Chloroacetic acid chlorination mother solution treatment method

A treatment method, the technology of chloroacetic acid, which is applied in the field of treatment of chloroacetic acid chlorination mother liquor, can solve the problems of high unit consumption of acetic anhydride, increase of by-products of hydrogenation reaction, expensive raw materials, etc., and achieve saving of acetic anhydride consumption and reduction of by-products , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

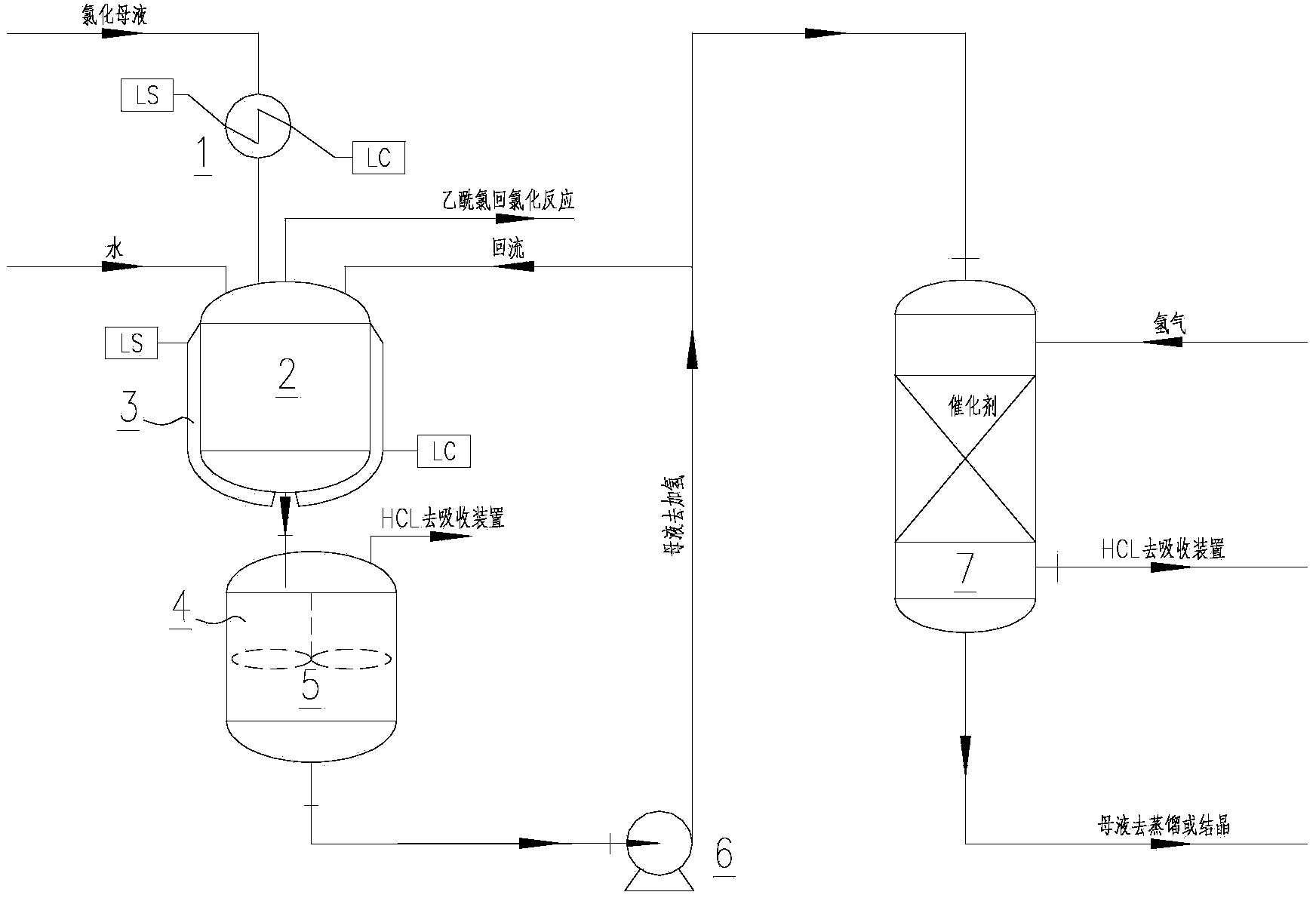

[0024] The chlorination mother liquor is heated by the heater 1; the heated chlorination mother liquor and water enter the hydrolysis reactor 2 respectively, and the temperature of the mother liquor increases, and part of the acetyl chloride evaporates; the unevaporated acetyl chloride and water are hydrolyzed with the water in the hydrolysis reactor 2 Reaction; after the hydrolysis reaction, the chlorinated mother liquor enters the secondary hydrolysis reactor 4 for flash evaporation, and separates HCL into the absorption device; the flashed mother liquor is pumped into the hydrogenation reactor 7 through the pump 6, and reacts under the action of the catalyst. The latter HCL enters the absorption device, and the chlorinated mother liquor enters the distillation or crystallization process.

Embodiment 2

[0026] The chlorination mother liquor is heated by the heater 1; the heated chlorination mother liquor and water enter the hydrolysis reactor 2 respectively, and the temperature of the mother liquor increases, and part of the acetyl chloride evaporates; the unevaporated acetyl chloride and water are hydrolyzed with the water in the hydrolysis reactor 2 Reaction; The steam jacket 3 is installed outside the hydrolysis reactor 2 to further increase the temperature of the chlorination mother liquor and reduce the saturation content of acetyl chloride; after the hydrolysis reaction, the chlorination mother liquor enters the secondary hydrolysis reactor 4 for flash evaporation, and separates HCL into the absorption device; The flashed mother liquor is pumped into the hydrogenation reactor 7 through the pump 6 and reacted under the action of the catalyst. The reacted HCL enters the absorption device, and the chlorinated mother liquor enters the distillation or crystallization process.

Embodiment 3

[0028] The chlorination mother liquor is heated by the heater 1; the heated chlorination mother liquor and water enter the hydrolysis reactor 2 respectively, and the temperature of the mother liquor increases, and part of the acetyl chloride evaporates; the unevaporated acetyl chloride and water are hydrolyzed with the water in the hydrolysis reactor 2 Reaction: The steam jacket 3 is installed outside the hydrolysis reactor 2 to further increase the temperature of the chlorination mother liquor and reduce the saturation content of acetyl chloride; after the hydrolysis reaction, the chlorination mother liquor enters the secondary hydrolysis reactor 4 for flash evaporation, and the secondary hydrolysis reactor 4 is equipped with stirring To promote the full progress of the hydrolysis reaction, separate HCL and enter the absorption device; the mother liquor after flashing is pumped into the hydrogenation reactor 7 through the pump 6 and reacts under the action of the catalyst. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com