Preparation method of 1-aminopolypropylether-3-methylimidazolium chloride ion liquid catalyst

A technology of methylimidazolium ions and liquid catalysts, which is applied in the fields of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., and can solve the problem of insufficient catalyst efficiency and selectivity, cycle Short service life, harsh reaction conditions and other problems, to achieve the effect of easy control, increased cycle times, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

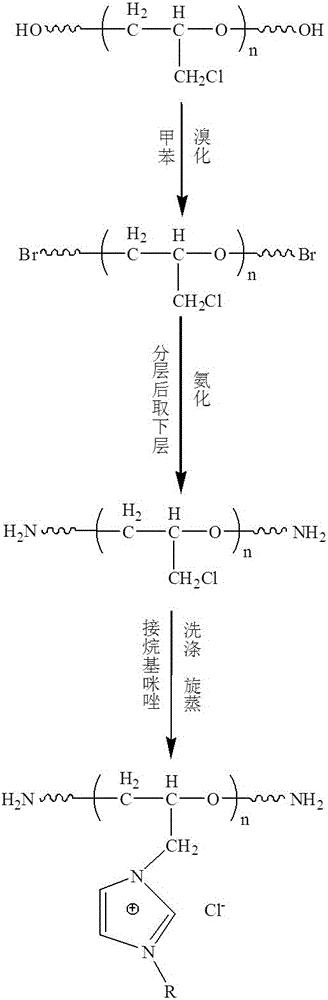

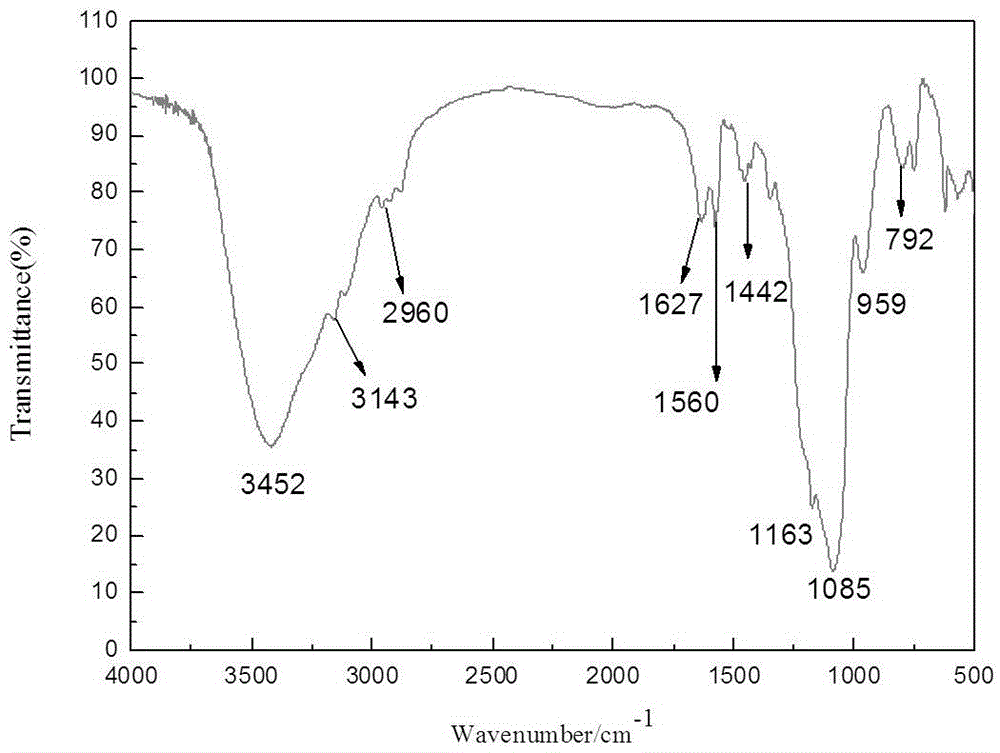

[0056] First weigh 10mL of hydroxyl-terminated polyepichlorohydrin, then measure 20mL of toluene to dissolve it, then pour the solution into a three-necked flask equipped with reflux condensation, add a magnet and stir at a speed of 150-200r / min; bromine and hydroxyl-terminated polyepichlorohydrin molar ratio of 3:1, bromine is poured into a separatory funnel, and slowly added dropwise at room temperature; after the dropwise addition, react at room temperature for 2 hours; 40°C, react for 1 hour; then raise the temperature to 50°C, react for 1 hour; then raise the temperature to 60°C, react for 1 hour, and obtain the initial product of the terminal brominated polyether solution.

[0057] According to the amount of ammonia water and polyepichlorohydrin molar ratio of 5:1, it was added to the separatory funnel, slowly added dropwise at room temperature, and continued to react after the dropwise addition until the color of the solution changed from reddish brown to colorless and s...

Embodiment 2

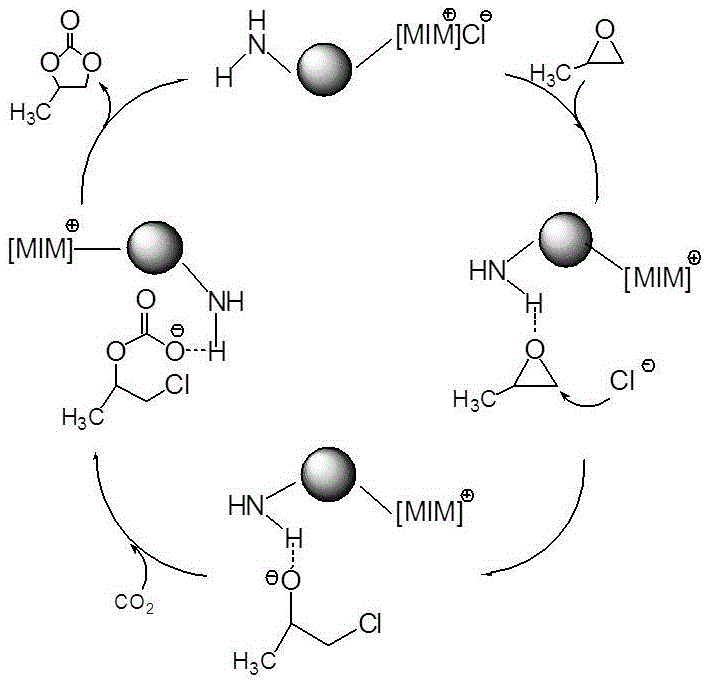

[0062] In the same equipment used in Example 1, under the same process conditions, just change N-methylimidazole into N-ethylimidazole, after the reaction, the purity of the propylene carbonate product is 98.3%, and the calculated epoxy The conversion rate of propane is 100%, the selectivity is 95.2%, and the conversion frequency is 3125h -1 .

Embodiment 3

[0064] In the same equipment used in Example 1, under the same process conditions, just change N-methylimidazole into N-methylpiperazine, after the completion of the reaction, the purity of the propylene carbonate product is 96.3%. The conversion rate of oxypropane is 98.5%, the selectivity is 94.1%, and the conversion frequency is 2866h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com