Patents

Literature

298results about How to "Easy to operate industrially" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel abrasion-resistant, anti-corrosion and anti-static coating and preparation method thereof

InactiveCN105219219AEffectively dissipate static electricityEffective anti-electromagnetic interference capabilityAnti-corrosive paintsEpoxy resin coatingsCarbon nanotubeSilicon dioxide

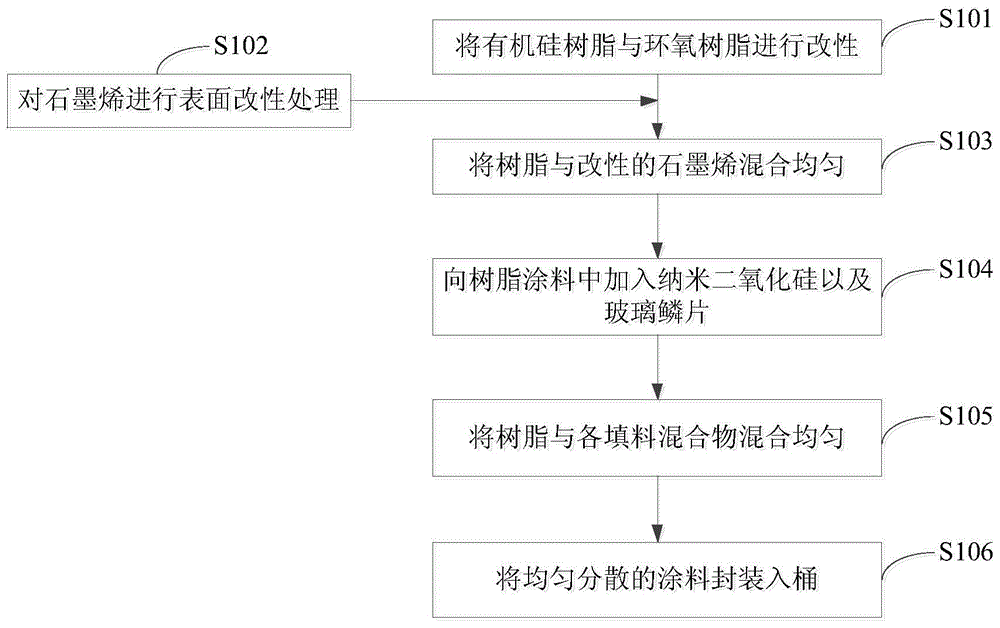

The invention relates to a novel highly-abrasion-resistant, anti-corrosion and anti-static coating and a preparation method thereof. The coating comprises basic thermosetting resin and a filler, wherein the basic thermosetting resin is modified resin for coatings; the filler is formed through blending and combining one or more of a carbon nano tube, carbon black, graphite, graphene, nano aluminum powder and conductive mica powder with one or more of quartz sand, glass flake, nano silicon dioxide, nano-molybdenum disulfide, aluminium oxide and modified montmorillonite. The coating is directly smeared or sprayed on the surface of a metal outer shell of electronic and electrical equipment, the equipment can be effectively prevented from being corroded by the environment for a long time, and the influence of pad points and electromagnetic interference on the safe, normal and stable use of the equipment is prevented.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Forming SCR catalyst with both water resistance and sulphur resistance and preparation method thereof

InactiveCN104475122ADurable and efficient operationImprove mechanical propertiesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

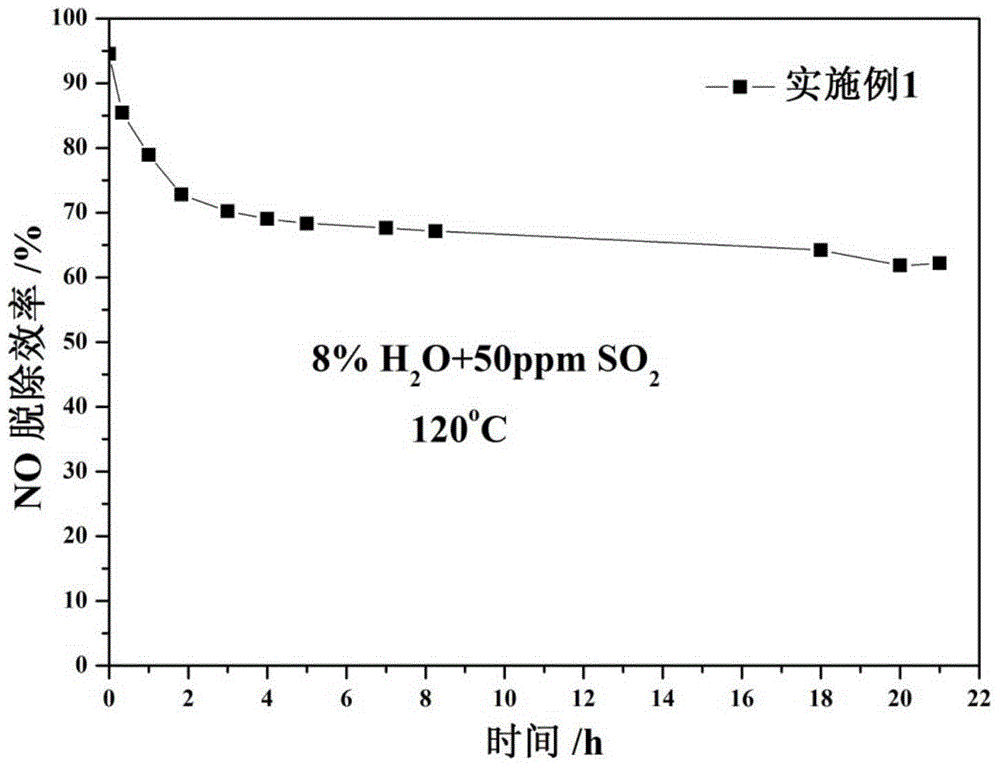

The invention discloses a forming SCR catalyst with both water resistance and sulphur resistance. According to the forming SCR catalyst, anatase TiO2 is taken as a carrier, the active ingredients are cerium, manganese and cobalt and is added with one or more elements of zirconium, tungsten and tin to form a composite oxide Ce-Mn-Co-X / TiO2, wherein the molar ratio of Ti: Mn: Ce: CO: X is equal to 1: (0.1-2): (0.05-2): (0.05-2): (0.1-2), and X is one or more elements of zirconium, tungsten and tin. The invention further discloses a preparation process of the catalyst, wherein the catalyst is prepared by an overall extrusion method through one-step forming, and the prepared catalyst has excellent denitration performance and good water resistance and sulphur resistance at a temperature of 90-150 DEG C, and can be used for denitration of tail flue gas with high vapour content and low SO2 content from a cement kiln furnace.

Owner:ZHEJIANG UNIV

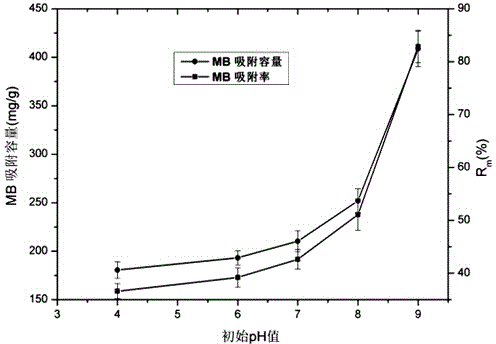

Method for preparing composite hydrogel through modifying bamboo shoot leftovers and application of composite hydrogel

ActiveCN104086785AImprove adsorption capacityRich sourcesOther chemical processesPaper material treatmentCelluloseSodium chloroacetate

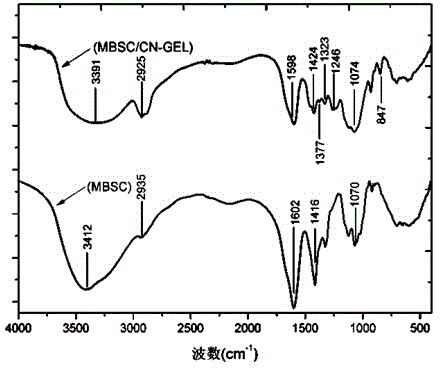

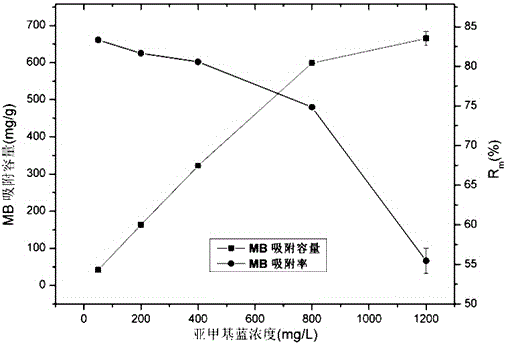

The invention provides a method for preparing composite hydrogel through modifying bamboo shoot leftovers and an application of the composite hydrogel. An adsorption material is prepared by the steps of extracting cellulose from the bamboo shoot leftovers, then modifying by sodium chloroacetate, carrying out epoxy chloropropane cross-linking, followed by carrying out inverse suspension polymerization, and finally carrying out freeze drying. The prepared hydrogel beads are used as a bio-adsorbent, methylene blue is used as a dye model molecule, an adsorption effect on methylene blue is studied, and a theoretical foundation is laid for adsorption and sustained release of the hydrogel. The novel composite hydrogel prepared by utilizing the bamboo shoot processing waste leftovers is rich in raw material sources and low in cost, can achieve waste utilization, and promotes recycling economy; and the prepared hydrogel can be applied to adsorption of dye wastewater and adsorption and sustained release of a model drug, reduces pollution of bamboo shoot leftover arbitrarily discarding on the environment, and can play a certain role in promoting green development of ecological resources.

Owner:SOUTH CHINA UNIV OF TECH

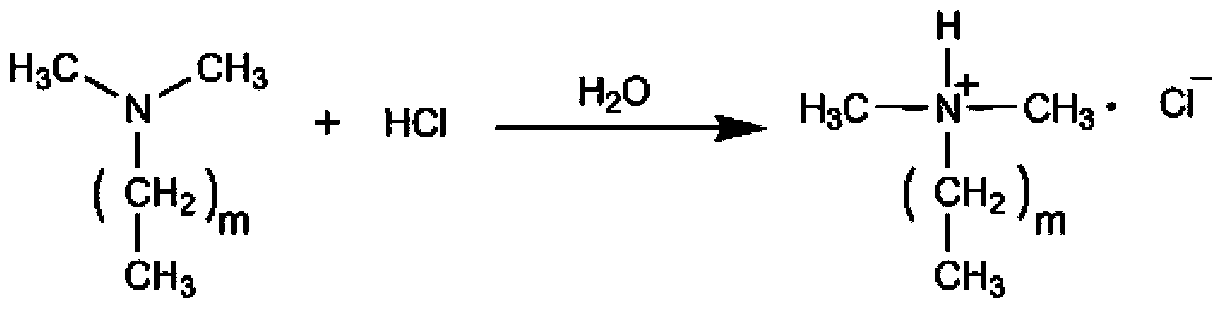

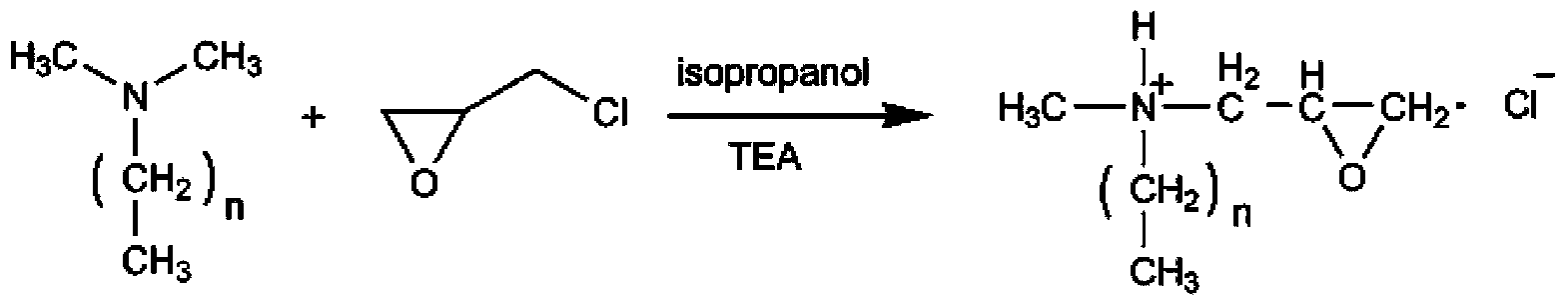

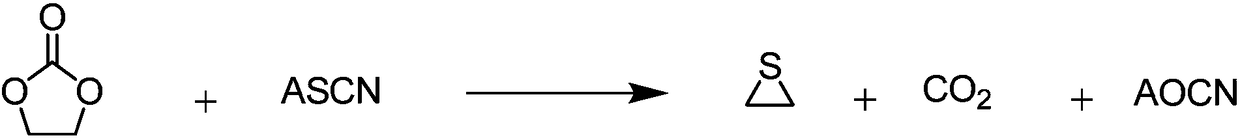

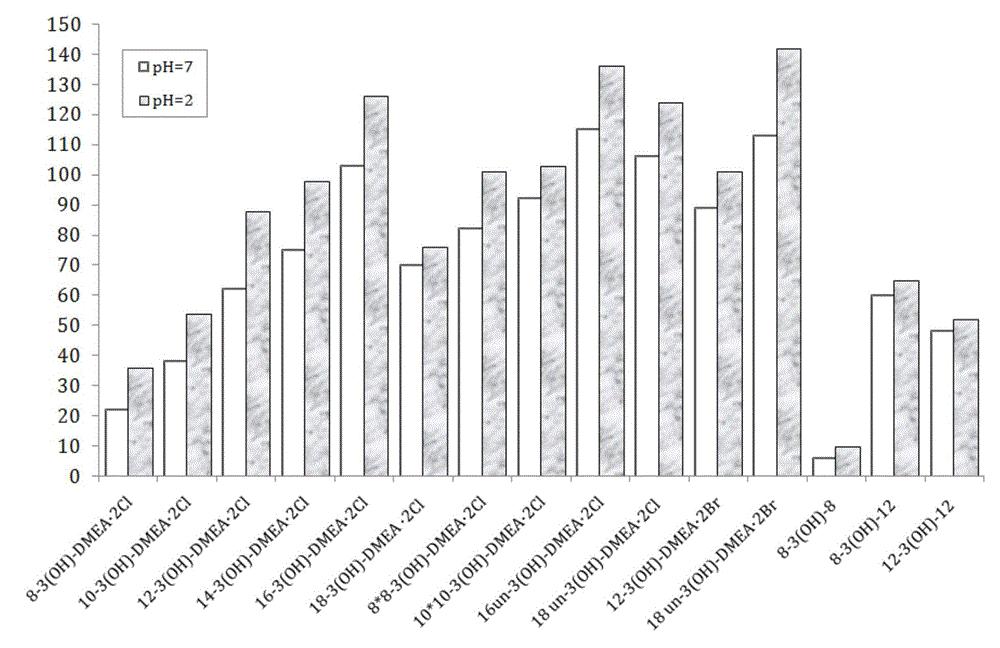

Cationic gemini surfactant preparation method

ActiveCN103406063AReduce special requirementsReduce reaction exothermOrganic compound preparationTransportation and packagingEpichlorohydrin1-Chloropropane

The invention belongs to the technical field of surfactants, and provides a method for preparing a cationic gemini surfactant (CH3(CH2)m-N(CH3)2-CH2CH(OH)CH2-N(CH3)2(CH2)nCH3.Cl2) by taking epoxy chloropropane and alkyl dimethyl tertiary amine (CH3-(CH2)n-N(CH3)2, wherein n equals to 7, 9, 11, 13, 15 or 17) as raw materials and taking 2-hydroxyl-1.3-propylidene as a linking group. The method provided by the invention overcomes the defect in the prior art that one extremely excessive material is required for improving the reaction yield, dispenses with separation and purification procedures for a finished product, is short in reaction period, leaves no epoxy chloropropane in the finished product, and is suitable for industrial scale production.

Owner:SHANGHAI FINE CHEM CO LTD +1

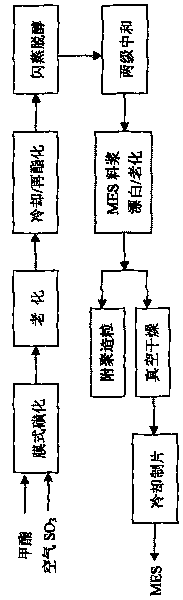

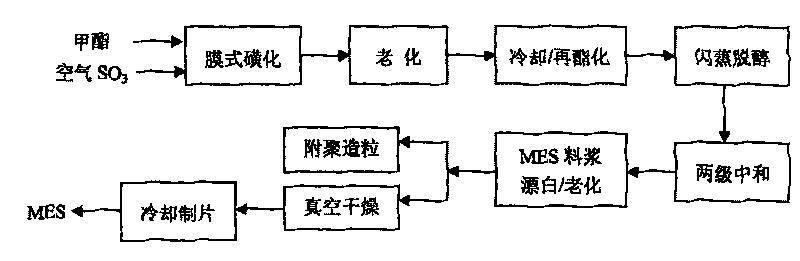

Method for producing sodium fatty acid methyl ester sulfonate

ActiveCN101759612AAvoid coexistenceReduce dosageSulfonic acids salts preparationSolventFatty acid methyl ester

The invention relates to a surfactant used in the production of washing powder, in particular to a method for producing sodium fatty acid methyl ester sulfonate, which solves the problem that the prior art cannot realize continuous, stable industrialized mass production. Hydrogenated palm-methyl stearate is adopted as material, and is sulfonated by SO3 gas on a multi-tube film reactor, steps, such as aging, reesterification, dealcoholization, neutralization, bleaching and vacuum drying, are then sequentially carried out, so that sodium fatty acid methyl ester sulfonate product is obtained, the content of MES is more than 80 percent, the content of disodium salt is less than 5 percent, the content of free oil is less than 2.5 percent, the content of sodium methyl sulfate is less than 8 percent, and color is less than 60 klett(5 percent A.M). Because highly selective catalyst is added in the aging process, the production of deep-colored by-product is reduced; because the reesterification reaction and the bleaching reaction are separately carried out, the safety of reaction is enhanced, and the consumption of methanol as solvent is greatly reduced; because vacuum dealcoholization is carried out before sulfoacid neutralization, industrialized operation can be easily carried out, and meanwhile, the safety problem of methanol in the subsequent bleaching step is eliminated.

Owner:南风化工(运城)集团有限公司

Method for degrading epoxy resin carbon fiber composite material

The invention discloses a method for degrading an epoxy resin carbon fiber composite material. The method comprises the following steps of: preparing a reaction solution by adding a metal salt into water, methanol, ethanol or propanol which is taken as the solvent; dipping the epoxy resin carbon fiber composite material in the reaction solution, and carrying out degradation at 160-240 DEG C for 1-20 hours; and separating and recycling the metal salt and obtaining the epoxy resin degraded product and the carbon fiber. The method disclosed by the invention has the advantages of simple process, mild condition, low cost and low damage on carbon fiber strength.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Modified titanium dioxide hydrosol and preparation method thereof

ActiveCN103806270AGuaranteed UV protectionImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsFibre treatmentRare earthStrong acids

The invention discloses modified titanium dioxide hydrosol and a preparation method thereof. The titanium dioxide hydrosol is prepared by the following steps: by taking butyl titanate as a raw material, by adopting a sol-gel technology, taking deionized water as a solvent and taking glacial acetic acid as a hydrolysis inhibitor, doping ethyl orthosilicate, a rare earth compound and a nitrogen compound without using an organic solvent and a strong acid, so as to perform three-element co-doped modification of three types including a compound semiconductor, rare earth metal ions and nonmetallic elements on the titanium dioxide sol. According to the titanium dioxide hydrosol, an ultraviolet-resistant function of titanium dioxide is guaranteed, the photocatalytic activity and efficiency of the titanium dioxide under visible light are improved, and the antistatic property is improved, so that multifunctional finishing agent is formed.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

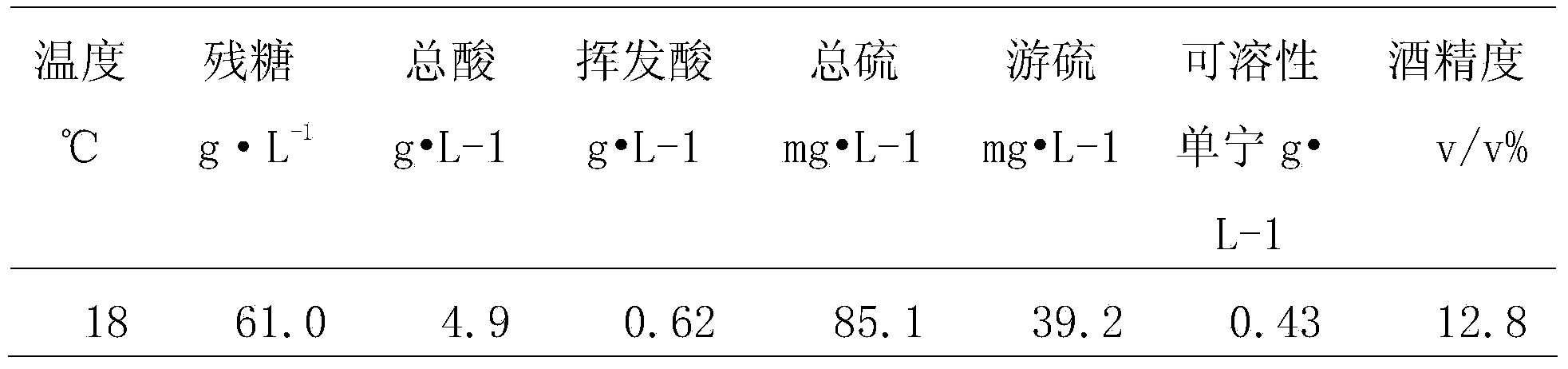

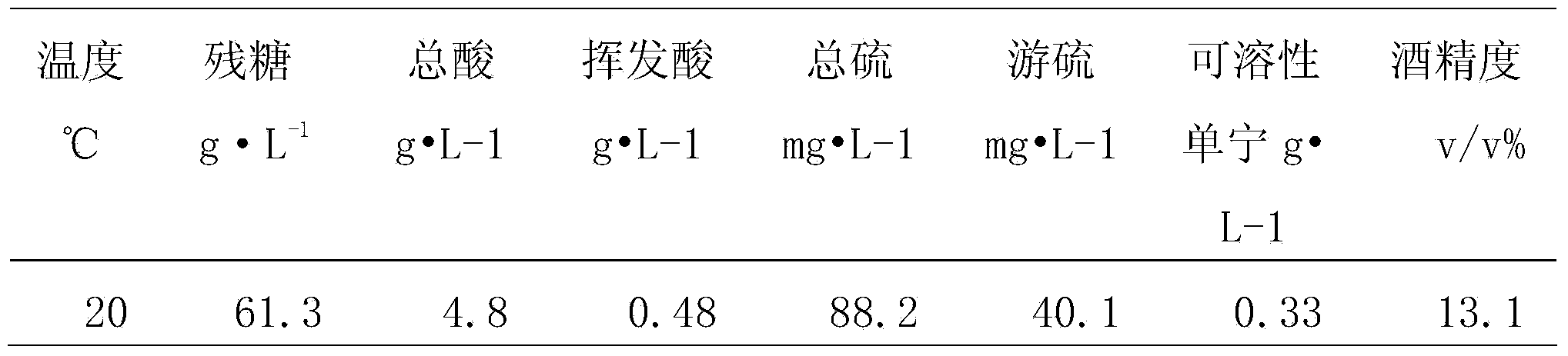

Application of candida utilis to loquat wine making and making method for loquat wine

InactiveCN102649926ASolve the problem of weak acid reduction abilitySoft tasteAlcoholic beverage preparationMicroorganism based processesFood flavorBiology

The invention discloses application of candida utilis to loquat wine making and also discloses a making method for the loquat wine. The method comprises the conventional steps of pretreating raw materials, performing enzymolysis and fermenting and further comprises the step of inoculating the candida utilis in the fermenting step, wherein in the fermenting step, the inoculation quantity of the candida utilis is 105 to 106 cfu / ml. The invention has the benefits that the candida utilis solves the problem of weak acid-reducing ability of the wine-making yeast and consumes malic acid with stimulating mouthfeel; the candida utilis increases the content of lactic acid and the like in the loquat wine and has soft mouthfeel; and the candida utilis increases the content and the type of ester in the loquat wine, improves the flavor and accelerating the ageing progress of the loquat wine. The method provided by the invention is high in technology implantation performance and simple and convenient in industrialized operation, shortens the ageing period of the loquat wine and improves mouthfeel, color and fragrance.

Owner:FUJIAN AGRI & FORESTRY UNIV

Microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and preparation method and application thereof

ActiveCN102585406AImproved creep propertiesGood flexibilityOther chemical processesOil and greaseTetrafluoroethylene

The invention discloses a microporous oil-containing self-lubricating polytetrafluoroethylene (PTFE) material for sealing and a preparation method and application thereof. The PTFE material consists of the following components in percentage by mass: 50 to 98 percent of PTFE resin, 1 to 30 percent of naphthalene and 1 to 20 percent of oil. The method comprises the following steps of: mixing the PTFE resin and the naphthalene, performing die pressing, and sintering to prepare a porous PTFE semi-finished product; and soaking the porous PTFE semi-finished product in the oil, putting into a vacuum box, and keeping in vacuum for at least 2 hours to obtain the microporous oil-containing self-lubricating PTFE material for sealing. The microporous oil-containing self-lubricating PTFE material for sealing has high self-sealing property, lubricating property and elasticity, a good self-lubricating effect can be achieved even if the oil is not changed for a long time when the material is used as a sealing material, and a long-acting sealing effect is achieved; and if an anti-rusting agent permeates pores, machine equipment can be protected, and the service life of a machine is prolonged.

Owner:GUANGZHOU MECHANICAL ENG RES INST

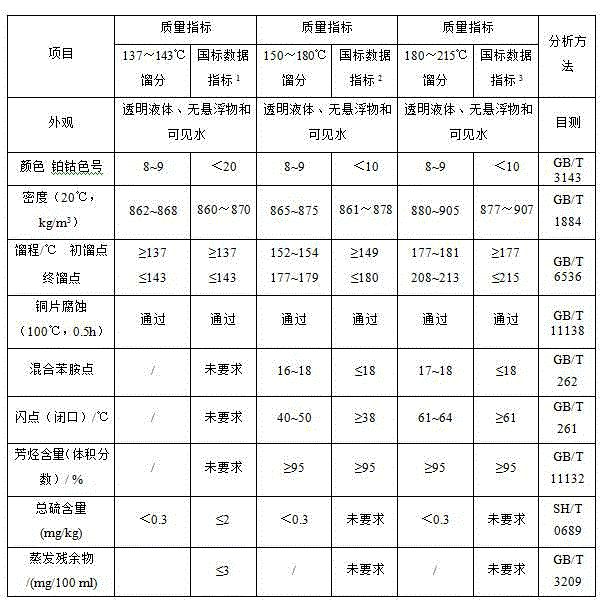

Production method of high-boiling-point aromatic solvent oil

ActiveCN104152179AHigh yieldReasonable designTreatment with hydrotreatment processesAromatic solventPtru catalyst

The invention discloses a production method of high-boiling-point aromatic solvent oil. The production method comprises the following steps: performing catalytic hydrogenation lightweight process on C10 aromatic hydrocarbon as a raw material, and performing rectification separation to obtain fraction with the temperature of 150-180 DEG C or fraction with the temperature of 180-215 DEG C as the high-boiling-point aromatic solvent oil, wherein a hydrogenation catalyst adopts an amorphous silicon aluminum composite carrier, and active ingredient-loaded oxides are nickel oxide, molybdenum oxide, tungsten oxide and phosphorus oxide; the total weight of the active ingredient oxides is 20%-60% the weight of the silicon aluminum composite carrier; the weight ratio of nickel oxide to molybdenum oxide to tungsten oxide to phosphorus oxide is (10 to 30):(50 to 85):(3 to 20):(0.5 to 10). The production method is simple in process and convenient for continuous production of industrialized operation.

Owner:江苏联东化工有限公司

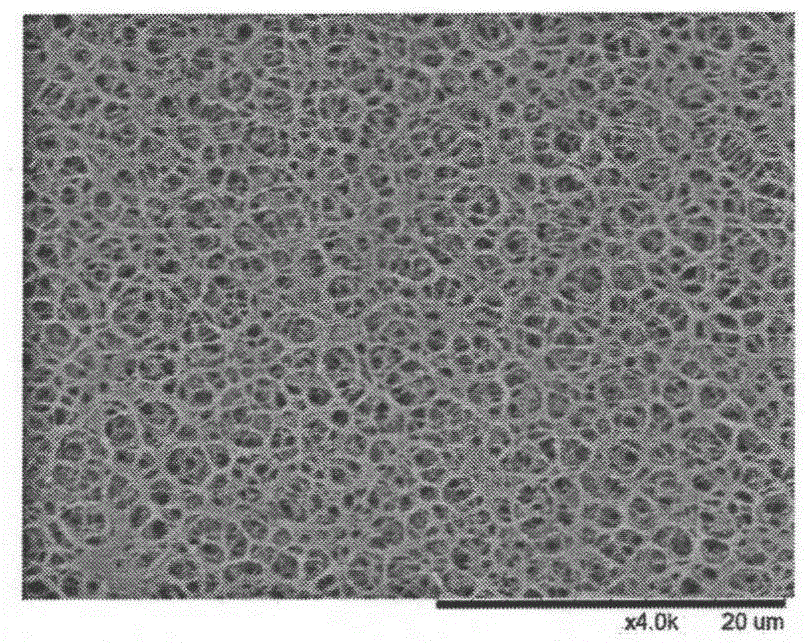

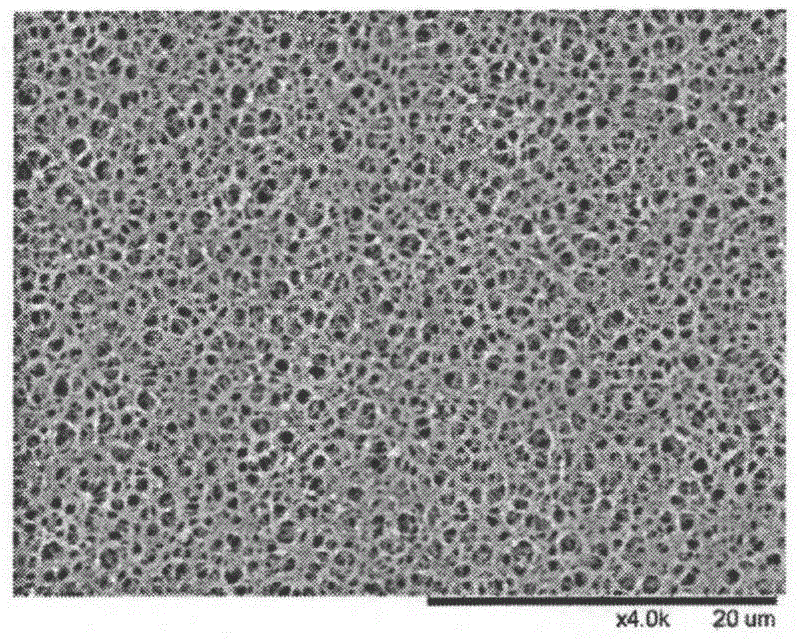

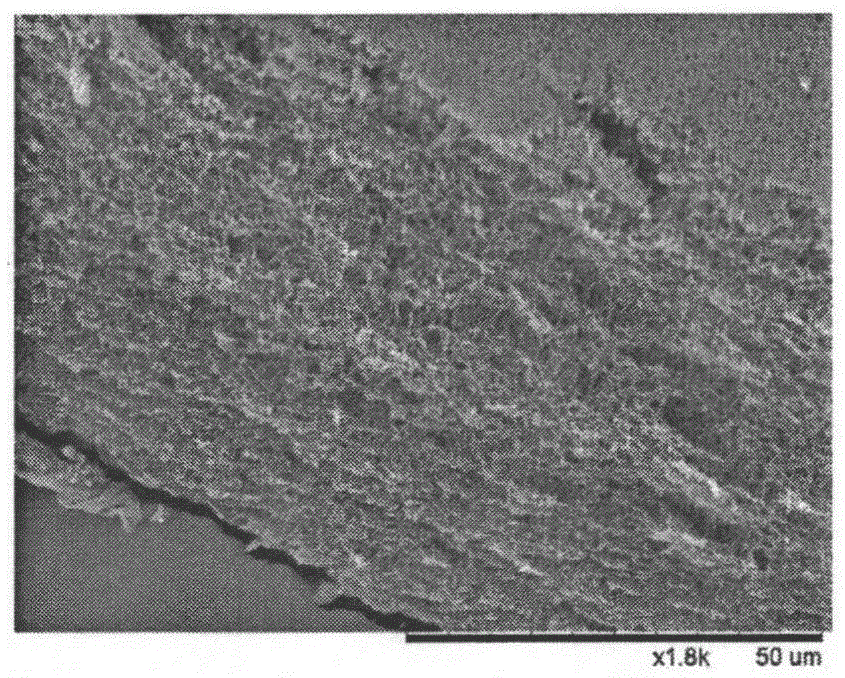

Preparation method of polyamide-imide lithium battery membrane

InactiveCN105552278AImprove temperature resistanceSimple processCell component detailsPolyamide-imidePhysical chemistry

The invention provides a preparation method of polyamide-imide lithium battery membrane, comprising following steps: dissolving polyamide-imide in a non-protonic polar solvent to obtain polyamide-imide solution, adding a pore-forming agent in the polyamide-imide solution, stirring and mixing to obtain film coating solution, deforming, carrying out knife coating on a substrate through a knife to form a primary membrane, carrying out gradient coagulating bath on the primary membrane, gradually coagulating to form a coagulating membrane, washing the coagulating membrane by water so as to remove the pore-forming agent in the coagulating membrane, thus obtaining a pore-forming membrane, drying, stretching, sizing, thus obtaining the polyamide-imide lithium battery membrane. The polyamide-imide lithium battery membrane prepared by the method provided by the invention has various performances demanded by the lithium battery membrane field; particularly, the temperature tolerance of the membrane is excellent and reaches 280 degrees centigrade or more.

Owner:JIANGSU JUXIAN SYNTHETIC MATERIAL

Printing method of Shu Velveteen mixed textile fabrics

ActiveCN103726366AImprove printing effectHigh color fastnessBleaching apparatusDyeing processEngineeringDehydration

The invention discloses a printing method of Shu Velveteen mixed textile fabrics. The method adopts the pre-processing technology of soak dehydration after twice washing, a special printing processing technology, self-made improved dyes, and the technology of ageing for color fixing, softening for sizing and shrunk finish to be finished. The method has the advantages that printing effects are good, color fastness is high, rubbing fastness is high, the technologies are simple, the method is simple in industrialized operation, the production efficiency of work is increased, and the product quality is increased.

Owner:苏州市居之禾服饰有限公司

Method for brewing persimmon ice wine

The invention discloses a method for brewing persimmon ice wine. The method comprises the following steps: 1) selecting fresh persimmon fruits with the same maturity, packaging into sterile freshening bags, and arranging tidily according to demands; 2) putting the packaged persimmon fruits into a refrigeration house, freezing for 10-12 hours at minus 5-8 DEG C, subsequently raising the temperature to be 2 DEG C, standing for 10-12 hours, repeatedly freezing twice in such a manner, wherein the detected sugar content of the persimmon fruits is greater than 240g / L, under the condition that the temperature is not greater than 2 DEG C, crushing and juicing the persimmon fruits by using a presser, and meanwhile, adding sulphurous acid at the amount of 80-100g / t; 3) adding pectinase and cellulose; 4) adjusting the pH value of the persimmon juice to be 4.0; 5) adding activated dry yeast; 6) terminating fermentation; and 7) fining. The method for brewing the persimmon ice wine takes persimmon as a raw material, the persimmon ice wine is brewed by using a fermentation method, and the brewed wine is yellowish in color, pure and harmony in fragrance, tender in taste, clear and transparent, and good in stability.

Owner:SHAANXI FUSIFANG PERSIMMON IND

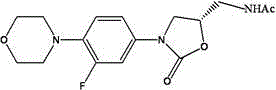

Preparation method of high-stability linezolid injection liquid

InactiveCN104666241ALow impurity contentImprove product qualityAntibacterial agentsOrganic active ingredientsPhosphoric acidImpurity

The invention discloses a preparation method of high-stability injection linezolid, wherein the preparation method comprises the steps: with linezolid as a raw material, adding water, glucose and sodium dihydrogen phosphate, dissolving, and then adjusting the pH with phosphoric acid or sodium dihydrogen phosphate to make the pH in a certain range. The content of impurities in a linezolid injection liquid is reduced, the product quality is improved, and the shelf life is extended.

Owner:北京众和民健医药科技有限公司 +2

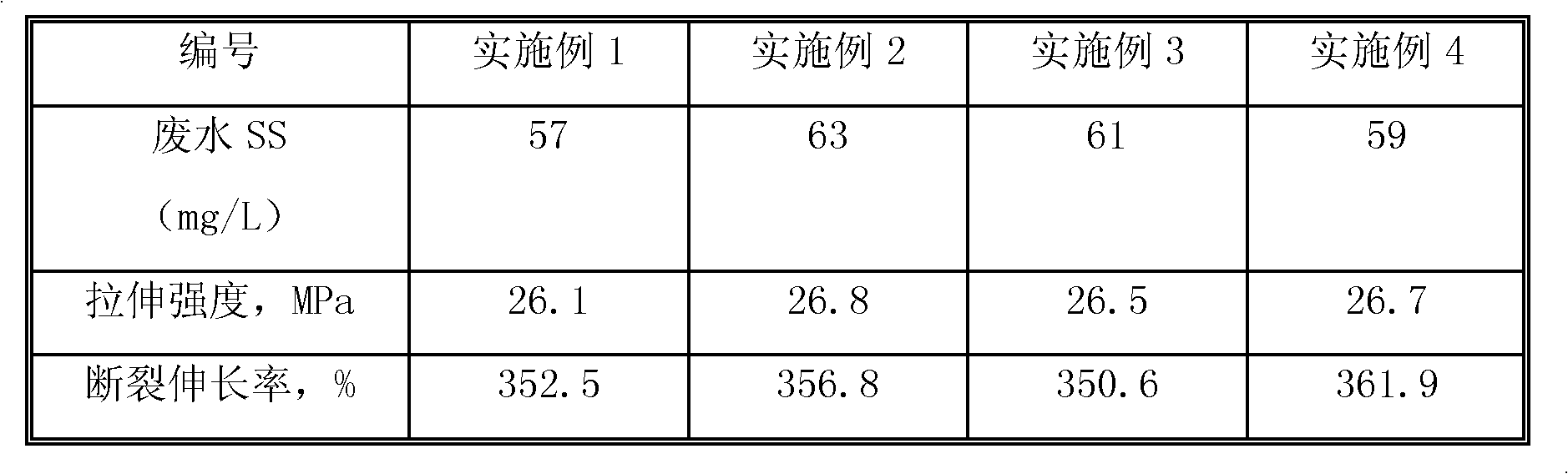

Method for processing industrial wastewater of polytetrafluoroethylene dispersion resins

ActiveCN102249362AEasy to recycleEmissions meet the requirementsPlastic recyclingNature of treatment waterFlocculationDissolved gas flotation

The invention relates to a method for processing industrial wastewater of polytetrafluoroethylene dispersion resins, belonging to the processing technology of industrial wastewater. Industrial wastewater of polytetrafluoroethylene dispersion resins is transmitted to a dissolved gas flotation machine; air is sent to a pressure air dissolving tank via a compressor, and the pressure is controlled to 0.5-1.0Mpa; then, the air enters an air flotation water tank, and the dissolved gas pressure is suddenly lowered to normal pressure; air dissolved in the wastewater is separated out to form a great quantity of compact microscopic bubbles; meanwhile, 5-50wt% of salt with a flocculation action is added into a water tank to cause the wastewater to break the emulsion to separate out the resins; under the action of salt, a flocculent solid is formed; the microscopic bubbles are adsorbed to the surface of the flocculent solid in the slowly-rising process; the flocculent solid is taken to the surface of the wastewater; and the wastewater of which the resins are separated out is discharged from the bottom of the flotation machine. According to the method, wastewater emission conforms to requirements, environment is protected, and the dispersion resins can be better recovered, thus waste material is changed into things of value.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

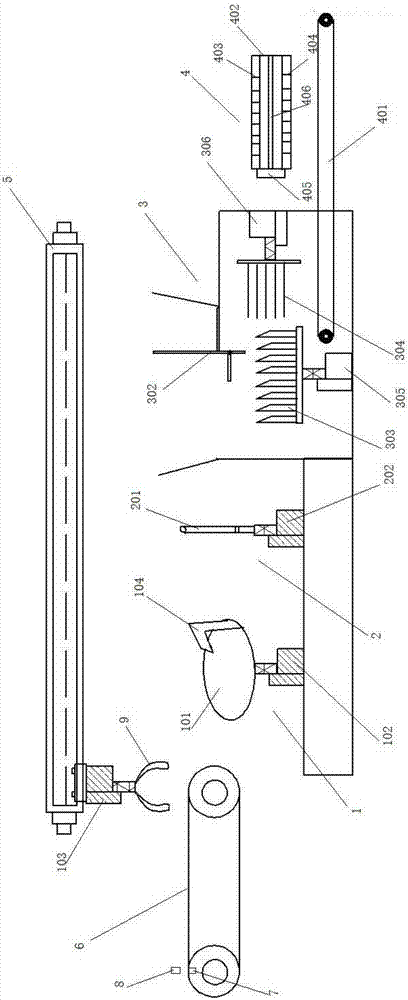

Melon and fruit processor

ActiveCN107007125AEasy to useImprove efficiencyKitchen fruit stoningFood shapingLife qualityIntelligent management

The invention discloses a melon and fruit processor. According to the processor, a guide rail is installed above a peeling system, a kernel removal system and a cutting system. A fixed device is hung on the guide rail in an inverted mode to form movable connection. A first conveying belt, a first rotary motor, a second rotary motor, a third rotary motor, a first stepping motor and a second stepping motor are connected with a controller through wires separately. A pressure sensor and a scanning device are installed at the initial end of the first conveying belt and are connected with the controller through wires separately. The processor is convenient and quick to use, intelligent control is used for melon and fruit processing, and the processor is very novel, high in efficiency, wide in application range and suitable for families and restaurants. Eating becomes more tasteful, life quality is improved, and the processor is the Gospel for people who like to eat melons and fruits; intelligent management is achieved, and industrial operation and large-scale operation are convenient.

Owner:JINLING INST OF TECH

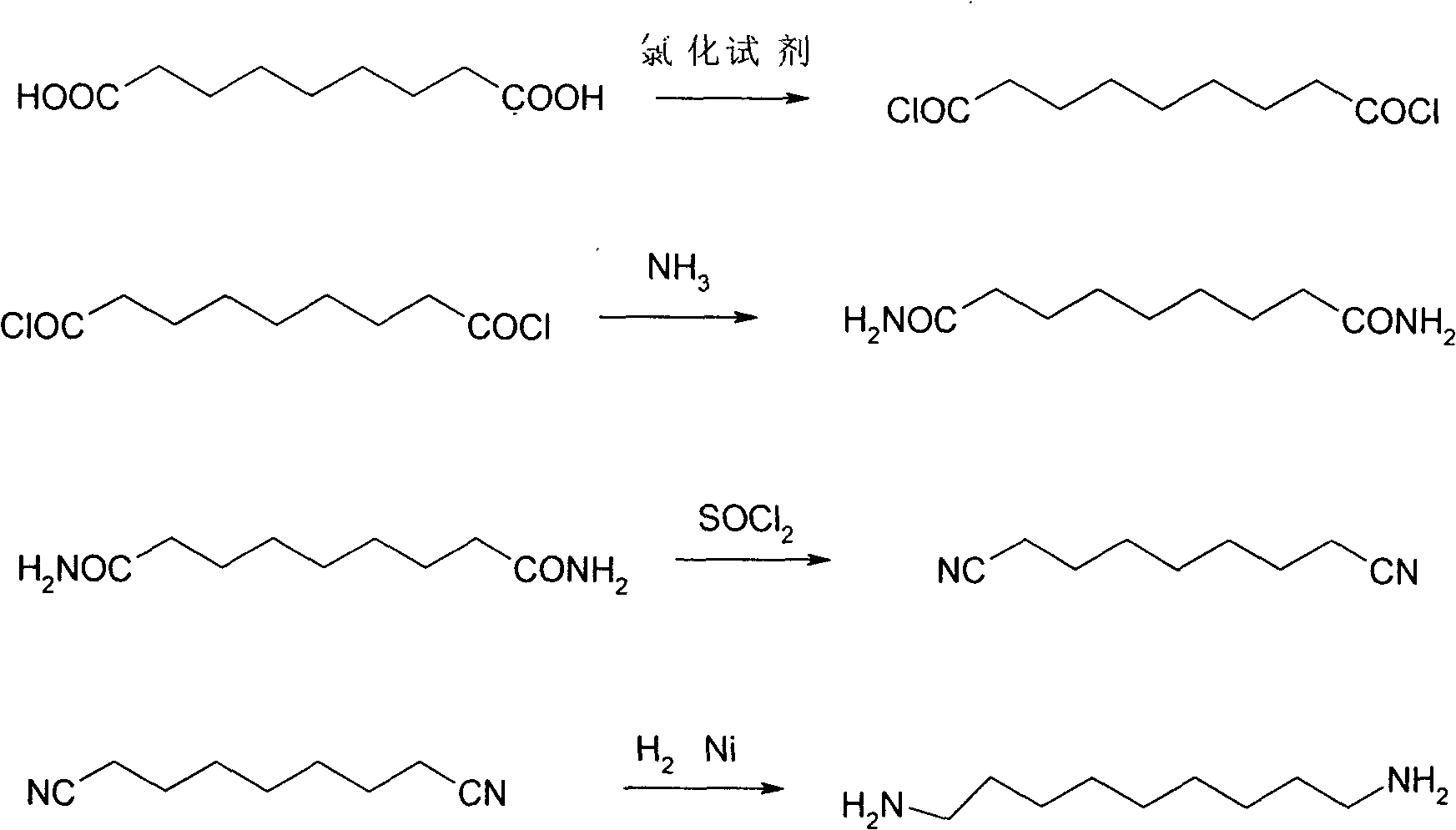

Method for preparing nonane diamine

ActiveCN102701991ASimple processMature technologyOrganic compound preparationAmino compound preparationPharmaceutical industryMature technology

The invention discloses a method for preparing nonane diamine. Azelaic acid is used as a raw material, and is chloridized, amidated, dewatered and hydrogenated to obtain the nonane diamine. The content of the nonane diamine prepared in the method disclosed by the invention achieves more than 99%, and not only can be used as the compounding raw material for polyamide, polyurethane and other fine chemicals, but also can be applied in food packaging and pharmaceuticals industries, and the application field of the nonane diamine is expanded. The preparation method has the characteristics of simple process, mature technology, less investment in devices, mild operation conditions and convenience in industrial production.

Owner:HEBEI YANUO CHEM IND

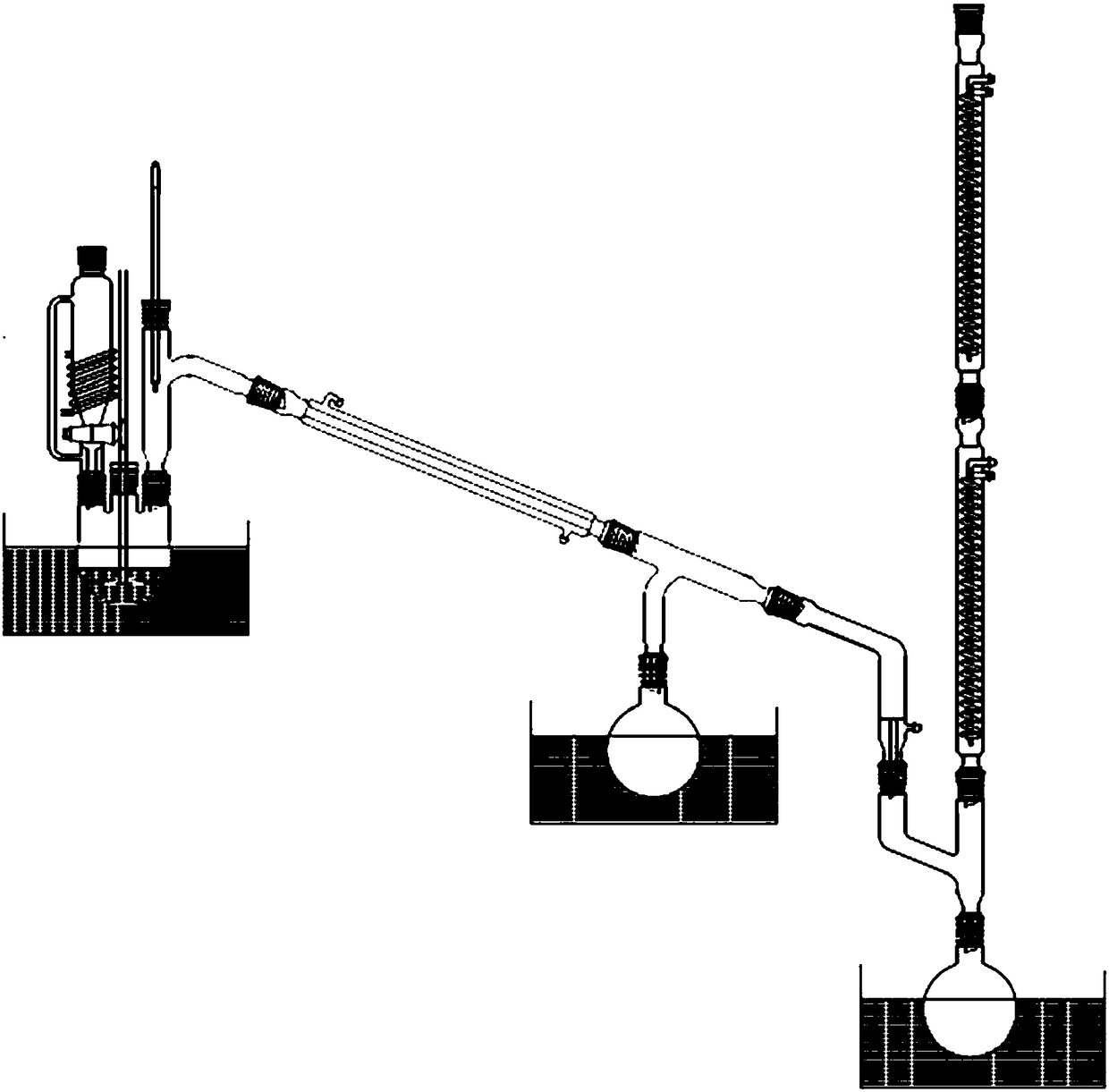

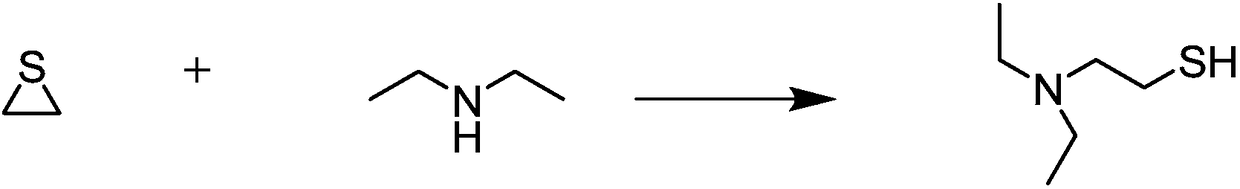

Method for preparing diethylaminoethanethiol

ActiveCN109134322AReduce generationLower requirementThiol preparationVapor–liquid separatorGas phase

The invention provides a method for preparing diethylaminoethanethiol. The method comprises the steps that 1, a part of pre-heated and liquefied ethylene carbonate with the amount being 0.2-0.7 time of the total feeding amount of ethylene carbonate is added and stirred, the temperature is controlled to be 40-70 DEG C, then thiocyanate is added, the temperature is quickly increased to 75-105 DEG C,thiirane generated by reactioni s collected through a condensation system and a gas-liquid separator, meanwhile, remaining ethylene carbonate with the temperature of 45-85 DEG C starts to be added dropwise, the temperature is controlled to be 80-110 DEG C in the dropwise adding process, the temperature continues to be increased to 130-140 DEG C after dropwise addition, and the reaction is finished until fractions cannot be evaporated; 2, thiirane and diethylamine are subjected to closed reaction and are gradually heated to 110-130 DEG C, the pressure of 0.3-0.7 MPa is kept for 0.5-1.5 h, andthe reaction is finished. The method avoids the outrush risk is avoided, the reaction time is short, the quantity of generated impurities is small, the yield of the obtained product, namely diethylaminoethanethiol, reaches 98% or above, and the gas-phase detection purity of the product is 99% or above.

Owner:保定加合精细化工有限公司

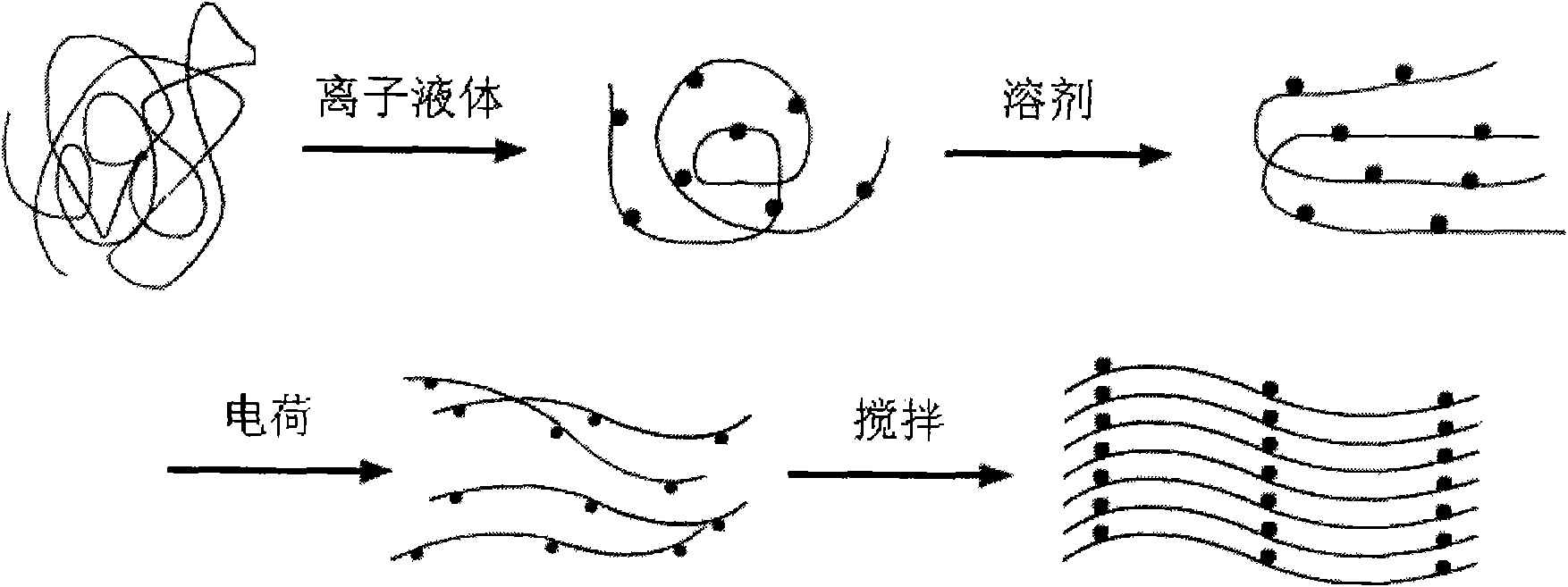

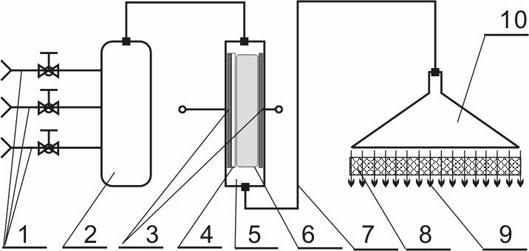

Method for fabricating superfine fiber by flash vaporization

InactiveCN101565861AReduce operational riskLow costSpinning solutions preparationFlash-spinning methodsViscous liquidPolyester

The invention relates to a fabricating method for fabricating superfine fiber by flash vaporization, of which the process is: polymers and ionic liquid are put into an autoclave according to a proportion of 10g of polymer to 5-20ml of ionic liquid and then is evenly stirred; then the standing pretreatment lasts for 0.5-3 hours under normal temperature so as to swell the polymer to be viscous liquid; polymer is added into the solvent in a ratio of 10g / 50-200ml and is stirred for 20-30min at the temperature of 150-350 DEG C and the pressure of 5-25MPa; after fully dissolving, a feeding control valve of the autoclave is opened so as to lead the filature to eject from a spinning nozzle to form the superfine fiber; devillication is automatically carried out; three-dimension network superfine fiber is formed on a receiving device by solidification; the polymer is polyolefine, polyester or polyvinylidene fluoride; the ionic liquid is 1-butyl-3-methyl-iminazole chloride or 1-allyl-3-methyll-iminazole chloride; and the solvent is 1, 2-dichloroethane, trichloromethane or cyclohexane.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing paeoniflorin

InactiveCN101418025AReduce extraction timeLess solvent usageSugar derivativesChemistryChromatography column

The invention relates to a method for preparing paeoniflorin, which is simple in operation and low in equipment investment. The method comprises the following process steps: a raw material containing paeoniflorin is placed into microwave extraction equipment and added with water for microwave extraction; filtrate is collected and filtered, so that the filtrate passes through a macroporous absorbent resin column for sample loading, water is used to elute impurities first, 20 to 80 percent ethanol is used for elution, ethanol eluate is collected, and the ethanol is decompressed, reclaimed and concentrated; the concentrated liquid is added into a chromatography column filled with active carbon, and then eluted by water; and eluate is collected, concentrated by a reverse osmosis membrane and dried to obtain the paeoniflorin. The method has the advantages of lowering production cost, improving product quality and facilitating industrialized operation.

Owner:ANHUI GUANGYINTANG CHINESE MEDICINE

Method for modifying carbon porous material

ActiveCN102522569ANo pollution hazardEnsure consistencyCell electrodesActivated carbonElectrical battery

The invention provides a method for modifying a carbon porous material, characterized in that by applying a high pressure pulse voltage on two opposite plate electrodes and inserting an electrolyte plate which has a high dielectric constant and a compact structure and has an area that is slightly larger than the size of the plate electrodes between the two opposite plate electrodes, a uniform discharge plasma reaction zone is formed between the plate electrodes; mixed gasses containing oxygen are uniformly mixed at normal temperatures and pressures, the mixed gasses are subject to ionization activation by the plasma reaction zone to generate a plurality of oxygen-containing plasma gasses, after gas distribution is carried out, the gasses vertically flow through a pre-cleaned carbon porous material in the thickness direction to react to obtain the activated carbon porous material. The method has the advantages of environmental protection, low cost, mild treatment conditions, easy control of function group quantity, and outstanding improvement of the activity of the electrode material, and the method can realize gradient treatment, can reduce the area resistance of the contacting surface of the porous material and the bipolar plate, so as to increase the battery efficiency. The method uses devices, thus the method is easy for industrialized operation.

Owner:DONGFANG TURBINE CO LTD

CO gas-phase oxidative coupling oxalate synthesizing palladium catalyst reactivating method

ActiveCN106540755AEfficient removalAvoid deactivationCatalyst regeneration/reactivationPreparation by carbon monoxide or formate reactionReduction treatmentGas phase

The invention discloses a CO gas-phase oxidative coupling oxalate synthesizing palladium catalyst reactivating method in coal ethylene glycol production technical synthesizing processes. The method comprises four steps of baking at high temperature CO gas-phase oxidative coupling oxalate synthesizing palladium catalyst of Pd / a-Al2O3 to remove impurities like organic matters and carbon carried by carriers, and converting palladium on the catalyst into palladium oxide; reacting the catalyst with acid to convert the palladium oxide into soluble palladium salt, and together drying and baking the reacted solution and the carriers to redistribute and load palladium products on the carriers; performing reduction treatment to obtain reactivated palladium catalyst of Pd / a-Al2O3. The reactivated catalyst can restore the quality of fresh catalyst. The CO gas-phase oxidative coupling oxalate synthesizing palladium catalyst reactivating method can effectively reactivate deactivated palladium catalyst to obtain the catalyst excellent in active indexes.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

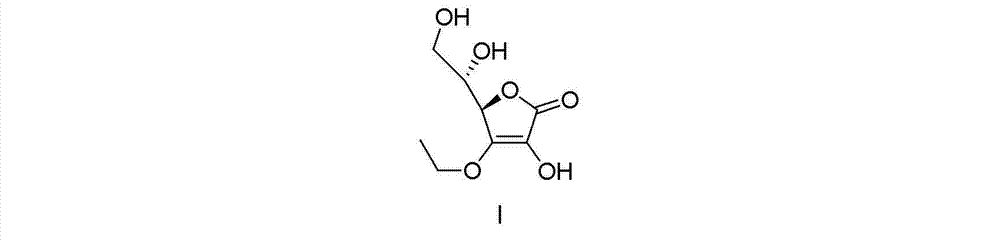

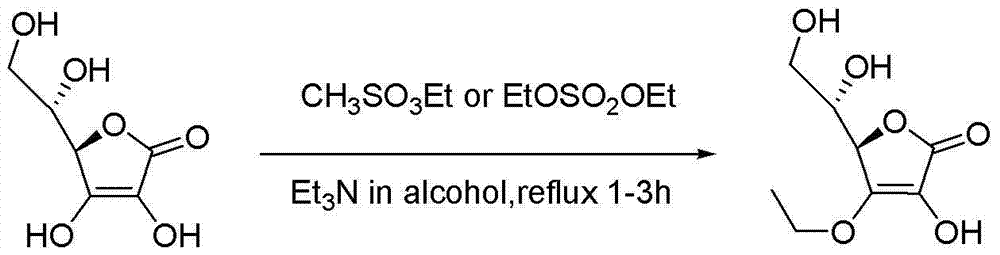

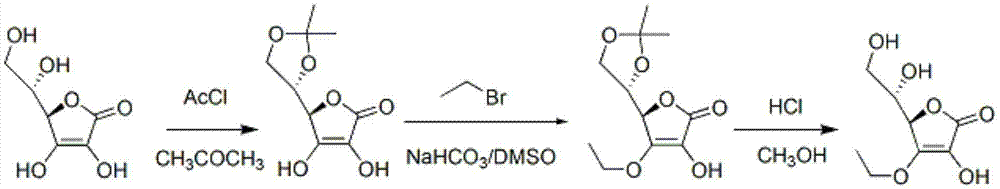

Synthesizing method of vitamin C ethyl ether

ActiveCN103113333AReduce dosageReagents are cheap and easy to getOrganic chemistryBulk chemical productionFuranKetone

The invention relates to the field of the synthesis of vitamin C derivatives, and in particular relates to a synthesizing method of vitamin C ethyl ether. The method comprises the following steps of: reacting vitamin C as an initiative raw material and dimethoxy propane as a reactant, thereby generating (R)-3,4-dyhydroxyl-5- [(S)-2,2-dimethyl-1,3-dioxolane-4-yl] furan-2(5H)-ketone; next, adding alkali and an alkylation reagent, thereby generating (R)-4-ethyoxyl-3-hydroxyl-5-[(S)-2,2-dimethyl-1,3-dioxolane-4-yl] furan-2(5H)-ketone; and removing a protecting group, thereby generating the vitamin C ethyl ether. According to the method, the reactions in the three steps can be finished in the same kettle, so that the industrialized operation is simplified greatly; and a large number of organic waste liquids cannot be generated. As a result, the total yield in the three steps is improved to 50%-53.4%.

Owner:ZHEJIANG APELOA KANGYU PHARMA +2

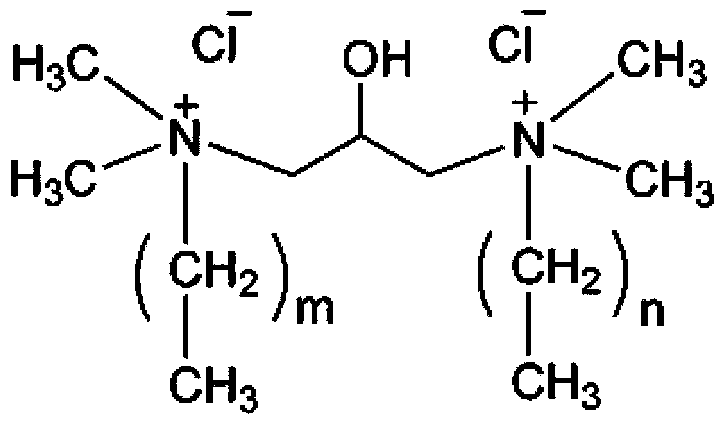

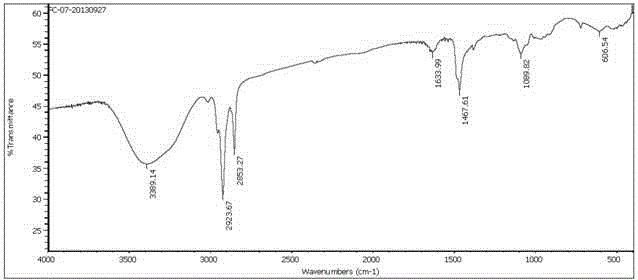

Dissymmetric cationic Gemini surfactant and preparation method thereof

ActiveCN104607094AImprove surface activityGood emulsificationOrganic compound preparationTransportation and packagingAlkaneHydrogen

The invention provides a dissymmetric cationic Gemini surfactant. A molecular structure of the dissymmetric cationic Gemini surfactant is as shown in a formula (IV), wherein X-=Cl- or Br- in the formula, and R1 and R2 in the formula conform to the following (1) or (2): (1) R1=-CH3, and R2 is long-chain alkane base-CnH2n+1, n=6-20; or R2 is long-chain olefin base-CnH2n, n=6-20; and (2) R1=R2=long-chain alkane base-CnH2n+1, n=6-12. According to the surfactant provided by the invention, a molecule of the surfactant contains two -OH groups, and in an aqueous solution, especially under the acidic condition, due to hydrogen-bonding action, molecules are arranged more closely when being enriched on a surface or an interface. Therefore, the series of dissymmetric cationic Gemini surfactant has excellent surface activity, foaming and foam stability, and emulsifying property. Especially under the acidic condition, the emulsifying stability is improved substantially.

Owner:SHANGHAI FINE CHEM CO LTD

Printing method of prolivon blended fabric

ActiveCN103669027AImprove printing effectHigh color fastnessFibre treatmentDyeing processEngineeringRubbing

The invention discloses a printing method of a prolivon blended fabric. A soaking and dehydration pretreatment process after secondary water washing is used, a special printing treatment process is used, self-blended improved dye is adopted, and finally, the prolivon blended fabric is obtained through ageing fixation, softness sizing and shrunk finish processes. The printing method has the advantages that the printing effect is good, the color fastness and the rubbing fastness are high, the processes are simple, the industrial operation is easy, and the operation production efficiency and the product quality are improved.

Owner:苏州市居之禾服饰有限公司

Polyethylene composite material for rotationally-molded buried product

ActiveCN105713278AHigh strengthSmooth inside and outsideSievingScreeningGlass fiberLinear low-density polyethylene

The invention discloses a polyethylene composite material for a rotationally-molded buried product. The polyethylene composite material is prepared by mixing, by mass, 10-30% of linear low density polyethylene fine powder, 40-80% of glass fiber reinforced high density polyethylene powder and 10-30% of linear low density polyethylene coarse powder. The product machined from the material through the rotational molding technology has the advantages of being high in strength and easy to demold and having smooth inner and outer surfaces.

Owner:ZHEJIANG ROTOUN PLASTIC TECH

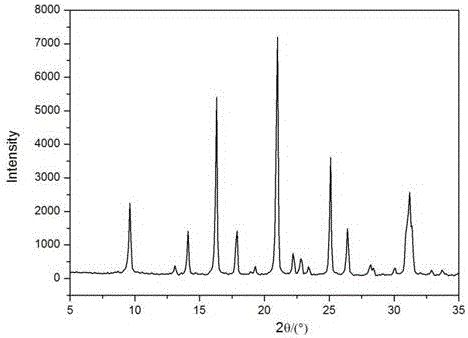

Preparation of luminescent material

InactiveCN101475204ALow growth temperatureReduced crystal shapeRare earth metal compoundsLuminescent compositionsFlux growthSolid reaction

The invention discloses a method for preparing a fluorescent material, namely a method for synthesizing Gd2O2S: Tb fluorescent powder and a flux composition used by the method. A co-precipitation method is adopted to prepare a precursor, and then the Gd2O2S: Tb fluorescent powder is prepared through a high-temperature solid-phase reaction. A flux growth method used by the method can reduce the growth temperature of crystals, and is easy for industrialized operation; the selected flux composition can remarkably improve the crystal shape and particle size distribution of the fluorescent powder; the obtained crystals have integral structures and less defects; and the method reduces the synthesis temperature of the high-temperature solid-phase reaction of the Gd2O2S: Tb fluorescent powder, improves crystal structures and the particle size distribution of the fluorescent powder, and ensures that the luminous brightness and service performance of the fluorescent powder are further improved.

Owner:KUNMING UNIV OF SCI & TECH

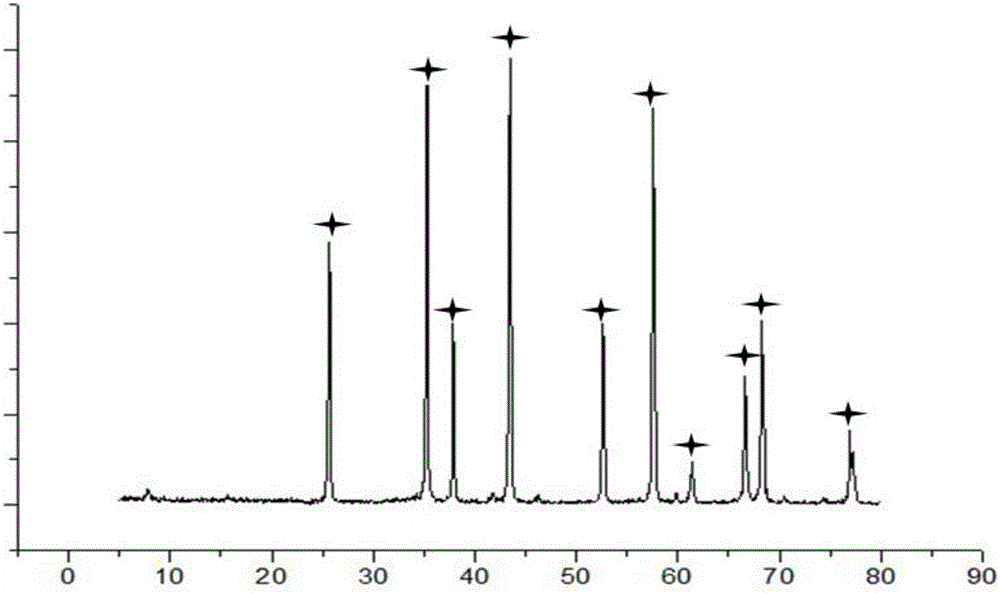

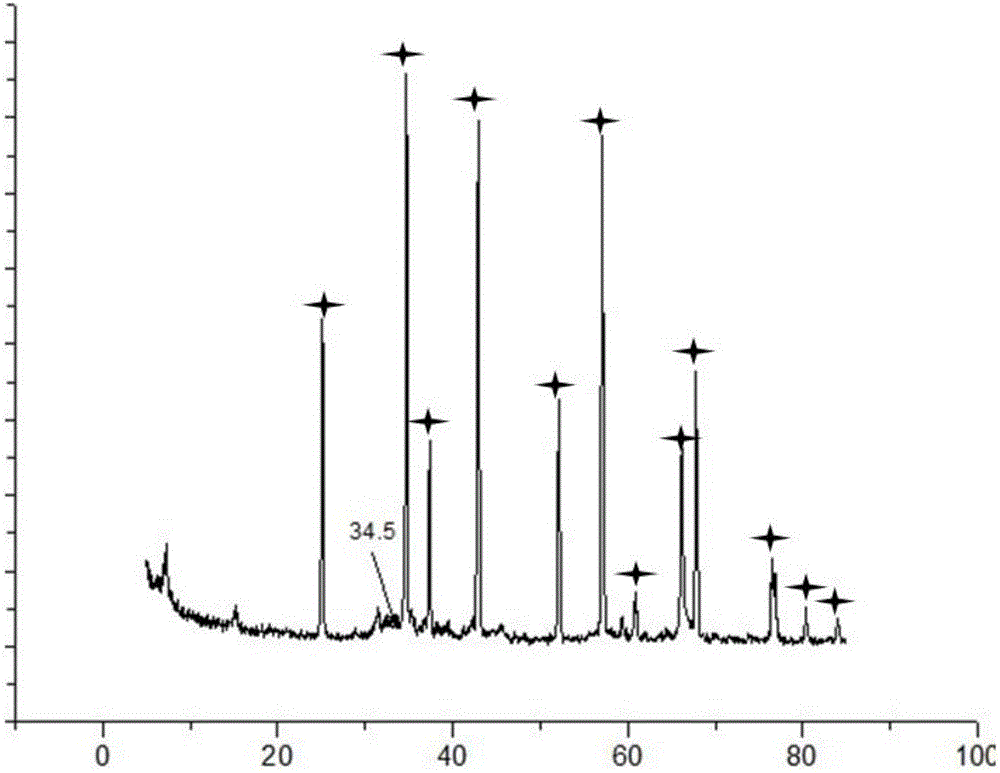

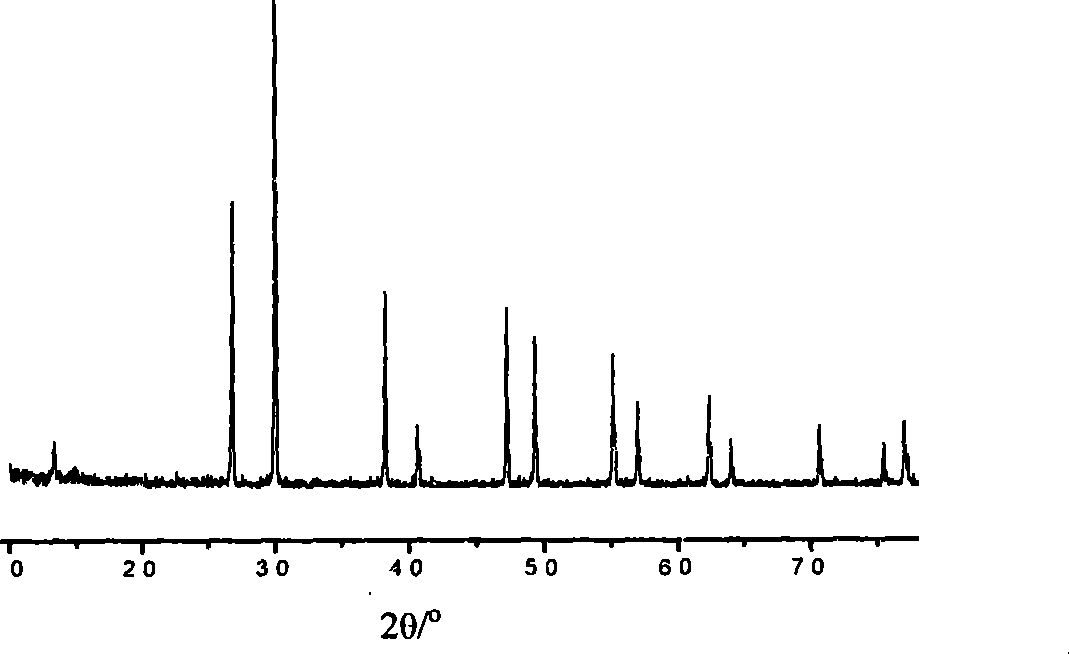

SSZ -13 molecular sieve preparing method

InactiveCN106315611AEasy to operateEasy to operate industriallyCrystalline aluminosilicate zeolitesIonAmmonium hydroxide

The invention discloses a SSZ -13 molecular sieve preparing method comprising the steps of (1) evenly mixing and putting N,N,N- trimethyl adamantane ammonium hydroxide and crystal growth agent into high-pressure reaction kettle, then adding silicon source, aluminium source and water successively into it and obtaining initial gel after mixing; (2) crystallizing the initial gel obtained in step (1) under 155-175oC for 17-72 hours and obtaining crystallized product; (3) centrifugalizing the crystallized product obtained in step (2) to obtain filter cake and filtrate, washing the obtained filter cake by deionized water to pH 7-8, then drying it for 10-13 hours under 100-120oC to obtain the SSZ -13 molecular sieve; the SSZ -13 molecular sieve preparing method in the invention may realize the free modulation for partical size of SSZ -13 molecular sieve from 0. 3-17Mum through adding crystal growth agent; the addition of crystal growth agent in the invention makes more even dispersion of molecular sieve crystal.

Owner:SHANDONG QILU HUAXIN HIGH TECH

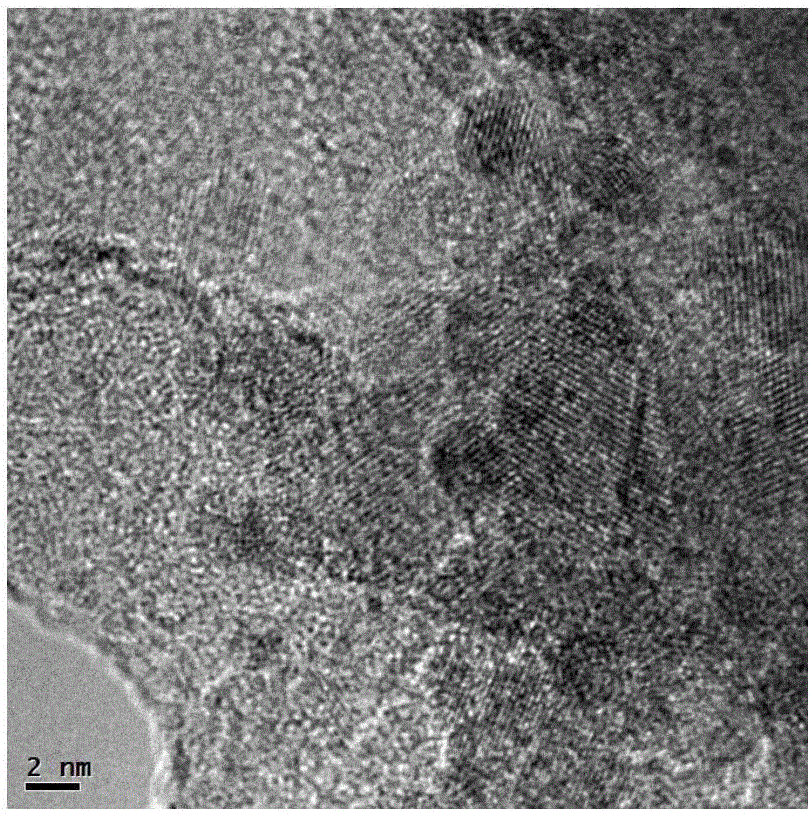

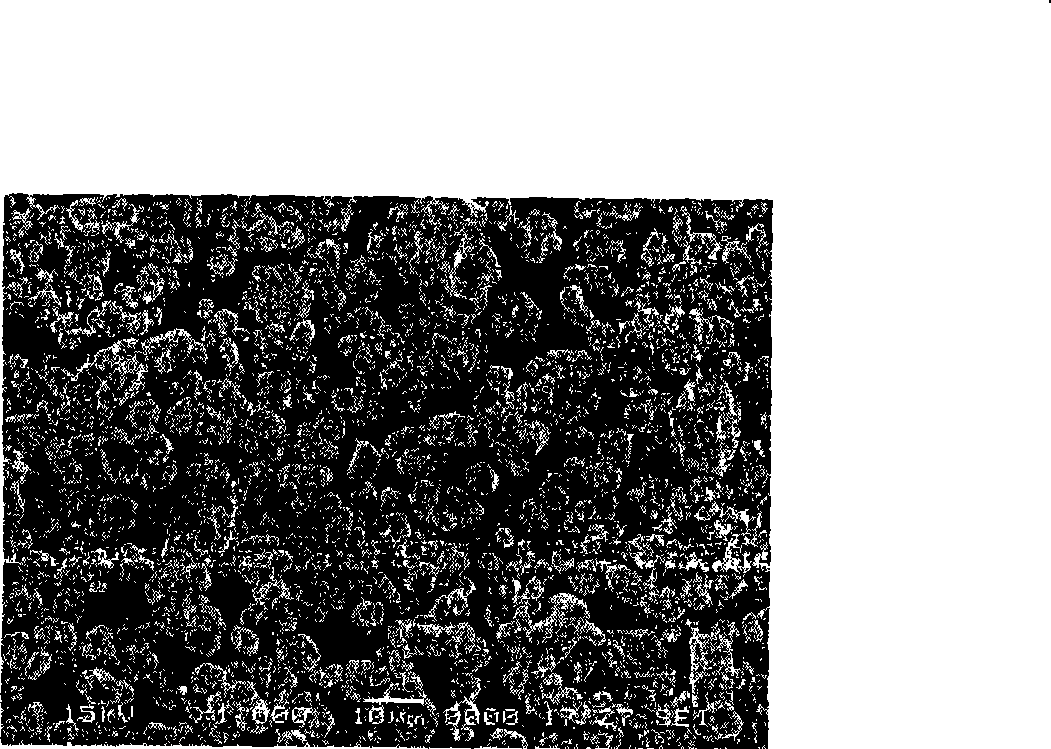

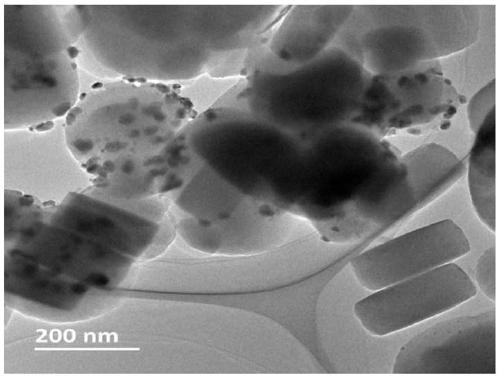

Metal-coated MFI hierarchical pore structure packaging catalyst and packaging method and application thereof

PendingCN111437870AEvenly distributedUniform particle sizeMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

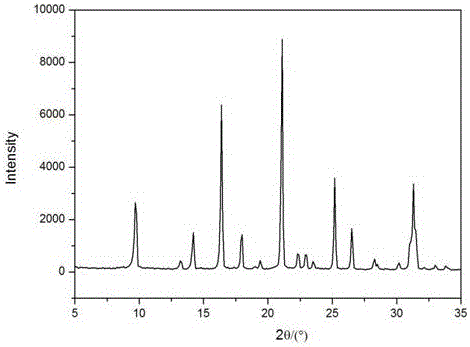

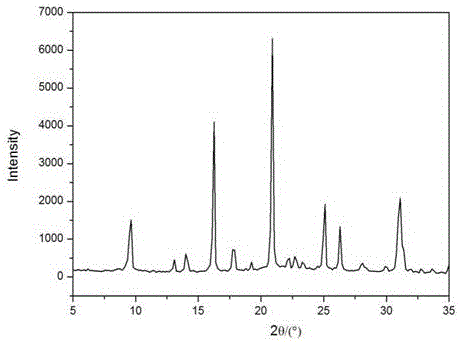

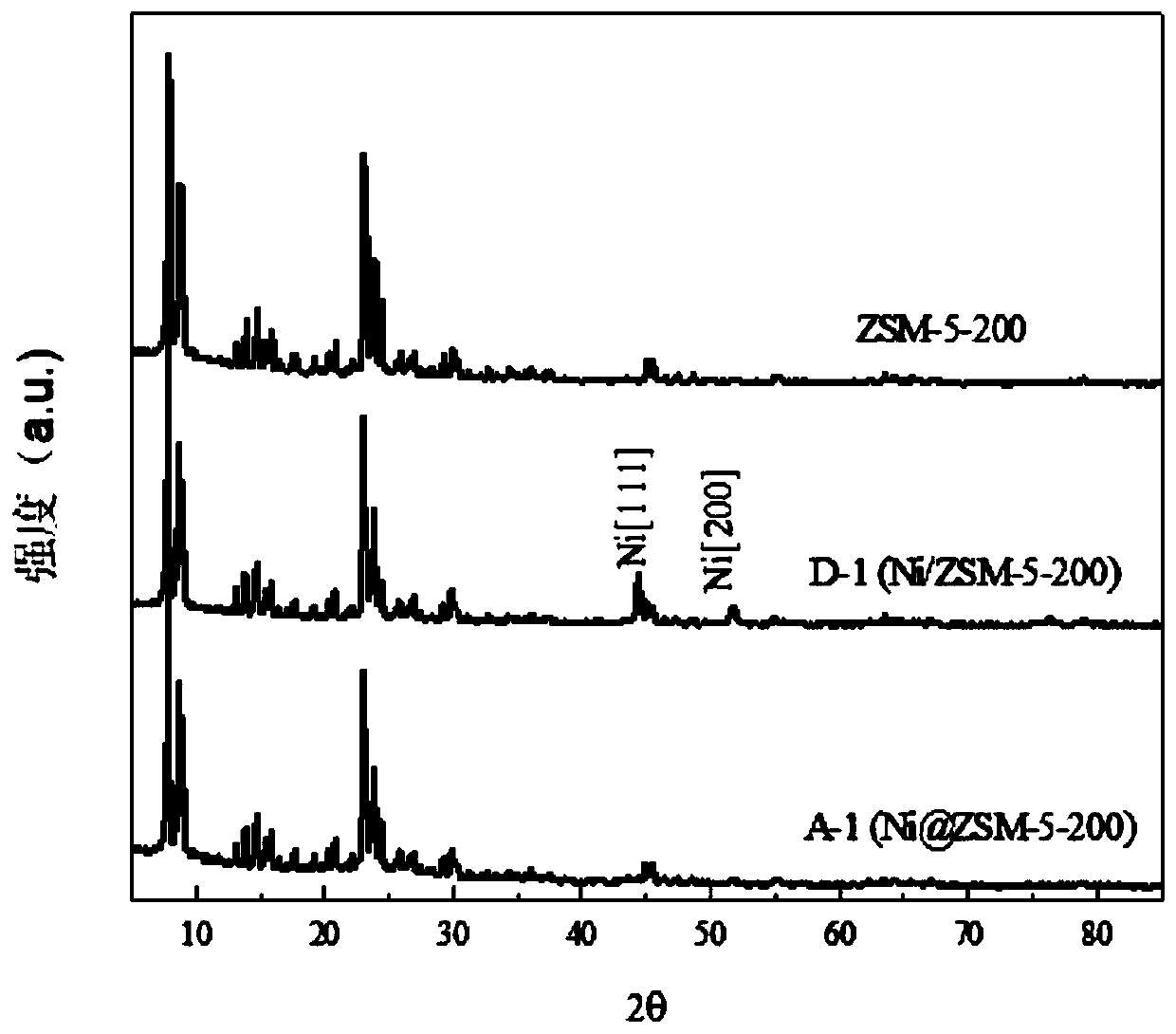

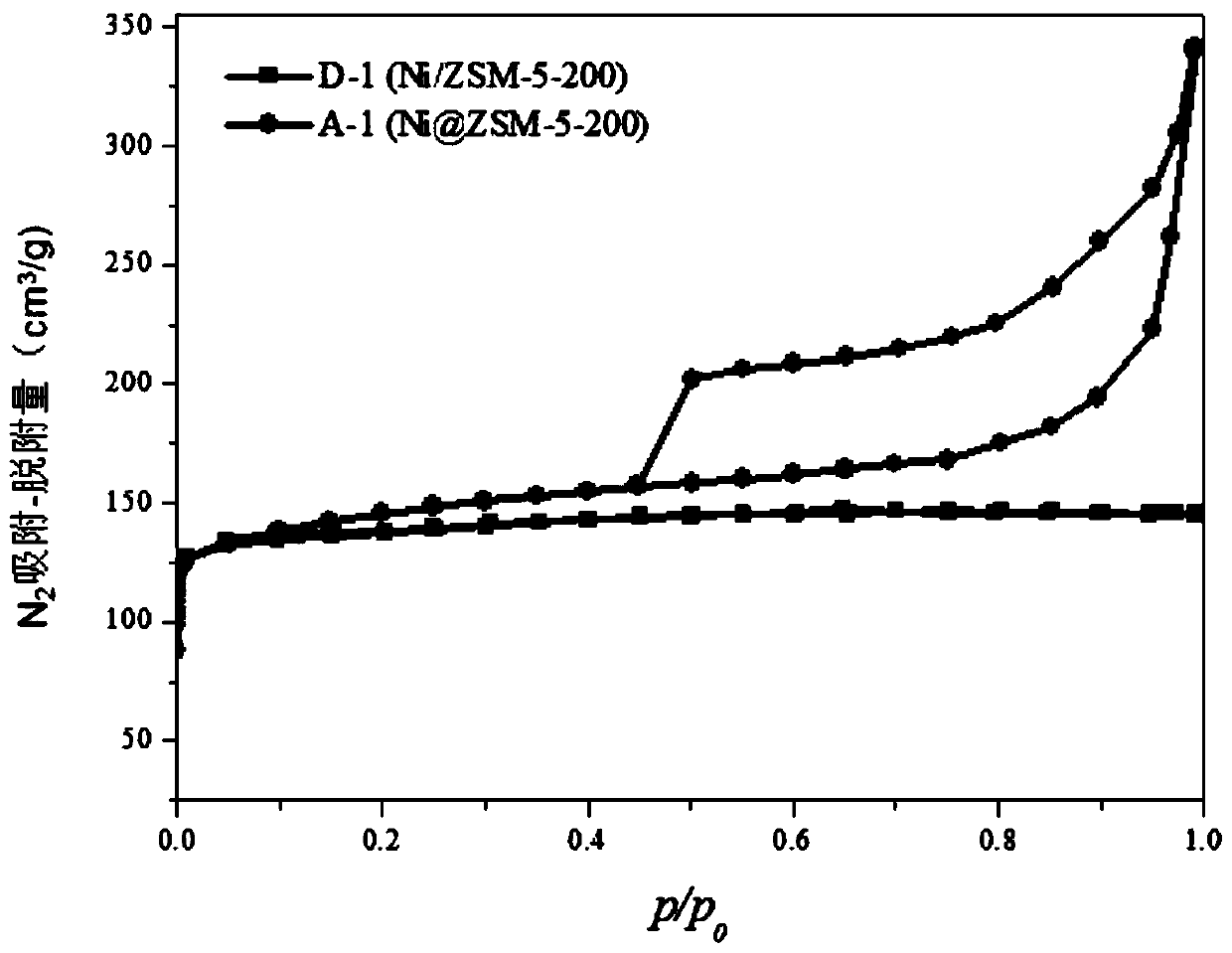

The invention relates to a metal-coated MFI hierarchical pore structure packaging catalyst and a packaging method and application thereof. Micropores and mesopores are contained in the pore channel structure of the packaging catalyst, the N2 adsorption-desorption curve of the packaging catalyst has an adsorption-desorption hysteresis loop under the condition that the relative pressure p / p0 is 0.1-1.0, and the particle size of metal nanoparticles in the packaging catalyst is 1-10 nm. In the preparation process of the packaging catalyst, the MFI structure molecular sieve is modified, the packaging of the metal nanoparticles and the reaming of the MFI structure molecular sieve are realized in one step, and the crystallinity of the molecular sieve parent is not reduced in the preparation process so that the problems of non-uniform distribution, non-uniform particle size, large particles and easiness in migration, agglomeration and loss of the metal nanoparticles in the catalyst prepared bythe traditional wet impregnation method are solved; meanwhile, high molecular sieve crystallinity is maintained through broaching treatment, and the diffusion performance is remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

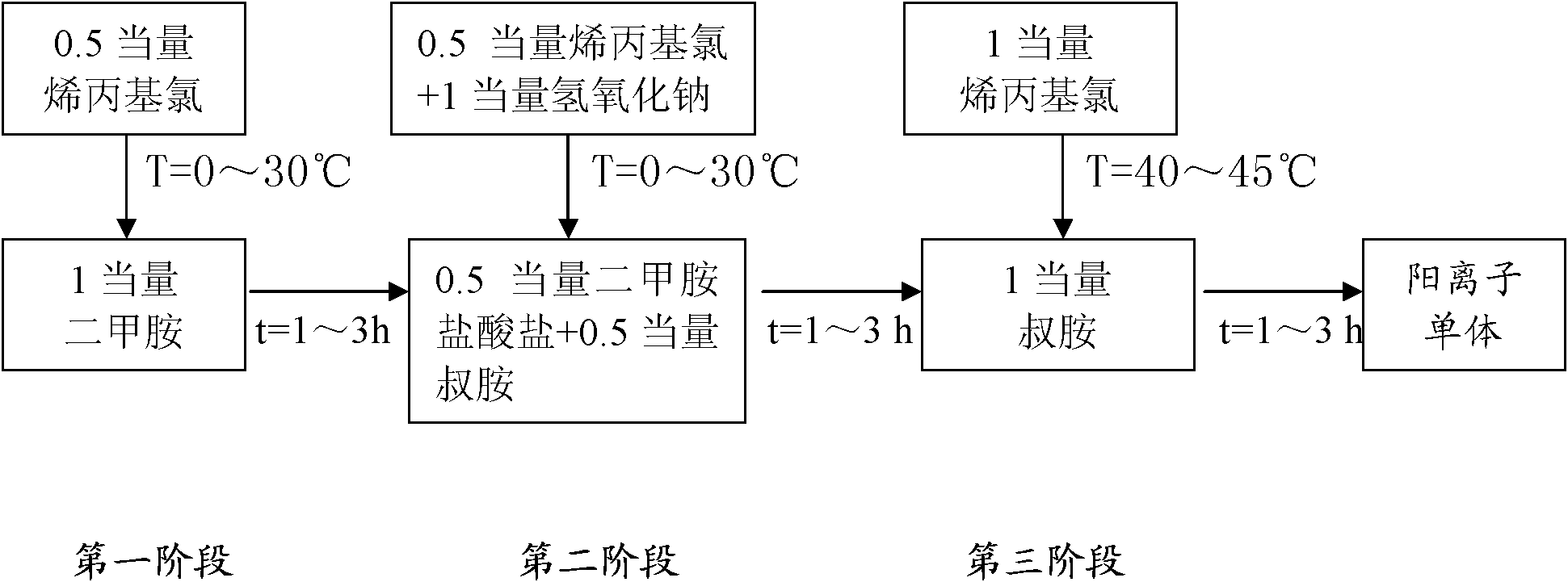

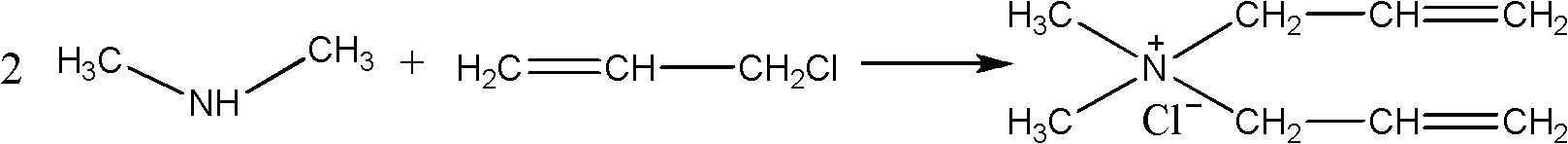

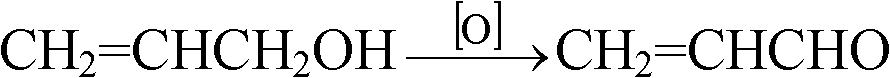

Method for synthesizing dimethyl diallyl ammonium chloride cationic monomer

InactiveCN102126965AReduce loss rateReduce manufacturing costOrganic compound preparationHydroxy compound preparationChemistryDimethyldiazene

The invention discloses a method for synthesizing a dimethyl diallyl ammonium chloride cationic monomer. In the method, a change is made to the conventional feeding mode that dimethylamine and allyl chloride are fed according to a ratio of 1:1, and the feeding mode that dimethylamine and allyl chloride are fed according to a ratio of 1:1 in a first stage is divided into two steps on the basis of the conventional one-step method, wherein in the first step, dimethylamine and allyl chloride are fed first according to a ratio of 1:0.5; and in the second step, allyl chloride and sodium hydroxide are fed according to a ratio of 0.5:1. After reaction for a certain time period, allyl chloride in the same amount is dripped continuously and thus the cationic monomer product is obtained. The cationic monomer product is distilled under reduced pressure to remove volatile impurities, sodium chloride is removed by suction filtration, an alkali is added to remove involatile impurities, and thus, thehigh-purity dimethyl diallyl ammonium chloride cationic monomer is obtained. In the invention, the dimethylamine loss caused by volatilization at normal temperature is avoided, the reaction is performed under a low pH value condition, the generation of impurities is reduced, and thus, high-purity cationic monomer is obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com