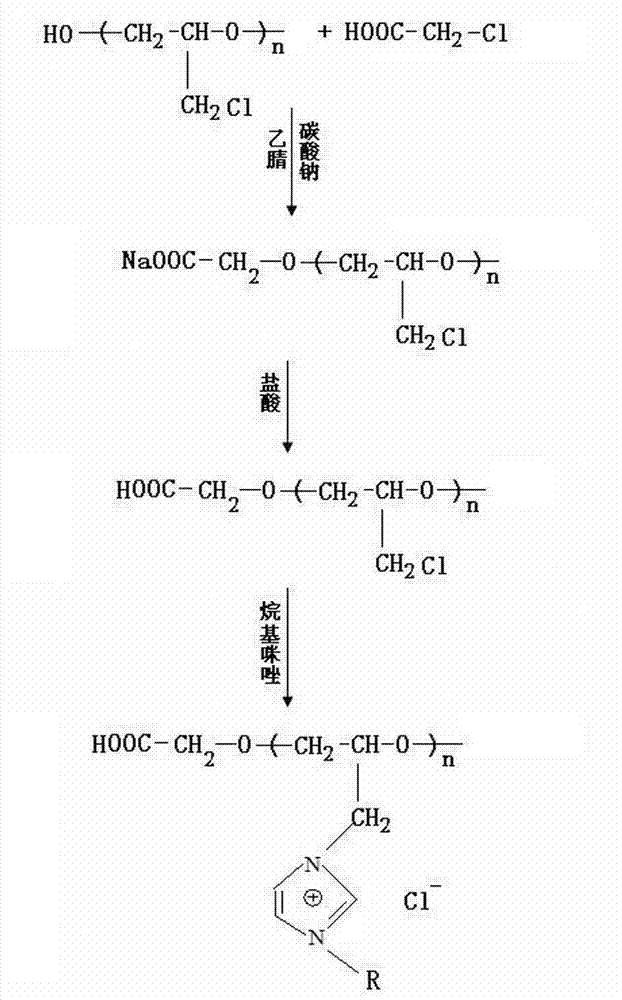

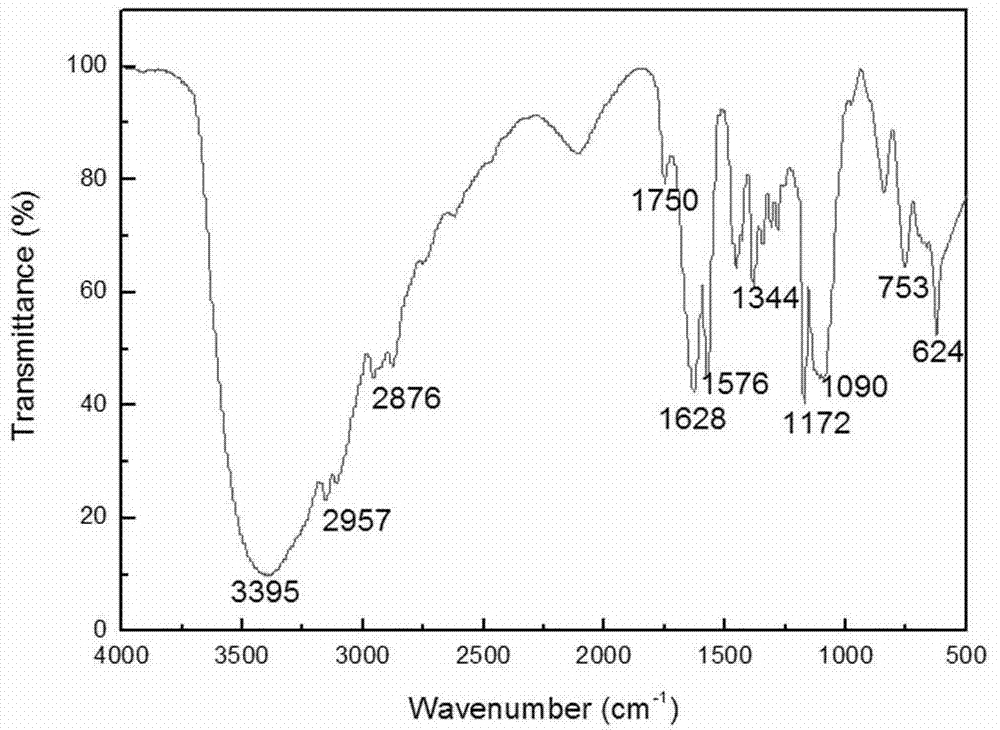

Carboxyl-terminated polyether ionic liquid catalyst and preparation method thereof

InactiveCN104707652AGood synergyHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIsolation effectCatalytic effect

The invention relates to a carboxyl-terminated polyether ionic liquid catalyst and a preparation method thereof. According to the prepared catalyst, an ionic liquid structure simultaneously contains active carboxyl-terminated functional groups and macromolecular polyether chains in a chemical bonding manner, so that the synergetic catalytic effects, site isolation effects and infinite dilution effects of the catalyst are well achieved, the generation of byproducts is effectively reduced, and the catalyst has excellent characteristics of high activity, high selectivity, stable active ingredients, small using amount, easiness in separation and recovery, reusability, long service life, environment friendliness and the like; the catalyst is used for a process of adding carbon dioxide and propylene oxide to prepare propylene carbonate, and a novel propylene carbonate product with high yield and high purity can be obtained under lower temperature and pressure.

Owner:SHENYANG POLYTECHNIC UNIV

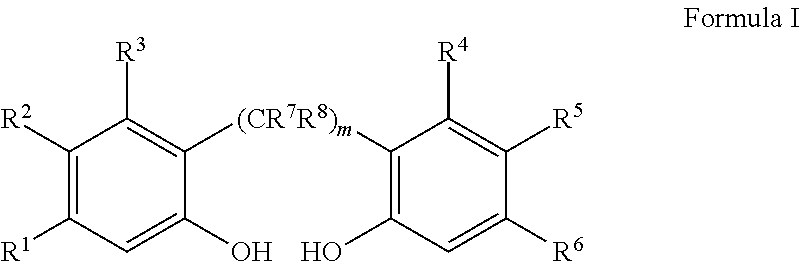

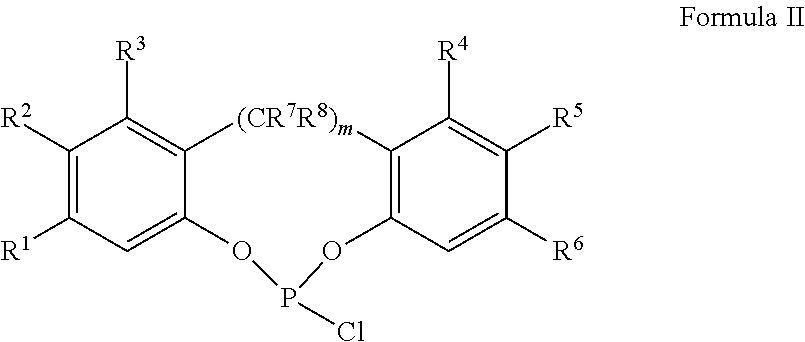

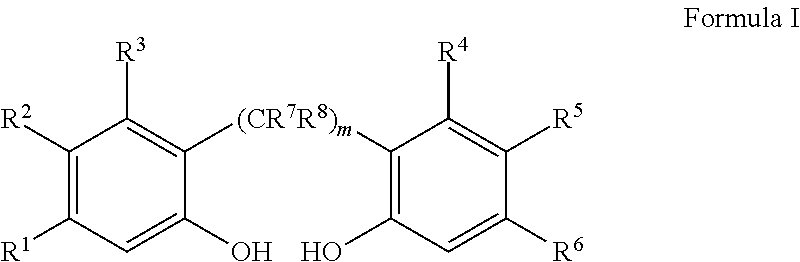

Slurry process for synthesis of bisphosphites and situ use thereof for producing bisphosphite

ActiveUS20110196166A1Reduce solubilityHigh yieldPhosphorus organic compoundsSolubilityOrganic solvent

The present invention provides a step-wise process for preparation of a bisphosphite. In step (a) the process prepares a phosphoromonochloridite in high yield, by contacting phosphorus trichloride with an aromatic diol in a slurry under reaction conditions and in the presence of a second aromatic diol to produce a mixture comprising the phosphoromonochloridite, the second aromatic diol, and excess PCl3. The slurry comprises less than 5 mole percent of a nitrogen base, and the organic solvent is selected for its low hydrogen chloride solubility. After removing the excess PCl3, a nitrogen base is added to effect condensation of the phosphoromonochloridite with the second aromatic diol to yield the bisphosphite. The invention particularly provides a process for preparing 6,6′-(3,3′,5,5′-tetra-tert-butylbiphenyl-2,2′-diyl)bis(oxy)didibenzo[d,f][1,3,2]dioxaphosphepine by the above route.

Owner:DOW TECH INVESTMENTS

Synthesis method of N-(Phosphonomethyl) iminodiacetic acid

ActiveCN103012473ANo emissionsCompletely hydrolyzedGroup 5/15 element organic compoundsPhosphorous acidHydrolysis

The invention discloses a synthesis method of N-(Phosphonomethyl) iminodiacetic acid (PMIDA) using iminodiacetonitrile as the raw material. The method comprises the following steps: using mixed acid as a hydrolytic reagent, hydrolyzing the iminodiacetonitrile in the mixed acid water solution to obtain acid salt of the iminodiacetic acid, and then performing the condensation reaction of the hydrolyzation solution with phosphorous acid and formaldehyde at the presence of hydrochloric acid to obtain the N-(Phosphonomethyl) iminodiacetic acid, wherein the mixed acid is hydrochloric acid and sulfuric acid, or hydrochloric acid and orthophosphorous acid. According to the invention, the mixed acid is used as a hydrolytic reagent; meanwhile, high temperature and high pressure are adopted to enable the hydrolyzation to be more thorough; at the same time, no waste gas is emitted; and the periodic time of the whole synthesis process is short, the operation is simple, the utilization ratio of the raw materials is high, the side product is few, energy consumption is low and the three wastes are less.

Owner:SHANDONG WEIFANG RAINBOW CHEM

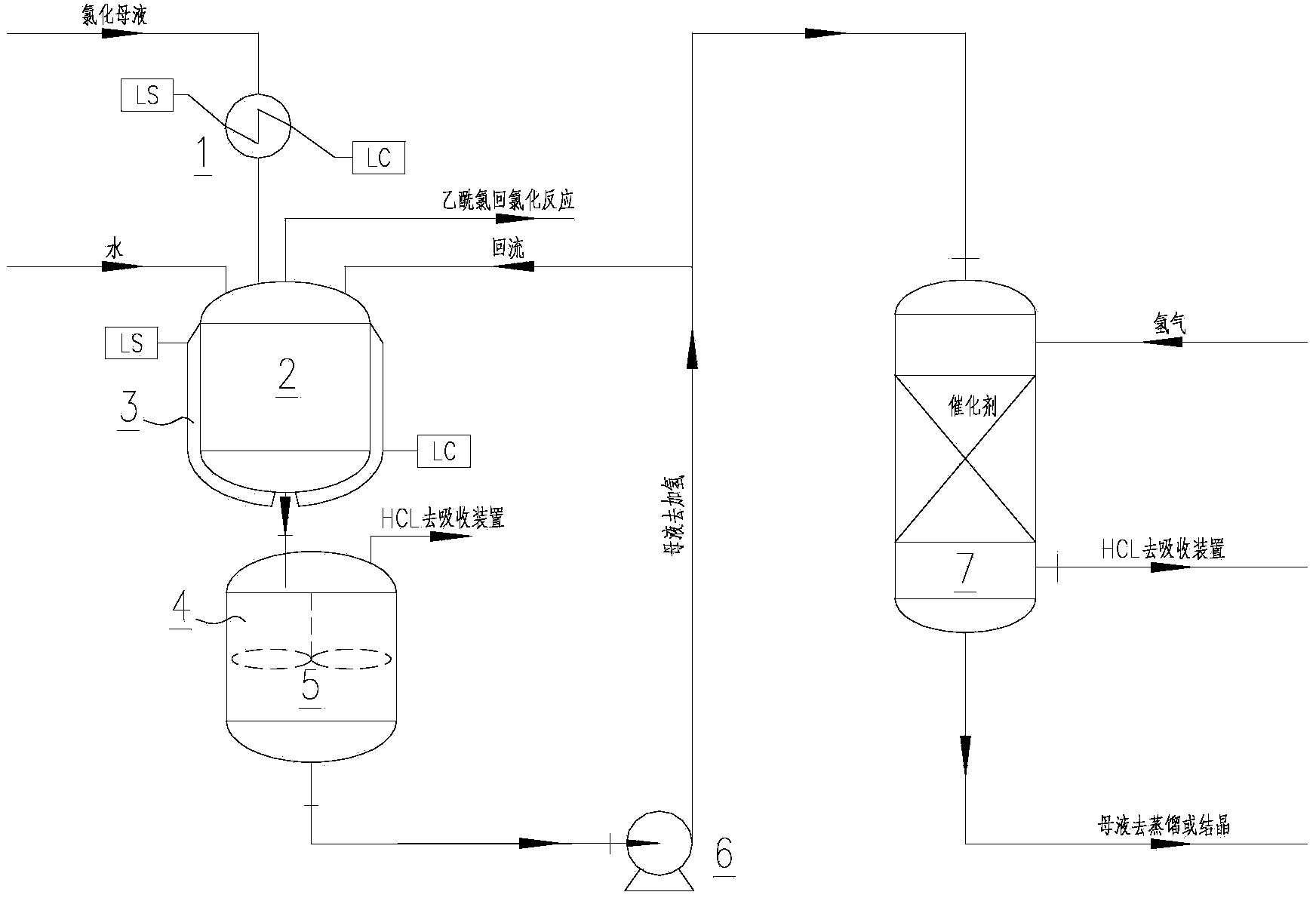

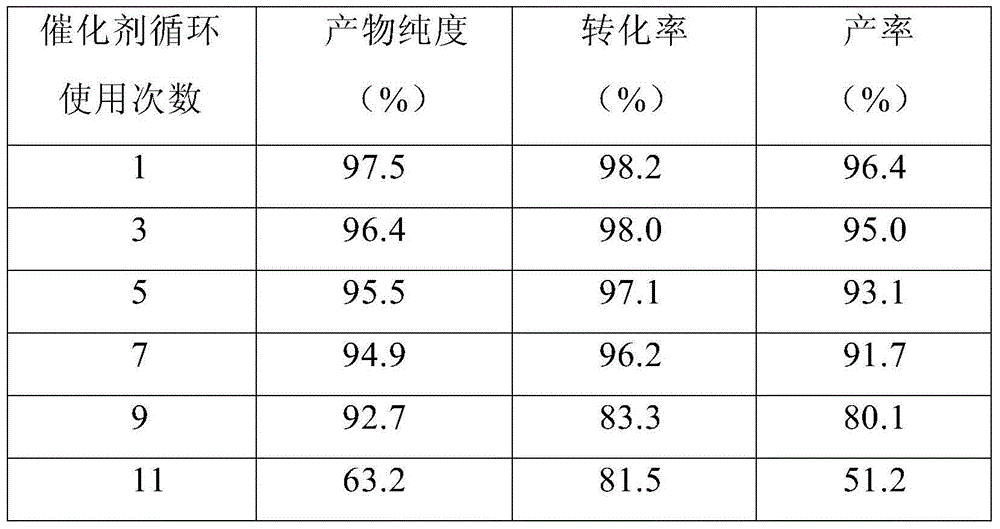

Chloroacetic acid chlorination mother solution treatment method

ActiveCN103922916AReduce concentrationReduce consumptionOrganic compound preparationCarboxylic compound preparationAcetic anhydrideDistillation

The invention discloses a chloroacetic acid chlorination mother solution treatment method, comprising the following steps of heating a chlorination mother solution through a heater; delivering the heated chlorination mother solution and water into a hydrolysis reactor respectively, and evaporating a part of acetyl chloride; reacting the other part of acetyl chloride with water; delivering the hydrolyzed chlorination mother solution into a secondary hydrolysis reactor, and performing flash evaporation to separate HCL out; pumping the mother solution subjected to the flash evaporation into a hydrogenation reactor through a pump, reacting in the presence of a catalyst, delivering HCL after reacting into an absorption device, and performing a distillation or crystallization process on the mother solution. The method has the advantages that acetyl chloride in the chlorination mother solution is recycled, so that the consumption of acetic anhydride in production is finally reduced, the HCL content of the chlorination mother solution is reduced, and the hydrogenation reaction efficiency is improved.

Owner:CHINA TIANCHEN ENG +2

Method of producing ethylene carbonate

ActiveCN105732566ALess by-productsHigh purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthylene oxideReaction temperature

The invention relates to a method of producing ethylene carbonate by catalytic addition from ethylene oxide and CO2. In the method, under the effect of an environment-friendly ionic liquid catalyst, the CO2 and the ethylene oxide are added to prepare the ethylene carbonate. When the reaction temperature is 90-130 DEG C, the reaction pressure is 1-3 MPa, the stirring speed is 200-300 r / min and the reaction time is 1-2 h, the conversion rate of the ethylene oxide reaches more than 98% and the yield of the ethylene carbonate reaches more than 94%. Conversion rate and yield are both higher than 90% even the catalyst is repeatedly used for seven times.

Owner:PETROCHINA CO LTD

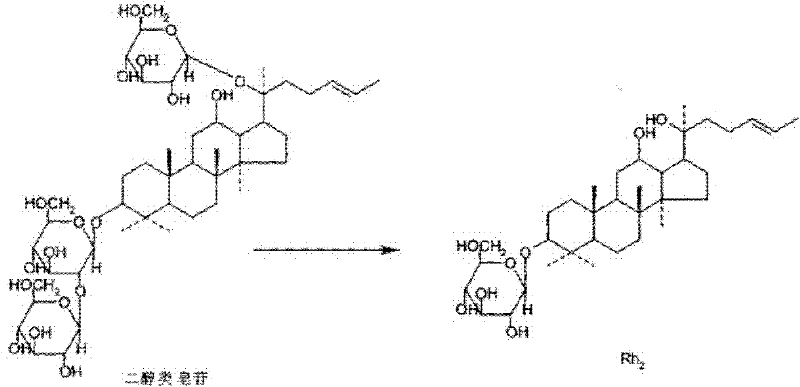

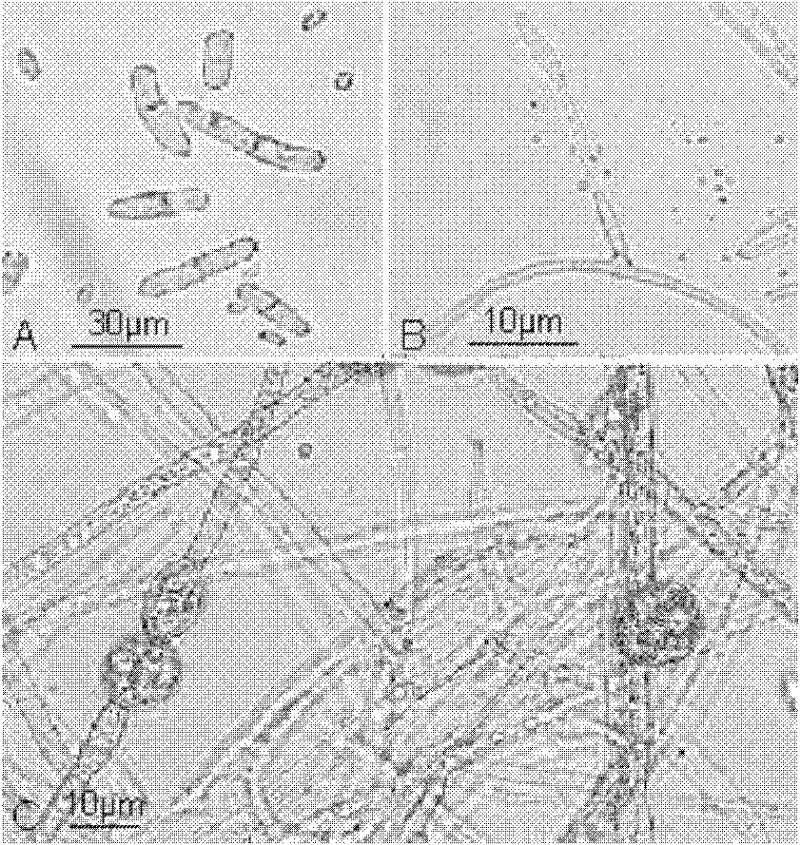

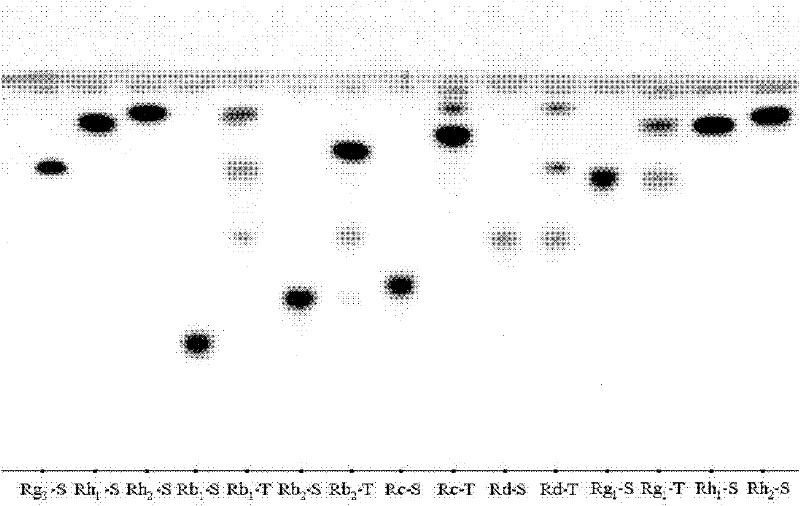

Cylindrocarpon didymium and method for preparing ginsenoside Rh2 by using same

InactiveCN102226152ALow costLess by-productsFungiMicroorganism based processesGinsenoside Rb1Potato dextrose agar

The invention relates to a pathogenic fungus of ginseng, in particular to Cylindrocarpon didymium (CGMCC NO.4681). The Cylindrocarpon didymium is capable of preparing ginsenoside Rh2 by converting substrate ginsenoside Rb1Rd. The method for preparing ginsenoside Rh2 by using the Cylindrocarpon didymium comprises the following steps: by adopting an in-situ conversion method, spot-inoculating the Cylindrocarpon didymium onto a PDA (Potato Dextrose Agar) culture medium containing ginsenoside Rb1 and / or Rd, and performing stationary culture at 25 DEG C for 5-7 days; or by adopting a microbial fermentation conversion method, inoculating the Cylindrocarpon didymium onto a liquid fermentation culture medium, and culturing at 28 DEG C for 5-7 days; and collecting the enzyme liquid, mixing with the ginsenoside Rb1 and / or Rd, and reacting at 40 DEG C for 24 hours. The technical scheme for producing ginsenoside Rh2 has the characteristics of high specificity, high simplicity and convenience, high safety and reliability, low cost and few byproducts. The purity of the fermented product Rh2 is above 85%, and the conversion rate can be up to 45% or above.

Owner:DALIAN NATIONALITIES UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com